Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

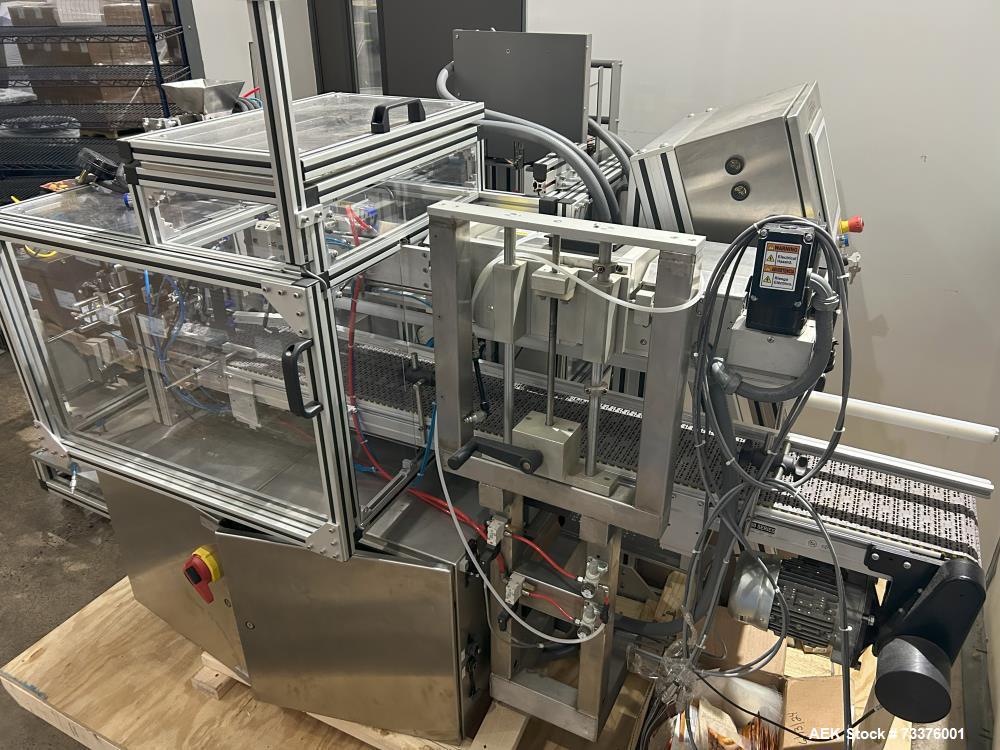

Used Urania "Packaging Answer" Pouch Pro Premade Pouch Filler & Sealer | 20-25 BPM

Used Urania "Packaging Answer" Pouch Pro Pemade Pouch Filler and Sealer. Capable of speeds from 20 - 25 bags per minute (depending on application. Set up for stand up bags with a zipper. Includes ID Technology model 252 label applicator. Has Allen Bradley PLC controls with internet conection. Originally designed to handle pouches up to 5.75" wide x 10" long pouch. System takes pre-made pouch, indexes to a single station indexing conveyor product loader. Loader was pushing pipette trays into bag, inserting a pouch desiccant and a prefolded leaflet, then pouch was sealed. Sealing belts made of Teflon coated fiberglass. Sealing bars tri-axial self-adjusting. Temperature range 100 degree C to 300 degree C. 304 Stainless steel and anodized 6061 aluminum construction. Pouches must be supplied for processing with the zipper open.

| Manufacturer | UraniaUrania |

| Model | Packaging Answer Pouch Pro |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Form & Fill Horizontal - Pre Made BagsForm & Fill Horizontal - Pre Made Bags |

| Make | Urania |

| Model Number | Packaging Answer Pouch Pro |

| Speed | 20 - 25 |

| Package Size Range (Length) | 10" |

| Package Size Range (Width) | 5.75" |

| Make and Model of PLC | Allen Bradley |

Description

This used Urania "Packaging Answer" Pouch Pro Premade Pouch Filler & Sealer is a high-speed automated packaging system, capable of filling and sealing stand-up pouches with zippers at speeds of 20-25 bags per minute (depending on the application). The system is designed to handle pouches up to 5.75” wide x 10” long and features a single-station indexing conveyor product loader for precise material handling.

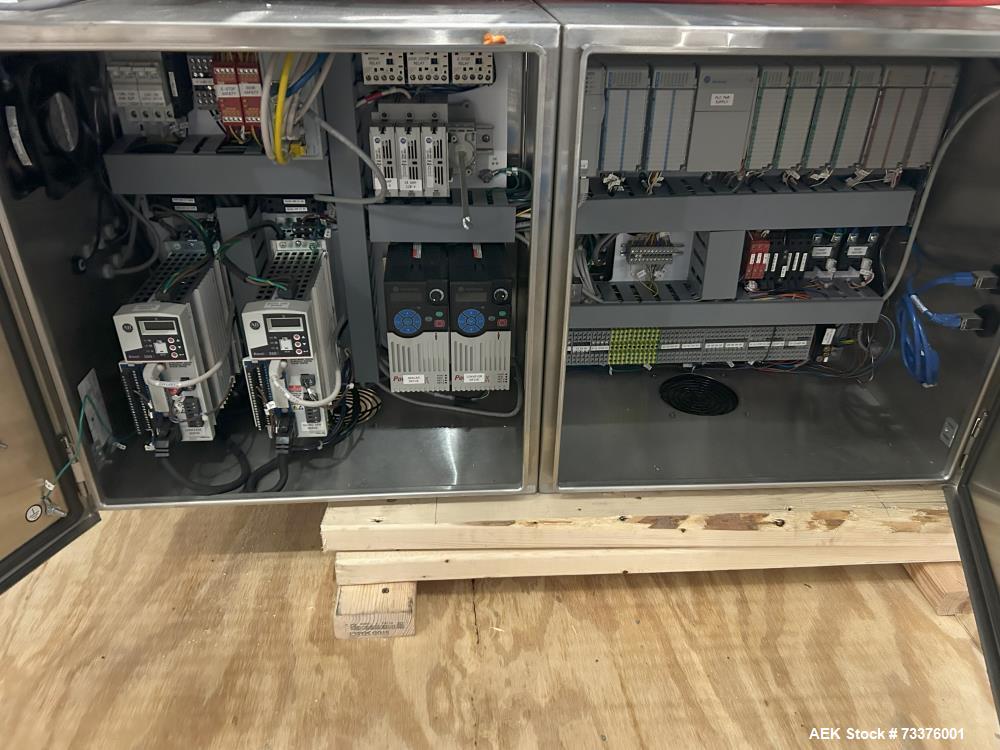

The machine includes an ID Technology Model 252 label applicator and is equipped with Allen Bradley PLC controls with internet connectivity for remote monitoring and operational efficiency. The system was previously set up for loading pipette trays into pouches, inserting a pouch desiccant and a prefolded leaflet, followed by heat sealing using Teflon-coated fiberglass sealing belts and tri-axial self-adjusting sealing bars.

The unit is constructed from 304 stainless steel and anodized 6061 aluminum, ensuring durability, sanitation, and compliance with industrial packaging standards.

Specifications

- Packaging Speed: 20-25 bags per minute (BPM)

- Pouch Size Range:

- Width: Up to 5.75”

- Length: Up to 10”

- Pouch Type: Stand-up bags with zippers (must be supplied with zippers open)

- Sealing System:

- Teflon-coated fiberglass sealing belts

- Tri-axial self-adjusting sealing bars

- Temperature Range: 100°C to 300°C

- Product Handling: Single-station indexing conveyor

- Additional Features:

- ID Technology Model 252 Label Applicator

- Allen Bradley PLC Controls with Internet Connectivity

- Construction Material: 304 Stainless Steel & Anodized 6061 Aluminum

Applications

This Urania Pouch Filler & Sealer is ideal for:

- Food Packaging – Snacks, coffee, dried goods, and powders.

- Pharmaceutical & Nutraceuticals – Pills, supplements, and medical components.

- Personal Care & Cosmetics – Lotions, wipes, and beauty products.

- Industrial & Chemical Packaging – Desiccants, small components, and non-food items.

Compatible Products

This pouch filler & sealer is suitable for packaging:

- Stand-up pouches with zippers

- Preloaded medical kits or laboratory materials

- Snack foods, dried goods, and powdered supplements

- Cosmetic and personal care products

- Chemical and industrial items requiring sealed packaging

Candied Products, Candies, Candy, Candy, Candy and Confectionary, Chemical, Chemical Powders, Chemical Products, Chemicals, Coffee, Coffee Beans, Coffee, Tea, Cosmetic, Cosmetics, Creams, Food Industry, Food Ingredients, Food Manufacturing, Food Packaging, Food Powder, Food Products, Foods, Fruits & Nuts, Packaging, Packaging Equipment, Pet Food, Pet Products, Pet Supplies, Pharmaceutical, Pharmaceutical Industries, Pharmaceutical Products, Pharmaceuticals, Powders

- Used Premade Pouch Filler & Sealer

- Urania Pouch Pro Packaging Machine

- High-Speed Stand-Up Pouch Filler

- Pouch Sealing Machine with Zipper Support

- Industrial Bagging System for Sale

- Used Urania "Packaging Answer" Pouch Pro Filler & Sealer for Sale

- Automated Premade Pouch Filler with Zipper Closure Support

- High-Speed Stand-Up Pouch Sealer with Label Applicator

- Industrial Pouch Filling & Sealing Machine for Food & Pharma

- Single-Station Indexing Conveyor Packaging Machine

- Used Urania Pouch Pro Premade Pouch Filler & Sealer with ID Technology Label Applicator

- High-Speed 20-25 BPM Stand-Up Pouch Packaging System with Allen Bradley PLC Controls

- Automated Zipper Pouch Filling & Sealing Machine with Adjustable Temperature Control

- Industrial-Grade Food & Pharmaceutical Pouch Packaging System with Internet Connectivity

- Used Premade Pouch Filler for Snacks, Supplements, and Chemical Packaging Applications

Used Urania "Packaging Answer" Pouch Pro Pemade Pouch Filler and Sealer. Capable of speeds from 20 - 25 bags per minute (depending on application. Set up for stand up bags with a zipper. Includes ID Technology model 252 label applicator. Has Allen Bradley PLC controls with internet conection. Originally designed to handle pouches up to 5.75" wide x 10" long pouch. System takes pre-made pouch, indexes to a single station indexing conveyor product loader. Loader was pushing pipette trays into bag, inserting a pouch desiccant and a prefolded leaflet, then pouch was sealed. Sealing belts made of Teflon coated fiberglass. Sealing bars tri-axial self-adjusting. Temperature range 100 degree C to 300 degree C. 304 Stainless steel and anodized 6061 aluminum construction. Pouches must be supplied for processing with the zipper open.

Description

This used Urania "Packaging Answer" Pouch Pro Premade Pouch Filler & Sealer is a high-speed automated packaging system, capable of filling and sealing stand-up pouches with zippers at speeds of 20-25 bags per minute (depending on the application). The system is designed to handle pouches up to 5.75” wide x 10” long and features a single-station indexing conveyor product loader for precise material handling.

The machine includes an ID Technology Model 252 label applicator and is equipped with Allen Bradley PLC controls with internet connectivity for remote monitoring and operational efficiency. The system was previously set up for loading pipette trays into pouches, inserting a pouch desiccant and a prefolded leaflet, followed by heat sealing using Teflon-coated fiberglass sealing belts and tri-axial self-adjusting sealing bars.

The unit is constructed from 304 stainless steel and anodized 6061 aluminum, ensuring durability, sanitation, and compliance with industrial packaging standards.

Specifications

- Packaging Speed: 20-25 bags per minute (BPM)

- Pouch Size Range:

- Width: Up to 5.75”

- Length: Up to 10”

- Pouch Type: Stand-up bags with zippers (must be supplied with zippers open)

- Sealing System:

- Teflon-coated fiberglass sealing belts

- Tri-axial self-adjusting sealing bars

- Temperature Range: 100°C to 300°C

- Product Handling: Single-station indexing conveyor

- Additional Features:

- ID Technology Model 252 Label Applicator

- Allen Bradley PLC Controls with Internet Connectivity

- Construction Material: 304 Stainless Steel & Anodized 6061 Aluminum

Applications

This Urania Pouch Filler & Sealer is ideal for:

- Food Packaging – Snacks, coffee, dried goods, and powders.

- Pharmaceutical & Nutraceuticals – Pills, supplements, and medical components.

- Personal Care & Cosmetics – Lotions, wipes, and beauty products.

- Industrial & Chemical Packaging – Desiccants, small components, and non-food items.

Compatible Products

This pouch filler & sealer is suitable for packaging:

- Stand-up pouches with zippers

- Preloaded medical kits or laboratory materials

- Snack foods, dried goods, and powdered supplements

- Cosmetic and personal care products

- Chemical and industrial items requiring sealed packaging

Candied Products, Candies, Candy, Candy, Candy and Confectionary, Chemical, Chemical Powders, Chemical Products, Chemicals, Coffee, Coffee Beans, Coffee, Tea, Cosmetic, Cosmetics, Creams, Food Industry, Food Ingredients, Food Manufacturing, Food Packaging, Food Powder, Food Products, Foods, Fruits & Nuts, Packaging, Packaging Equipment, Pet Food, Pet Products, Pet Supplies, Pharmaceutical, Pharmaceutical Industries, Pharmaceutical Products, Pharmaceuticals, Powders

| Manufacturer | Urania |

| Model | Packaging Answer Pouch Pro |

| Category | Packaging Equipment |

| Subcategory | Form & Fill Horizontal - Pre Made Bags |

| Make | Urania |

| Model Number | Packaging Answer Pouch Pro |

| Speed | 20 - 25 |

| Package Size Range (Length) | 10" |

| Package Size Range (Width) | 5.75" |

| Make and Model of PLC | Allen Bradley |

- Used Premade Pouch Filler & Sealer

- Urania Pouch Pro Packaging Machine

- High-Speed Stand-Up Pouch Filler

- Pouch Sealing Machine with Zipper Support

- Industrial Bagging System for Sale

- Used Urania "Packaging Answer" Pouch Pro Filler & Sealer for Sale

- Automated Premade Pouch Filler with Zipper Closure Support

- High-Speed Stand-Up Pouch Sealer with Label Applicator

- Industrial Pouch Filling & Sealing Machine for Food & Pharma

- Single-Station Indexing Conveyor Packaging Machine

- Used Urania Pouch Pro Premade Pouch Filler & Sealer with ID Technology Label Applicator

- High-Speed 20-25 BPM Stand-Up Pouch Packaging System with Allen Bradley PLC Controls

- Automated Zipper Pouch Filling & Sealing Machine with Adjustable Temperature Control

- Industrial-Grade Food & Pharmaceutical Pouch Packaging System with Internet Connectivity

- Used Premade Pouch Filler for Snacks, Supplements, and Chemical Packaging Applications

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)