About

About

New Mixing & Blending Equipment

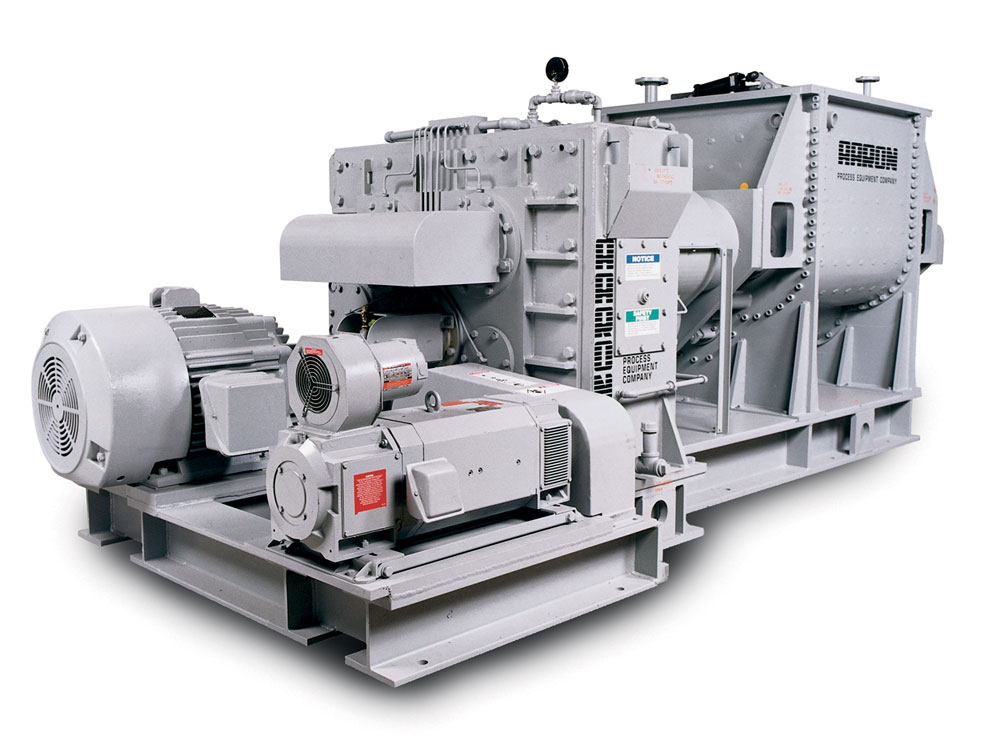

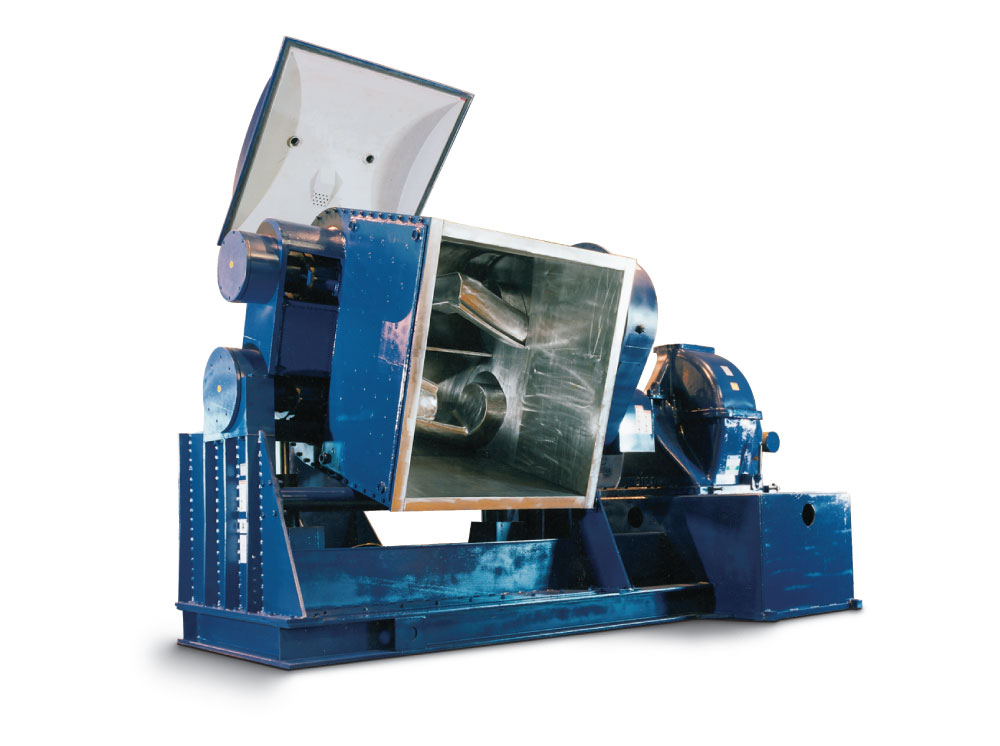

Aaron Process Equipment

For over 80 years, Aaron Process Equipment recognized the demand for competitively priced new process equipment. Their new line of processing equipment is designed and engineered for the most demanding applications with unsurpassed quality and dependability. Today, Aaron Process is recognized for designing and manufacturing the most advanced line of quality mixing and blending machinery in the industry.

Aaron Process offers a complete line of Sigma Blade Mixers, Mixer Extruders, Plow Mixers, FDA approved Sanitary Ribbon Blenders, Planetary Mixers and a Laboratory style mixers. All of their mixers are available in many sizes and available with standard design features and upgradeable options.