Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Welex 3.5" 30:1 L/D Extruder – 150 HP, Vented Barrel, Melt Pump & Screen Changer

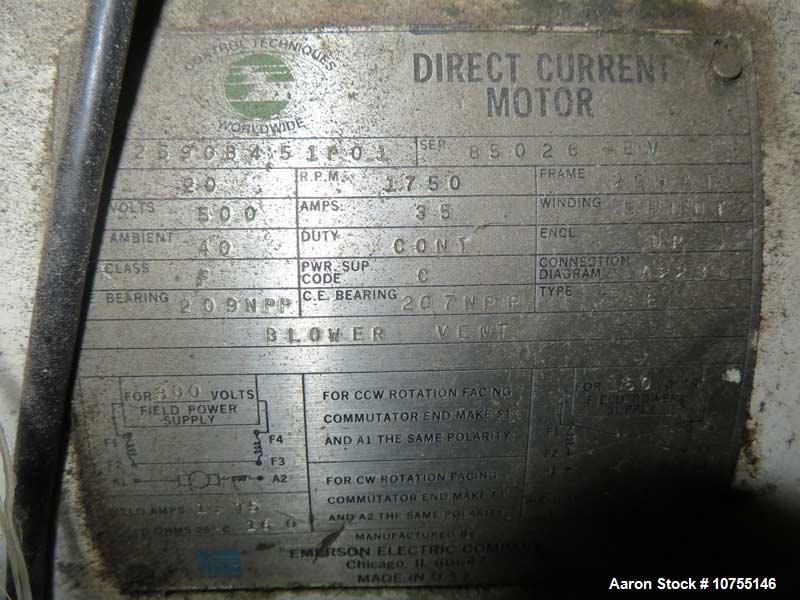

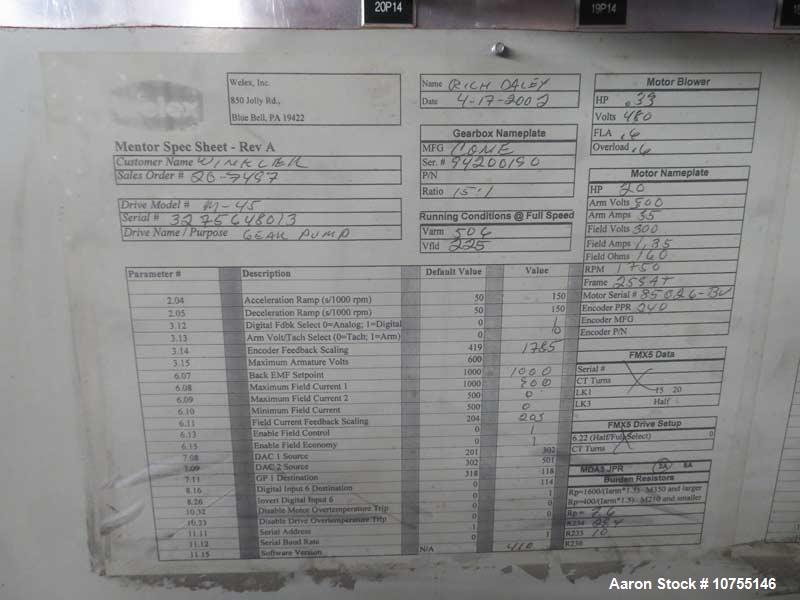

Used Welex 3.5" 30:1 L/D Extruder. Electrically heated water cooled (closed loop) and vented barrel at an approximate 69" center line height. Center line height can be reduced approximately 8" by removing an additional base. Lufkin change gear gearbox is direct driven in a tuck under manner by a 150 HP Emerson DC motor with Control Technique Mentor II SCR control. Present reduction ratio is 13.89:1. Includes integral panel having fourteen (14) zones of temperature control. Dynisco model EH-35 screen changer with 3 HP hydraulic pack is mounted on the extruder discharge. Also includes 20 HP melt pump with controls.

| Manufacturer | WelexWelex |

| Category | Plastics EquipmentPlastics Equipment |

| Subcategory | Extruders - Single Screw ExtruderExtruders - Single Screw Extruder |

Manufacturer Information:

- Manufacturer: Welex

- Model: 3.5" 30:1 L/D Extruder

- Condition: Used

Description:

The Welex 3.5" 30:1 L/D Extruder is a high-performance extrusion system, ideal for plastic processing, compounding, and recycling applications. Featuring an electrically heated, water-cooled (closed-loop) vented barrel, this extruder ensures efficient temperature management and consistent melt quality.

Mounted at an approximate 69" centerline height, this extruder's height can be reduced by 8 inches by removing the additional base, allowing for greater flexibility in plant integration.

The system is powered by a 150 HP Emerson DC motor, which is direct-driven in a tuck-under manner via a Lufkin change gear gearbox with a 13.89:1 reduction ratio. A Control Technique Mentor II SCR drive ensures precise speed and torque control for optimal performance.

For enhanced material processing, the unit includes a Dynisco EH-35 hydraulic screen changer with a 3 HP hydraulic pack, mounted on the extruder discharge, along with a 20 HP melt pump with integrated controls.

The integral control panel features fourteen (14) zones of temperature control, providing advanced process optimization for various extrusion applications.

Specifications:

- Screw Diameter: 3.5 inches

- L/D Ratio: 30:1

- Barrel Features:

- Electrically heated, water-cooled (closed-loop) system

- Vented barrel for enhanced degassing

- Centerline Height:

- Approx. 69 inches

- Can be reduced by 8 inches by removing base

- Gearbox:

- Lufkin change gear gearbox

- Reduction Ratio: 13.89:1

- Direct-driven, tuck-under configuration

- Motor & Drive System:

- 150 HP Emerson DC Motor

- Control Technique Mentor II SCR control

- Screen Changer:

- Dynisco EH-35 hydraulic screen changer

- 3 HP hydraulic pack

- Melt Pump:

- 20 HP melt pump with integrated controls

- Control Panel:

- Fourteen (14) temperature control zones

Applications:

- Plastics & Polymer Extrusion: Pelletizing, sheet extrusion, compounding

- Recycling & Reprocessing: Scrap plastic extrusion and polymer recovery

- Industrial Manufacturing: Pipe, tubing, profile, and sheet extrusion

- Chemical & Specialty Material Processing: Thermoplastics and engineered polymers

Common Product Uses:

- High-efficiency extrusion for plastics and polymer production

- Temperature-controlled extrusion with closed-loop water cooling

- Vented barrel design for improved degassing and impurity removal

- Hydraulic screen changer for seamless filtration and material purity

- Optimized extrusion process with 14 temperature control zones

- Welex 3.5" extruder

- Used plastic extrusion machine

- 150 HP extruder for sale

- Industrial extrusion system

- Polymer processing extruder

- Extruder with screen changer and melt pump

- Used Welex 3.5" 30:1 L/D extruder for sale

- Industrial plastic extrusion machine

- 150 HP extrusion system with vented barrel

- Welex extruder with melt pump and screen changer

- High-performance polymer extruder with DC motor

- Used Welex extrusion equipment with hydraulic screen changer

- 30:1 L/D ratio extrusion system for sale

- Industrial plastic sheet extrusion machine

- Used Extruder

- Used Single Screw Extruder

- Used Plastic Equipment

- Used Extrusion Equipment

Used Welex 3.5" 30:1 L/D Extruder. Electrically heated water cooled (closed loop) and vented barrel at an approximate 69" center line height. Center line height can be reduced approximately 8" by removing an additional base. Lufkin change gear gearbox is direct driven in a tuck under manner by a 150 HP Emerson DC motor with Control Technique Mentor II SCR control. Present reduction ratio is 13.89:1. Includes integral panel having fourteen (14) zones of temperature control. Dynisco model EH-35 screen changer with 3 HP hydraulic pack is mounted on the extruder discharge. Also includes 20 HP melt pump with controls.

Manufacturer Information:

- Manufacturer: Welex

- Model: 3.5" 30:1 L/D Extruder

- Condition: Used

Description:

The Welex 3.5" 30:1 L/D Extruder is a high-performance extrusion system, ideal for plastic processing, compounding, and recycling applications. Featuring an electrically heated, water-cooled (closed-loop) vented barrel, this extruder ensures efficient temperature management and consistent melt quality.

Mounted at an approximate 69" centerline height, this extruder's height can be reduced by 8 inches by removing the additional base, allowing for greater flexibility in plant integration.

The system is powered by a 150 HP Emerson DC motor, which is direct-driven in a tuck-under manner via a Lufkin change gear gearbox with a 13.89:1 reduction ratio. A Control Technique Mentor II SCR drive ensures precise speed and torque control for optimal performance.

For enhanced material processing, the unit includes a Dynisco EH-35 hydraulic screen changer with a 3 HP hydraulic pack, mounted on the extruder discharge, along with a 20 HP melt pump with integrated controls.

The integral control panel features fourteen (14) zones of temperature control, providing advanced process optimization for various extrusion applications.

Specifications:

- Screw Diameter: 3.5 inches

- L/D Ratio: 30:1

- Barrel Features:

- Electrically heated, water-cooled (closed-loop) system

- Vented barrel for enhanced degassing

- Centerline Height:

- Approx. 69 inches

- Can be reduced by 8 inches by removing base

- Gearbox:

- Lufkin change gear gearbox

- Reduction Ratio: 13.89:1

- Direct-driven, tuck-under configuration

- Motor & Drive System:

- 150 HP Emerson DC Motor

- Control Technique Mentor II SCR control

- Screen Changer:

- Dynisco EH-35 hydraulic screen changer

- 3 HP hydraulic pack

- Melt Pump:

- 20 HP melt pump with integrated controls

- Control Panel:

- Fourteen (14) temperature control zones

Applications:

- Plastics & Polymer Extrusion: Pelletizing, sheet extrusion, compounding

- Recycling & Reprocessing: Scrap plastic extrusion and polymer recovery

- Industrial Manufacturing: Pipe, tubing, profile, and sheet extrusion

- Chemical & Specialty Material Processing: Thermoplastics and engineered polymers

Common Product Uses:

- High-efficiency extrusion for plastics and polymer production

- Temperature-controlled extrusion with closed-loop water cooling

- Vented barrel design for improved degassing and impurity removal

- Hydraulic screen changer for seamless filtration and material purity

- Optimized extrusion process with 14 temperature control zones

| Manufacturer | Welex |

| Category | Plastics Equipment |

| Subcategory | Extruders - Single Screw Extruder |

- Welex 3.5" extruder

- Used plastic extrusion machine

- 150 HP extruder for sale

- Industrial extrusion system

- Polymer processing extruder

- Extruder with screen changer and melt pump

- Used Welex 3.5" 30:1 L/D extruder for sale

- Industrial plastic extrusion machine

- 150 HP extrusion system with vented barrel

- Welex extruder with melt pump and screen changer

- High-performance polymer extruder with DC motor

- Used Welex extrusion equipment with hydraulic screen changer

- 30:1 L/D ratio extrusion system for sale

- Industrial plastic sheet extrusion machine

- Used Extruder

- Used Single Screw Extruder

- Used Plastic Equipment

- Used Extrusion Equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory