Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

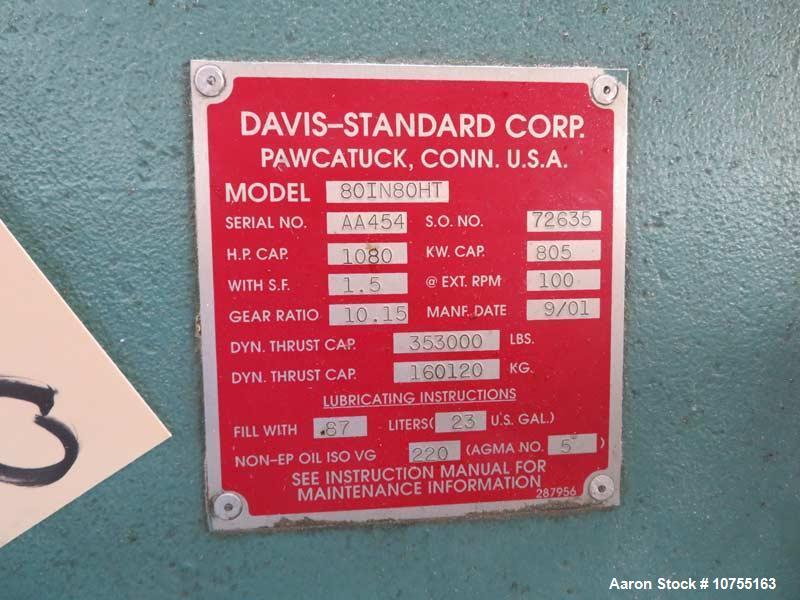

Used Davis Standard 9" Extruder, Model 80IN80HT – 32:1 L/D, 900 HP Motor, Built 2001

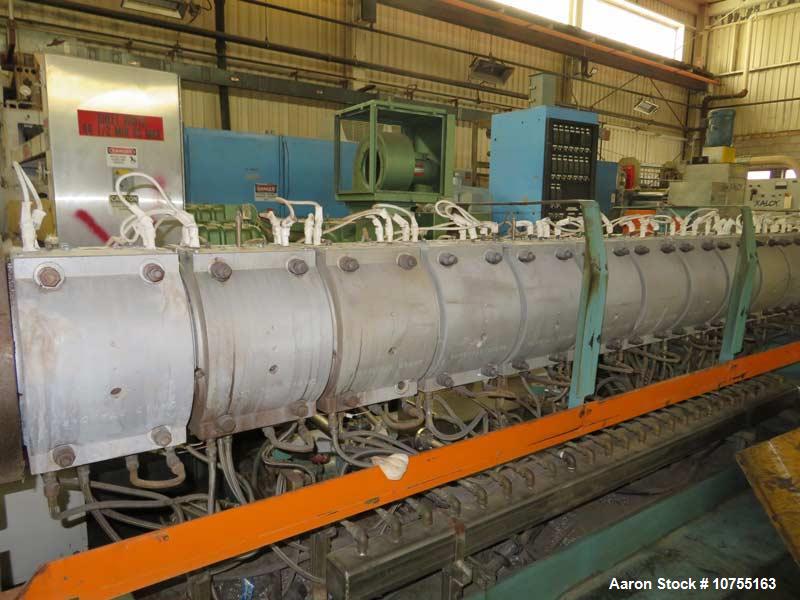

Used Davis Standard 9" Extruder, Model 80IN80HT. 32:1 L/D ratio; (7) zone electrically heated, water cooled (closed loop), and vented barrel at a 44" center-line; 10.15:1 Gearbox reduction ratio; Gearbox rated at 1080 HP at a service factor of 1.5; Gearbox is direct driven in a wrap-around manner by a 900 HP Reliance Super RPM D/C motor; Liquid cooling system with heat exchanger for gearbox protection; 16" x 9 1/2" on center feed throat entrance; PSI continuous screen changer w/ stand is mounted on the extruder discharge. 16" x 9.5" feed throat with magnet; 52,000 lbs. extruder weight; 1,000 lbs. motor weight. Rare opportunity to purchase an extruder of this size. Per Davis Standard the thrust bearing rating is actually 1,468,000 pounds or 665,874 kgs. Unit was miss tagged at the factory. Serial# AA454. Built 2001. Last used in the extrusion of PP sheet. SCR and temperature control panel not included.

| Manufacturer | Davis StandardDavis Standard |

| Model | 80IN80HT |

| Serial # | AA454 |

| Category | Plastics EquipmentPlastics Equipment |

| Subcategory | Extruders - Single Screw ExtruderExtruders - Single Screw Extruder |

Description

The Used Davis Standard 9" Extruder, Model 80IN80HT, is a high-capacity extrusion system designed for polymer sheet and film processing. Featuring a 32:1 L/D ratio, this extruder is equipped with a 7-zone electrically heated, water-cooled (closed-loop) vented barrel, ensuring precise temperature control and optimal polymer melt quality.

The gearbox has a 10.15:1 reduction ratio and is rated for 1,080 HP at a 1.5 service factor, providing high torque and efficient performance. It is direct-driven in a wrap-around manner by a 900 HP Reliance Super RPM D/C motor. The unit also features a liquid cooling system with a heat exchanger to protect the gearbox and maintain consistent operation.

For continuous melt filtration, this extruder is equipped with a PSI continuous screen changer mounted on the extruder discharge, along with a 16" x 9.5" feed throat with an integrated magnet for metal contamination control.

Weighing 52,000 lbs. (extruder) and 1,000 lbs. (motor), this unit offers industrial-grade durability and high-output polymer processing capabilities. It was last used for polypropylene (PP) sheet extrusion.

Rare opportunity: Per Davis Standard, the thrust bearing rating is actually 1,468,000 pounds (665,874 kgs) due to a factory mislabeling.

Note: SCR and temperature control panel not included.

Specifications

- Barrel Diameter: 9"

- L/D Ratio: 32:1

- Barrel Type: Vented, electrically heated, water-cooled (closed-loop)

- Heating Zones: 7 zones

- Gearbox Reduction Ratio: 10.15:1

- Gearbox Power Rating: 1,080 HP (1.5 service factor)

- Drive System:

- 900 HP Reliance Super RPM D/C motor (direct-driven in a wrap-around manner)

- Cooling System: Liquid cooling with heat exchanger for gearbox protection

- Feed Throat: 16" x 9.5" with magnet for metal detection

- Screen Changer: PSI continuous screen changer mounted on discharge

- Extruder Weight: 52,000 lbs.

- Motor Weight: 1,000 lbs.

- Thrust Bearing Rating: 1,468,000 lbs. (665,874 kg) per Davis Standard

Applications

This Davis Standard 9" extruder is ideal for:

- Polypropylene (PP) sheet extrusion

- Plastic sheet and film manufacturing

- Polymer compounding and pelletizing

- Industrial plastic processing

- Packaging film and specialty sheet production

What Products Would This Be Used For?

- Polypropylene (PP) sheet

- High-performance plastic sheeting

- Thermoformed plastic materials

- Packaging films and industrial sheets

- Custom extrusion applications

Automotive, Building Materials, Construction Materials, Extrusion Blow Molding, Industrial, medical, Medical Device, Packaging, Plastic, Plastic Bag, Plastic Blow Molding, Rubber, Wire and cable, Wire products

- Used Davis Standard extruder

- Used Extruder

- Used Extrusion Equipment

- Used Single Screw Extruder

- Used Plastics Equipment

- 9-inch industrial extruder for sale

- PP sheet extrusion machine

- High-output polymer extruder

- Heavy-duty extrusion equipment

- Used Davis Standard 9-inch extruder for plastic sheet processing

- High-performance polymer extrusion system with 900 HP motor

- Industrial extruder with PSI continuous screen changer

- 32:1 L/D extruder for polypropylene sheet manufacturing

- Davis Standard extrusion machine with liquid cooling system

- Used Davis Standard 9" extruder with 32:1 L/D ratio and 900 HP motor

- Industrial polymer extrusion system with 1,080 HP gearbox and direct drive

- Heavy-duty extruder for PP sheet and thermoformed plastic production

- Davis Standard extruder with PSI screen changer and closed-loop water cooling

- High-output plastic extrusion machine for packaging and industrial applications

Used Davis Standard 9" Extruder, Model 80IN80HT. 32:1 L/D ratio; (7) zone electrically heated, water cooled (closed loop), and vented barrel at a 44" center-line; 10.15:1 Gearbox reduction ratio; Gearbox rated at 1080 HP at a service factor of 1.5; Gearbox is direct driven in a wrap-around manner by a 900 HP Reliance Super RPM D/C motor; Liquid cooling system with heat exchanger for gearbox protection; 16" x 9 1/2" on center feed throat entrance; PSI continuous screen changer w/ stand is mounted on the extruder discharge. 16" x 9.5" feed throat with magnet; 52,000 lbs. extruder weight; 1,000 lbs. motor weight. Rare opportunity to purchase an extruder of this size. Per Davis Standard the thrust bearing rating is actually 1,468,000 pounds or 665,874 kgs. Unit was miss tagged at the factory. Serial# AA454. Built 2001. Last used in the extrusion of PP sheet. SCR and temperature control panel not included.

Description

The Used Davis Standard 9" Extruder, Model 80IN80HT, is a high-capacity extrusion system designed for polymer sheet and film processing. Featuring a 32:1 L/D ratio, this extruder is equipped with a 7-zone electrically heated, water-cooled (closed-loop) vented barrel, ensuring precise temperature control and optimal polymer melt quality.

The gearbox has a 10.15:1 reduction ratio and is rated for 1,080 HP at a 1.5 service factor, providing high torque and efficient performance. It is direct-driven in a wrap-around manner by a 900 HP Reliance Super RPM D/C motor. The unit also features a liquid cooling system with a heat exchanger to protect the gearbox and maintain consistent operation.

For continuous melt filtration, this extruder is equipped with a PSI continuous screen changer mounted on the extruder discharge, along with a 16" x 9.5" feed throat with an integrated magnet for metal contamination control.

Weighing 52,000 lbs. (extruder) and 1,000 lbs. (motor), this unit offers industrial-grade durability and high-output polymer processing capabilities. It was last used for polypropylene (PP) sheet extrusion.

Rare opportunity: Per Davis Standard, the thrust bearing rating is actually 1,468,000 pounds (665,874 kgs) due to a factory mislabeling.

Note: SCR and temperature control panel not included.

Specifications

- Barrel Diameter: 9"

- L/D Ratio: 32:1

- Barrel Type: Vented, electrically heated, water-cooled (closed-loop)

- Heating Zones: 7 zones

- Gearbox Reduction Ratio: 10.15:1

- Gearbox Power Rating: 1,080 HP (1.5 service factor)

- Drive System:

- 900 HP Reliance Super RPM D/C motor (direct-driven in a wrap-around manner)

- Cooling System: Liquid cooling with heat exchanger for gearbox protection

- Feed Throat: 16" x 9.5" with magnet for metal detection

- Screen Changer: PSI continuous screen changer mounted on discharge

- Extruder Weight: 52,000 lbs.

- Motor Weight: 1,000 lbs.

- Thrust Bearing Rating: 1,468,000 lbs. (665,874 kg) per Davis Standard

Applications

This Davis Standard 9" extruder is ideal for:

- Polypropylene (PP) sheet extrusion

- Plastic sheet and film manufacturing

- Polymer compounding and pelletizing

- Industrial plastic processing

- Packaging film and specialty sheet production

What Products Would This Be Used For?

- Polypropylene (PP) sheet

- High-performance plastic sheeting

- Thermoformed plastic materials

- Packaging films and industrial sheets

- Custom extrusion applications

Automotive, Building Materials, Construction Materials, Extrusion Blow Molding, Industrial, medical, Medical Device, Packaging, Plastic, Plastic Bag, Plastic Blow Molding, Rubber, Wire and cable, Wire products

| Manufacturer | Davis Standard |

| Model | 80IN80HT |

| Serial # | AA454 |

| Category | Plastics Equipment |

| Subcategory | Extruders - Single Screw Extruder |

- Used Davis Standard extruder

- Used Extruder

- Used Extrusion Equipment

- Used Single Screw Extruder

- Used Plastics Equipment

- 9-inch industrial extruder for sale

- PP sheet extrusion machine

- High-output polymer extruder

- Heavy-duty extrusion equipment

- Used Davis Standard 9-inch extruder for plastic sheet processing

- High-performance polymer extrusion system with 900 HP motor

- Industrial extruder with PSI continuous screen changer

- 32:1 L/D extruder for polypropylene sheet manufacturing

- Davis Standard extrusion machine with liquid cooling system

- Used Davis Standard 9" extruder with 32:1 L/D ratio and 900 HP motor

- Industrial polymer extrusion system with 1,080 HP gearbox and direct drive

- Heavy-duty extruder for PP sheet and thermoformed plastic production

- Davis Standard extruder with PSI screen changer and closed-loop water cooling

- High-output plastic extrusion machine for packaging and industrial applications

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory