Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Gloucester 3.5" Single Screw Extruder – Model 35250R2, 32:1 L/D, 100 HP Motor

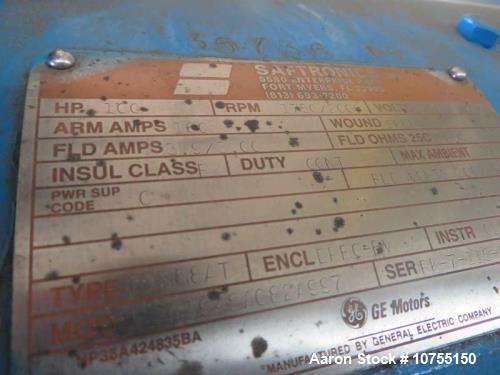

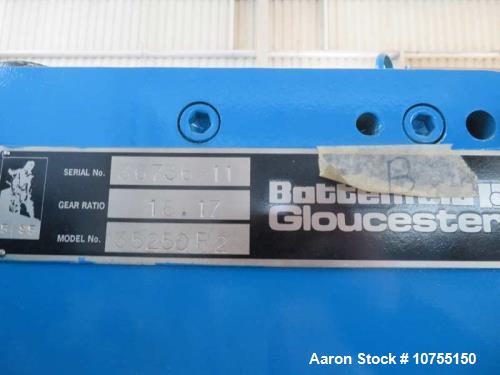

Used Gloucester 3.5" Single Screw Extruder, Model 35250R2. 3.5" diameter screw, 32:1 L/D. Having an electrically heated, air cooled, and non-vented barrel at approximately a 65" center line height. Barrel is set up for Contra-Cool but does not include blower. Gearbox has a reduction ratio of 18.17:1 and is directly driven in a wraparound manner by a 100 HP Baldor D/C motor with Saftronics SCR control. Oil pump with heat exchanger on the gearbox for cooling. Originally manufactured in 1995 and completely reconditioned in 2011 and never put back into service. All wiring on the extruder is run to a terminal strip. New control panel has fourteen (14) zones of temperature controls. Drive control is loose. Includes two (2) new / rebuilt screws. 460/3/60. Serial# 36736/11.

| Manufacturer | GloucesterGloucester |

| Model | 35250R2 |

| Serial # | 36736/11 |

| Category | Plastics EquipmentPlastics Equipment |

| Subcategory | Extruders - Single Screw ExtruderExtruders - Single Screw Extruder |

Manufacturer Information:

- Manufacturer: Gloucester

- Model: 35250R2

- Condition: Used (Reconditioned in 2011, Never Put Back into Service)

- Serial Number: 36736/11

- Year Manufactured: 1995

- Year Reconditioned: 2011

Description:

The Gloucester 35250R2 3.5” Single Screw Extruder is a high-performance, industrial-grade extrusion system, designed for efficient polymer processing in sheet extrusion, compounding, and recycling applications. This system features a 3.5" diameter screw with a 32:1 L/D ratio, providing consistent material processing and superior melt quality.

The electrically heated, air-cooled, non-vented barrel operates at an approximate 65” centerline height and is Contra-Cool ready (blower not included). The 18.17:1 reduction ratio gearbox is directly driven in a wraparound configuration by a 100 HP Baldor DC motor, offering smooth and reliable extrusion performance. The Saftronics SCR control system ensures precise speed and torque control for optimized extrusion efficiency.

For temperature regulation, the system includes an oil pump with a heat exchanger for gearbox cooling. The new control panel features fourteen (14) temperature control zones, offering advanced thermal stability and process control. Additionally, all wiring on the extruder is run to a terminal strip for easy installation and connectivity.

This extruder includes two (2) new/rebuilt screws, adding extra value and process flexibility. The drive control is supplied loose, allowing for customized system integration.

Originally built in 1995 and completely reconditioned in 2011, this extruder was never put back into service, making it an excellent choice for those seeking a near-new extrusion system at a used price.

Specifications:

- Screw Diameter: 3.5 inches

- L/D Ratio: 32:1

- Barrel Features:

- Electrically heated, air-cooled

- Non-vented

- Set up for Contra-Cool (Blower Not Included)

- Approximate 65” centerline height

- Gearbox:

- Reduction Ratio: 18.17:1

- Direct-driven, wraparound configuration

- Drive System:

- 100 HP Baldor DC Motor

- Saftronics SCR Control System

- Cooling System:

- Oil pump with heat exchanger for gearbox cooling

- Control System:

- New Control Panel with 14 Temperature Control Zones

- All wiring run to a terminal strip

- Drive control supplied loose

- Additional Features:

- Includes two (2) new/rebuilt screws

- Power Requirements: 460V / 3-Phase / 60Hz

Applications:

- Plastics & Polymer Processing: Sheet extrusion, compounding, and pelletizing

- Industrial Manufacturing: Extrusion of pipes, tubing, films, and profiles

- Recycling & Reprocessing: Repurposing scrap plastic into reusable pellets

- Chemical & Specialty Material Processing: Processing engineered polymers and composites

Common Product Uses:

- Industrial extrusion for high-efficiency plastic processing

- Temperature-controlled extrusion with air-cooled barrel

- Direct-driven gearbox with Saftronics SCR drive control

- Reconditioned extruder with new screws and control panel

Plastic Blow Molding, Plastic blown film, Plastic Colorants, Plastic Colour-concentrates, Plastic Composite Decking, Plastic film, Plastic Granules, Plastic Injection Molding, Plastic Parts, Plastic Pellets, Plastic Thermoforming, Plasticizing, Plastics, Plastics Blow Molding, Plastics Blown Film, Plastics Equipment

- Used Single Screw Extruder

- Used Extruder

- Used 3.5" Extruder

- Used Extrusion Equipment

- Used Plastics Extruder

- Used Plastics Equipment

- Used Industrial Equipment

- Used Process Equipment

- Gloucester 35250R2 single screw extruder

- Used plastic extrusion machine

- High-efficiency polymer extruder

- Industrial plastic extrusion system

- Extruder with temperature control panel

- Reconditioned extruder with new screws

- Used Gloucester 35250R2 single screw extruder for sale

- 3.5-inch plastic extrusion machine with 32:1 L/D ratio

- Industrial extruder with 100 HP Baldor motor

- Reconditioned Gloucester extruder with new control panel

- High-performance extrusion system with temperature control

- Used extruder with Saftronics SCR drive system

- Air-cooled non-vented extruder for polymer processing

- Direct-driven extruder with new/rebuilt screws included

Used Gloucester 3.5" Single Screw Extruder, Model 35250R2. 3.5" diameter screw, 32:1 L/D. Having an electrically heated, air cooled, and non-vented barrel at approximately a 65" center line height. Barrel is set up for Contra-Cool but does not include blower. Gearbox has a reduction ratio of 18.17:1 and is directly driven in a wraparound manner by a 100 HP Baldor D/C motor with Saftronics SCR control. Oil pump with heat exchanger on the gearbox for cooling. Originally manufactured in 1995 and completely reconditioned in 2011 and never put back into service. All wiring on the extruder is run to a terminal strip. New control panel has fourteen (14) zones of temperature controls. Drive control is loose. Includes two (2) new / rebuilt screws. 460/3/60. Serial# 36736/11.

Manufacturer Information:

- Manufacturer: Gloucester

- Model: 35250R2

- Condition: Used (Reconditioned in 2011, Never Put Back into Service)

- Serial Number: 36736/11

- Year Manufactured: 1995

- Year Reconditioned: 2011

Description:

The Gloucester 35250R2 3.5” Single Screw Extruder is a high-performance, industrial-grade extrusion system, designed for efficient polymer processing in sheet extrusion, compounding, and recycling applications. This system features a 3.5" diameter screw with a 32:1 L/D ratio, providing consistent material processing and superior melt quality.

The electrically heated, air-cooled, non-vented barrel operates at an approximate 65” centerline height and is Contra-Cool ready (blower not included). The 18.17:1 reduction ratio gearbox is directly driven in a wraparound configuration by a 100 HP Baldor DC motor, offering smooth and reliable extrusion performance. The Saftronics SCR control system ensures precise speed and torque control for optimized extrusion efficiency.

For temperature regulation, the system includes an oil pump with a heat exchanger for gearbox cooling. The new control panel features fourteen (14) temperature control zones, offering advanced thermal stability and process control. Additionally, all wiring on the extruder is run to a terminal strip for easy installation and connectivity.

This extruder includes two (2) new/rebuilt screws, adding extra value and process flexibility. The drive control is supplied loose, allowing for customized system integration.

Originally built in 1995 and completely reconditioned in 2011, this extruder was never put back into service, making it an excellent choice for those seeking a near-new extrusion system at a used price.

Specifications:

- Screw Diameter: 3.5 inches

- L/D Ratio: 32:1

- Barrel Features:

- Electrically heated, air-cooled

- Non-vented

- Set up for Contra-Cool (Blower Not Included)

- Approximate 65” centerline height

- Gearbox:

- Reduction Ratio: 18.17:1

- Direct-driven, wraparound configuration

- Drive System:

- 100 HP Baldor DC Motor

- Saftronics SCR Control System

- Cooling System:

- Oil pump with heat exchanger for gearbox cooling

- Control System:

- New Control Panel with 14 Temperature Control Zones

- All wiring run to a terminal strip

- Drive control supplied loose

- Additional Features:

- Includes two (2) new/rebuilt screws

- Power Requirements: 460V / 3-Phase / 60Hz

Applications:

- Plastics & Polymer Processing: Sheet extrusion, compounding, and pelletizing

- Industrial Manufacturing: Extrusion of pipes, tubing, films, and profiles

- Recycling & Reprocessing: Repurposing scrap plastic into reusable pellets

- Chemical & Specialty Material Processing: Processing engineered polymers and composites

Common Product Uses:

- Industrial extrusion for high-efficiency plastic processing

- Temperature-controlled extrusion with air-cooled barrel

- Direct-driven gearbox with Saftronics SCR drive control

- Reconditioned extruder with new screws and control panel

Plastic Blow Molding, Plastic blown film, Plastic Colorants, Plastic Colour-concentrates, Plastic Composite Decking, Plastic film, Plastic Granules, Plastic Injection Molding, Plastic Parts, Plastic Pellets, Plastic Thermoforming, Plasticizing, Plastics, Plastics Blow Molding, Plastics Blown Film, Plastics Equipment

| Manufacturer | Gloucester |

| Model | 35250R2 |

| Serial # | 36736/11 |

| Category | Plastics Equipment |

| Subcategory | Extruders - Single Screw Extruder |

- Used Single Screw Extruder

- Used Extruder

- Used 3.5" Extruder

- Used Extrusion Equipment

- Used Plastics Extruder

- Used Plastics Equipment

- Used Industrial Equipment

- Used Process Equipment

- Gloucester 35250R2 single screw extruder

- Used plastic extrusion machine

- High-efficiency polymer extruder

- Industrial plastic extrusion system

- Extruder with temperature control panel

- Reconditioned extruder with new screws

- Used Gloucester 35250R2 single screw extruder for sale

- 3.5-inch plastic extrusion machine with 32:1 L/D ratio

- Industrial extruder with 100 HP Baldor motor

- Reconditioned Gloucester extruder with new control panel

- High-performance extrusion system with temperature control

- Used extruder with Saftronics SCR drive system

- Air-cooled non-vented extruder for polymer processing

- Direct-driven extruder with new/rebuilt screws included

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory