Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

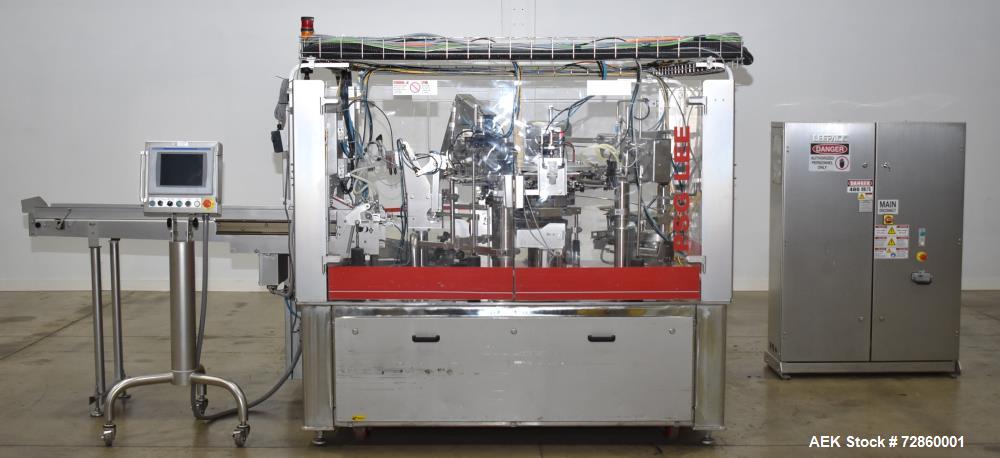

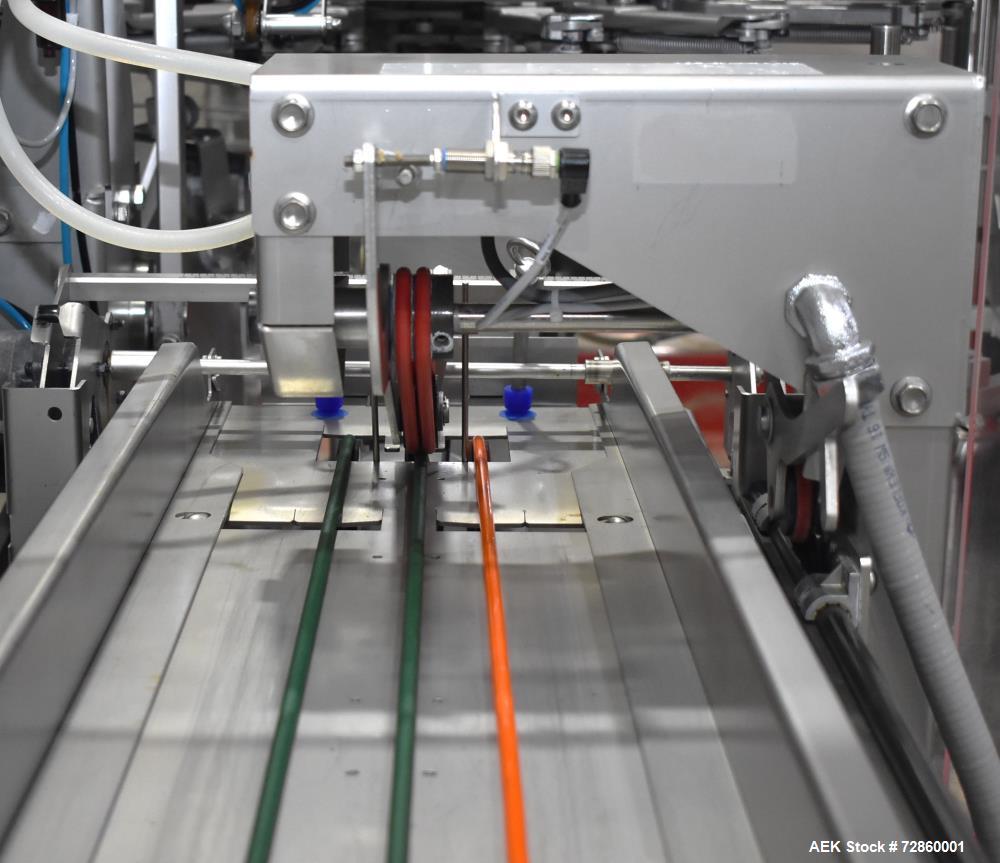

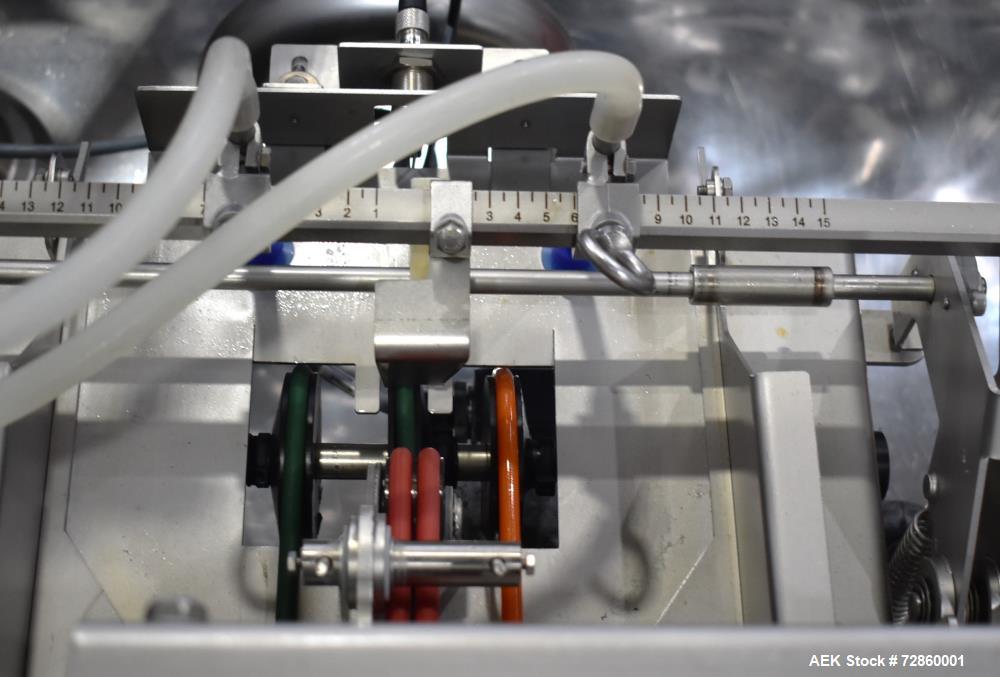

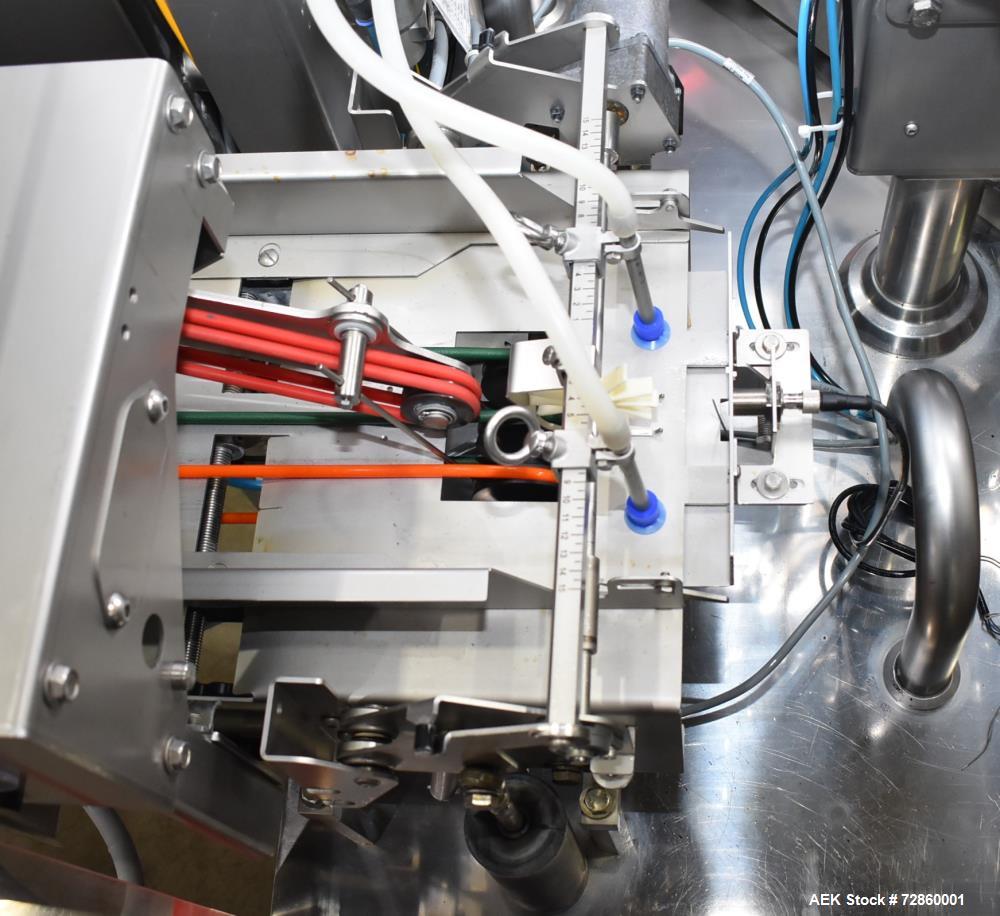

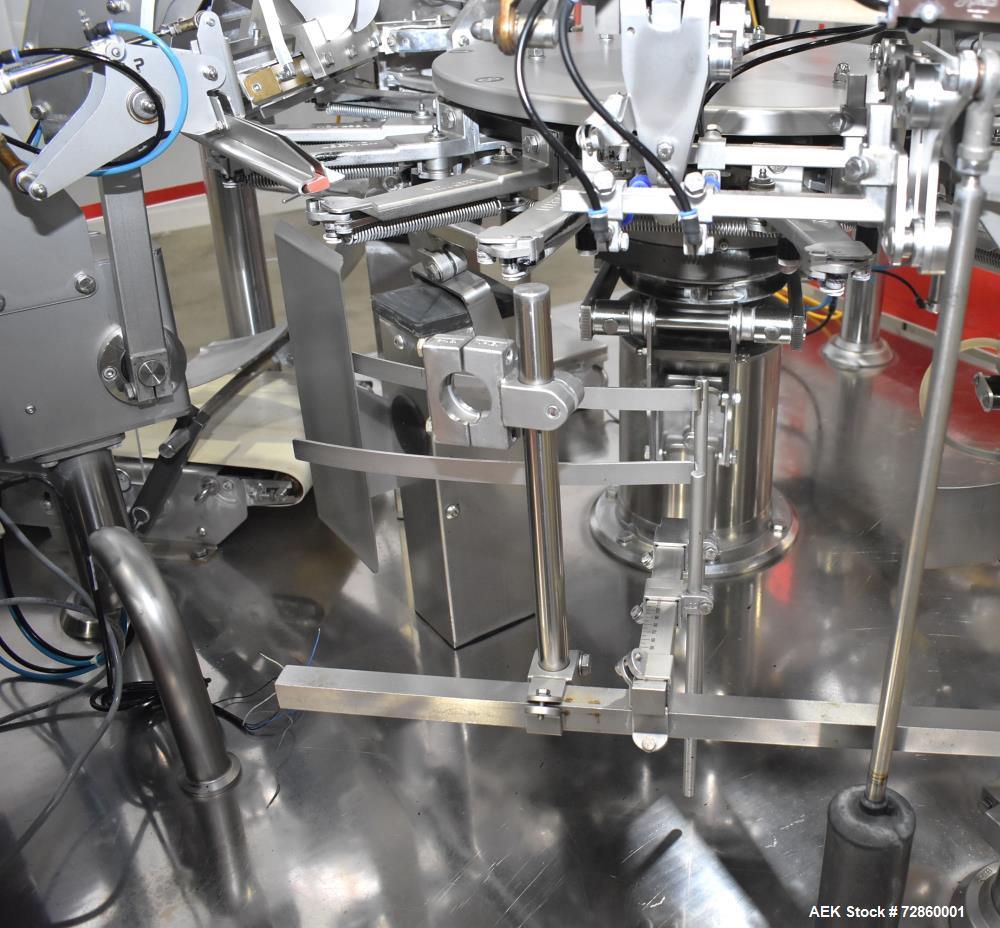

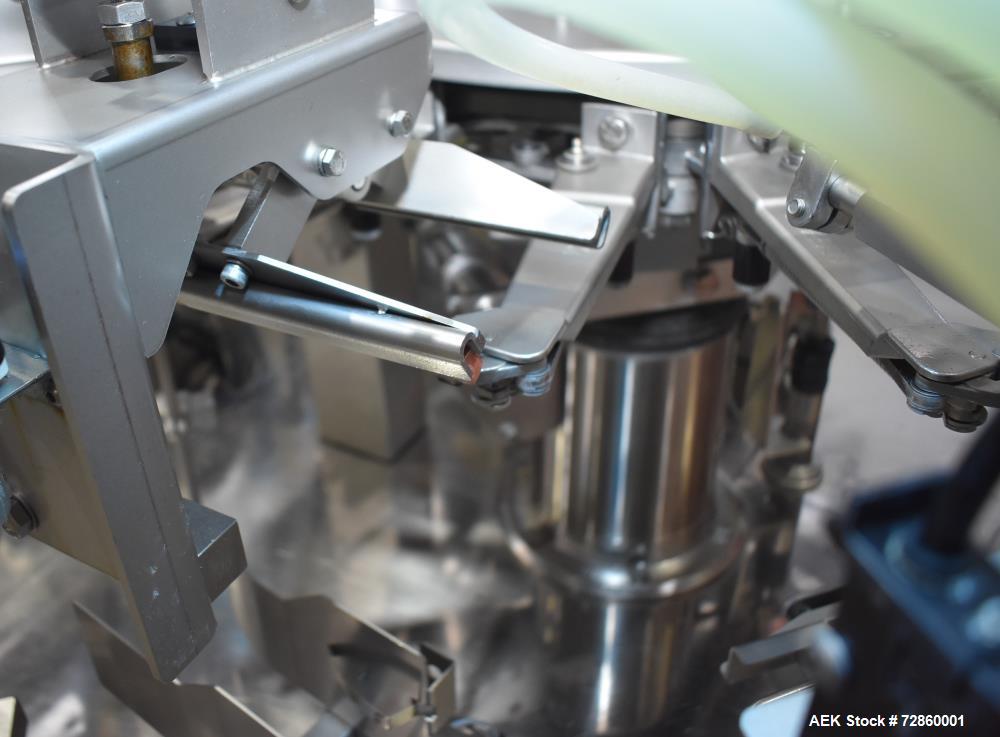

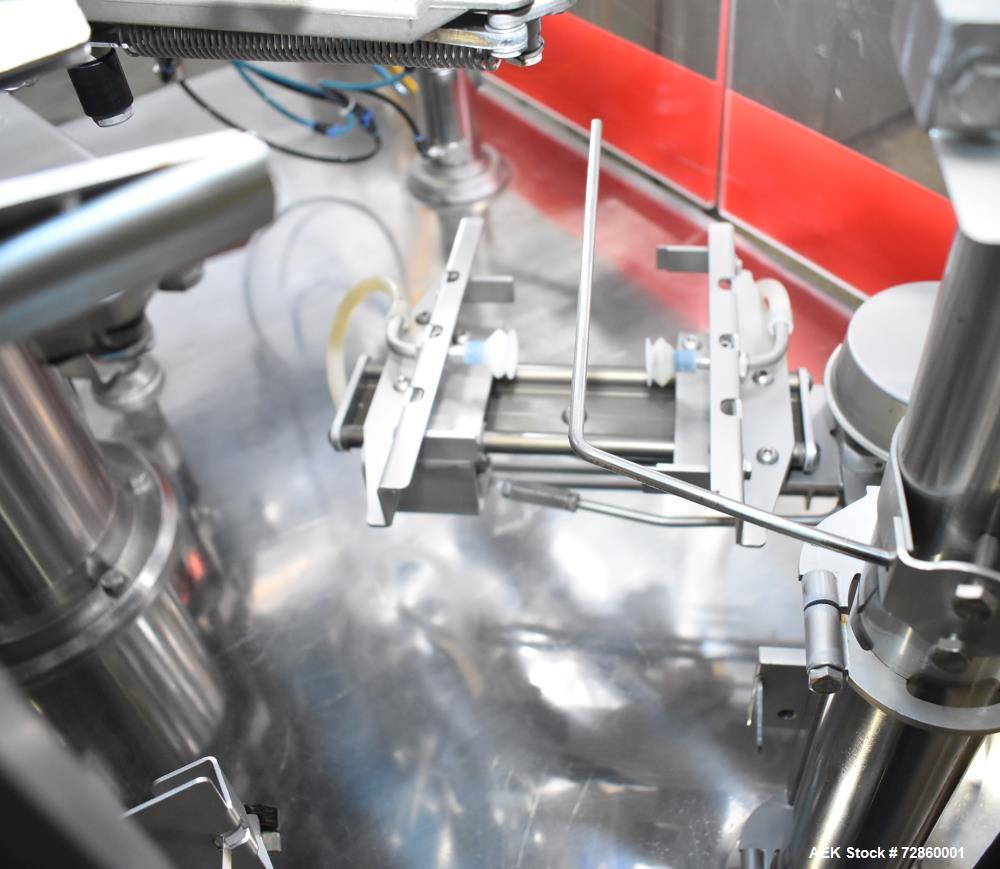

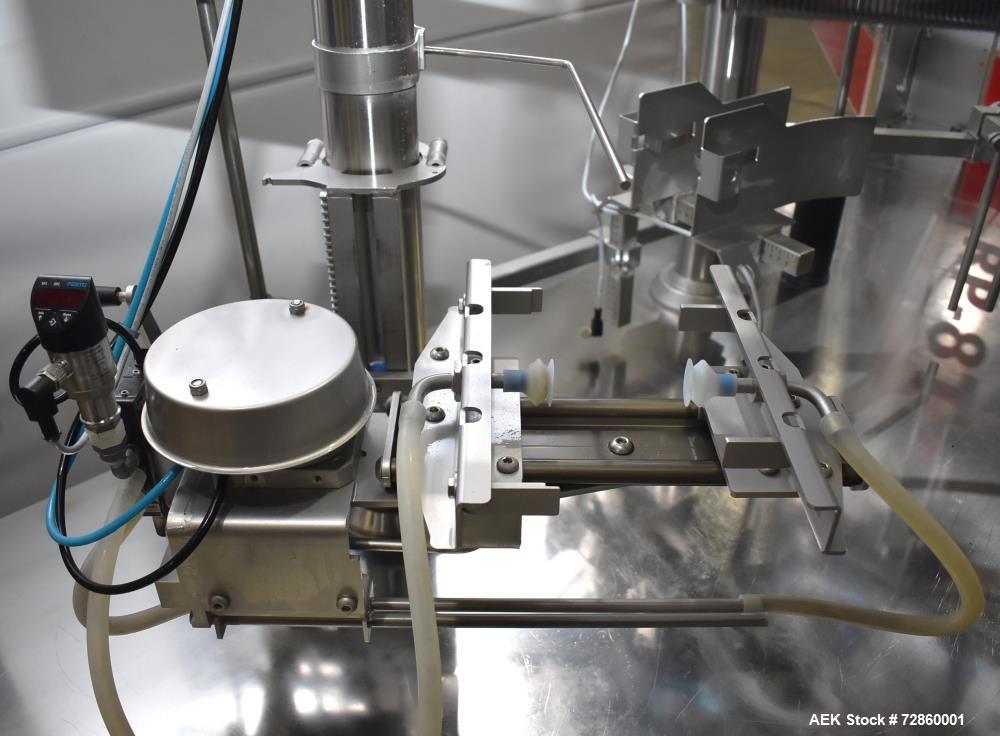

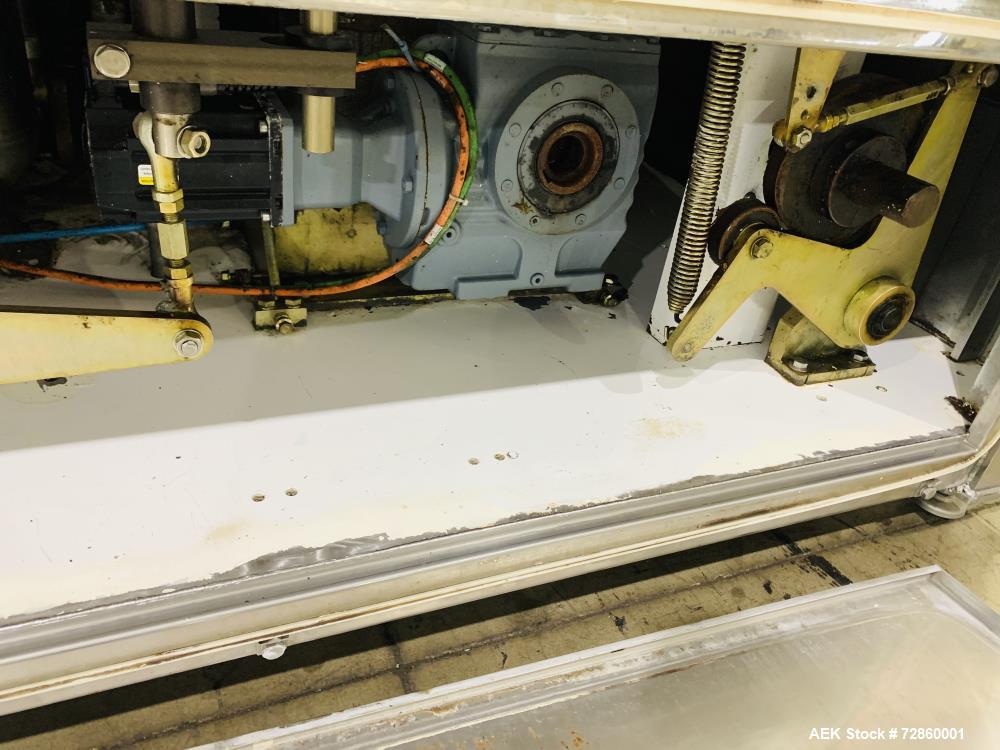

PSG-Lee Model RP-8TZ Washdown Pouch Machine

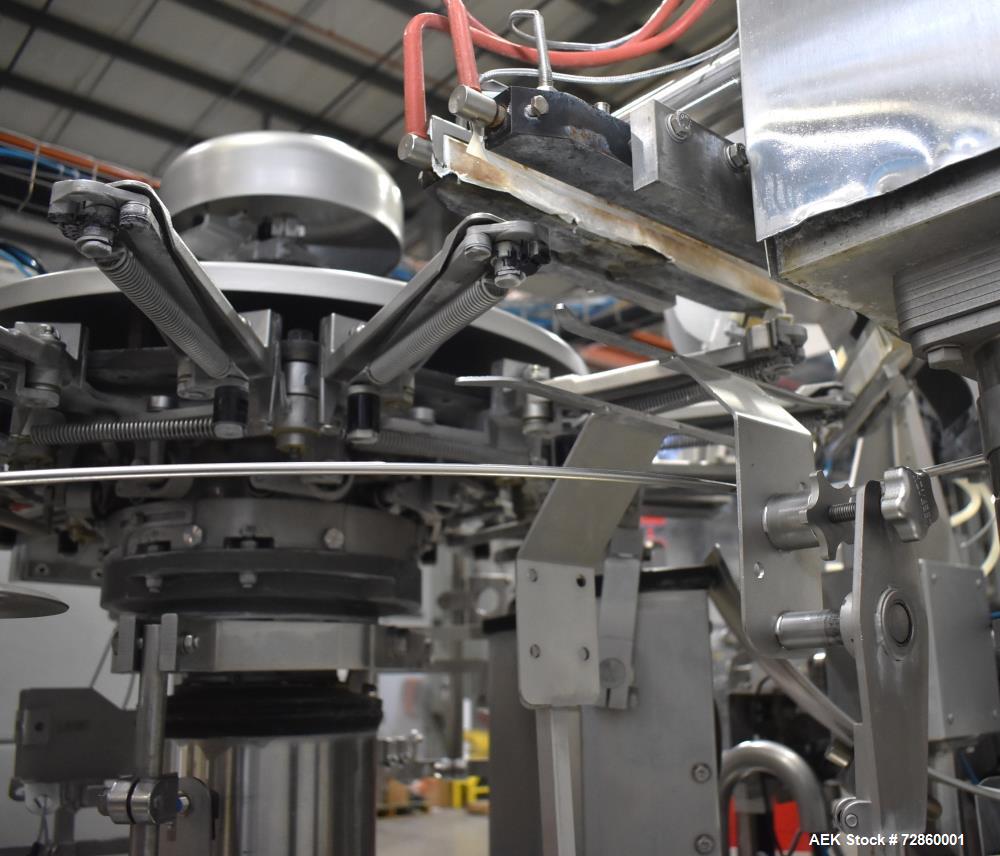

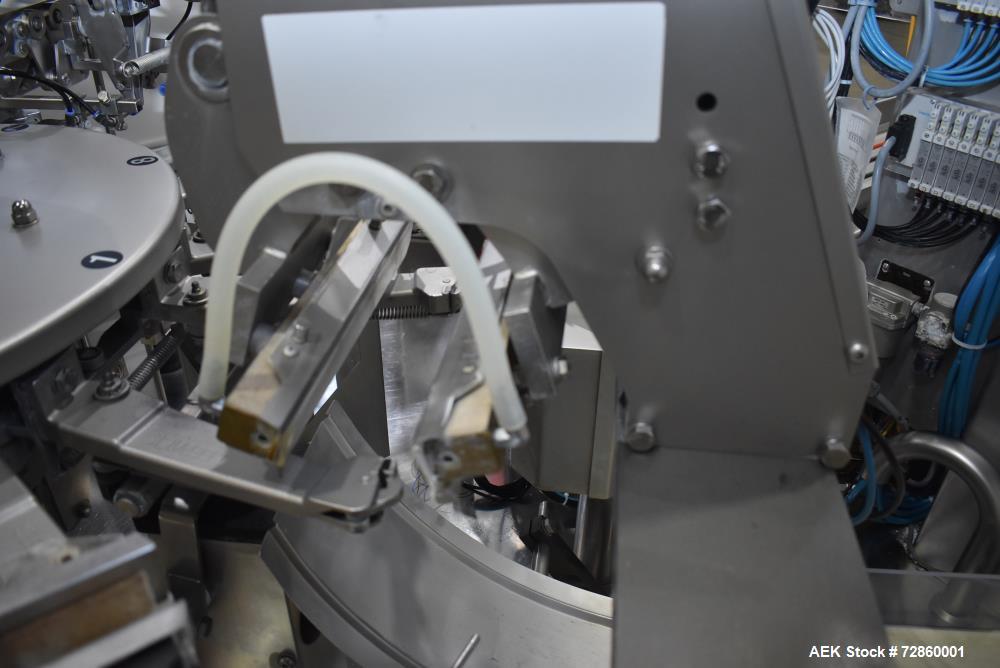

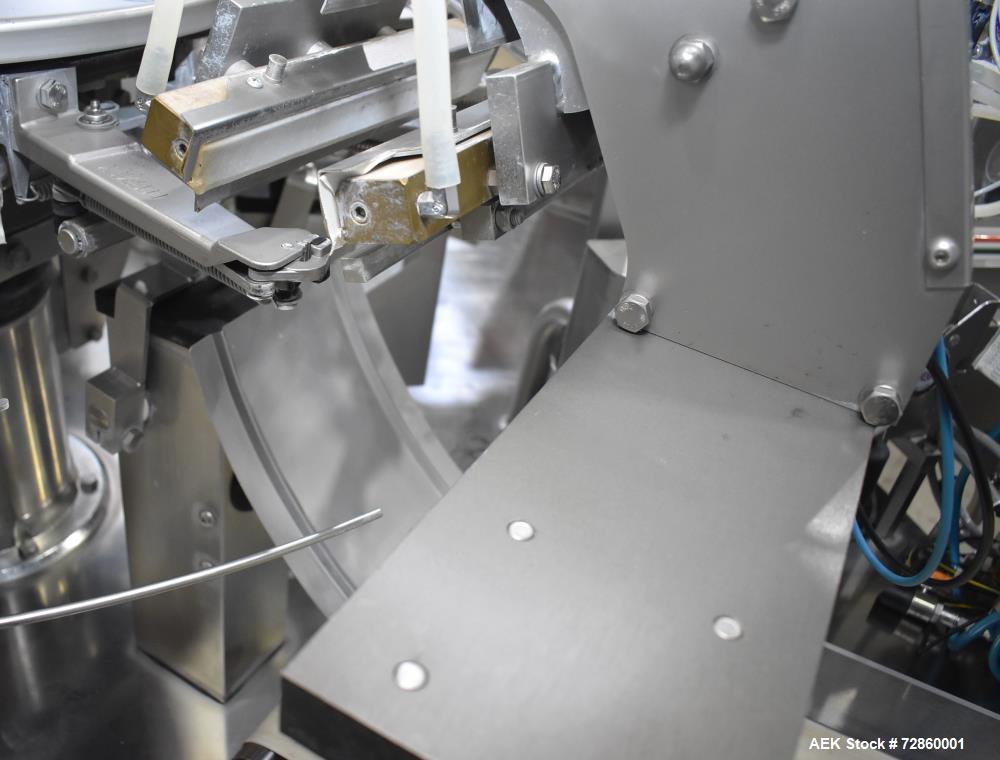

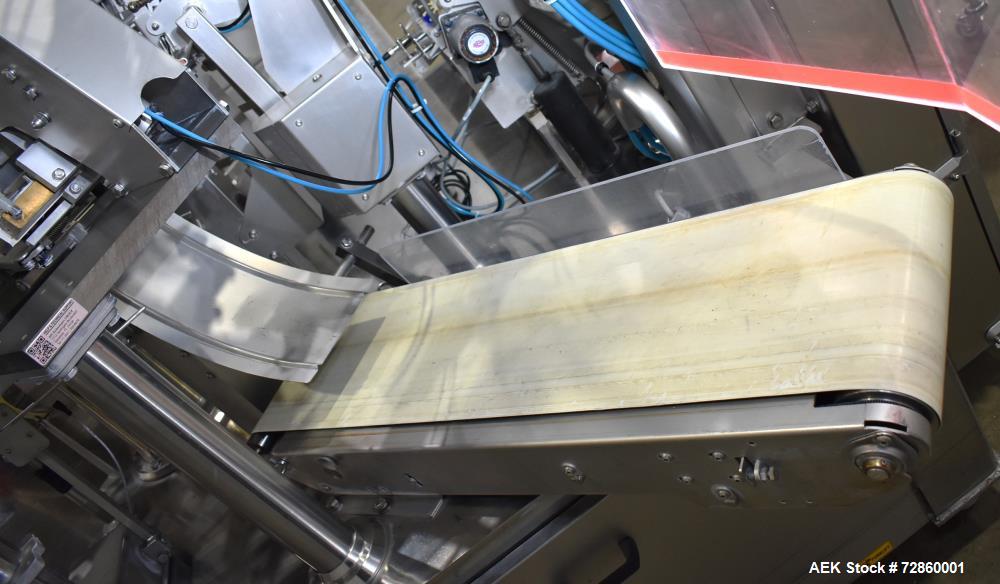

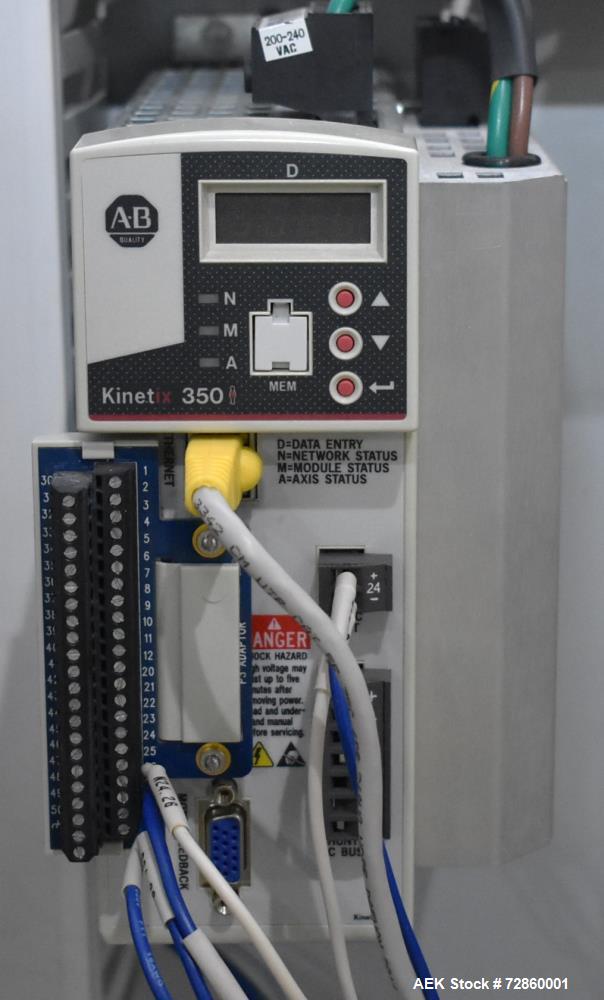

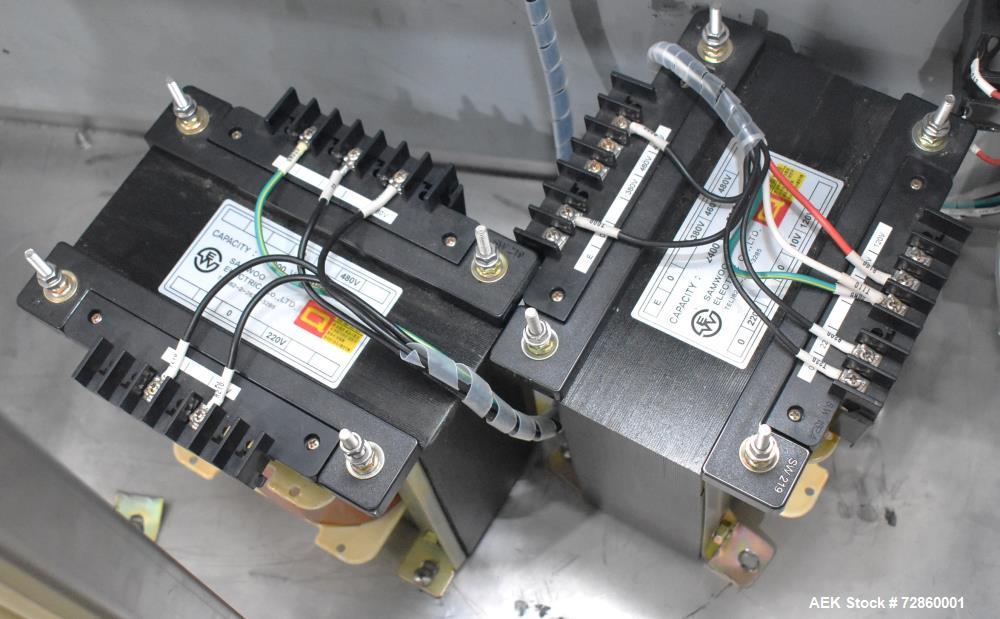

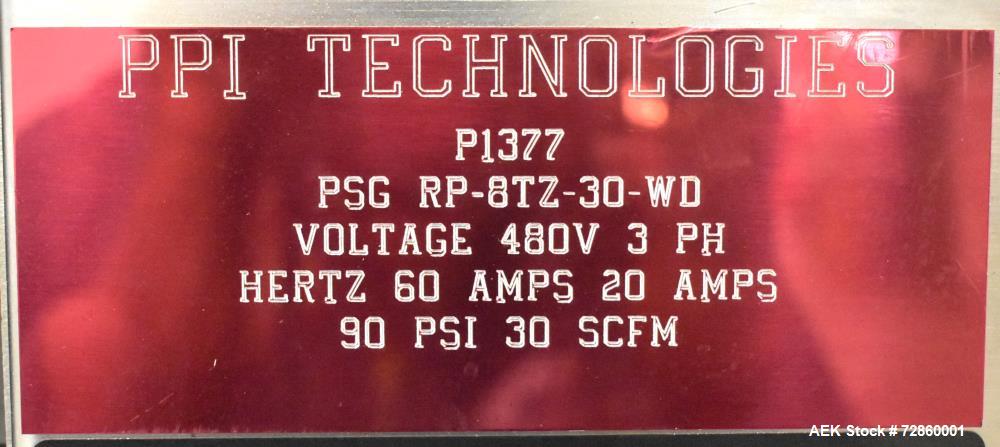

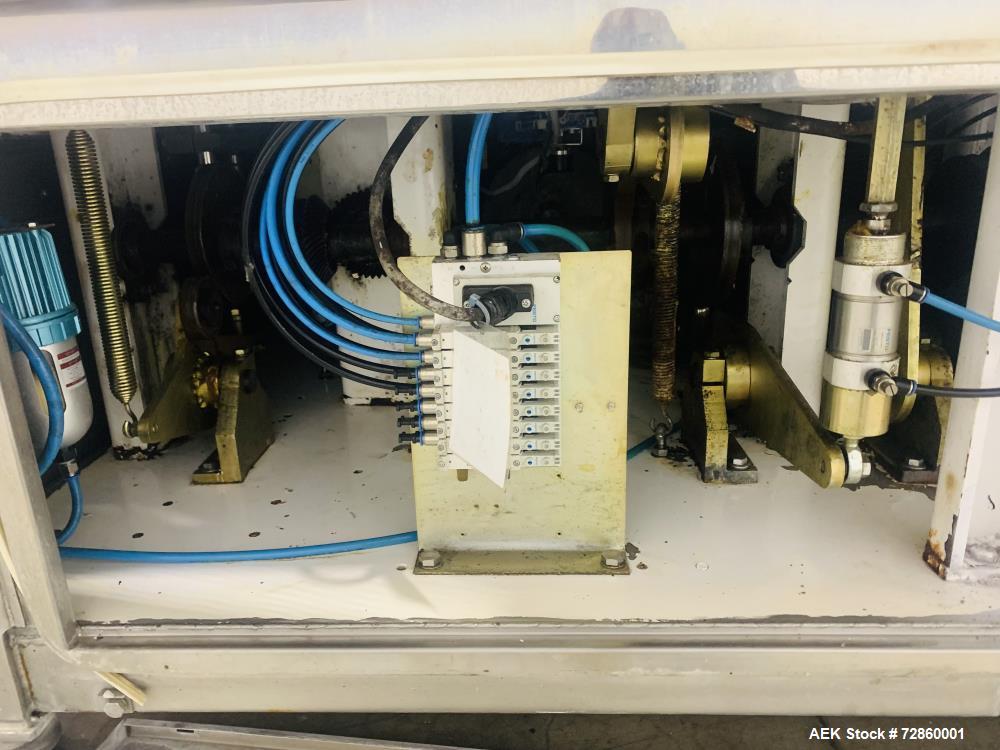

Used PSG-Lee (PPi Technoligies) Model RP-8TZ (30)-WD Stainless Steel Washdown Rotary Pouch Machine. Machine is capable of speeds from 10 - 50 pouches per minute, subject to pouch and product variables. Pouch size range: (Width) 5.9" - 11.8" or 150mm - 300mm, (Length) 4.7" - 13.7" or 120mm - 350mm. Designed for pouches with gusset, stand-up bottom, and zipper seal. Last used in USDA ready to eat facility on frozen meatballs and frozen sausage links. Has an 8-station turret for: #1 pouch pick-up, #2 Zipper Opening & Date Coding (holder for ink jet), #3 Bag Bottom Open, #4 pouch bottom open with pouch present detection, #5 open pouch transfer to fill station with product settler, #6 gas flush, #7 Top heat seal, #8 Top seal cooling, quench, and discharge. Fill station can be adapted for product filler per application, last used in frozen meat packaging operation with combination radial scale (not included). Uses an Allen Bradley compactlogix L30ERM PLC, Allen Bradley PanelView plus 1000 HMI, and A/B Kinetix 350 drive. Gas flush. Is of stainless steel construction with barrier guarding. 10 cfm at 90 psi. 3/60/480 Volt.

Alcohol, Baby Food, Food and Beverage, Food Industry, Juices, k-Cup, Pet Food, Pet Products, Pet Treats, Sauce, Soup, Soups, Wine

Used PSG-Lee (PPi Technoligies) Model RP-8TZ (30)-WD Stainless Steel Washdown Rotary Pouch Machine. Machine is capable of speeds from 10 - 50 pouches per minute, subject to pouch and product variables. Pouch size range: (Width) 5.9" - 11.8" or 150mm - 300mm, (Length) 4.7" - 13.7" or 120mm - 350mm. Designed for pouches with gusset, stand-up bottom, and zipper seal. Last used in USDA ready to eat facility on frozen meatballs and frozen sausage links. Has an 8-station turret for: #1 pouch pick-up, #2 Zipper Opening & Date Coding (holder for ink jet), #3 Bag Bottom Open, #4 pouch bottom open with pouch present detection, #5 open pouch transfer to fill station with product settler, #6 gas flush, #7 Top heat seal, #8 Top seal cooling, quench, and discharge. Fill station can be adapted for product filler per application, last used in frozen meat packaging operation with combination radial scale (not included). Uses an Allen Bradley compactlogix L30ERM PLC, Allen Bradley PanelView plus 1000 HMI, and A/B Kinetix 350 drive. Gas flush. Is of stainless steel construction with barrier guarding. 10 cfm at 90 psi. 3/60/480 Volt.

Alcohol, Baby Food, Food and Beverage, Food Industry, Juices, k-Cup, Pet Food, Pet Products, Pet Treats, Sauce, Soup, Soups, Wine

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)