Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

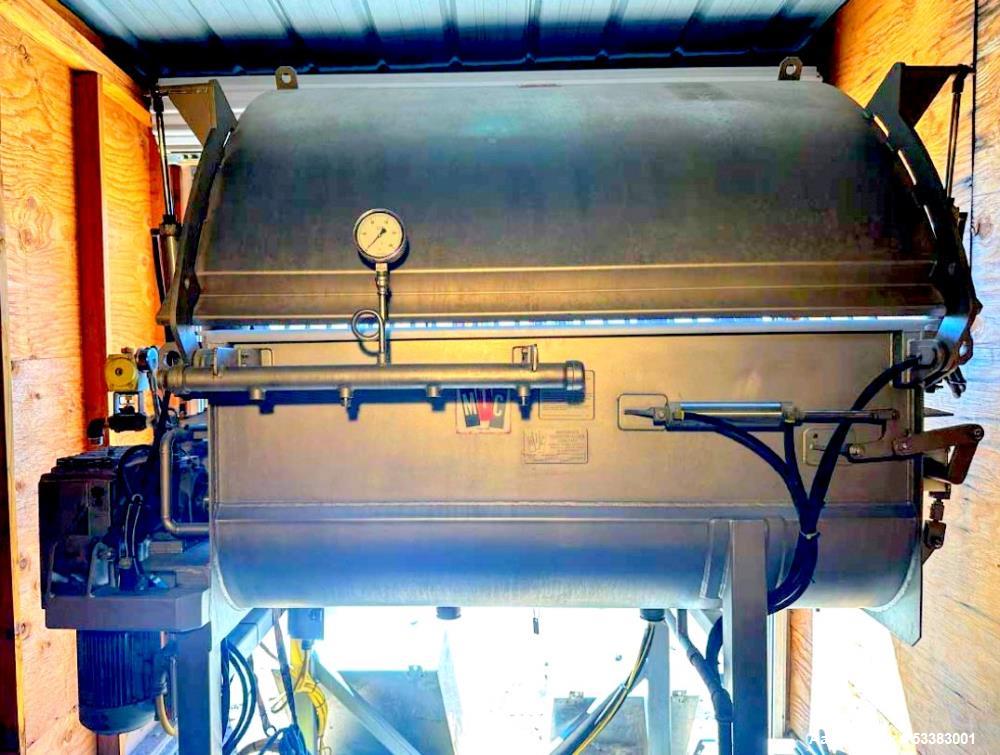

Used MTC SC-1000 Twin Screw Jacketed Smart Cooker – 1,000 lb. Capacity

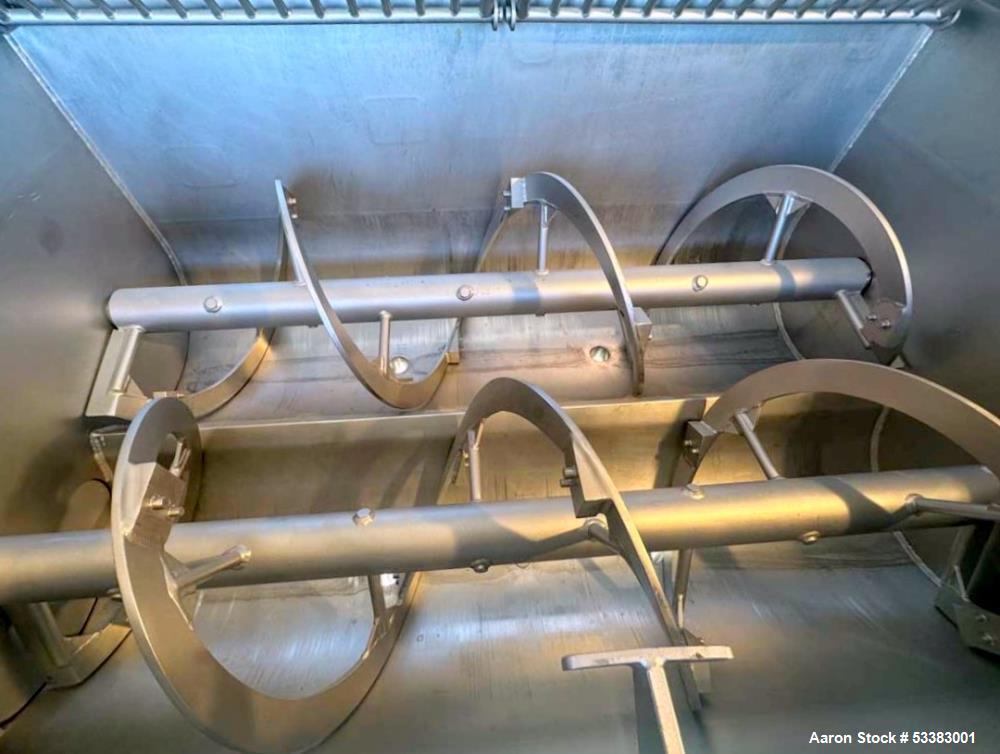

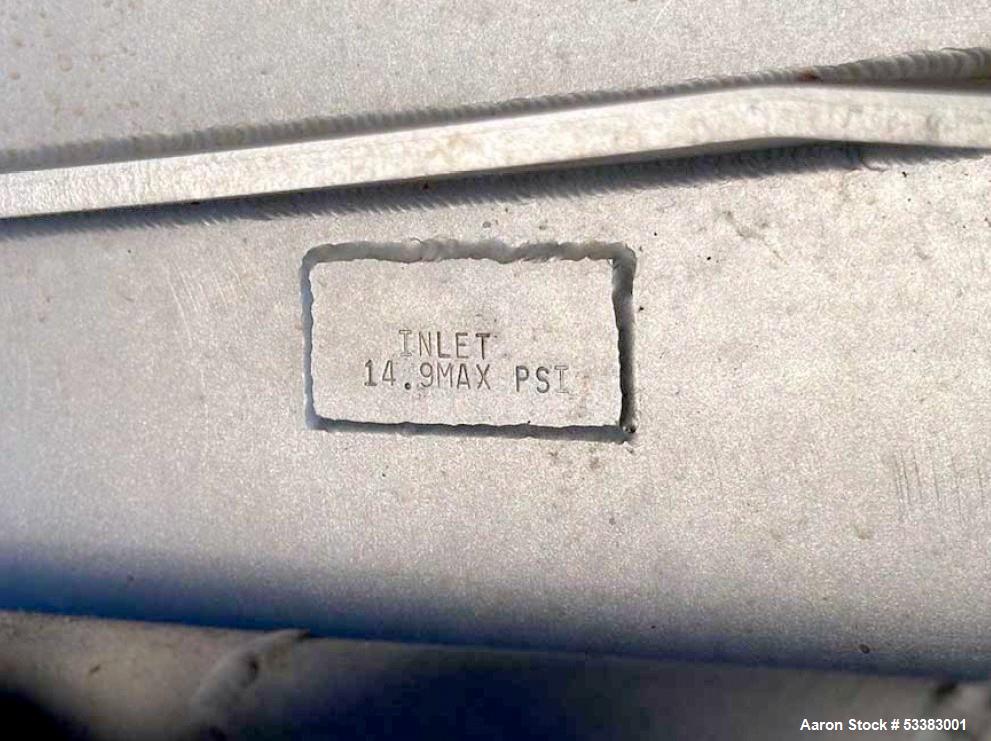

Used MTC Twin Screw Jacketed Smart Cooker, Model SC-1000, 304 Stainless Steel. 1,000 lb. capacity based on 55 per cubic foot of material. Approximate 37" wide x 60" long jacketed trough. 14.9 Stainless steel steam jacket with gauge and relief valve. (2) Stainless steel ribbon screws with scrapers. Driven by (2) 5hp, 3/60/230 volt inverter motors with controls. Shaft seals, double sanitary split seals. (2) Air operated discharge doors with stainless steel cylinders, stainless steel guard and safety interlock. One piece, air operated, hinged cover. Full two piece hinged grate. Steel coated pillow blocks on drive and Delrin plug on discharge end. Controls with digital speed readout, E-stop, agitator controls, start/stop, doors open and close, cover open and close, product temperature probe with digital readout. 80psi Minimum air requirements. Serial # 10251, Built 2004. Last product that this mixer produced imitation cheese base for individually wrapped cheese.

Manufacturer Information:

- Manufacturer: MTC

- Model: SC-1000

- Condition: Used

- Serial #: 10251

- Year Built: 2004

Manufacturing Data:

- Capacity: 1,000 lbs. (based on 55 lbs. per cubic foot of material)

- Material: 304 Stainless Steel

- Trough Dimensions: Approx. 37” W x 60” L

- Jacket Type: 14.9 Stainless Steel Steam Jacket with Gauge and Relief Valve

- Mixing Mechanism:

- (2) Stainless steel ribbon screws with scrapers

- Driven by (2) 5 HP, 3/60/230V inverter motors with controls

- Double sanitary split shaft seals

- Discharge System:

- (2) Air-operated discharge doors with stainless steel cylinders

- Stainless steel guard with safety interlock

- Cover:

- One-piece, air-operated, hinged cover

- Full two-piece hinged grate

- Support Components:

- Steel-coated pillow blocks on drive

- Delrin plug on discharge end

- Control System:

- Digital speed readout

- E-stop

- Agitator controls

- Start/Stop functions

- Doors open/close controls

- Cover open/close controls

- Product temperature probe with digital readout

- Air Requirements: 80 PSI minimum

Description:

The MTC SC-1000 Twin Screw Jacketed Smart Cooker is an industrial-grade processing system designed for efficient mixing, heating, and cooking in food and chemical processing applications. Constructed from 304 stainless steel, this system features a jacketed trough for steam heating, along with twin ribbon screws with scrapers for uniform product mixing and agitation.

Equipped with air-operated discharge doors, a hinged safety cover, and digital controls, the SC-1000 is built for precise temperature management and efficient material handling. The system also includes an advanced control panel with speed readout, temperature monitoring, and automated door operations.

Previously used in the food industry, this unit was last utilized for the production of imitation cheese base for individually wrapped cheese.

Specifications:

- Capacity: 1,000 lbs.

- Material: 304 Stainless Steel

- Trough Dimensions: 37” W x 60” L

- Steam Jacket: 14.9 Stainless Steel with gauge and relief valve

- Mixing System: Twin stainless steel ribbon screws with scrapers

- Motors: (2) 5 HP, 3/60/230V inverter motors

- Seals: Double sanitary split shaft seals

- Discharge System: Air-operated stainless steel discharge doors

- Safety Features: Stainless steel guard, safety interlock, and air-operated hinged cover

- Controls: Digital speed readout, E-stop, agitator controls, temperature probe with digital readout

- Air Requirements: 80 PSI minimum

Applications:

- Processed cheese and dairy-based products

- Sauces, soups, and purees

- Bakery and confectionery mixing

- Pharmaceutical and nutraceutical formulations

- Chemical and industrial product mixing

Potential Products for Processing:

- Imitation cheese base

- Processed dairy blends

- Sauces and dressings

- Liquid and semi-solid food products

- Nutritional and pharmaceutical mixtures

- Used MTC twin screw cooker

- Stainless steel industrial mixer

- Jacketed steam cooker

- Food processing equipment

- Industrial batch cooker

- Used MTC SC-1000 twin screw cooker for food production

- Stainless steel jacketed mixer with air-operated discharge doors

- Industrial twin screw cooker for processed cheese and dairy products

- High-capacity ribbon screw cooker with steam jacket heating

- Food-grade batch processing system with digital controls

- Used MTC SC-1000 stainless steel twin screw batch cooker for processed food production

- Industrial jacketed twin screw mixer with automated controls and temperature monitoring

- Food-grade mixing and cooking system with stainless steel ribbon screws and scrapers

- High-efficiency jacketed batch cooker for sauces, cheese, and liquid food processing

- Used 1,000 lb. capacity industrial steam cooker with air-operated discharge doors

Used MTC Twin Screw Jacketed Smart Cooker, Model SC-1000, 304 Stainless Steel. 1,000 lb. capacity based on 55 per cubic foot of material. Approximate 37" wide x 60" long jacketed trough. 14.9 Stainless steel steam jacket with gauge and relief valve. (2) Stainless steel ribbon screws with scrapers. Driven by (2) 5hp, 3/60/230 volt inverter motors with controls. Shaft seals, double sanitary split seals. (2) Air operated discharge doors with stainless steel cylinders, stainless steel guard and safety interlock. One piece, air operated, hinged cover. Full two piece hinged grate. Steel coated pillow blocks on drive and Delrin plug on discharge end. Controls with digital speed readout, E-stop, agitator controls, start/stop, doors open and close, cover open and close, product temperature probe with digital readout. 80psi Minimum air requirements. Serial # 10251, Built 2004. Last product that this mixer produced imitation cheese base for individually wrapped cheese.

Manufacturer Information:

- Manufacturer: MTC

- Model: SC-1000

- Condition: Used

- Serial #: 10251

- Year Built: 2004

Manufacturing Data:

- Capacity: 1,000 lbs. (based on 55 lbs. per cubic foot of material)

- Material: 304 Stainless Steel

- Trough Dimensions: Approx. 37” W x 60” L

- Jacket Type: 14.9 Stainless Steel Steam Jacket with Gauge and Relief Valve

- Mixing Mechanism:

- (2) Stainless steel ribbon screws with scrapers

- Driven by (2) 5 HP, 3/60/230V inverter motors with controls

- Double sanitary split shaft seals

- Discharge System:

- (2) Air-operated discharge doors with stainless steel cylinders

- Stainless steel guard with safety interlock

- Cover:

- One-piece, air-operated, hinged cover

- Full two-piece hinged grate

- Support Components:

- Steel-coated pillow blocks on drive

- Delrin plug on discharge end

- Control System:

- Digital speed readout

- E-stop

- Agitator controls

- Start/Stop functions

- Doors open/close controls

- Cover open/close controls

- Product temperature probe with digital readout

- Air Requirements: 80 PSI minimum

Description:

The MTC SC-1000 Twin Screw Jacketed Smart Cooker is an industrial-grade processing system designed for efficient mixing, heating, and cooking in food and chemical processing applications. Constructed from 304 stainless steel, this system features a jacketed trough for steam heating, along with twin ribbon screws with scrapers for uniform product mixing and agitation.

Equipped with air-operated discharge doors, a hinged safety cover, and digital controls, the SC-1000 is built for precise temperature management and efficient material handling. The system also includes an advanced control panel with speed readout, temperature monitoring, and automated door operations.

Previously used in the food industry, this unit was last utilized for the production of imitation cheese base for individually wrapped cheese.

Specifications:

- Capacity: 1,000 lbs.

- Material: 304 Stainless Steel

- Trough Dimensions: 37” W x 60” L

- Steam Jacket: 14.9 Stainless Steel with gauge and relief valve

- Mixing System: Twin stainless steel ribbon screws with scrapers

- Motors: (2) 5 HP, 3/60/230V inverter motors

- Seals: Double sanitary split shaft seals

- Discharge System: Air-operated stainless steel discharge doors

- Safety Features: Stainless steel guard, safety interlock, and air-operated hinged cover

- Controls: Digital speed readout, E-stop, agitator controls, temperature probe with digital readout

- Air Requirements: 80 PSI minimum

Applications:

- Processed cheese and dairy-based products

- Sauces, soups, and purees

- Bakery and confectionery mixing

- Pharmaceutical and nutraceutical formulations

- Chemical and industrial product mixing

Potential Products for Processing:

- Imitation cheese base

- Processed dairy blends

- Sauces and dressings

- Liquid and semi-solid food products

- Nutritional and pharmaceutical mixtures

- Used MTC twin screw cooker

- Stainless steel industrial mixer

- Jacketed steam cooker

- Food processing equipment

- Industrial batch cooker

- Used MTC SC-1000 twin screw cooker for food production

- Stainless steel jacketed mixer with air-operated discharge doors

- Industrial twin screw cooker for processed cheese and dairy products

- High-capacity ribbon screw cooker with steam jacket heating

- Food-grade batch processing system with digital controls

- Used MTC SC-1000 stainless steel twin screw batch cooker for processed food production

- Industrial jacketed twin screw mixer with automated controls and temperature monitoring

- Food-grade mixing and cooking system with stainless steel ribbon screws and scrapers

- High-efficiency jacketed batch cooker for sauces, cheese, and liquid food processing

- Used 1,000 lb. capacity industrial steam cooker with air-operated discharge doors

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory