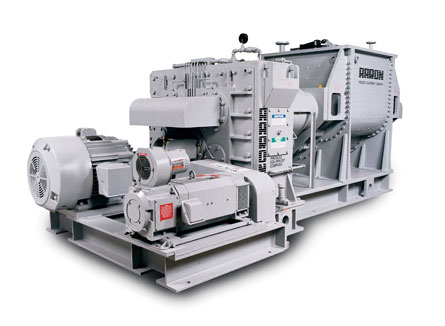

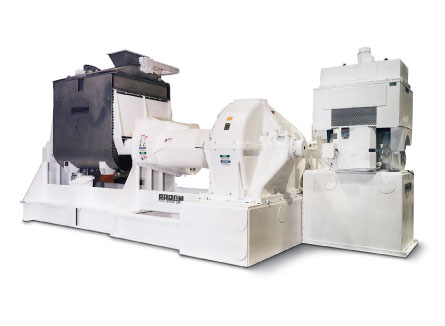

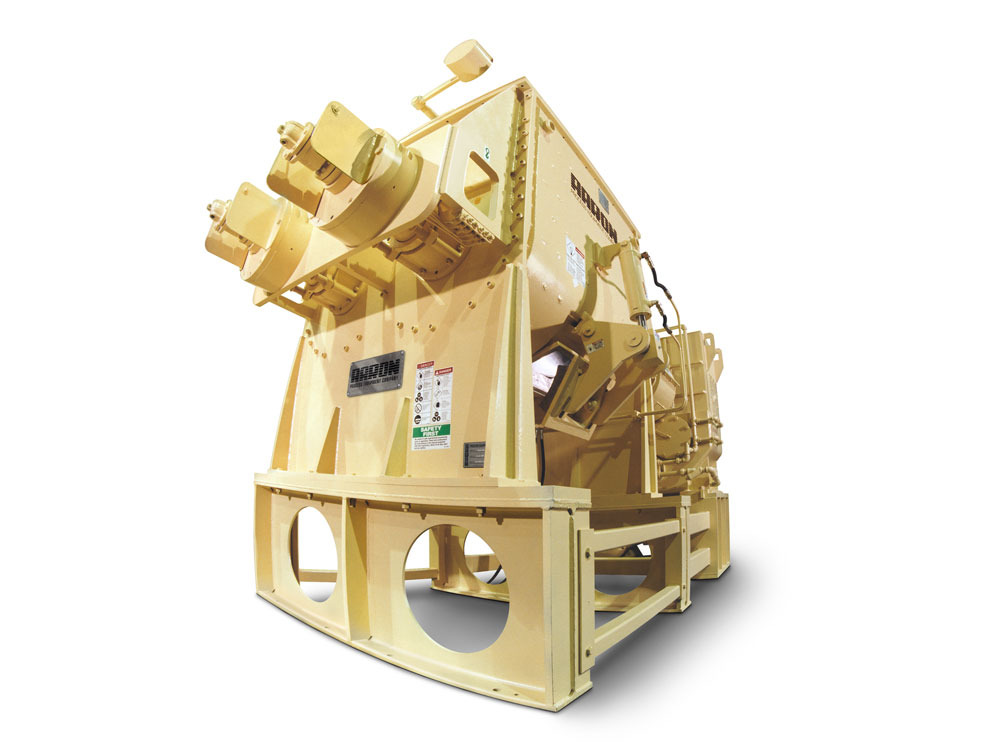

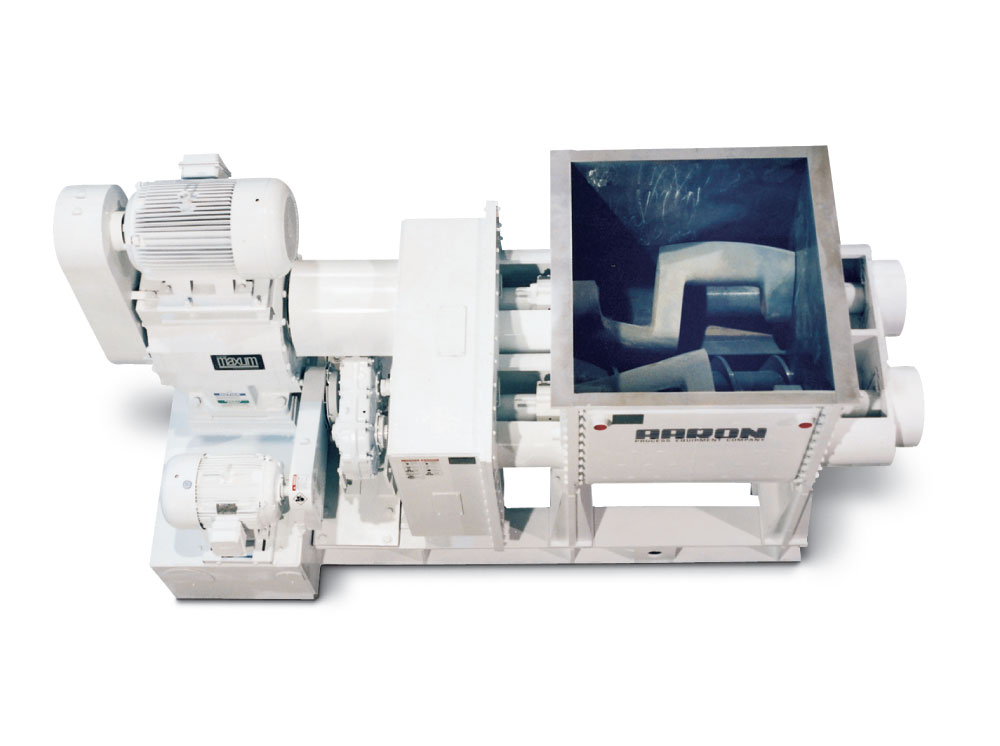

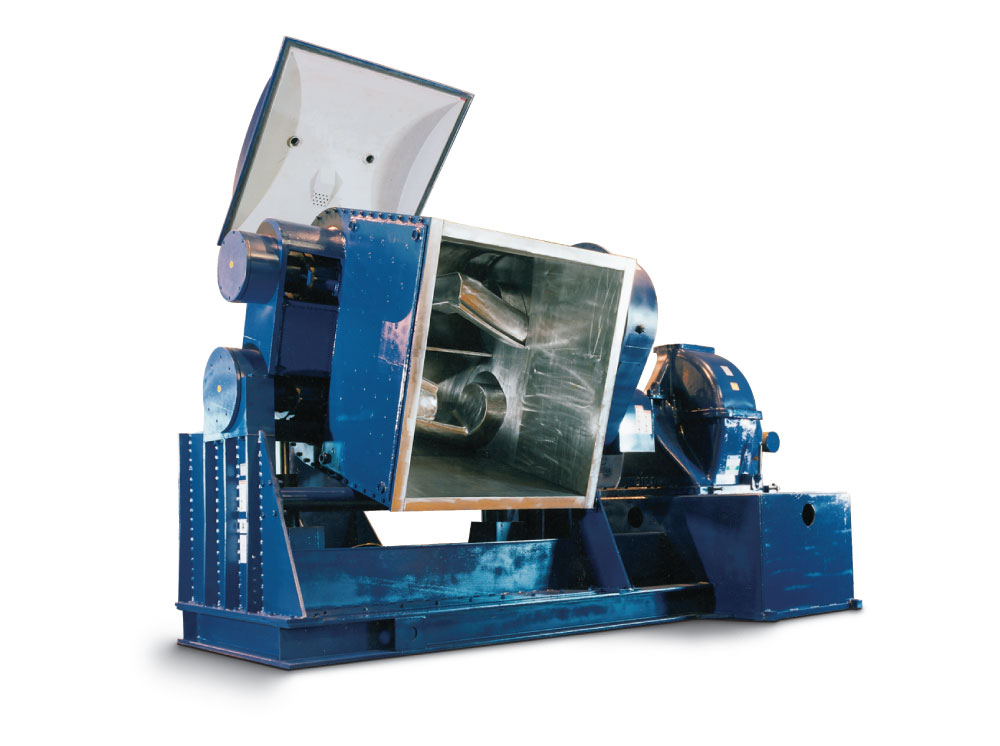

MBG & ZBG Models

Double Arm Mixers

The Aaron Process MBG & ZBG bottom discharge double arm mixer is known for ease of operation, mixing efficiency and variable bottom discharge options from flush valves to typical flange mounted ball & gate valves.

Mixing adhesives, ceramics, lubricants, carbon pastes or any other semi flow-able viscous products can easily be handled in the Aaron Process MBG & ZBG mixer.

The MBG mixer is also suitable for mixing and drying of heat-sensitive materials that undergo phase changes during processing, such as liquids to plastics to powders.