Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

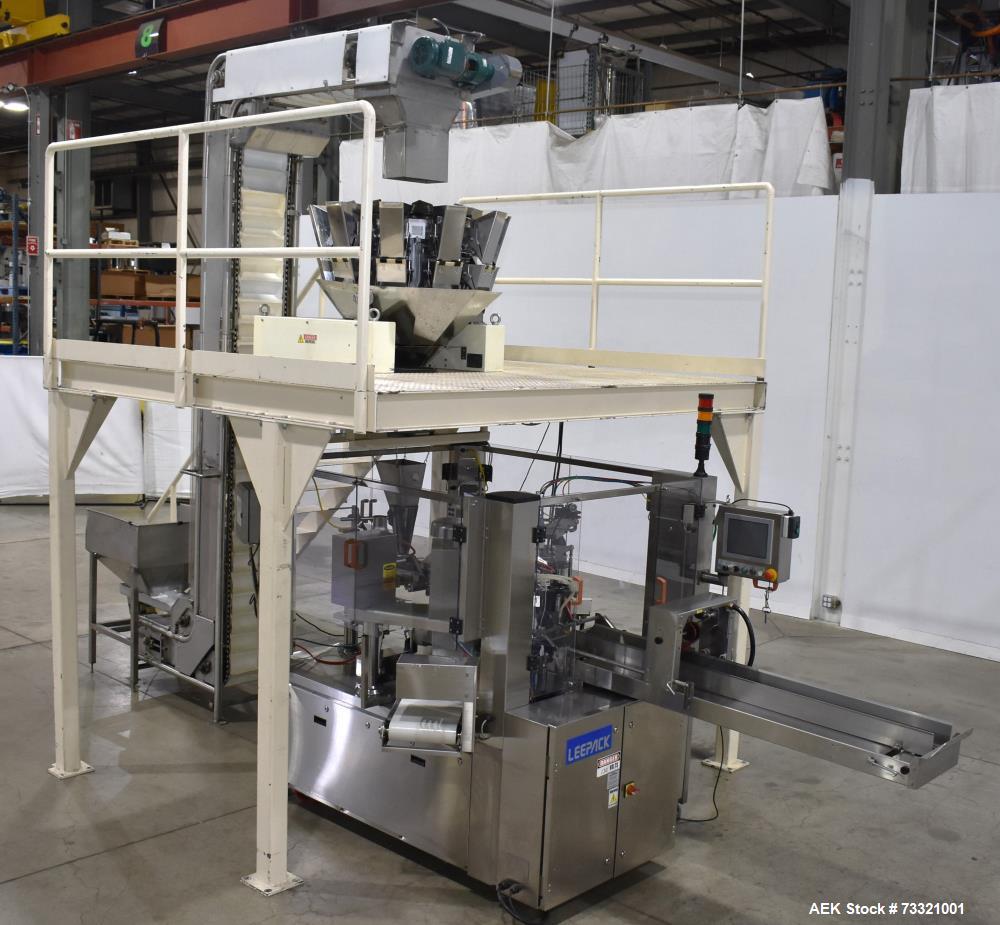

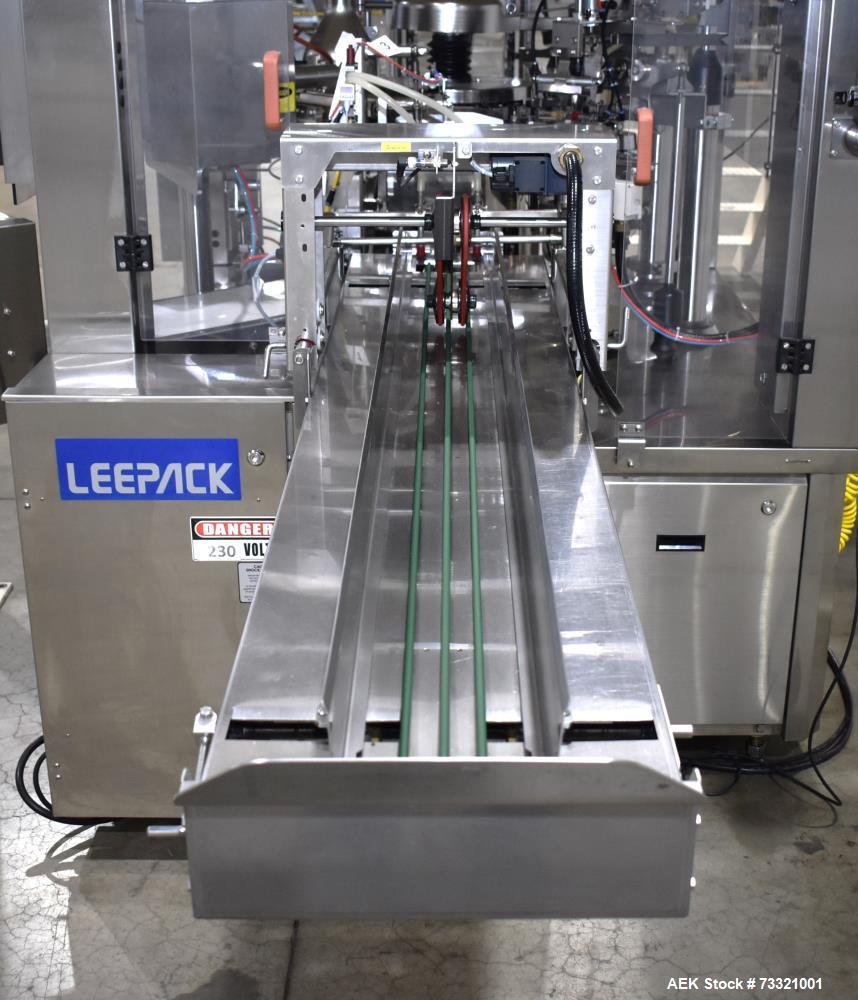

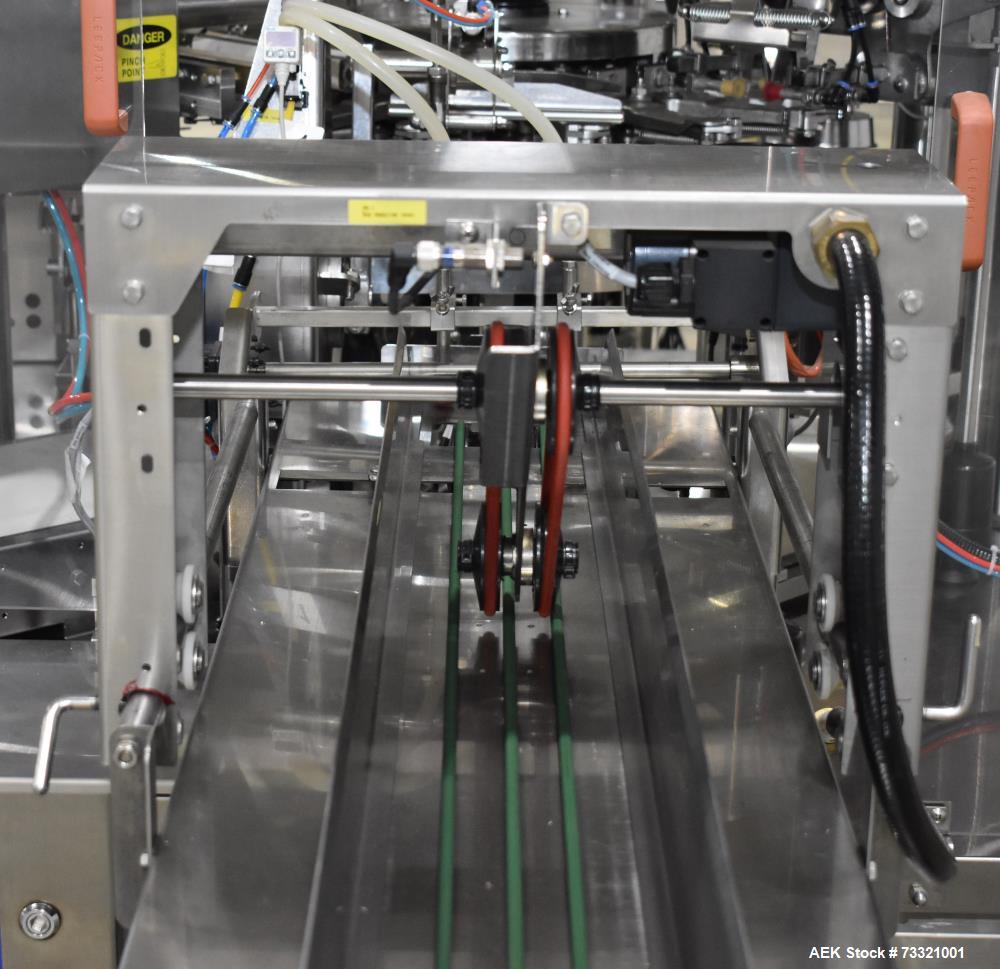

Used PSG Lee RP-8BT-Z Pre-Made Pouch Packager System

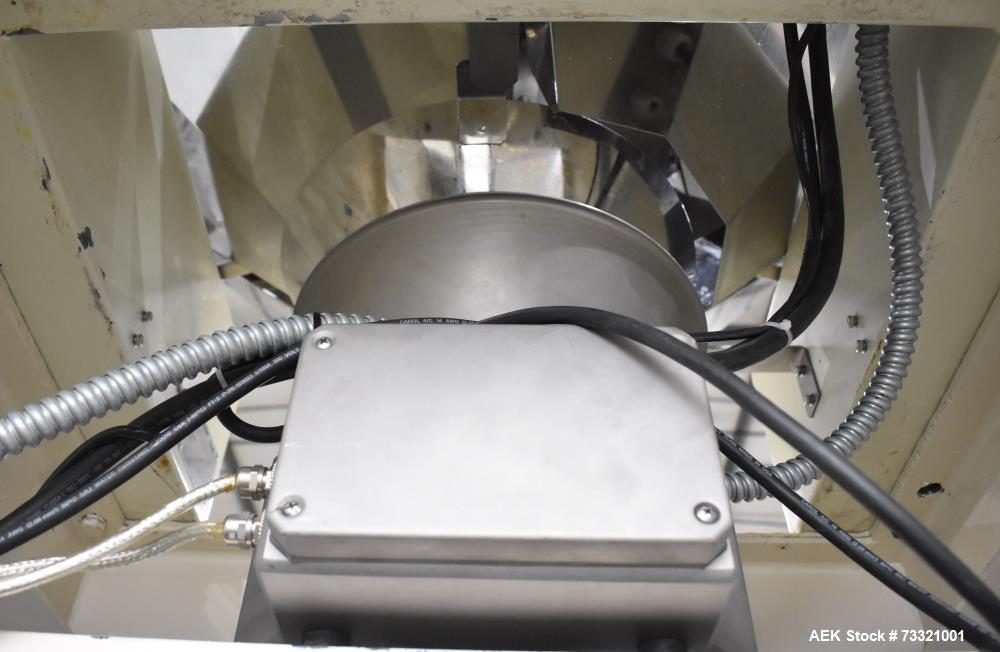

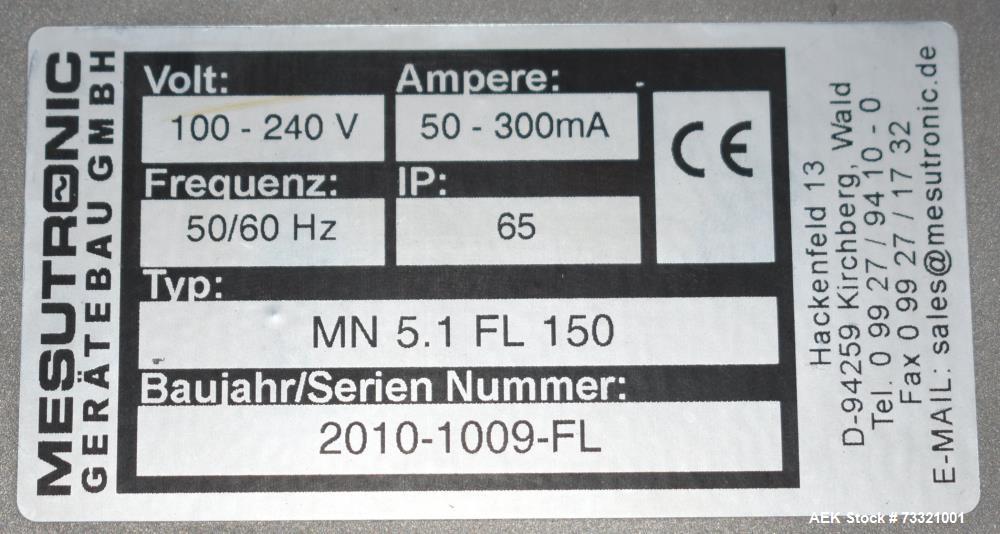

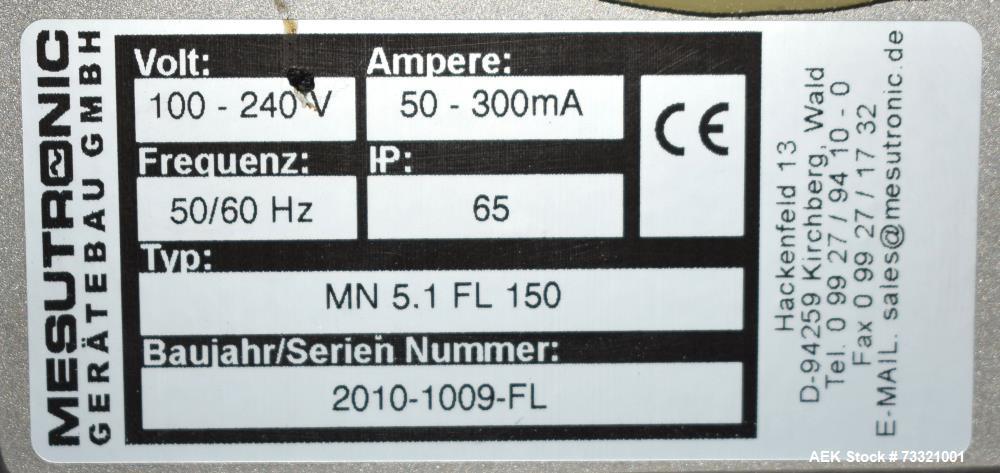

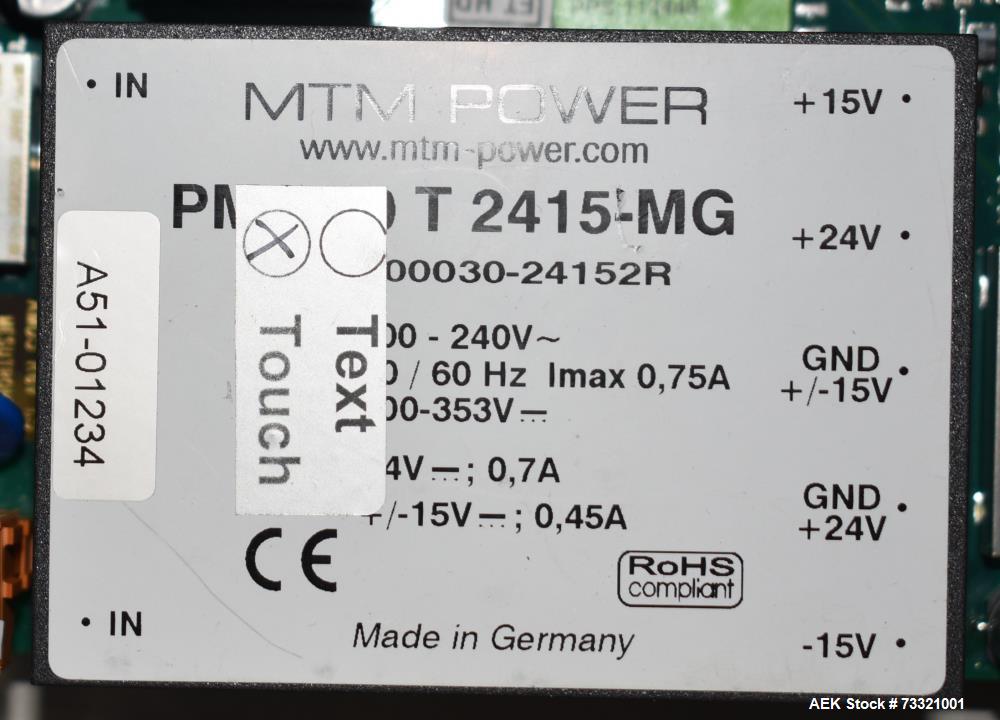

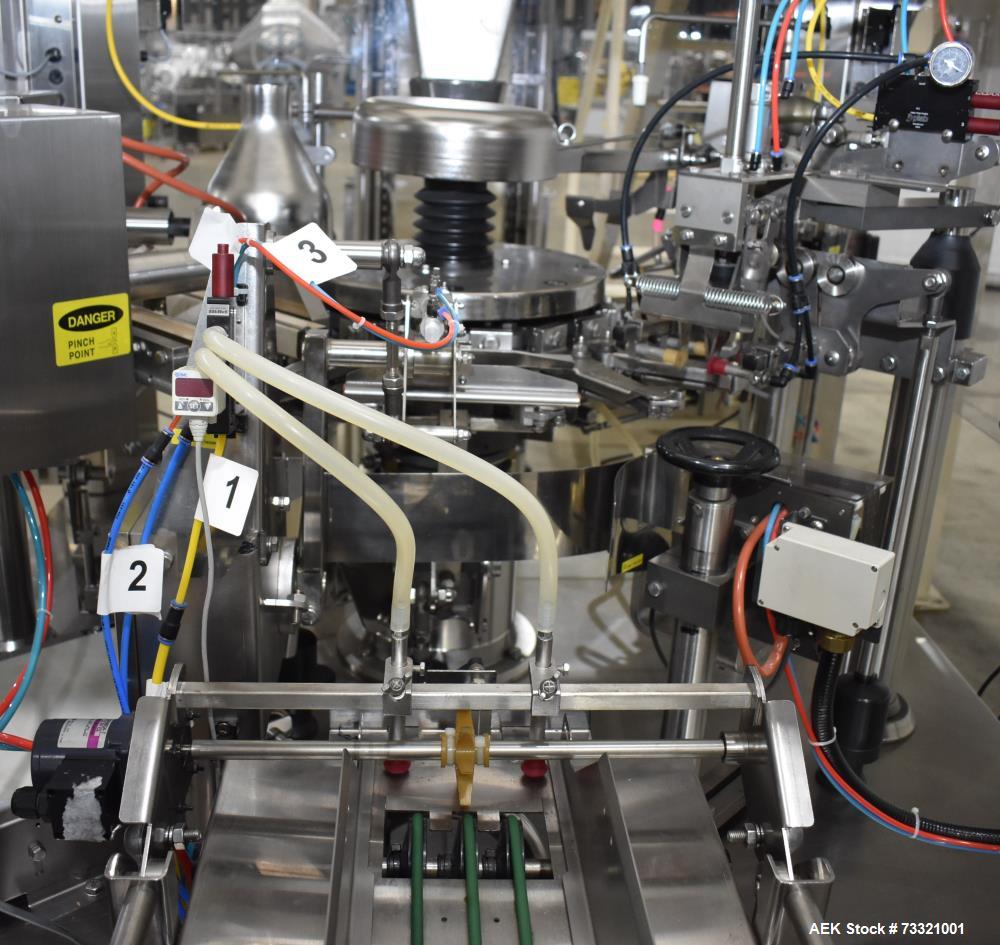

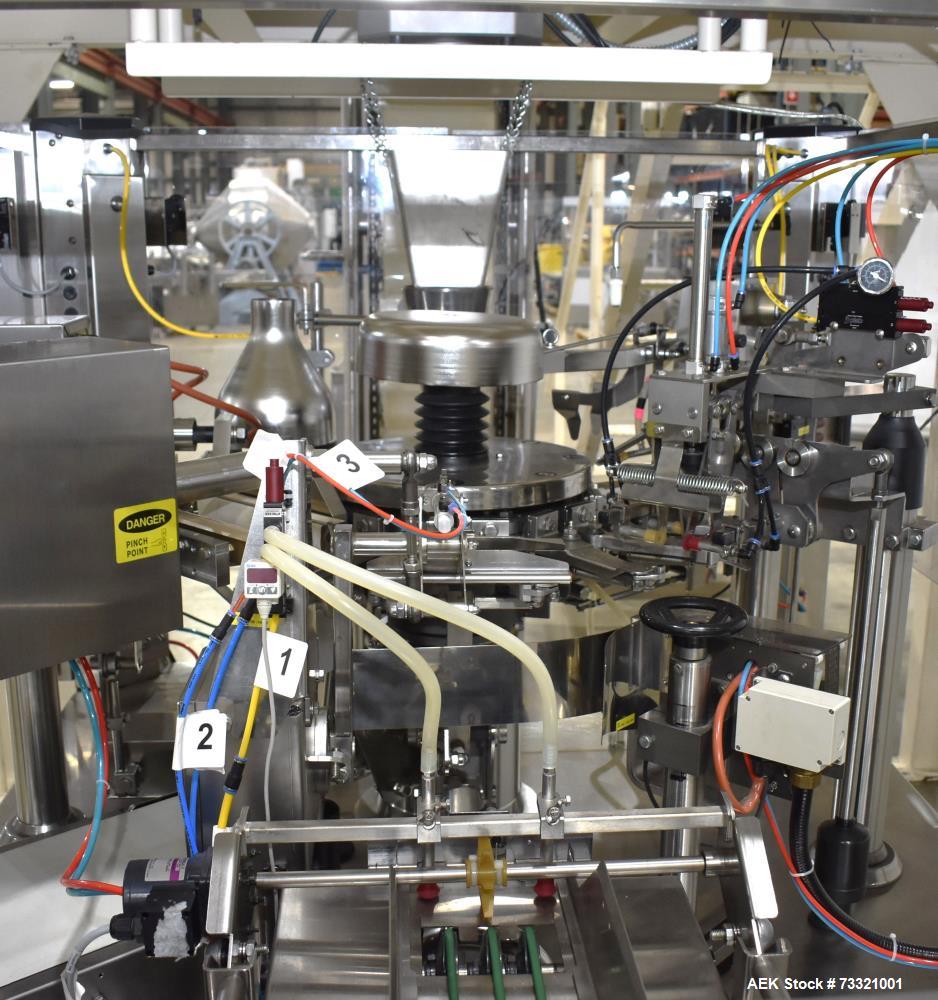

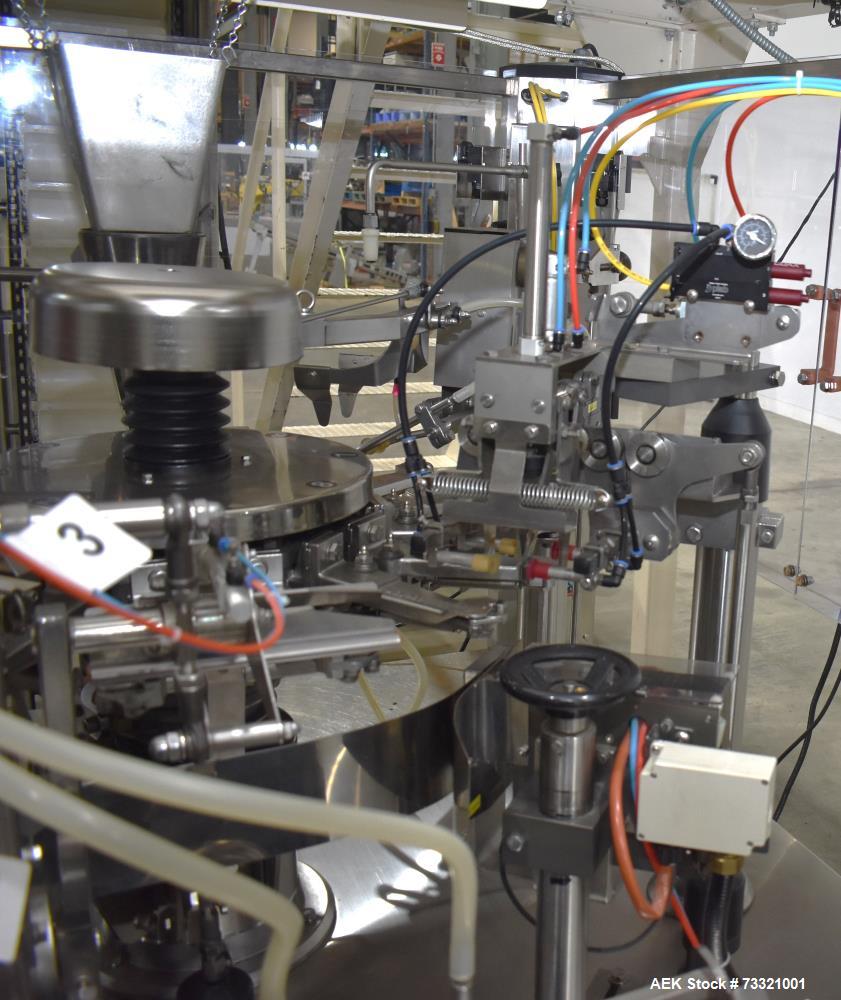

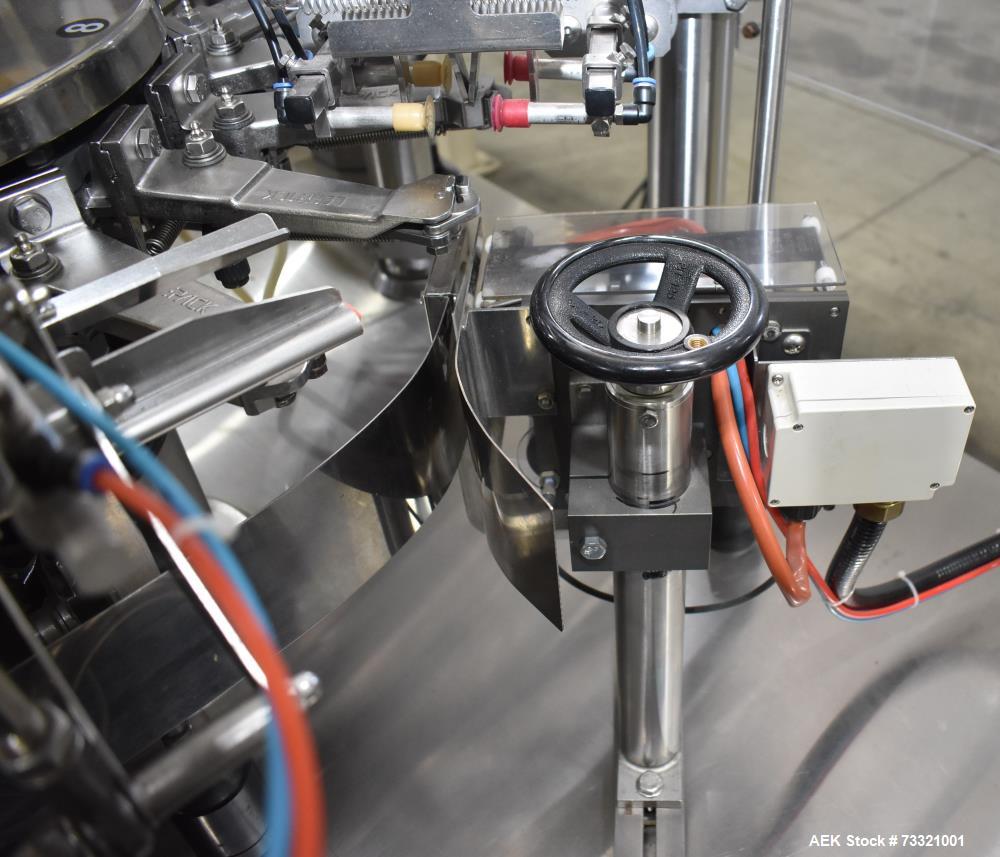

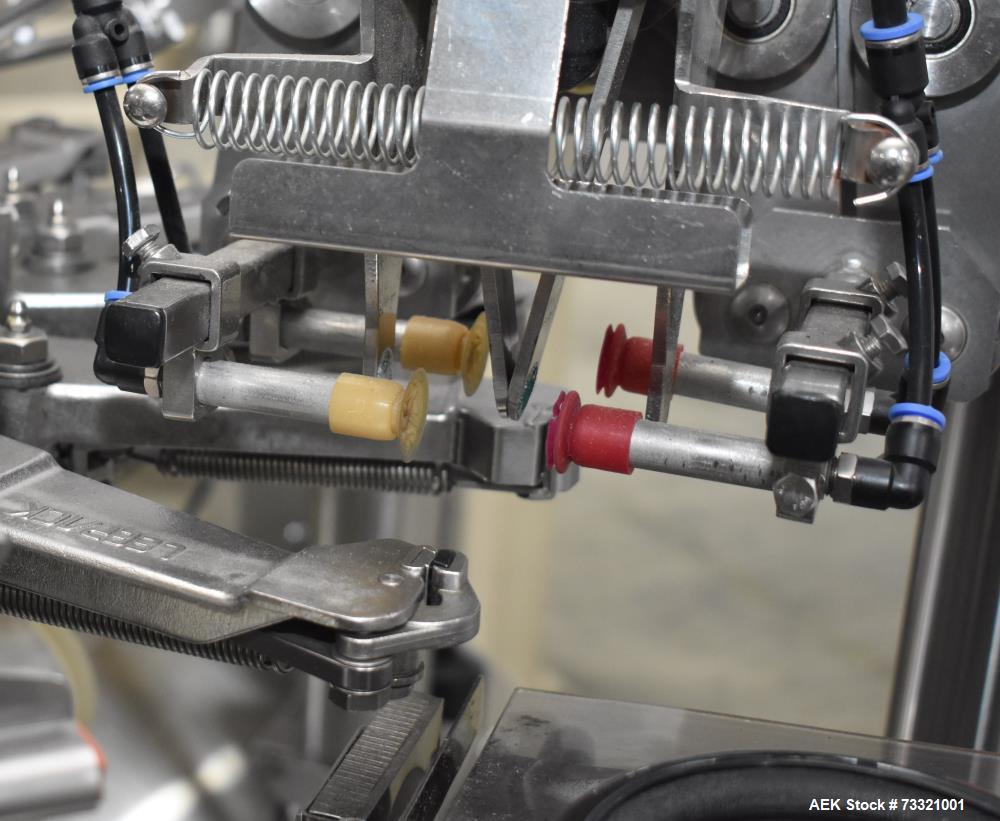

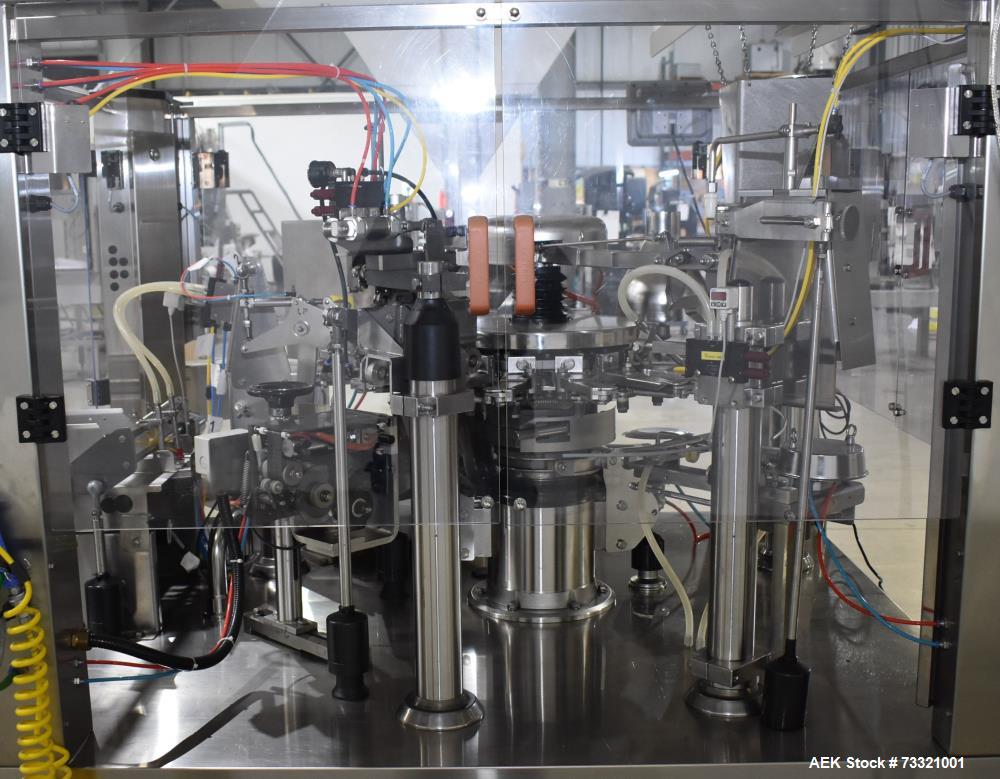

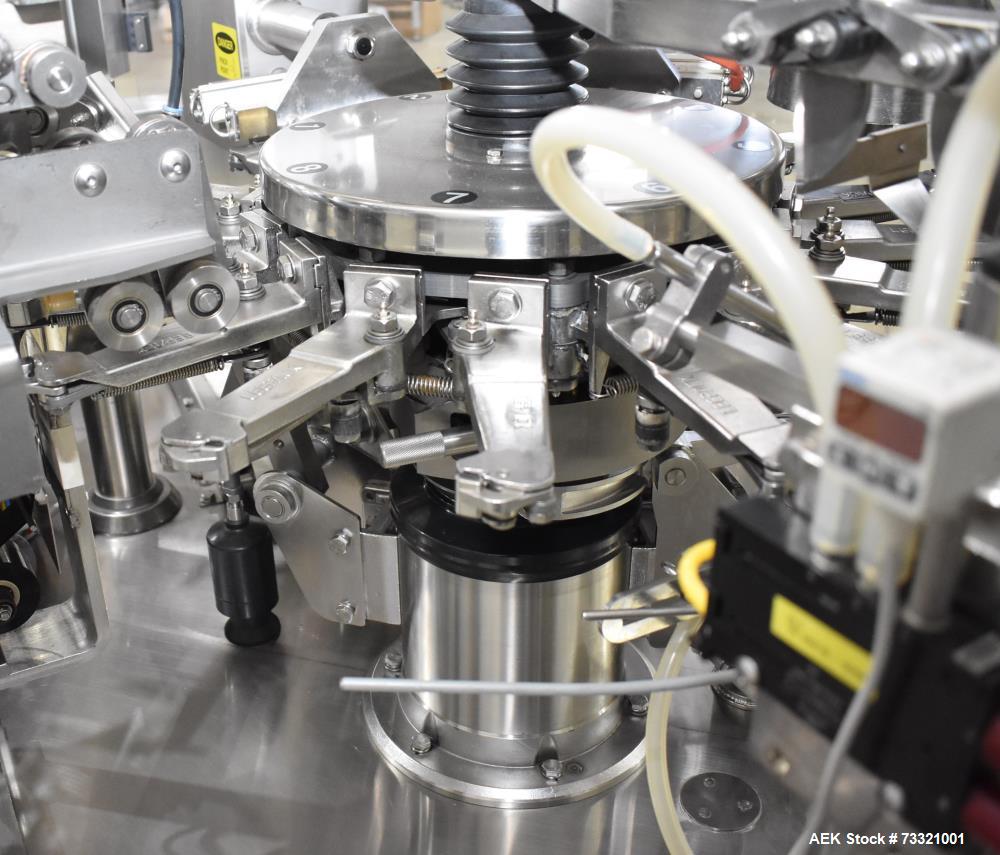

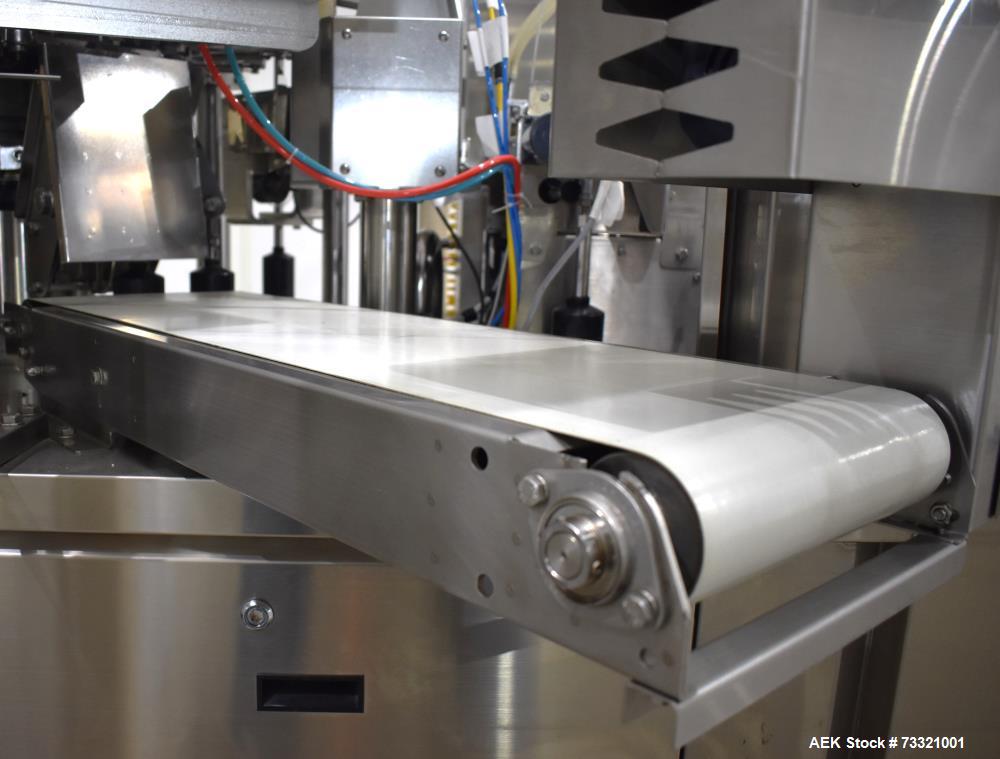

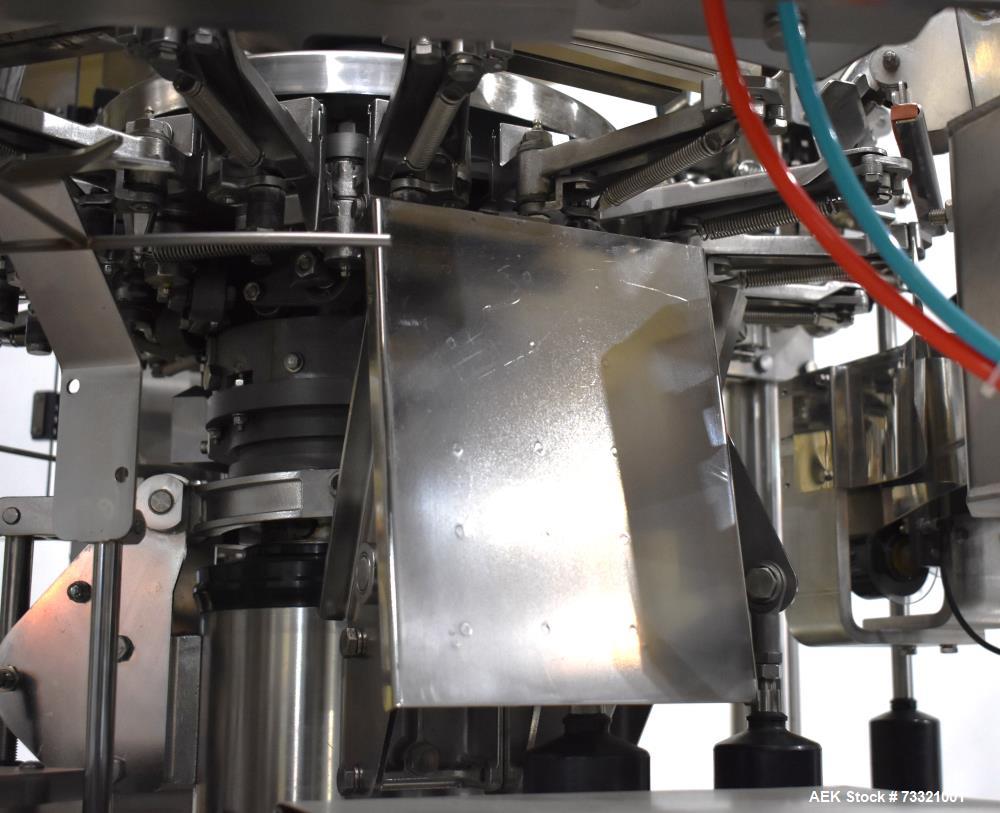

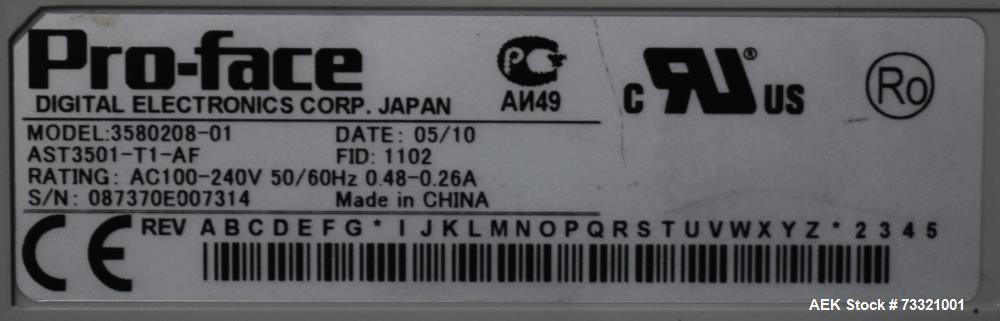

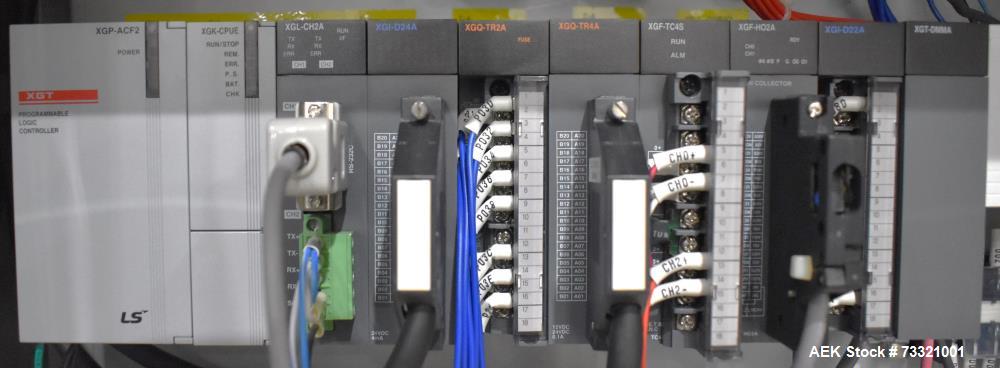

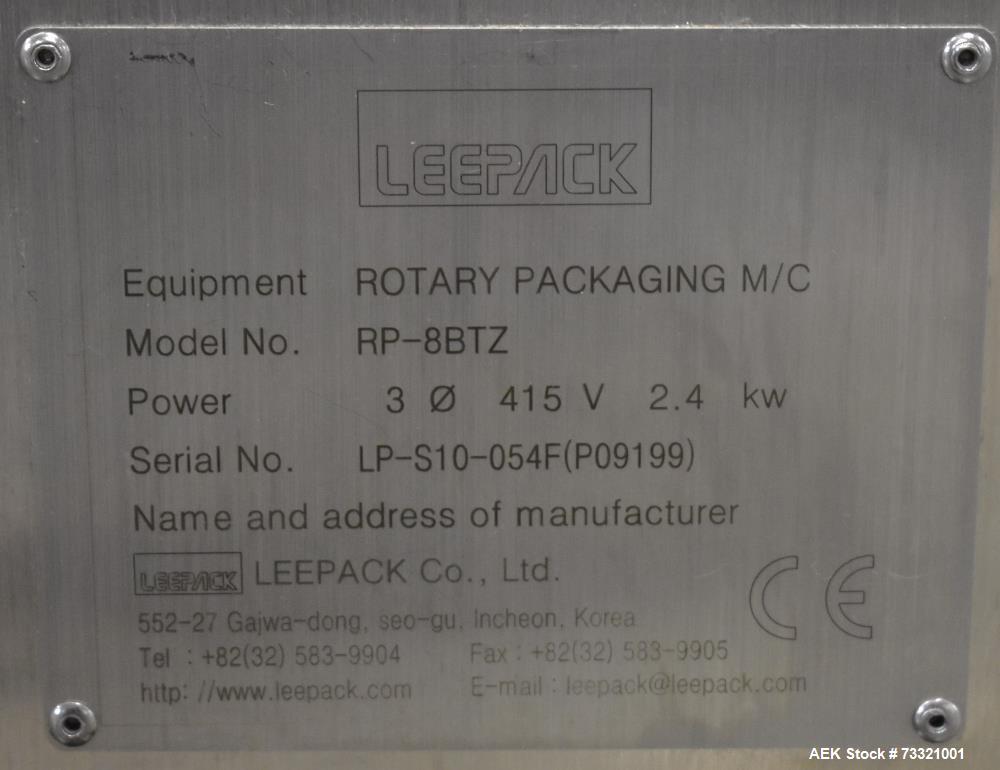

Used PSG-Lee (Leepack) Model RP-8BT-Z Pre-Made Pouch Packager System. Dimpled vibratory feed pans. Poucher has bag size range: 3.9"-9.4"W x up to 13.8"H and is capable of speeds up to 40 packages per minute (depending on product specifications). Last running Licorice in a stand-up zipper pouch sizes 100 to 160mm W X 180 to 215mm L. Agitation for bag opening, product settler, zipper, gas flush, vibratory station after film. Integrated Mesutronic Quicktron 05 drop through metal detector, 150mm aperture. Dimpled embossed feeder. Control panel with LS Electric XGT model XGP-ACF2 PLC and Proface model 3580208-1 HMI.FMC vibratory feeder. Bucket elevator, approximate 12" long x 4-3/4" wide x 2-1/2" deep buckets. System includes poucher, bucket elevator and mezzanine. Stainless steel construction. 3/60/230/480V. **Doesn't include a scale.****

Manufacturers Info:

- Manufacturer: PSG Lee (Leepack)

- Model: RP-8BT-Z

- Condition: Used

- Construction: Stainless Steel

Facts About the PSG Lee RP-8BT-Z Pouch Packager System:

- Automated pre-made pouch packaging system with integrated multi-head weighing and metal detection.

- Bag size range: 3.9"-9.4"W x up to 13.8"H, suitable for stand-up zipper pouches.

- Capable of speeds up to 40 packages per minute, depending on product specifications.

- Last used for packaging licorice in stand-up zipper pouches (100-160mm W x 180-215mm L).

- Agitation system for bag opening and a vibratory station after film application for product settling.

- Zipper, gas flush, and product settler features for improved pouch integrity and freshness.

- Integrated Mesutronic Quicktron 05 drop-through metal detector with a 150mm aperture ensures contaminant detection.

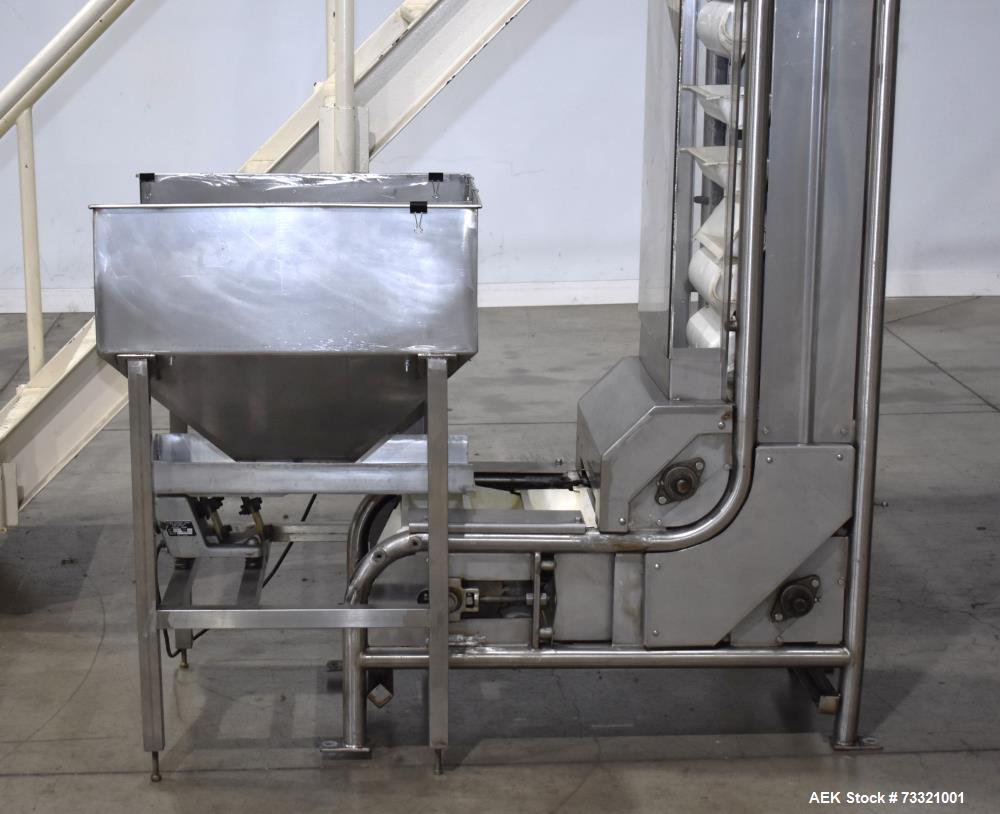

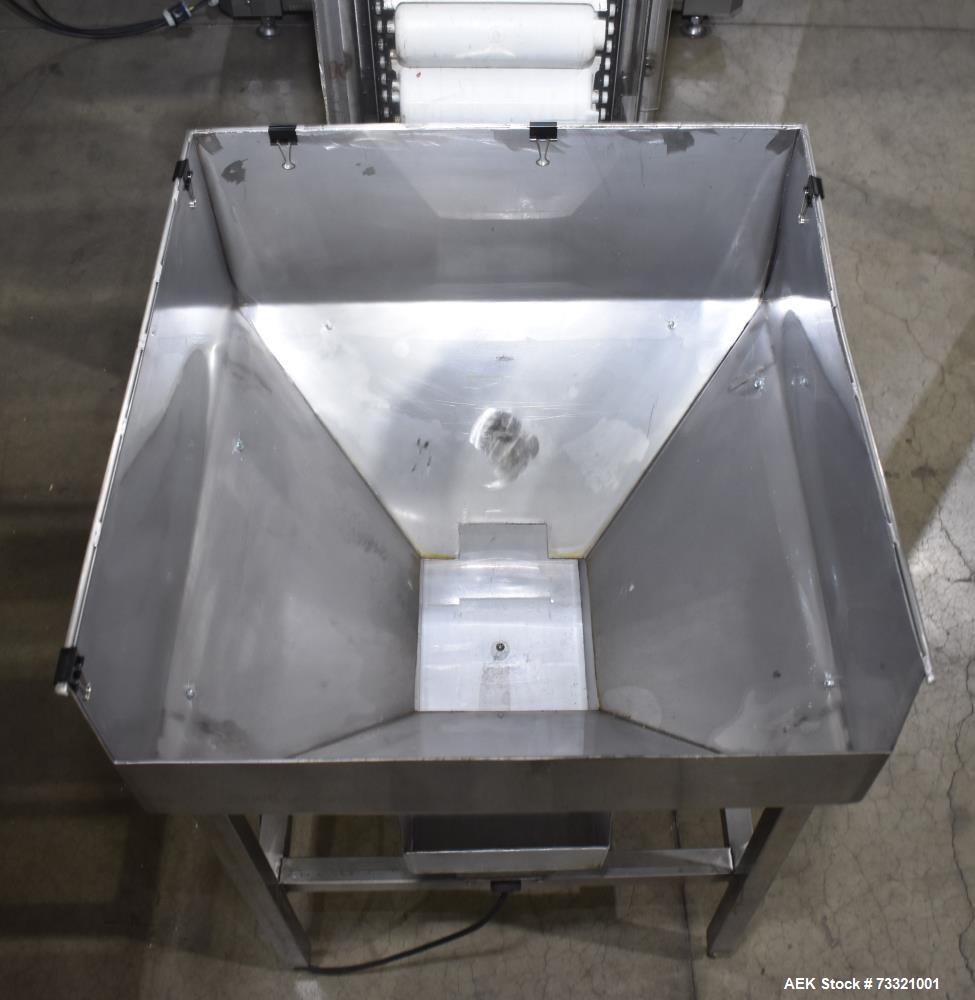

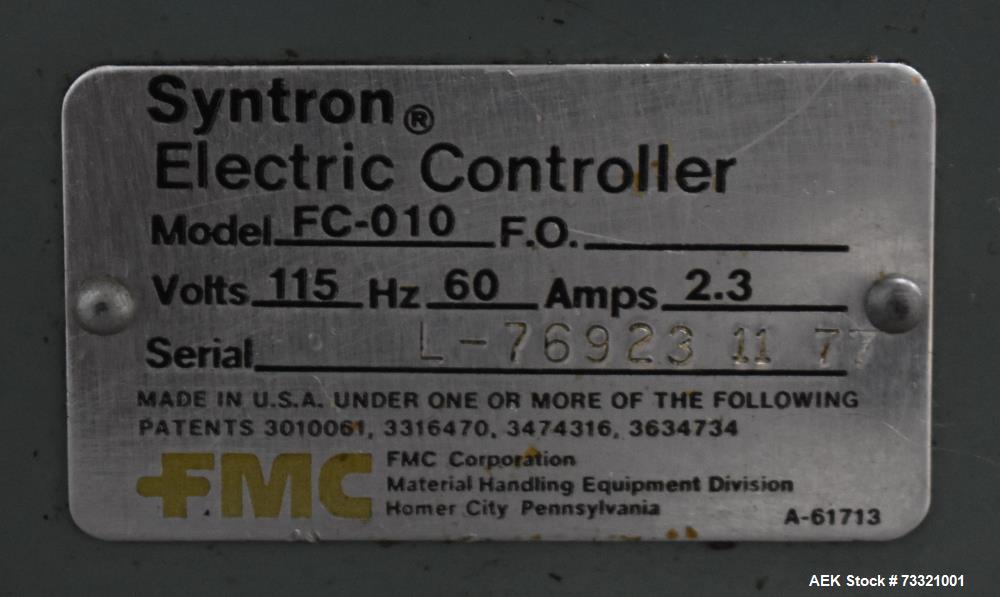

- FMC Vibratory Feeder and Bucket Elevator System provide efficient product handling.

- Control panel features:

- LS Electric XGT XGP-ACF2 PLC for precise automation.

- Proface Model 3580208-1 HMI for user-friendly operation.

- Mezzanine included, providing stability and accessibility to the system.

- Stainless steel construction, ensuring durability and compliance with food-grade processing.

- Electrical Specs: 3-phase, 60 Hz, 230/480V.

Description:

This used PSG Lee RP-8BT-Z Pre-Made Pouch Packager System is an automated, high-speed packaging solution for food, snacks, confectionery, and granular products. Mesutronic Quicktron 05 drop-through metal detector for enhanced product safety.

With a bag size range of 3.9"-9.4"W x up to 13.8"H, this system is capable of packaging at speeds of up to 40 pouches per minute, depending on product specifications. The system includes a bucket elevator, vibratory feeder, and mezzanine, making it a fully integrated turnkey solution for high-volume stand-up pouch packaging applications.

The system is ideal for packaging granular, powder, and snack foods, with features like zipper closure, gas flush, and product settling. The stainless steel construction ensures compliance with food industry hygiene standards, while the LS Electric XGT PLC and Proface HMI provide an intuitive control interface for seamless operation.

Specifications:

- Bag Size Range: 3.9" - 9.4"W x up to 13.8"H

- Speed: Up to 40 packages per minute

- Metal Detector: Mesutronic Quicktron 05 Drop-Through Metal Detector (150mm Aperture)

- Feeding System:

- Dimpled embossed feeder

- FMC Vibratory Feeder

- Bucket Elevator: 12" long x 4-3/4" wide x 2-1/2" deep buckets

- Control System:

- LS Electric XGT XGP-ACF2 PLC

- Proface Model 3580208-1 HMI

- Power Requirements: 3-Phase, 60 Hz, 230/480V

- Construction: Stainless Steel

- Mounting: Mezzanine Included

Applications:

- Snack & Confectionery Packaging

- Food & Beverage Packaging

- Powder & Granular Product Filling

- Dried Fruits & Nuts Packaging

- Pet Food & Treats Packaging

- Pharmaceutical & Nutraceutical Pouch Packaging

What Products Would This Be Used For?

- Candy, Licorice, & Gummies

- Dried Fruits & Nuts

- Coffee & Tea

- Granulated & Powdered Products

- Chips & Snack Foods

- Pet Food & Supplements

- Spices & Seasonings

Food Manufacturing, Food Packaging, Food Plants, Food Processing, Food Production, Food Products, Foods, Packaging, Packaging Equipment, Pouch Filler, Pouches

- PSG Lee Pouch Packager

- Used Premade Pouch Machine

- Yamato 10-Head Scale

- Food Packaging System

- High-Speed Pouch Filling

- Used PSG Lee RP-8BT-Z Pouch Packing Machine for Sale

- High-Speed Pouch Packager with Yamato 10-Head Scale

- Automated Stand-Up Zipper Pouch Packaging System

- Pre-Made Pouch Filling Machine with Metal Detector

- Stainless Steel Food Pouch Packaging Equipment

- Used PSG Lee RP-8BT-Z Pre-Made Pouch Packager System – Yamato 10-Head Scale, 40 ppm

- Industrial Food Packaging System with Vibratory Feeder, Bucket Elevator, & PLC Control

- Automated Zipper Pouch Filling Machine with Mesutronic Quicktron Metal Detector

- High-Speed Confectionery & Snack Packaging System with Allen Bradley PLC

- Stainless Steel Pouch Packaging System for Food, Pet Food, & Powdered Products

Used PSG-Lee (Leepack) Model RP-8BT-Z Pre-Made Pouch Packager System. Dimpled vibratory feed pans. Poucher has bag size range: 3.9"-9.4"W x up to 13.8"H and is capable of speeds up to 40 packages per minute (depending on product specifications). Last running Licorice in a stand-up zipper pouch sizes 100 to 160mm W X 180 to 215mm L. Agitation for bag opening, product settler, zipper, gas flush, vibratory station after film. Integrated Mesutronic Quicktron 05 drop through metal detector, 150mm aperture. Dimpled embossed feeder. Control panel with LS Electric XGT model XGP-ACF2 PLC and Proface model 3580208-1 HMI.FMC vibratory feeder. Bucket elevator, approximate 12" long x 4-3/4" wide x 2-1/2" deep buckets. System includes poucher, bucket elevator and mezzanine. Stainless steel construction. 3/60/230/480V. **Doesn't include a scale.****

Manufacturers Info:

- Manufacturer: PSG Lee (Leepack)

- Model: RP-8BT-Z

- Condition: Used

- Construction: Stainless Steel

Facts About the PSG Lee RP-8BT-Z Pouch Packager System:

- Automated pre-made pouch packaging system with integrated multi-head weighing and metal detection.

- Bag size range: 3.9"-9.4"W x up to 13.8"H, suitable for stand-up zipper pouches.

- Capable of speeds up to 40 packages per minute, depending on product specifications.

- Last used for packaging licorice in stand-up zipper pouches (100-160mm W x 180-215mm L).

- Agitation system for bag opening and a vibratory station after film application for product settling.

- Zipper, gas flush, and product settler features for improved pouch integrity and freshness.

- Integrated Mesutronic Quicktron 05 drop-through metal detector with a 150mm aperture ensures contaminant detection.

- FMC Vibratory Feeder and Bucket Elevator System provide efficient product handling.

- Control panel features:

- LS Electric XGT XGP-ACF2 PLC for precise automation.

- Proface Model 3580208-1 HMI for user-friendly operation.

- Mezzanine included, providing stability and accessibility to the system.

- Stainless steel construction, ensuring durability and compliance with food-grade processing.

- Electrical Specs: 3-phase, 60 Hz, 230/480V.

Description:

This used PSG Lee RP-8BT-Z Pre-Made Pouch Packager System is an automated, high-speed packaging solution for food, snacks, confectionery, and granular products. Mesutronic Quicktron 05 drop-through metal detector for enhanced product safety.

With a bag size range of 3.9"-9.4"W x up to 13.8"H, this system is capable of packaging at speeds of up to 40 pouches per minute, depending on product specifications. The system includes a bucket elevator, vibratory feeder, and mezzanine, making it a fully integrated turnkey solution for high-volume stand-up pouch packaging applications.

The system is ideal for packaging granular, powder, and snack foods, with features like zipper closure, gas flush, and product settling. The stainless steel construction ensures compliance with food industry hygiene standards, while the LS Electric XGT PLC and Proface HMI provide an intuitive control interface for seamless operation.

Specifications:

- Bag Size Range: 3.9" - 9.4"W x up to 13.8"H

- Speed: Up to 40 packages per minute

- Metal Detector: Mesutronic Quicktron 05 Drop-Through Metal Detector (150mm Aperture)

- Feeding System:

- Dimpled embossed feeder

- FMC Vibratory Feeder

- Bucket Elevator: 12" long x 4-3/4" wide x 2-1/2" deep buckets

- Control System:

- LS Electric XGT XGP-ACF2 PLC

- Proface Model 3580208-1 HMI

- Power Requirements: 3-Phase, 60 Hz, 230/480V

- Construction: Stainless Steel

- Mounting: Mezzanine Included

Applications:

- Snack & Confectionery Packaging

- Food & Beverage Packaging

- Powder & Granular Product Filling

- Dried Fruits & Nuts Packaging

- Pet Food & Treats Packaging

- Pharmaceutical & Nutraceutical Pouch Packaging

What Products Would This Be Used For?

- Candy, Licorice, & Gummies

- Dried Fruits & Nuts

- Coffee & Tea

- Granulated & Powdered Products

- Chips & Snack Foods

- Pet Food & Supplements

- Spices & Seasonings

Food Manufacturing, Food Packaging, Food Plants, Food Processing, Food Production, Food Products, Foods, Packaging, Packaging Equipment, Pouch Filler, Pouches

- PSG Lee Pouch Packager

- Used Premade Pouch Machine

- Yamato 10-Head Scale

- Food Packaging System

- High-Speed Pouch Filling

- Used PSG Lee RP-8BT-Z Pouch Packing Machine for Sale

- High-Speed Pouch Packager with Yamato 10-Head Scale

- Automated Stand-Up Zipper Pouch Packaging System

- Pre-Made Pouch Filling Machine with Metal Detector

- Stainless Steel Food Pouch Packaging Equipment

- Used PSG Lee RP-8BT-Z Pre-Made Pouch Packager System – Yamato 10-Head Scale, 40 ppm

- Industrial Food Packaging System with Vibratory Feeder, Bucket Elevator, & PLC Control

- Automated Zipper Pouch Filling Machine with Mesutronic Quicktron Metal Detector

- High-Speed Confectionery & Snack Packaging System with Allen Bradley PLC

- Stainless Steel Pouch Packaging System for Food, Pet Food, & Powdered Products

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory