Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: [email protected]

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

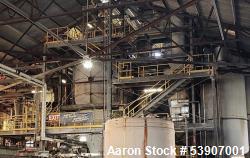

Niro Spray and Fluid Bed Drying System

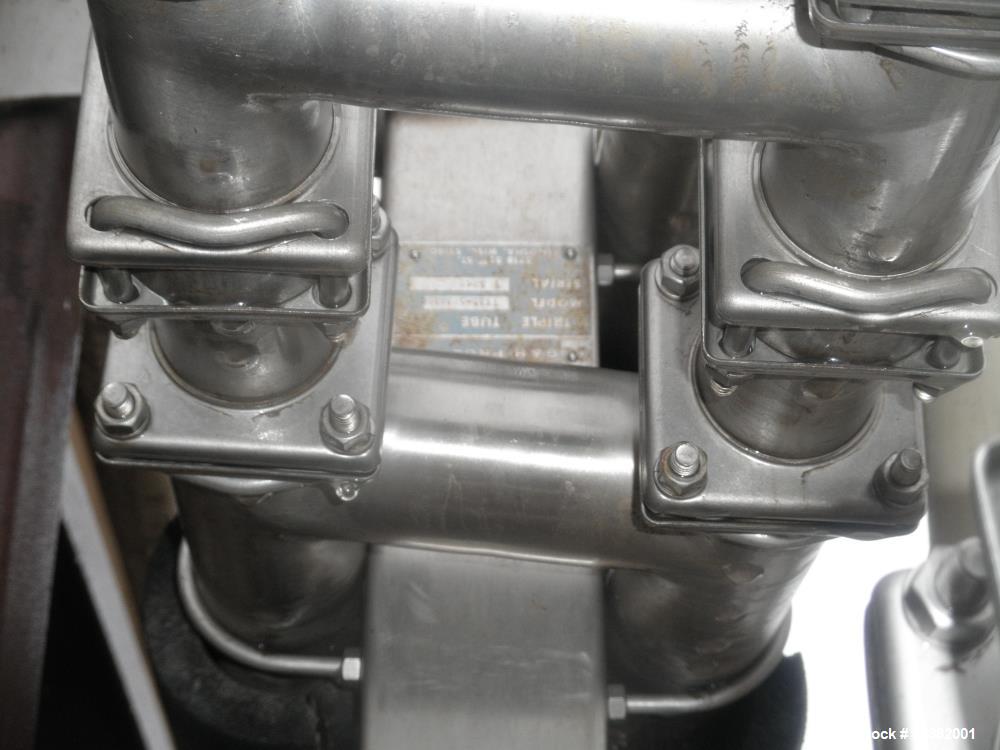

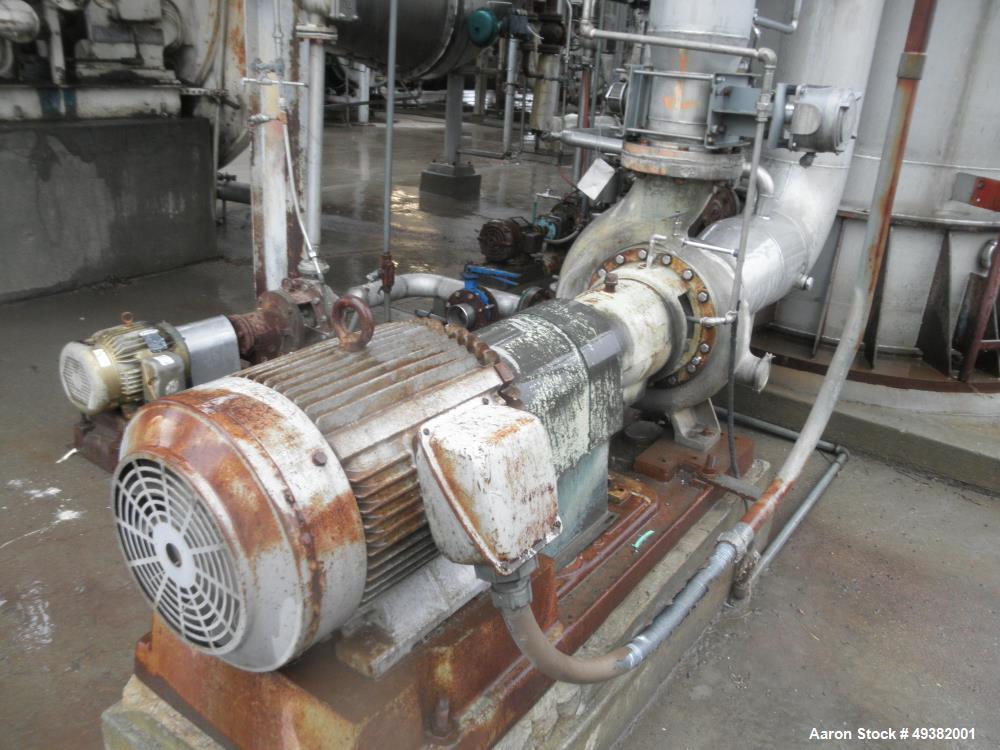

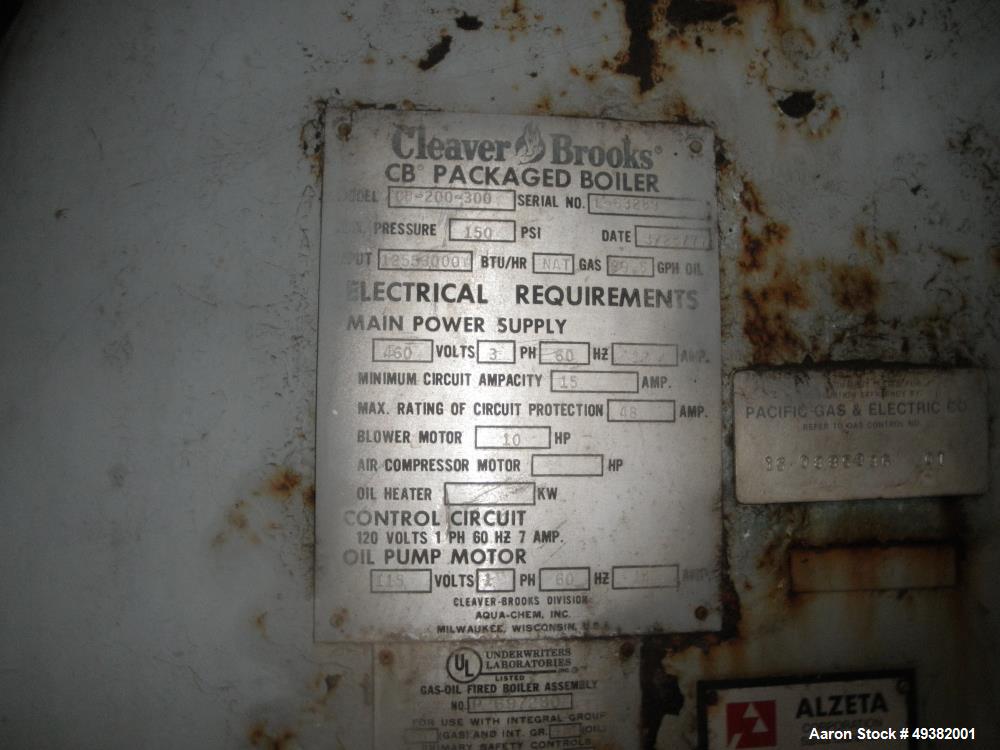

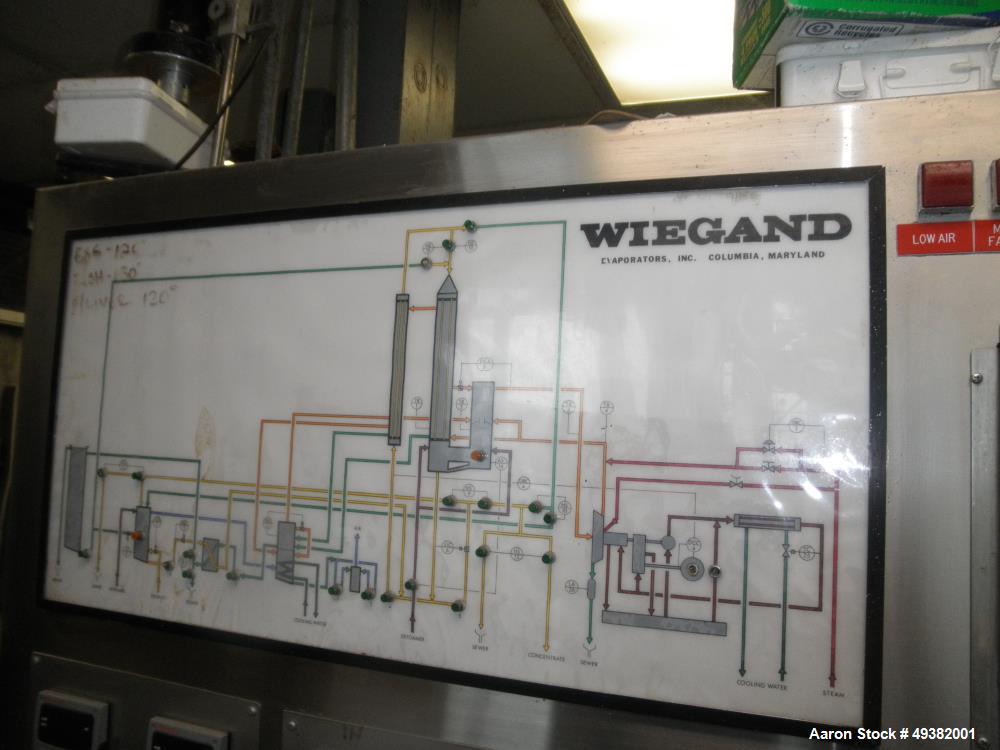

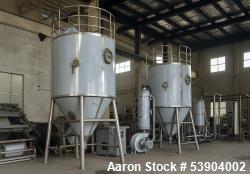

Used Niro Spray and Fluid Bed Drying System: Rated 24 MMBTU. Double effect evaporator, last used on animal blood, poultry hydrolysis, egg, liver products, pork plasma. Includes (2) towers with titanium tube sheets, titanium heads, stainless steel shell. Rated for approximately 50,000 pounds/hour water, 30,000 pounds/hour product. System includes horizontal condenser, shell and tube heat exchanger, stainless steel tubes, carbon steel shell. Circulation pumps are in storage, Goulds stainless steel with CD4 impellers. Missing control system. Arthur Zimmer Spray drying system, approximately 30' diameter, manufactured by Niro, stainless steel contacts, fed by Niro Savoi 125 hp high pressure feed pump, rated for 1800 - 2500 PSI feed. Top of dryer includes (8) feed nozzles (typically fed four nozzles at a time). Also includes Waukesha 130 stainless steel pump, Milpointe 50,000 CFM vertical scrubber, (4) stainless steel cyclones, etc. With Wiegand single effect evaporator, rated for approximately 45,000 - 50,000 pounds/hour product, 35,000 pounds/hour water evaporation rate, 304 stainless steel construction, with dedicated boiler, Needs vacuum pump. Includes 400 hp DC drive, vari-speed, SIHI vacuum pumps, Goulds centrifugal pumps. Last used on blood products, eggs, brewers yeast, liver products, poultry products, etc. With Rotary screen, 5' diameter x 12' long, manufacture by Baycore Fibre, Type SDS 60120, Serial# 99-0210. Current replacement cost is $200,000. Includes approximately 6" diameter flange feed inlet, leading to internal distributor. Equipment has fine mesh internal screen. Spare screens. Last screening eggs. With AirChem scrubber, rated for approximately 50,000 CFM, single stage with packed bed, No controls, last used as scrubber for hydrolysis building. New in 1998, 840 GPM, 1.5" W.C., ambient. With G&H Products Tube-in-tube heat exchanger, stainless steel construction, approximately 3" diameter outer tube, 2" diameter inner tube, 25' long, (20) tubes in 2x10 sections, insulated. Brought product from 180? to 40?. Used on Dairy / Milk Products. Food Grade.

| Manufacturer | NiroNiro |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Spray DryerSpray Dryer |

Manufacturer Information

- Brand: Niro

- Condition: Used

- Year Built: 1998 (Some Components)

- Previous Applications: Animal Blood, Poultry Hydrolysis, Egg, Liver Products, Pork Plasma, Brewers Yeast, Dairy/Milk Products

Description

The Niro Spray & Fluid Bed Drying System is a high-capacity industrial drying system, designed for food-grade, pharmaceutical, and industrial applications. Rated at 24 MMBTU, this system includes spray drying, evaporation, and fluid bed processing components, making it ideal for liquid-to-powder conversion in food, dairy, and protein-based products.

The double-effect evaporator can process up to 50,000 lbs/hr of water and 30,000 lbs/hr of product. It features titanium tube sheets, titanium heads, and a stainless steel shell, ensuring durability and resistance to corrosion. The system also includes:

- Horizontal condenser

- Shell & tube heat exchanger with stainless steel tubes & carbon steel shell

- Goulds stainless steel circulation pumps with CD4 impellers (currently in storage)

- Missing control system (needs replacement)

The Arthur Zimmer Spray Drying System is a 30' diameter stainless steel drying unit, manufactured by Niro. The system is fed by a Niro Savoi 125 HP high-pressure feed pump, rated at 1,800 - 2,500 PSI. The top of the dryer includes (8) feed nozzles (typically 4 nozzles fed at a time).

Additional equipment includes:

- Waukesha 130 Stainless Steel Pump

- Milpointe 50,000 CFM Vertical Scrubber

- (4) Stainless Steel Cyclones

- Wiegand Single-Effect Evaporator (Rated for 45,000 - 50,000 lbs/hr product, 35,000 lbs/hr water evaporation), 304 Stainless Steel Construction

- Dedicated Boiler (Vacuum pump required)

- 400 HP DC Drive (Variable Speed)

- SIHI Vacuum Pumps & Goulds Centrifugal Pumps

The system also includes a Baycore Fibre Rotary Screen (5' diameter x 12' long), designed for fine mesh internal screening, with spare screens available. It was last used for egg screening.

The AirChem Scrubber, rated for 50,000 CFM, is a single-stage scrubber with a packed bed, last used in a hydrolysis building.

A G&H Products Tube-in-Tube Heat Exchanger is also included, featuring:

- Stainless Steel Construction

- (20) Tubes in 2x10 Sections

- 3" Outer Tube, 2" Inner Tube

- 25' Length, Insulated

- Temperature Control: From 180°F to 40°F

- Last Used on Dairy/Milk Products

Specifications

- System Capacity: 24 MMBTU

- Evaporator Capacity:

- Water Processing: ~50,000 lbs/hr

- Product Processing: ~30,000 lbs/hr

- Spray Dryer:

- Manufacturer: Niro

- Diameter: 30'

- Feed System: Niro Savoi 125 HP Pump (1,800 - 2,500 PSI)

- Feed Nozzles: 8 (Operates with 4 Nozzles at a Time)

- Heat Exchanger: Tube-in-Tube, Stainless Steel

- Outer Tube Diameter: 3"

- Inner Tube Diameter: 2"

- Length: 25'

- Temperature Control: 180°F → 40°F

- Rotary Screen: Baycore Fibre Type SDS 60120

- Diameter: 5'

- Length: 12'

- Fine Mesh Screen with Spare Screens

- Scrubber: AirChem, 50,000 CFM, Single Stage, Packed Bed

- Vacuum & Pumps:

- SIHI Vacuum Pumps

- Goulds Centrifugal Pumps with CD4 Impellers

- Additional Equipment:

- Condenser & Shell-Tube Heat Exchanger

- Waukesha 130 Stainless Steel Pump

- Milpointe 50,000 CFM Vertical Scrubber

- Dedicated Boiler (Vacuum Pump Needed)

- 400 HP DC Drive (Variable Speed)

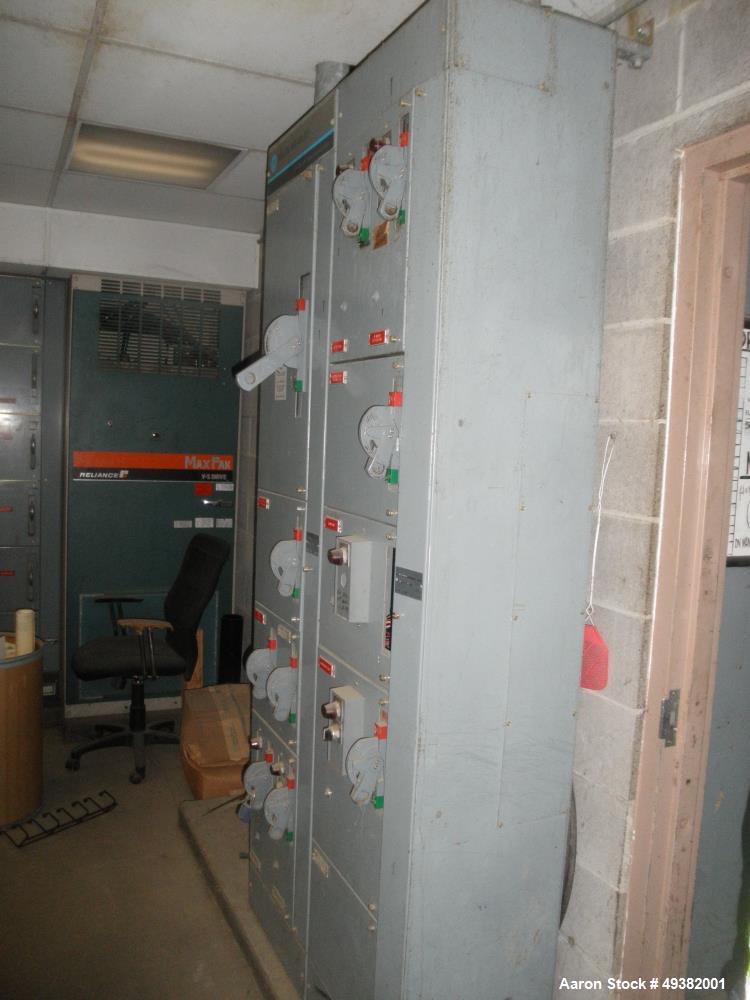

- Control System: Missing (Needs Replacement)

Applications

- Dairy & Milk Processing – Spray drying of milk powders, whey protein, and dairy-based formulations

- Animal Protein Processing – Drying of blood plasma, poultry hydrolysis, and egg/liver products

- Food & Beverage Industry – Powder production for protein supplements, flavorings, and extracts

- Pharmaceutical & Biotech – Spray drying of active pharmaceutical ingredients (APIs)

- Chemical Processing – Conversion of liquid solutions to powdered chemical compounds

Compatible Products

- Industrial spray dryers and fluid bed drying systems

- High-capacity evaporation and concentration equipment

- Food and pharmaceutical-grade powder processing systems

- Heat exchangers and scrubber systems for industrial drying

- Spray dryer, fluid bed dryer, evaporator system

- Used Niro spray drying system, industrial fluid bed drying plant, 24 MMBTU evaporation system

- Niro 30' diameter spray dryer with 50,000 lbs/hr evaporator, used industrial food-grade spray drying and evaporation system, high-capacity animal protein and dairy processing plant

"Dealing with Aaron is an easy and enjoyable process"

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

"This is my first time using Aaron Equipment to purchase equipment. They were easy to work with and things were done quickly and efficiently. I will be a repeat customer when the need arises. This is a trustworthy company that delivers what they advertise."

"I have purchased multiple pieces of equipment through Aaron equipment over the past 15 years. The staff has been very knowledgeable on every request & have spent countless hours ensuring that the equipment I was purchasing met my expectations."

"I have been doing business with Aaron equipment for many years. This year I had the need for some used equipment in a new business Venture. I got in touch with Ryan Davies. I could not be happier with the response and honesty exhibited by him. Dealing with them was a pleasure and everything was as represented. Fair an Honest is how I would describe them."

“Aaron Equipment was very easy to get into contact with and get a price on a un-used chiller they were selling. The process was seamless and very easy on our end and we had the equipment much faster than going out for bid on it to multiple vendors and we able to come in under budget on the project.”

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

Used Niro Spray and Fluid Bed Drying System: Rated 24 MMBTU. Double effect evaporator, last used on animal blood, poultry hydrolysis, egg, liver products, pork plasma. Includes (2) towers with titanium tube sheets, titanium heads, stainless steel shell. Rated for approximately 50,000 pounds/hour water, 30,000 pounds/hour product. System includes horizontal condenser, shell and tube heat exchanger, stainless steel tubes, carbon steel shell. Circulation pumps are in storage, Goulds stainless steel with CD4 impellers. Missing control system. Arthur Zimmer Spray drying system, approximately 30' diameter, manufactured by Niro, stainless steel contacts, fed by Niro Savoi 125 hp high pressure feed pump, rated for 1800 - 2500 PSI feed. Top of dryer includes (8) feed nozzles (typically fed four nozzles at a time). Also includes Waukesha 130 stainless steel pump, Milpointe 50,000 CFM vertical scrubber, (4) stainless steel cyclones, etc. With Wiegand single effect evaporator, rated for approximately 45,000 - 50,000 pounds/hour product, 35,000 pounds/hour water evaporation rate, 304 stainless steel construction, with dedicated boiler, Needs vacuum pump. Includes 400 hp DC drive, vari-speed, SIHI vacuum pumps, Goulds centrifugal pumps. Last used on blood products, eggs, brewers yeast, liver products, poultry products, etc. With Rotary screen, 5' diameter x 12' long, manufacture by Baycore Fibre, Type SDS 60120, Serial# 99-0210. Current replacement cost is $200,000. Includes approximately 6" diameter flange feed inlet, leading to internal distributor. Equipment has fine mesh internal screen. Spare screens. Last screening eggs. With AirChem scrubber, rated for approximately 50,000 CFM, single stage with packed bed, No controls, last used as scrubber for hydrolysis building. New in 1998, 840 GPM, 1.5" W.C., ambient. With G&H Products Tube-in-tube heat exchanger, stainless steel construction, approximately 3" diameter outer tube, 2" diameter inner tube, 25' long, (20) tubes in 2x10 sections, insulated. Brought product from 180? to 40?. Used on Dairy / Milk Products. Food Grade.

Manufacturer Information

- Brand: Niro

- Condition: Used

- Year Built: 1998 (Some Components)

- Previous Applications: Animal Blood, Poultry Hydrolysis, Egg, Liver Products, Pork Plasma, Brewers Yeast, Dairy/Milk Products

Description

The Niro Spray & Fluid Bed Drying System is a high-capacity industrial drying system, designed for food-grade, pharmaceutical, and industrial applications. Rated at 24 MMBTU, this system includes spray drying, evaporation, and fluid bed processing components, making it ideal for liquid-to-powder conversion in food, dairy, and protein-based products.

The double-effect evaporator can process up to 50,000 lbs/hr of water and 30,000 lbs/hr of product. It features titanium tube sheets, titanium heads, and a stainless steel shell, ensuring durability and resistance to corrosion. The system also includes:

- Horizontal condenser

- Shell & tube heat exchanger with stainless steel tubes & carbon steel shell

- Goulds stainless steel circulation pumps with CD4 impellers (currently in storage)

- Missing control system (needs replacement)

The Arthur Zimmer Spray Drying System is a 30' diameter stainless steel drying unit, manufactured by Niro. The system is fed by a Niro Savoi 125 HP high-pressure feed pump, rated at 1,800 - 2,500 PSI. The top of the dryer includes (8) feed nozzles (typically 4 nozzles fed at a time).

Additional equipment includes:

- Waukesha 130 Stainless Steel Pump

- Milpointe 50,000 CFM Vertical Scrubber

- (4) Stainless Steel Cyclones

- Wiegand Single-Effect Evaporator (Rated for 45,000 - 50,000 lbs/hr product, 35,000 lbs/hr water evaporation), 304 Stainless Steel Construction

- Dedicated Boiler (Vacuum pump required)

- 400 HP DC Drive (Variable Speed)

- SIHI Vacuum Pumps & Goulds Centrifugal Pumps

The system also includes a Baycore Fibre Rotary Screen (5' diameter x 12' long), designed for fine mesh internal screening, with spare screens available. It was last used for egg screening.

The AirChem Scrubber, rated for 50,000 CFM, is a single-stage scrubber with a packed bed, last used in a hydrolysis building.

A G&H Products Tube-in-Tube Heat Exchanger is also included, featuring:

- Stainless Steel Construction

- (20) Tubes in 2x10 Sections

- 3" Outer Tube, 2" Inner Tube

- 25' Length, Insulated

- Temperature Control: From 180°F to 40°F

- Last Used on Dairy/Milk Products

Specifications

- System Capacity: 24 MMBTU

- Evaporator Capacity:

- Water Processing: ~50,000 lbs/hr

- Product Processing: ~30,000 lbs/hr

- Spray Dryer:

- Manufacturer: Niro

- Diameter: 30'

- Feed System: Niro Savoi 125 HP Pump (1,800 - 2,500 PSI)

- Feed Nozzles: 8 (Operates with 4 Nozzles at a Time)

- Heat Exchanger: Tube-in-Tube, Stainless Steel

- Outer Tube Diameter: 3"

- Inner Tube Diameter: 2"

- Length: 25'

- Temperature Control: 180°F → 40°F

- Rotary Screen: Baycore Fibre Type SDS 60120

- Diameter: 5'

- Length: 12'

- Fine Mesh Screen with Spare Screens

- Scrubber: AirChem, 50,000 CFM, Single Stage, Packed Bed

- Vacuum & Pumps:

- SIHI Vacuum Pumps

- Goulds Centrifugal Pumps with CD4 Impellers

- Additional Equipment:

- Condenser & Shell-Tube Heat Exchanger

- Waukesha 130 Stainless Steel Pump

- Milpointe 50,000 CFM Vertical Scrubber

- Dedicated Boiler (Vacuum Pump Needed)

- 400 HP DC Drive (Variable Speed)

- Control System: Missing (Needs Replacement)

Applications

- Dairy & Milk Processing – Spray drying of milk powders, whey protein, and dairy-based formulations

- Animal Protein Processing – Drying of blood plasma, poultry hydrolysis, and egg/liver products

- Food & Beverage Industry – Powder production for protein supplements, flavorings, and extracts

- Pharmaceutical & Biotech – Spray drying of active pharmaceutical ingredients (APIs)

- Chemical Processing – Conversion of liquid solutions to powdered chemical compounds

Compatible Products

- Industrial spray dryers and fluid bed drying systems

- High-capacity evaporation and concentration equipment

- Food and pharmaceutical-grade powder processing systems

- Heat exchangers and scrubber systems for industrial drying

| Manufacturer | Niro |

| Category | Dryers - Drying Equipment |

| Subcategory | Spray Dryer |

- Spray dryer, fluid bed dryer, evaporator system

- Used Niro spray drying system, industrial fluid bed drying plant, 24 MMBTU evaporation system

- Niro 30' diameter spray dryer with 50,000 lbs/hr evaporator, used industrial food-grade spray drying and evaporation system, high-capacity animal protein and dairy processing plant

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory