Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Bartelt (Klockner) IM7-14 Servo HFFS Pouch Machine – Up to 100 CPM

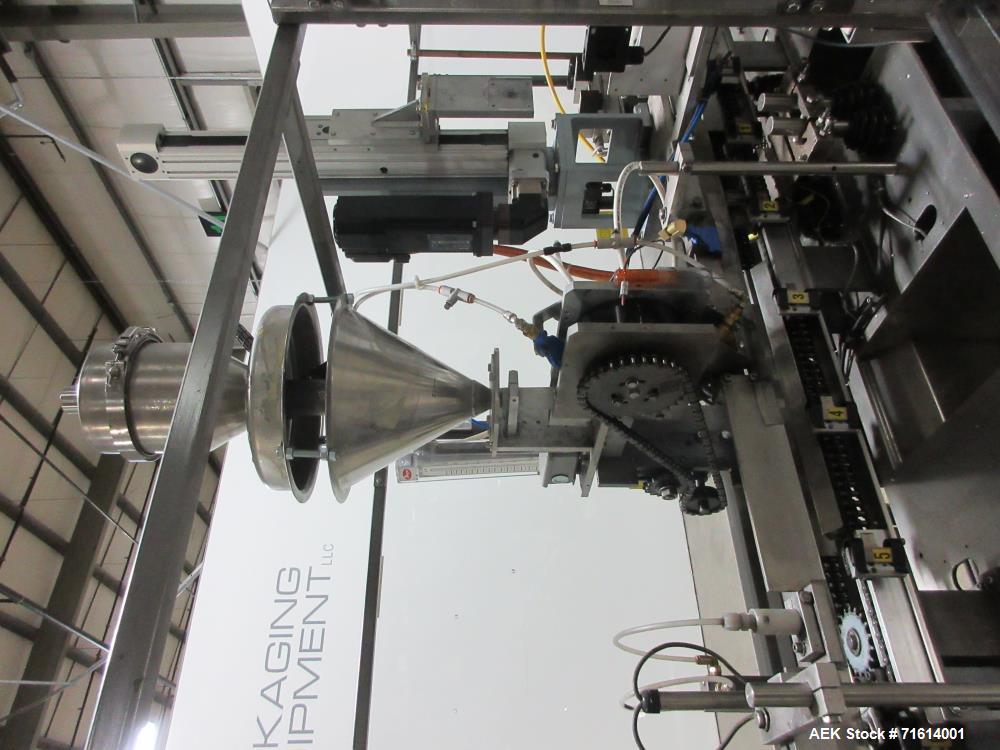

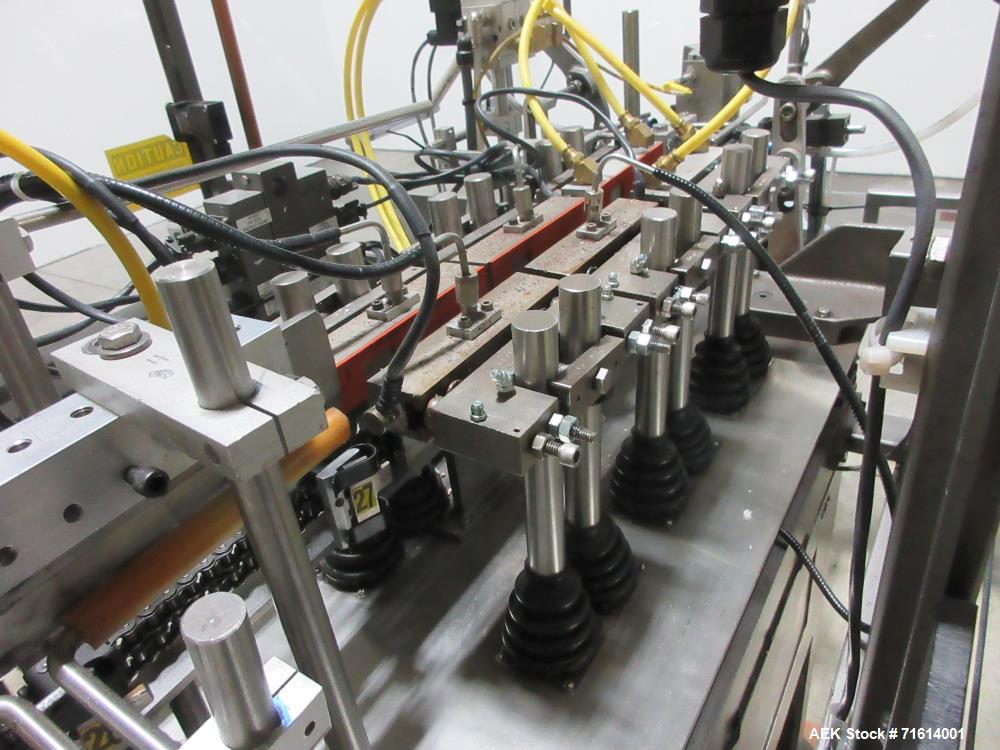

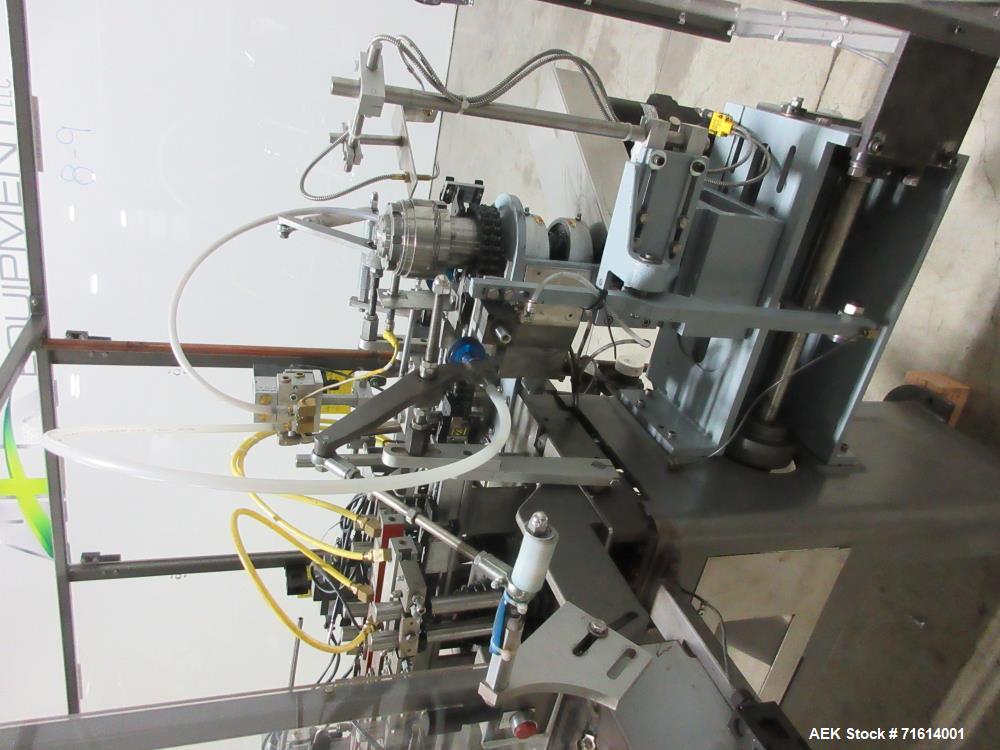

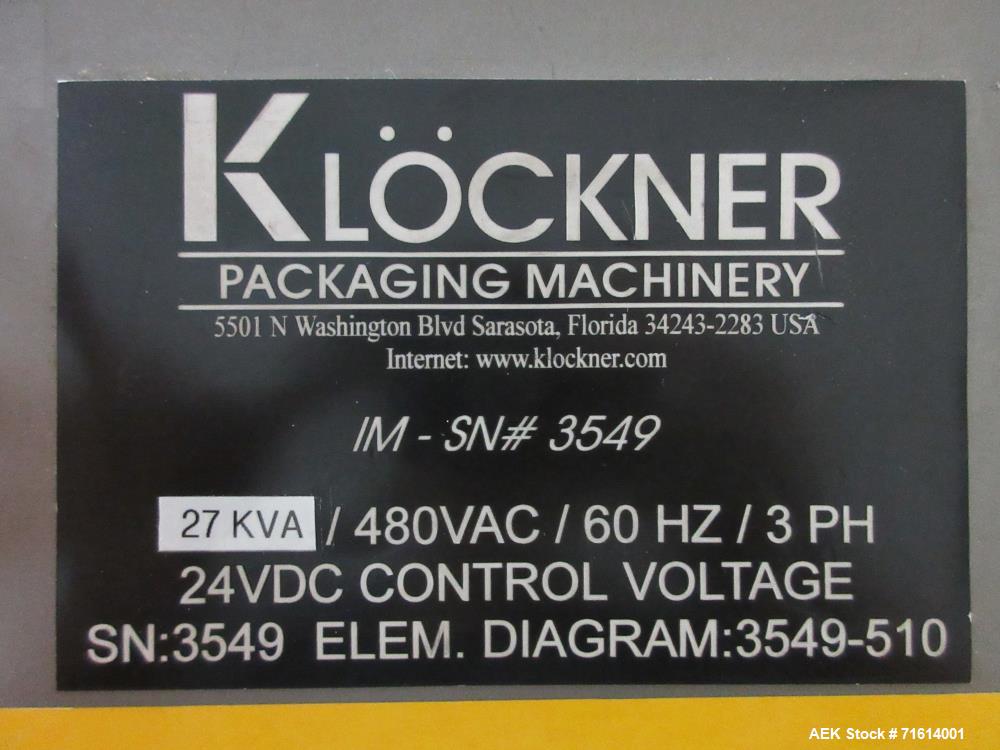

Used Bartelt (Klockner) Model IM7-14 Servo Horizontal Form Fill and Seal Machine. Rated for speeds up to 100 cpm. Has pouch size range: width 2" - 5-3/4"; height 2" - 9" (change parts may be required). Now tooled for 5-1/2" wide x 4-5/8" tall pouch. Has 2 product fill stations. Now equipped with desiccant bead filler and laboratory med device inserter, other fillers can be retrofitted as needed, consult AEK Sales Department. Equipped with servo film feed and servo indexer, has film feed with web tracking and splice table, pre-heat, final heat and quench vertical seal stations, 2 fill stations with air knife openers, dual front-and-back alternate pick and place pouch discharge. 6" core, Power Unwind, Splice Table, Versatec Web Tension Control, Web Tracking Control, Automatic Web Alignment. Cluster Lube. Uses Schneider Elec PLC Controls and Eco Drive Servos. 3/60/480V.

| Manufacturer | BarteltBartelt |

| Model | IM7-14 |

| Serial # | 3549 |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Form & Fill Horizontal - Horizontal PouchForm & Fill Horizontal - Horizontal Pouch |

| Make | Klockner |

| Model Number | IM7-14 |

| Serial # | 3549 |

| Speed Range CPM | 100 |

| Package Size Range (Width) | 5-1/2" |

| Package Size Range (Height) | 4-5/8" |

| Make and Model of PLC | Schneider |

| Make and Model of HMI | Quick Panel |

| Make and Model of Servo | Eco Drive |

| Maximum Roll Diameter | 24" |

| Current Voltage | 480V |

| OAD (Height) | 97 |

| OAD (Length) | 65 |

| OAD (Width) | 255 |

| Manual | Yes |

| Low Film Sensor | No |

| Hole Punch | No |

| Year Built | 1999 |

Manufacturer Info

-

Manufacturer: Bartelt (Klockner / Klöckner)

-

Model: IM7‑14 Servo HFFS

-

Configuration: 2 product fill stations; currently set up for desiccant bead filler + laboratory medical device inserter (other fillers retrofit‑ready; consult AEK Sales)

-

Rated Speed: Up to 100 cycles per minute (application dependent)

-

Power: 3/60/480V

-

Controls: Schneider Electric PLC & EcoDrive servos

-

Condition: Used

Description

Industrial‑grade Bartelt (Klockner) IM7‑14 Servo Horizontal Form Fill & Seal pouching system configured for high‑speed production. This machine features servo film feed and servo indexing for precise registration, web tracking with automatic alignment, and a full vertical sealing suite (pre‑heat, final heat, quench). It’s presently tooled for 5‑1/2" W × 4‑5/8" H pouches within an adjustable range of 2"–5‑3/4" width and 2"–9" height (change parts may be required). Dual fill stations with air‑knife openers support multi‑component packaging; current tooling includes a desiccant bead filler and a laboratory medical device inserter. Discharge uses dual front‑and‑back alternating pick‑and‑place for smooth downstream transfer. A robust unwind package (6" core, power unwind, splice table) plus Versatec web tension, web tracking control, and automatic web alignment enhances run stability. Cluster Lube system simplifies maintenance.

Specifications

-

Machine Type: Servo Horizontal Form Fill & Seal (HFFS)

-

Model: IM7‑14 (intermittent motion)

-

Rated Speed: Up to 100 CPM

-

Pouch Size Range:

-

Width: 2" to 5‑3/4"

-

Height: 2" to 9"

-

Current Tooling: 5‑1/2" W × 4‑5/8" H

-

(Change parts may be required for other sizes)

-

-

Stations & Tooling:

-

2 product fill stations with air‑knife pouch openers

-

Desiccant bead filler (installed)

-

Laboratory medical device inserter (installed)

-

Other fillers retrofittable (consult AEK Sales)

-

-

Film/Web Handling:

-

Servo film feed & servo indexer

-

6" core power unwind

-

Splice table

-

Versatec web tension control

-

Web tracking control & automatic web alignment

-

-

Sealing: Pre‑heat, final heat, and quench vertical seal stations

-

Discharge: Dual front‑and‑back alternating pick‑and‑place pouch discharge

-

Lubrication: Cluster Lube

-

Controls: Schneider Electric PLC & EcoDrive servo drives

-

Utilities: 3/60/480V electrical

Applications

-

High‑speed pouching for pharma, medical device, and nutraceutical lines

-

Dry goods, desiccants, components, and small device kitting into flat pouches

-

Lab/IVD kits, trials, and contract packaging where quick changeovers are needed

-

Multi‑component or sequential fill operations (e.g., device + desiccant)

What Products Would This Be Used For (Bulleted)

-

Desiccant sachets & humidity control pouches

-

Single‑use medical device components (e.g., swabs, lancets, test cassettes)

-

Diagnostics/IVD items with desiccant inclusion

-

Nutraceutical sample pouches & tablets/capsules in pouches

-

Dry powders, granules, and pellets

-

Hardware/small parts kits

-

Wipes or sterile barrier flat packs (where compatible)

-

Cosmetic samples & sachets

-

Specialty chemical additives

-

Food & beverage dry mix samples (where suitable)

- Used Bartelt Klockner Model IM7-14 Servo Horizontal Form Fill and Seal Machine

- Bartelt Klockner IM7-14 Servo Horizontal Form Fill and Seal Machine

- Klockner IM7-14 Servo Horizontal Form Fill and Seal Machine

- Bartelt IM7-14 Servo Horizontal Form Fill and Seal Machine

- IM7-14 Servo Horizontal Form Fill and Seal Machine

- Horizontal Form Fill and Seal Machine

- Bartelt Horizontal Form Fill and Seal Machine

- Klockner Horizontal Form Fill and Seal Machine

- Used Packaging Machinery

- Used Horizontal Form Fill

- Used Bartelt Horizontal Form Fill

- Used Klockner Horizontal Form Fill

- Pouch Packaging Machine

- Snack Food Pouch Packager

-

HFFS machine

-

Bartelt IM7-14

-

Klockner pouch

-

Servo pouching

-

Form fill seal

-

Pouch machine

-

Industrial sealer

-

Packaging line

-

Desiccant filler

-

Used HFFS

-

Bartelt IM7-14 HFFS for sale

-

Used horizontal form fill seal

-

Servo driven pouch machine

-

Klockner Bartelt pouching line

-

100 cpm pouch equipment

-

Schneider PLC packaging machine

-

Dual fill station HFFS

-

Desiccant pouch inserter

-

Automatic web alignment HFFS

-

Industrial pouch packaging system

-

Used Bartelt Klockner IM7-14 servo horizontal form fill and seal machine

-

Pre-owned HFFS pouch machine with desiccant filler and device inserter

-

Industrial pouching equipment with web tracking and power unwind

-

IM7-14 pouch size range 2 to 5-3/4 inches wide and 2 to 9 inches tall

-

High speed 100 cpm servo form fill seal pouch packer

-

HFFS machine with dual pick and place pouch discharge

-

Schneider Electric PLC EcoDrive servo packaging line

-

Pouch machine with pre-heat final heat and quench vertical seals

-

Horizontal pouching system with Versatec web tension control

-

Retrofit-ready HFFS for medical and nutraceutical packaging

-

Used pouch machine

-

Bartelt packaging

-

Klockner HFFS

-

IM7-14

-

Horizontal form fill seal

-

Servo packaging machine

-

Medical device pouching

-

Desiccant pouch filler

-

Industrial packaging equipment

-

Pouch sealing machine

-

Buy used pouch machine

-

Sell HFFS equipment

-

Used Bartelt for sale

-

Klockner IM7-14 price

-

Pre-owned form fill seal

-

Where to buy pouch machine

-

HFFS with desiccant filler

-

Industrial pouching line sale

-

Used packaging machine dealer

-

Sell used pouching equipment

Used Bartelt (Klockner) Model IM7-14 Servo Horizontal Form Fill and Seal Machine. Rated for speeds up to 100 cpm. Has pouch size range: width 2" - 5-3/4"; height 2" - 9" (change parts may be required). Now tooled for 5-1/2" wide x 4-5/8" tall pouch. Has 2 product fill stations. Now equipped with desiccant bead filler and laboratory med device inserter, other fillers can be retrofitted as needed, consult AEK Sales Department. Equipped with servo film feed and servo indexer, has film feed with web tracking and splice table, pre-heat, final heat and quench vertical seal stations, 2 fill stations with air knife openers, dual front-and-back alternate pick and place pouch discharge. 6" core, Power Unwind, Splice Table, Versatec Web Tension Control, Web Tracking Control, Automatic Web Alignment. Cluster Lube. Uses Schneider Elec PLC Controls and Eco Drive Servos. 3/60/480V.

Manufacturer Info

-

Manufacturer: Bartelt (Klockner / Klöckner)

-

Model: IM7‑14 Servo HFFS

-

Configuration: 2 product fill stations; currently set up for desiccant bead filler + laboratory medical device inserter (other fillers retrofit‑ready; consult AEK Sales)

-

Rated Speed: Up to 100 cycles per minute (application dependent)

-

Power: 3/60/480V

-

Controls: Schneider Electric PLC & EcoDrive servos

-

Condition: Used

Description

Industrial‑grade Bartelt (Klockner) IM7‑14 Servo Horizontal Form Fill & Seal pouching system configured for high‑speed production. This machine features servo film feed and servo indexing for precise registration, web tracking with automatic alignment, and a full vertical sealing suite (pre‑heat, final heat, quench). It’s presently tooled for 5‑1/2" W × 4‑5/8" H pouches within an adjustable range of 2"–5‑3/4" width and 2"–9" height (change parts may be required). Dual fill stations with air‑knife openers support multi‑component packaging; current tooling includes a desiccant bead filler and a laboratory medical device inserter. Discharge uses dual front‑and‑back alternating pick‑and‑place for smooth downstream transfer. A robust unwind package (6" core, power unwind, splice table) plus Versatec web tension, web tracking control, and automatic web alignment enhances run stability. Cluster Lube system simplifies maintenance.

Specifications

-

Machine Type: Servo Horizontal Form Fill & Seal (HFFS)

-

Model: IM7‑14 (intermittent motion)

-

Rated Speed: Up to 100 CPM

-

Pouch Size Range:

-

Width: 2" to 5‑3/4"

-

Height: 2" to 9"

-

Current Tooling: 5‑1/2" W × 4‑5/8" H

-

(Change parts may be required for other sizes)

-

-

Stations & Tooling:

-

2 product fill stations with air‑knife pouch openers

-

Desiccant bead filler (installed)

-

Laboratory medical device inserter (installed)

-

Other fillers retrofittable (consult AEK Sales)

-

-

Film/Web Handling:

-

Servo film feed & servo indexer

-

6" core power unwind

-

Splice table

-

Versatec web tension control

-

Web tracking control & automatic web alignment

-

-

Sealing: Pre‑heat, final heat, and quench vertical seal stations

-

Discharge: Dual front‑and‑back alternating pick‑and‑place pouch discharge

-

Lubrication: Cluster Lube

-

Controls: Schneider Electric PLC & EcoDrive servo drives

-

Utilities: 3/60/480V electrical

Applications

-

High‑speed pouching for pharma, medical device, and nutraceutical lines

-

Dry goods, desiccants, components, and small device kitting into flat pouches

-

Lab/IVD kits, trials, and contract packaging where quick changeovers are needed

-

Multi‑component or sequential fill operations (e.g., device + desiccant)

What Products Would This Be Used For (Bulleted)

-

Desiccant sachets & humidity control pouches

-

Single‑use medical device components (e.g., swabs, lancets, test cassettes)

-

Diagnostics/IVD items with desiccant inclusion

-

Nutraceutical sample pouches & tablets/capsules in pouches

-

Dry powders, granules, and pellets

-

Hardware/small parts kits

-

Wipes or sterile barrier flat packs (where compatible)

-

Cosmetic samples & sachets

-

Specialty chemical additives

-

Food & beverage dry mix samples (where suitable)

| Manufacturer | Bartelt |

| Model | IM7-14 |

| Serial # | 3549 |

| Category | Packaging Equipment |

| Subcategory | Form & Fill Horizontal - Horizontal Pouch |

| Make | Klockner |

| Model Number | IM7-14 |

| Serial # | 3549 |

| Speed Range CPM | 100 |

| Package Size Range (Width) | 5-1/2" |

| Package Size Range (Height) | 4-5/8" |

| Make and Model of PLC | Schneider |

| Make and Model of HMI | Quick Panel |

| Make and Model of Servo | Eco Drive |

| Maximum Roll Diameter | 24" |

| Current Voltage | 480V |

| OAD (Height) | 97 |

| OAD (Length) | 65 |

| OAD (Width) | 255 |

| Manual | Yes |

| Low Film Sensor | No |

| Hole Punch | No |

| Year Built | 1999 |

- Used Bartelt Klockner Model IM7-14 Servo Horizontal Form Fill and Seal Machine

- Bartelt Klockner IM7-14 Servo Horizontal Form Fill and Seal Machine

- Klockner IM7-14 Servo Horizontal Form Fill and Seal Machine

- Bartelt IM7-14 Servo Horizontal Form Fill and Seal Machine

- IM7-14 Servo Horizontal Form Fill and Seal Machine

- Horizontal Form Fill and Seal Machine

- Bartelt Horizontal Form Fill and Seal Machine

- Klockner Horizontal Form Fill and Seal Machine

- Used Packaging Machinery

- Used Horizontal Form Fill

- Used Bartelt Horizontal Form Fill

- Used Klockner Horizontal Form Fill

- Pouch Packaging Machine

- Snack Food Pouch Packager

-

HFFS machine

-

Bartelt IM7-14

-

Klockner pouch

-

Servo pouching

-

Form fill seal

-

Pouch machine

-

Industrial sealer

-

Packaging line

-

Desiccant filler

-

Used HFFS

-

Bartelt IM7-14 HFFS for sale

-

Used horizontal form fill seal

-

Servo driven pouch machine

-

Klockner Bartelt pouching line

-

100 cpm pouch equipment

-

Schneider PLC packaging machine

-

Dual fill station HFFS

-

Desiccant pouch inserter

-

Automatic web alignment HFFS

-

Industrial pouch packaging system

-

Used Bartelt Klockner IM7-14 servo horizontal form fill and seal machine

-

Pre-owned HFFS pouch machine with desiccant filler and device inserter

-

Industrial pouching equipment with web tracking and power unwind

-

IM7-14 pouch size range 2 to 5-3/4 inches wide and 2 to 9 inches tall

-

High speed 100 cpm servo form fill seal pouch packer

-

HFFS machine with dual pick and place pouch discharge

-

Schneider Electric PLC EcoDrive servo packaging line

-

Pouch machine with pre-heat final heat and quench vertical seals

-

Horizontal pouching system with Versatec web tension control

-

Retrofit-ready HFFS for medical and nutraceutical packaging

-

Used pouch machine

-

Bartelt packaging

-

Klockner HFFS

-

IM7-14

-

Horizontal form fill seal

-

Servo packaging machine

-

Medical device pouching

-

Desiccant pouch filler

-

Industrial packaging equipment

-

Pouch sealing machine

-

Buy used pouch machine

-

Sell HFFS equipment

-

Used Bartelt for sale

-

Klockner IM7-14 price

-

Pre-owned form fill seal

-

Where to buy pouch machine

-

HFFS with desiccant filler

-

Industrial pouching line sale

-

Used packaging machine dealer

-

Sell used pouching equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)

.jpg)

.jpg)