Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

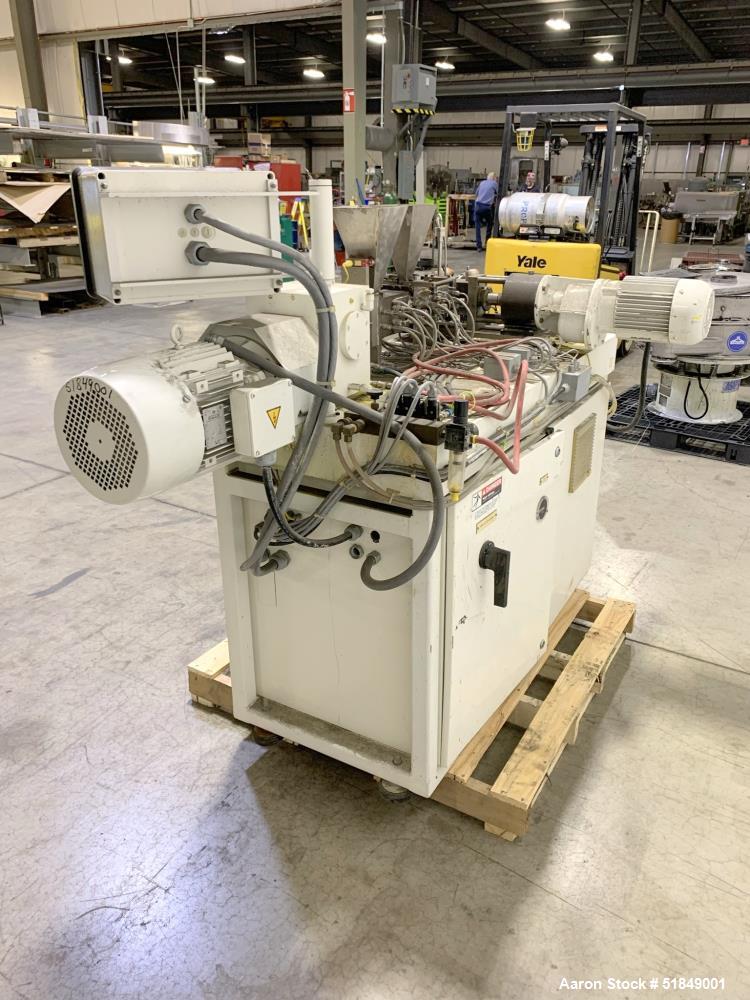

Buss Model MKS 30 Laboratory Ko-Kneader Extruder

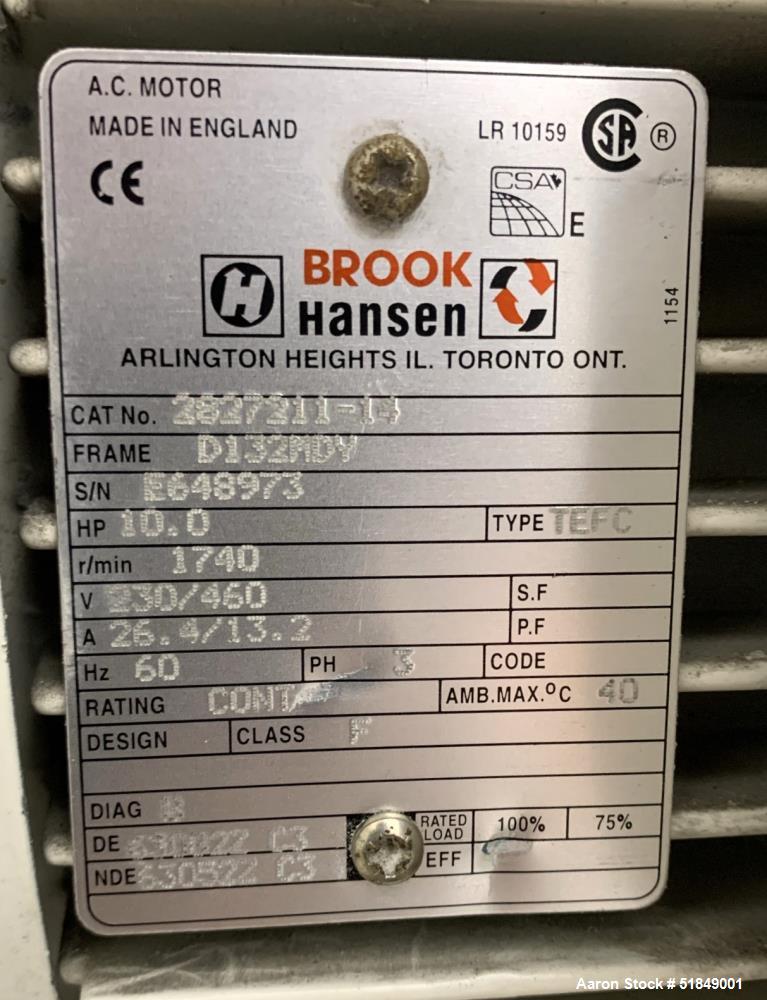

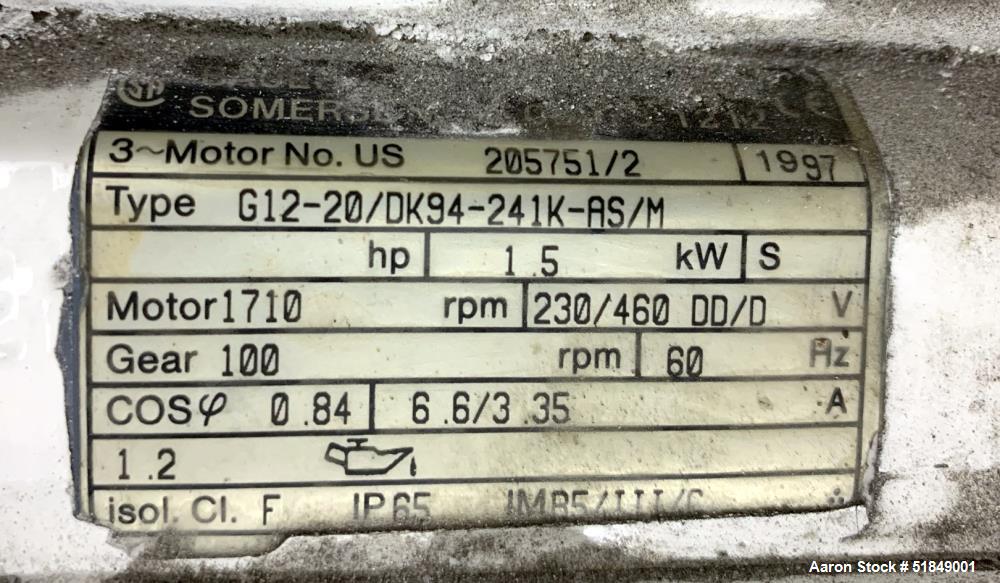

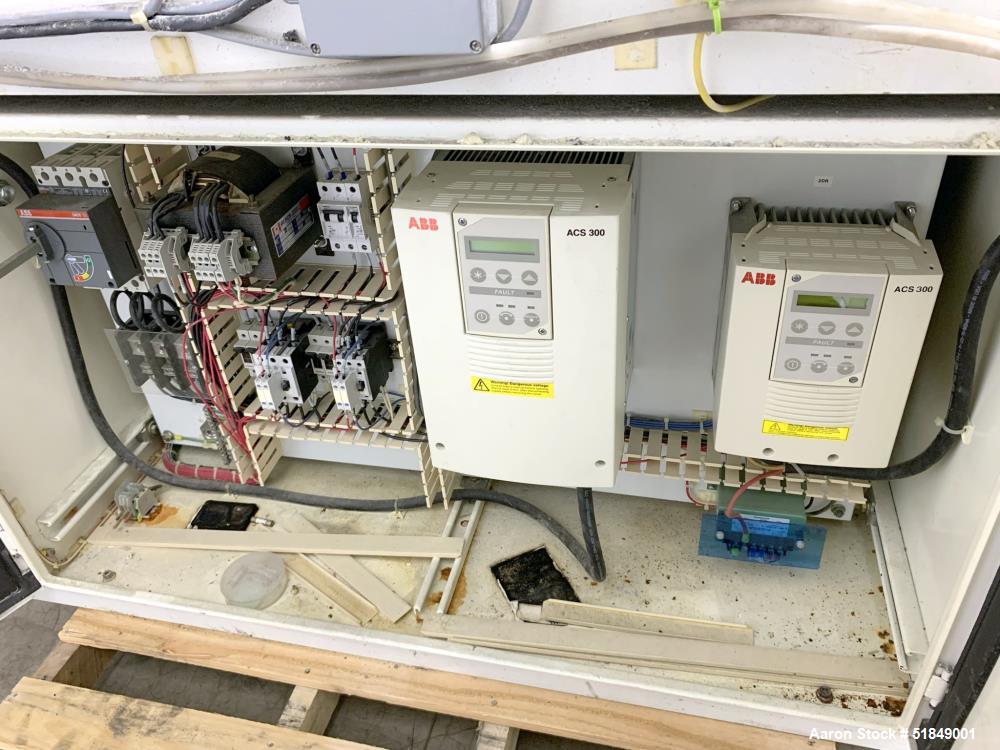

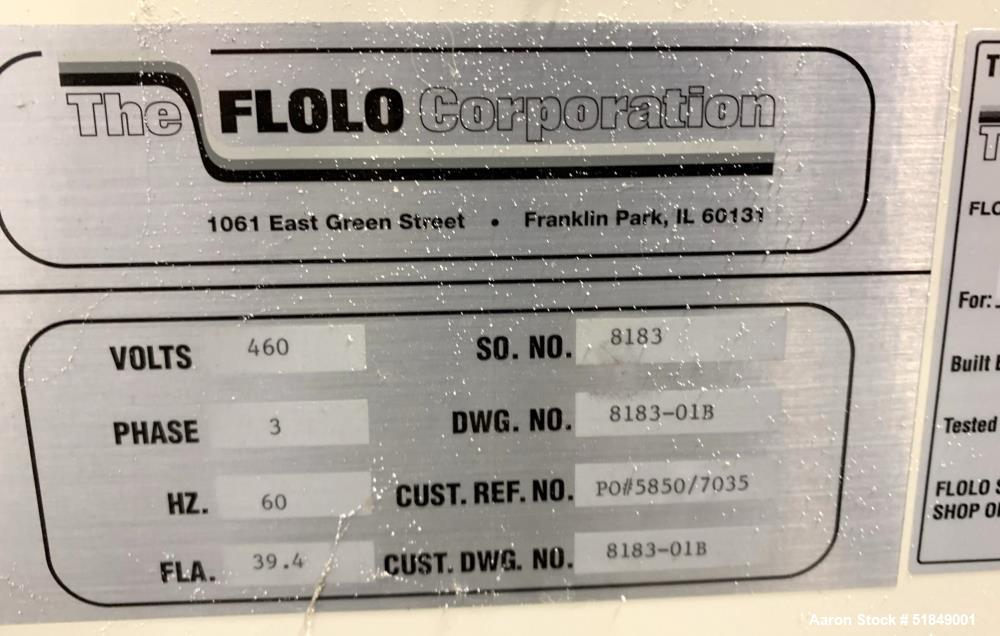

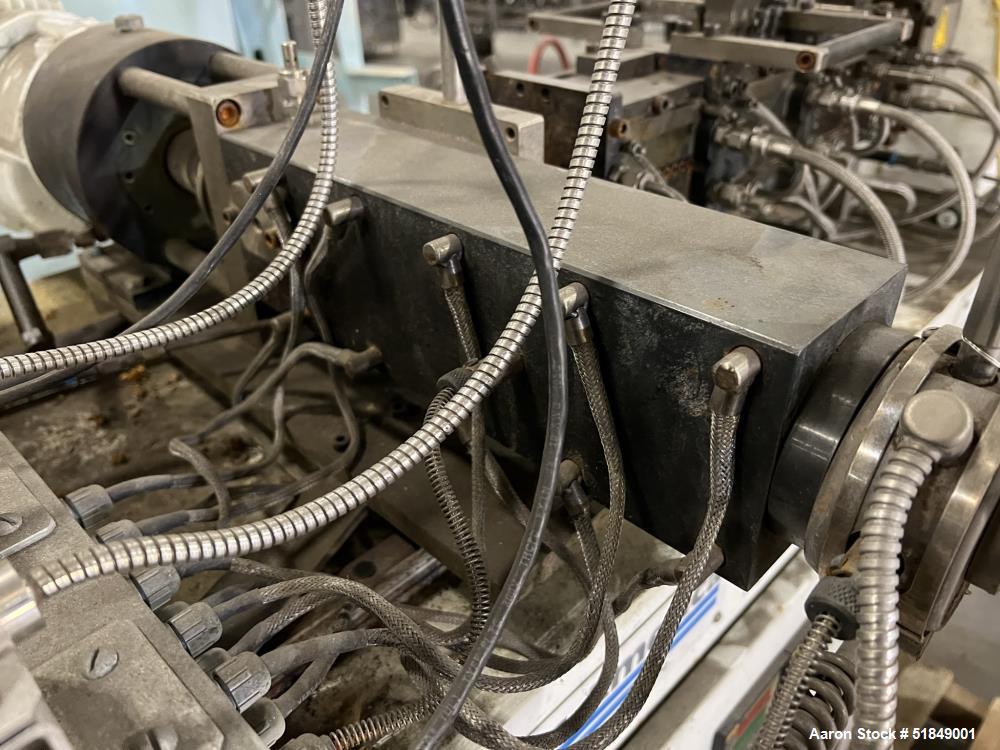

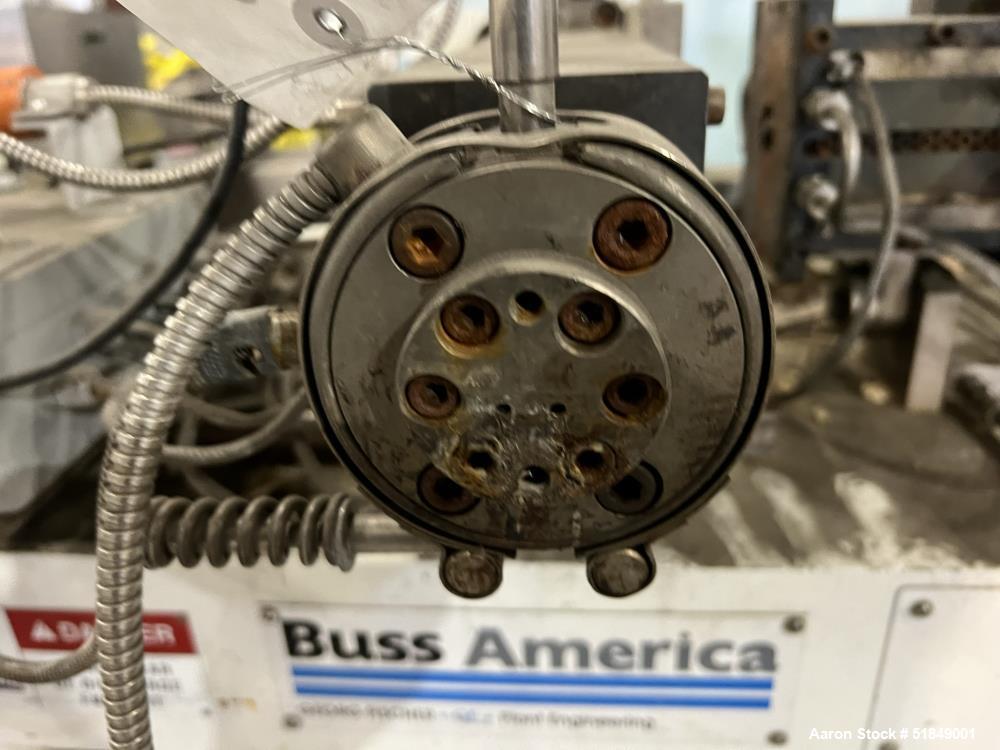

Used Buss Model MKS 30 Laboratory Ko-Kneader Extruder, Serial# 97-1030 (1997). 30mm Diameter x approximate 17" long single screw. Throughput rates up to 30kg per hour. 3 Zone barrel electrically heated, water cooled. Water cooled feed throat with hopper. Driven by a 10 hp, 3/60/230/460 volt, 1740 rpm AC motor with reducer. Includes a discharge screw extruder, driven by an approximately 1.5 kw, 3/60/230/460 volt, 1710 rpm gear motor with 2 hole strand die. Includes an operators panel, a control panel with Eurotherm controllers, (2) ABB drive panels. 837 Hours used on the meter.

| Manufacturer | BussBuss |

| Model | MKS30 |

| Serial # | 97-1030 |

| Category | Plastics EquipmentPlastics Equipment |

| Subcategory | Extruders - Single Screw ExtruderExtruders - Single Screw Extruder |

Manufacturer: Buss

Model: MKS 30

Serial #: 97-1030

Condition: Used

Description:

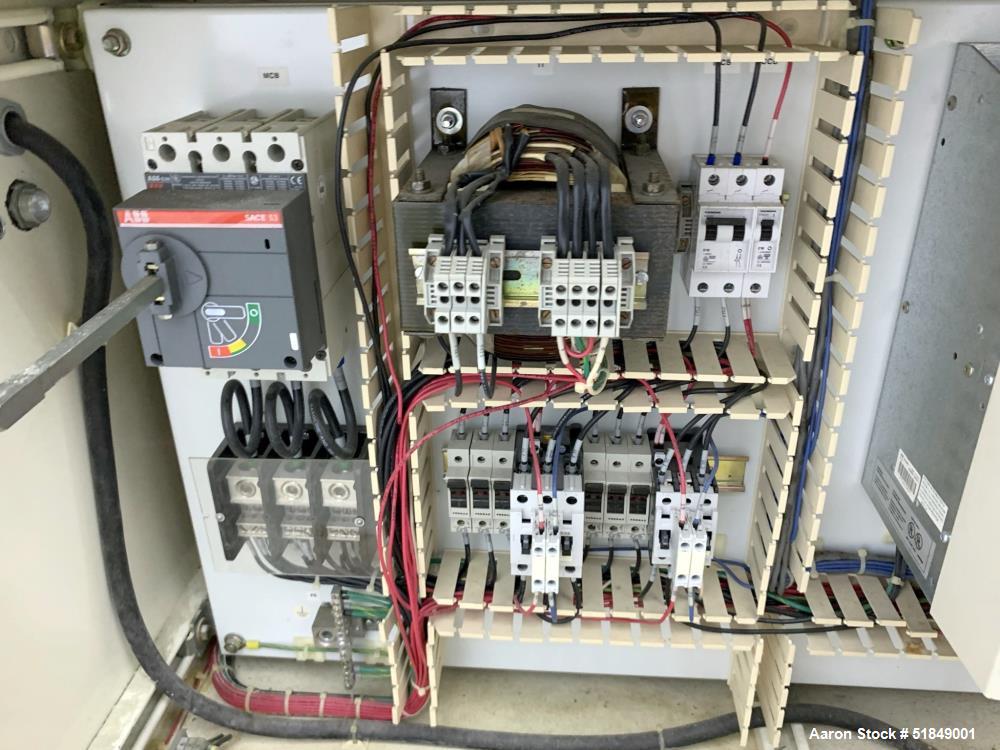

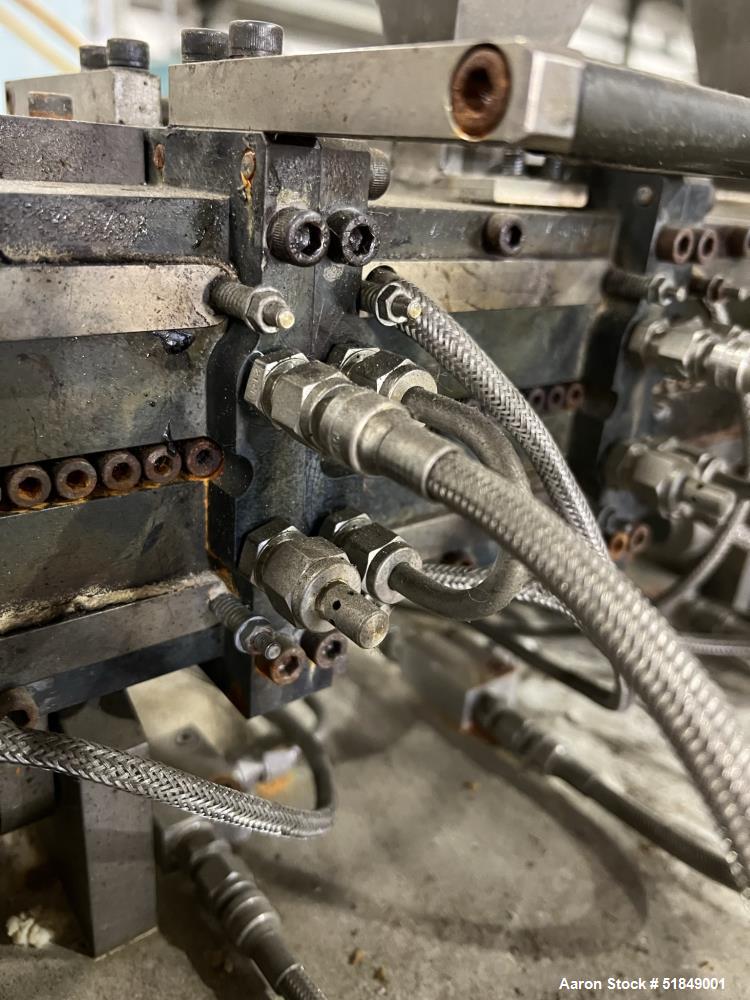

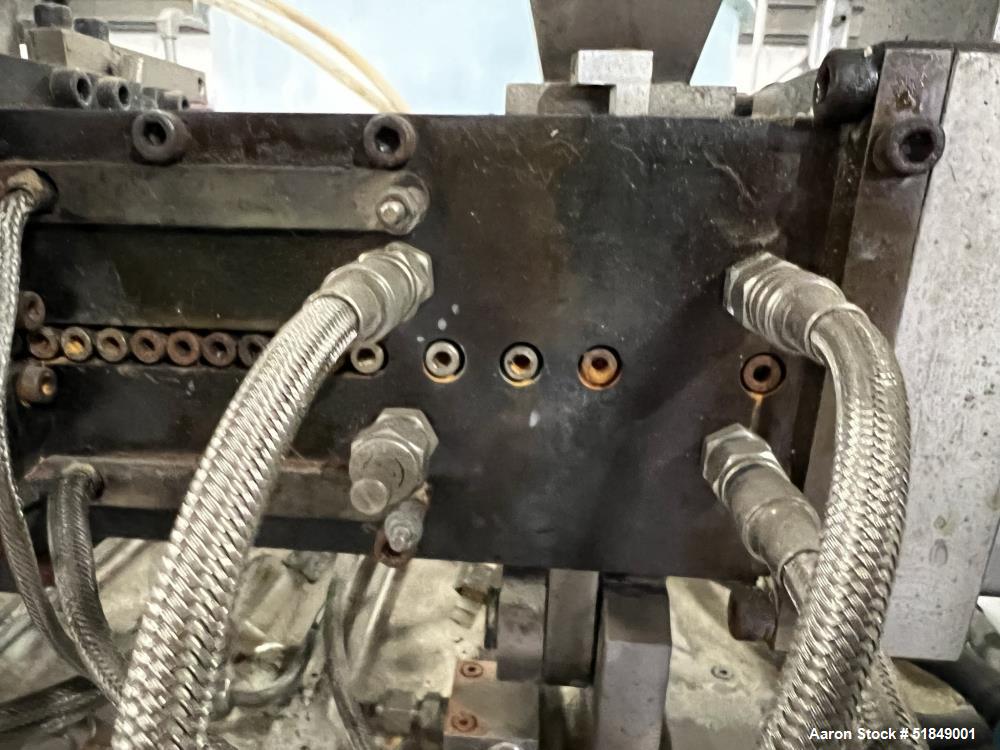

The Buss MKS 30 Laboratory Ko-Kneader Extruder is a precision-engineered system designed for small-scale compounding and material processing. This unit features a 30mm diameter, 17" long single screw with throughput rates of up to 30 kg per hour. The three-zone barrel is electrically heated and water-cooled, ensuring precise temperature regulation. The feed throat is water-cooled and includes a hopper for material input. The main extruder is powered by a 10 HP AC motor with a reducer, while the discharge screw extruder is driven by a 1.5 kW gear motor operating at 1710 RPM. The system includes a 2-hole strand die for shaping extruded materials. Additionally, the extruder is equipped with an operator panel, a control panel with Eurotherm controllers, and two ABB drive panels for efficient and precise control.

Specifications:

- Screw Diameter: 30mm

- Screw Length: Approx. 17"

- Throughput Capacity: Up to 30 kg/hour

- Barrel Heating & Cooling:

- 3-zone barrel, electrically heated, water-cooled

- Water-cooled feed throat with hopper

- Main Drive:

- 10 HP AC motor, 3/60/230/460V, 1740 RPM

- Gear reducer for controlled operation

- Discharge Screw Extruder:

- 1.5 kW, 3/60/230/460V, 1710 RPM gear motor

- 2-hole strand die

- Control System:

- Operator panel

- Control panel with Eurotherm controllers

- (2) ABB drive panels

- Condition: Used

Applications:

- Laboratory-scale polymer compounding

- Pharmaceutical material extrusion

- Specialty chemical processing

- Food and additive manufacturing

- Research and development of extrusion processes

Common Uses in Industries:

- Plastics & Polymers – pilot-scale compounding and formulation testing

- Pharmaceuticals – development of drug formulations using hot melt extrusion

- Chemical Processing – specialty material compounding

- Food Processing – extrusion of food-grade materials and ingredients

- Research & Development – small-scale testing of new material formulations

Epoxy Resins, Polyester Resins, Polyurethane Resins, Powder Coating

- Buss MKS 30 Ko-Kneader Extruder

- Used Laboratory Extruder for Sale

- 30mm Single Screw Extruder

- Small-Scale Twin Screw Extruder

- Eurotherm Controlled Extruder

- ABB Drive Panel Extruder

- Research & Development Extruder

- Buss Kneader for Plastic & Pharma

Used Buss Model MKS 30 Laboratory Ko-Kneader Extruder, Serial# 97-1030 (1997). 30mm Diameter x approximate 17" long single screw. Throughput rates up to 30kg per hour. 3 Zone barrel electrically heated, water cooled. Water cooled feed throat with hopper. Driven by a 10 hp, 3/60/230/460 volt, 1740 rpm AC motor with reducer. Includes a discharge screw extruder, driven by an approximately 1.5 kw, 3/60/230/460 volt, 1710 rpm gear motor with 2 hole strand die. Includes an operators panel, a control panel with Eurotherm controllers, (2) ABB drive panels. 837 Hours used on the meter.

Manufacturer: Buss

Model: MKS 30

Serial #: 97-1030

Condition: Used

Description:

The Buss MKS 30 Laboratory Ko-Kneader Extruder is a precision-engineered system designed for small-scale compounding and material processing. This unit features a 30mm diameter, 17" long single screw with throughput rates of up to 30 kg per hour. The three-zone barrel is electrically heated and water-cooled, ensuring precise temperature regulation. The feed throat is water-cooled and includes a hopper for material input. The main extruder is powered by a 10 HP AC motor with a reducer, while the discharge screw extruder is driven by a 1.5 kW gear motor operating at 1710 RPM. The system includes a 2-hole strand die for shaping extruded materials. Additionally, the extruder is equipped with an operator panel, a control panel with Eurotherm controllers, and two ABB drive panels for efficient and precise control.

Specifications:

- Screw Diameter: 30mm

- Screw Length: Approx. 17"

- Throughput Capacity: Up to 30 kg/hour

- Barrel Heating & Cooling:

- 3-zone barrel, electrically heated, water-cooled

- Water-cooled feed throat with hopper

- Main Drive:

- 10 HP AC motor, 3/60/230/460V, 1740 RPM

- Gear reducer for controlled operation

- Discharge Screw Extruder:

- 1.5 kW, 3/60/230/460V, 1710 RPM gear motor

- 2-hole strand die

- Control System:

- Operator panel

- Control panel with Eurotherm controllers

- (2) ABB drive panels

- Condition: Used

Applications:

- Laboratory-scale polymer compounding

- Pharmaceutical material extrusion

- Specialty chemical processing

- Food and additive manufacturing

- Research and development of extrusion processes

Common Uses in Industries:

- Plastics & Polymers – pilot-scale compounding and formulation testing

- Pharmaceuticals – development of drug formulations using hot melt extrusion

- Chemical Processing – specialty material compounding

- Food Processing – extrusion of food-grade materials and ingredients

- Research & Development – small-scale testing of new material formulations

Epoxy Resins, Polyester Resins, Polyurethane Resins, Powder Coating

| Manufacturer | Buss |

| Model | MKS30 |

| Serial # | 97-1030 |

| Category | Plastics Equipment |

| Subcategory | Extruders - Single Screw Extruder |

- Buss MKS 30 Ko-Kneader Extruder

- Used Laboratory Extruder for Sale

- 30mm Single Screw Extruder

- Small-Scale Twin Screw Extruder

- Eurotherm Controlled Extruder

- ABB Drive Panel Extruder

- Research & Development Extruder

- Buss Kneader for Plastic & Pharma

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory