Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

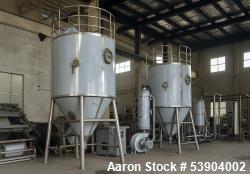

Used GEA Niro PSD4 Stainless Steel Spray Drying System – Industrial Powder Dryer

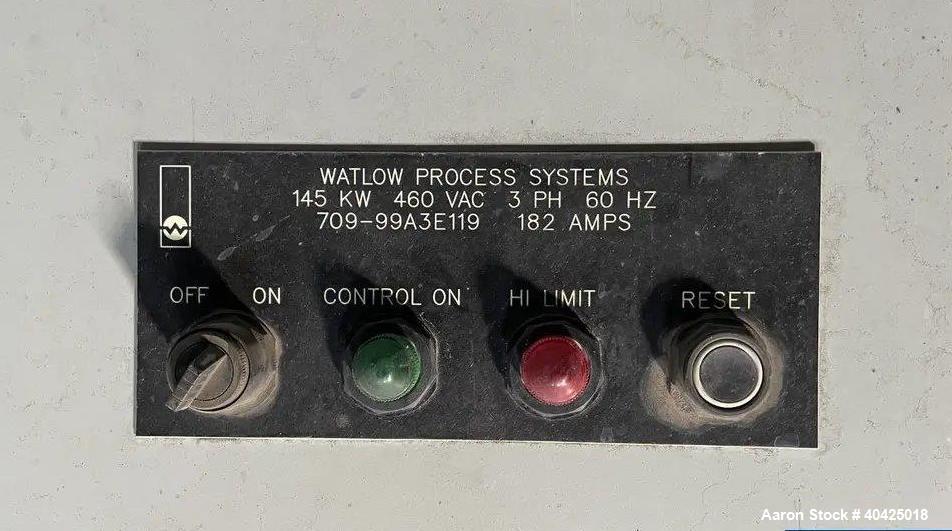

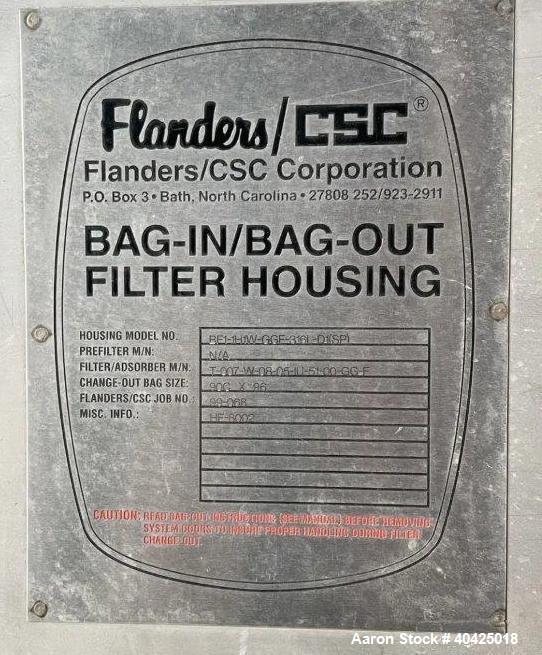

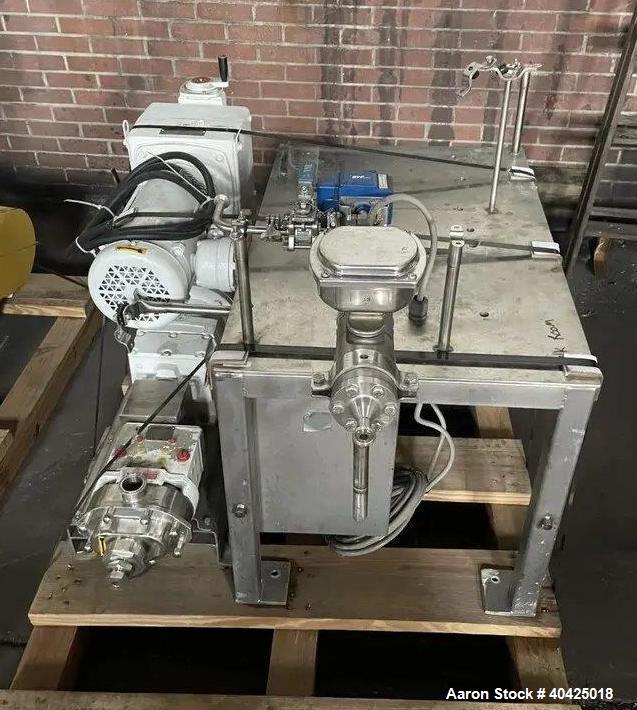

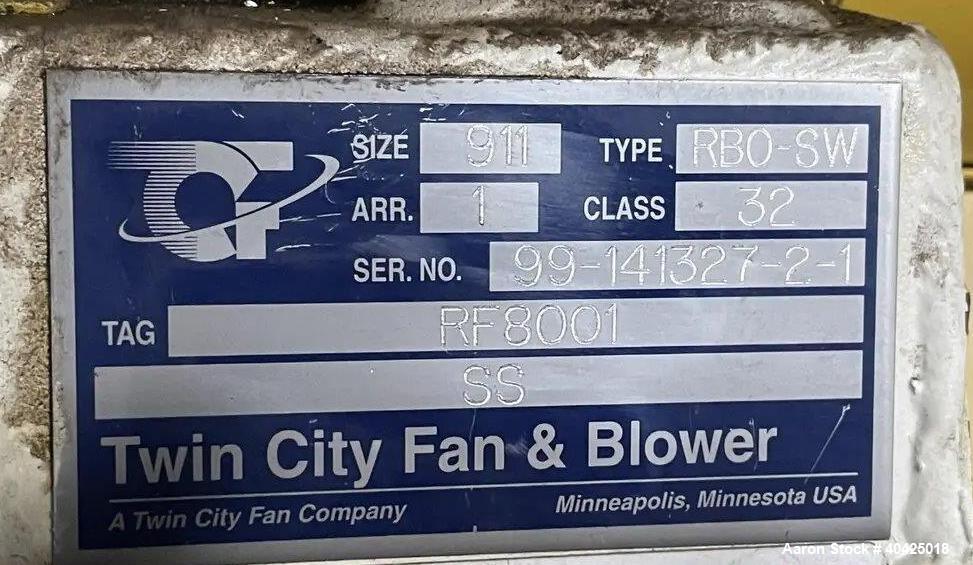

Used GEA Niro Sanitary Stainless Steel Spray Drying System. Consisting of: Model PSD4 GEA Niro spray dryer, approximately 8' inner diameter x 8'6" straight side x 8'9" deep cone bottom spray dryer chamber, 316 stainless steel product contact surfaces, mirror internal finish, with fluid nozzle and centrifugal rotary atomizers, approximately 17" diameter, sanitary stainless steel cyclone fines collector, approximately 6' diameter dust collector, sanitary stainless steel construction, pulse jet, cone bottom, set up for electric or steam heating with Watlow, 145 kw electric heater with external Hepa filter, air handler with steam coil and Watlow 37.25 kw electric heater, internal Hepa filter, designed for nitrogen purge, 7.5 hp process air supply blower, 7.5 hp process air return blower, set up for solvent recovery with condensor(less receiver pot), solution feed pump with Micro Motion flow meter, inter connecting pipe work from dryer, to dust collector and cyclone, GEA Niro control panel and HMI panel, 460 volt, 3 phase, GEA Niro fabrication# 099-0013-00, built 1999.

| Manufacturer | Gea-NiroGea-Niro |

| Model | PSD4 |

| Serial # | 099-0013-00 |

| Category | Dryers - Drying EquipmentDryers - Drying Equipment |

| Subcategory | Spray DryerSpray Dryer |

| KW | 145 |

| Diameter | 8' |

| Straight Side | 8'6" |

| Bottom | Coned Bottom |

| Year Built | 1999 |

Manufacturer Information:

- Manufacturer: GEA Niro

- Model: PSD4 Spray Dryer

- Year of Manufacture: 1999

- Fabrication Number: 099-0013-00

- Voltage: 460V, 3 Phase

System Components & Specifications:

-

Spray Dryer Chamber:

- Diameter: 8’ inner diameter

- Straight Side Height: 8’6”

- Cone Bottom Depth: 8’9”

- Material: 316 Stainless Steel (Product Contact Surfaces)

- Finish: Mirror Internal Finish

- Atomization: Fluid Nozzle & Centrifugal Rotary Atomizers (Approx. 17” Diameter)

-

Cyclone Fines Collector:

- Diameter: Approx. 6'

- Material: Sanitary Stainless Steel

-

Dust Collector:

- Material: Sanitary Stainless Steel Construction

- Design: Pulse Jet, Cone Bottom

-

Heating System:

- Heating Options: Electric or Steam

- Watlow 145 kW Electric Heater with External HEPA Filter

- Air Handler: Steam Coil & Watlow 37.25 kW Electric Heater with Internal HEPA Filter

-

Process Features:

- Designed for Nitrogen Purge

- Solvent Recovery Capability (with Condenser, Less Receiver Pot)

- Solution Feed Pump with Micro Motion Flow Meter

-

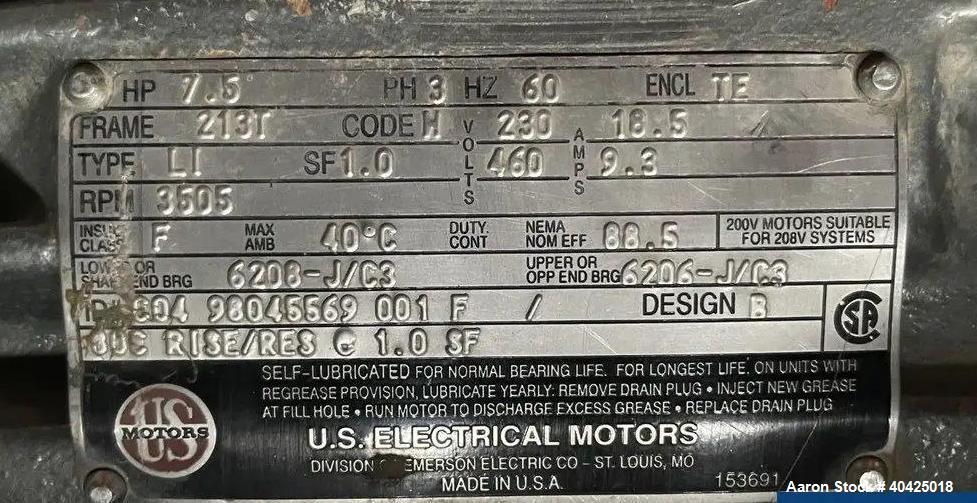

Air Handling & Blowers:

- 7.5 HP Process Air Supply Blower

- 7.5 HP Process Air Return Blower

-

Control System:

- GEA Niro Control Panel & HMI Panel

- Interconnecting Pipework from Dryer to Dust Collector and Cyclone

Applications:

- Food & Dairy Industry: Drying of milk powders, whey, proteins, starches, coffee, and flavors

- Pharmaceutical Industry: Drying of APIs, excipients, probiotics, and pharmaceutical powders

- Chemical Industry: Spray drying of catalysts, polymers, and specialty chemicals

- Nutraceuticals & Supplements: Production of powdered vitamins, herbal extracts, and protein powders

- Cosmetic & Personal Care: Drying of powdered ingredients for skincare and beauty products

- Industrial Solvent Recovery: Spray drying with nitrogen purge for sensitive or volatile materials

Chemical, Chemical Plants, Chemical Powders, Dry Granulation, Drying, Food Powder, pharma, Pharmaceutical, Pharmaceutical Industries, Pharmaceutical Products, Pharmaceuticals, Powder Production, Powders

- Feldmeier 12,000 Gallon Storage Tank

- Used GEA Niro PSD4 stainless steel spray drying system for sale

- Industrial spray dryer with nitrogen purge and solvent recovery

- Pharmaceutical-grade spray dryer with centrifugal rotary atomizers

- Food and dairy spray drying machine with HEPA filtration

- Used stainless steel spray dryer with cyclone fines collector

- High-efficiency spray dryer for powdered food and chemical applications

- GEA Niro spray drying system with Watlow 145 kW heater

- Large-capacity industrial spray dryer for nutraceuticals and supplements

- Pre-owned spray drying equipment with HMI control panel

- Used sanitary spray dryer with solvent recovery and stainless steel construction

Used GEA Niro Sanitary Stainless Steel Spray Drying System. Consisting of: Model PSD4 GEA Niro spray dryer, approximately 8' inner diameter x 8'6" straight side x 8'9" deep cone bottom spray dryer chamber, 316 stainless steel product contact surfaces, mirror internal finish, with fluid nozzle and centrifugal rotary atomizers, approximately 17" diameter, sanitary stainless steel cyclone fines collector, approximately 6' diameter dust collector, sanitary stainless steel construction, pulse jet, cone bottom, set up for electric or steam heating with Watlow, 145 kw electric heater with external Hepa filter, air handler with steam coil and Watlow 37.25 kw electric heater, internal Hepa filter, designed for nitrogen purge, 7.5 hp process air supply blower, 7.5 hp process air return blower, set up for solvent recovery with condensor(less receiver pot), solution feed pump with Micro Motion flow meter, inter connecting pipe work from dryer, to dust collector and cyclone, GEA Niro control panel and HMI panel, 460 volt, 3 phase, GEA Niro fabrication# 099-0013-00, built 1999.

Manufacturer Information:

- Manufacturer: GEA Niro

- Model: PSD4 Spray Dryer

- Year of Manufacture: 1999

- Fabrication Number: 099-0013-00

- Voltage: 460V, 3 Phase

System Components & Specifications:

-

Spray Dryer Chamber:

- Diameter: 8’ inner diameter

- Straight Side Height: 8’6”

- Cone Bottom Depth: 8’9”

- Material: 316 Stainless Steel (Product Contact Surfaces)

- Finish: Mirror Internal Finish

- Atomization: Fluid Nozzle & Centrifugal Rotary Atomizers (Approx. 17” Diameter)

-

Cyclone Fines Collector:

- Diameter: Approx. 6'

- Material: Sanitary Stainless Steel

-

Dust Collector:

- Material: Sanitary Stainless Steel Construction

- Design: Pulse Jet, Cone Bottom

-

Heating System:

- Heating Options: Electric or Steam

- Watlow 145 kW Electric Heater with External HEPA Filter

- Air Handler: Steam Coil & Watlow 37.25 kW Electric Heater with Internal HEPA Filter

-

Process Features:

- Designed for Nitrogen Purge

- Solvent Recovery Capability (with Condenser, Less Receiver Pot)

- Solution Feed Pump with Micro Motion Flow Meter

-

Air Handling & Blowers:

- 7.5 HP Process Air Supply Blower

- 7.5 HP Process Air Return Blower

-

Control System:

- GEA Niro Control Panel & HMI Panel

- Interconnecting Pipework from Dryer to Dust Collector and Cyclone

Applications:

- Food & Dairy Industry: Drying of milk powders, whey, proteins, starches, coffee, and flavors

- Pharmaceutical Industry: Drying of APIs, excipients, probiotics, and pharmaceutical powders

- Chemical Industry: Spray drying of catalysts, polymers, and specialty chemicals

- Nutraceuticals & Supplements: Production of powdered vitamins, herbal extracts, and protein powders

- Cosmetic & Personal Care: Drying of powdered ingredients for skincare and beauty products

- Industrial Solvent Recovery: Spray drying with nitrogen purge for sensitive or volatile materials

Chemical, Chemical Plants, Chemical Powders, Dry Granulation, Drying, Food Powder, pharma, Pharmaceutical, Pharmaceutical Industries, Pharmaceutical Products, Pharmaceuticals, Powder Production, Powders

| Manufacturer | Gea-Niro |

| Model | PSD4 |

| Serial # | 099-0013-00 |

| Category | Dryers - Drying Equipment |

| Subcategory | Spray Dryer |

| KW | 145 |

| Diameter | 8' |

| Straight Side | 8'6" |

| Bottom | Coned Bottom |

| Year Built | 1999 |

- Feldmeier 12,000 Gallon Storage Tank

- Used GEA Niro PSD4 stainless steel spray drying system for sale

- Industrial spray dryer with nitrogen purge and solvent recovery

- Pharmaceutical-grade spray dryer with centrifugal rotary atomizers

- Food and dairy spray drying machine with HEPA filtration

- Used stainless steel spray dryer with cyclone fines collector

- High-efficiency spray dryer for powdered food and chemical applications

- GEA Niro spray drying system with Watlow 145 kW heater

- Large-capacity industrial spray dryer for nutraceuticals and supplements

- Pre-owned spray drying equipment with HMI control panel

- Used sanitary spray dryer with solvent recovery and stainless steel construction

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory