Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Bossar BL3000 STU3 Horizontal FFS Machine – Liquid Stand-Up Pouch Filler, 150 PPM

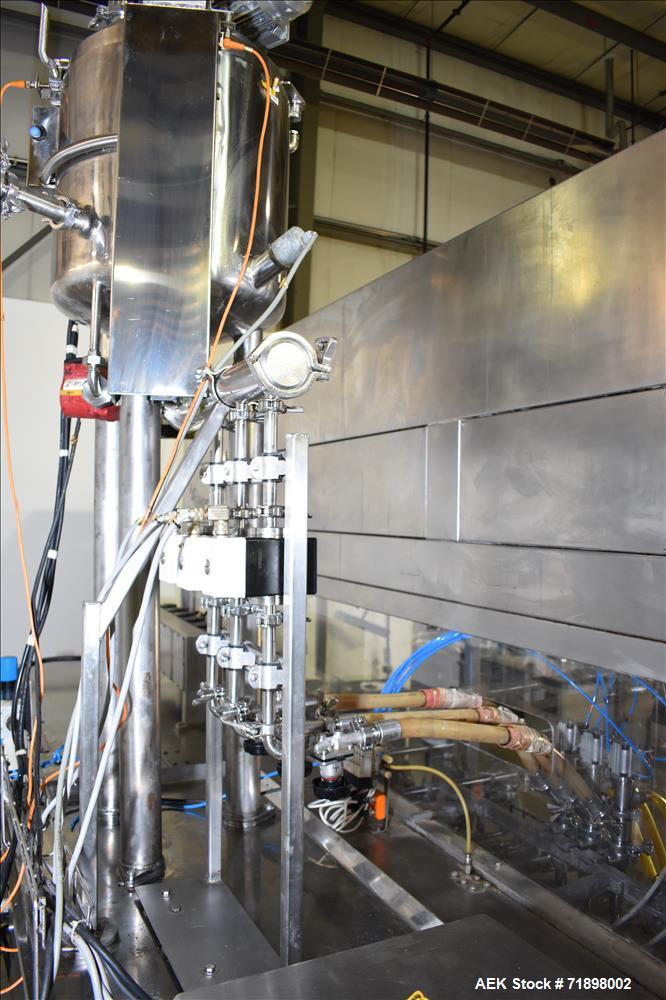

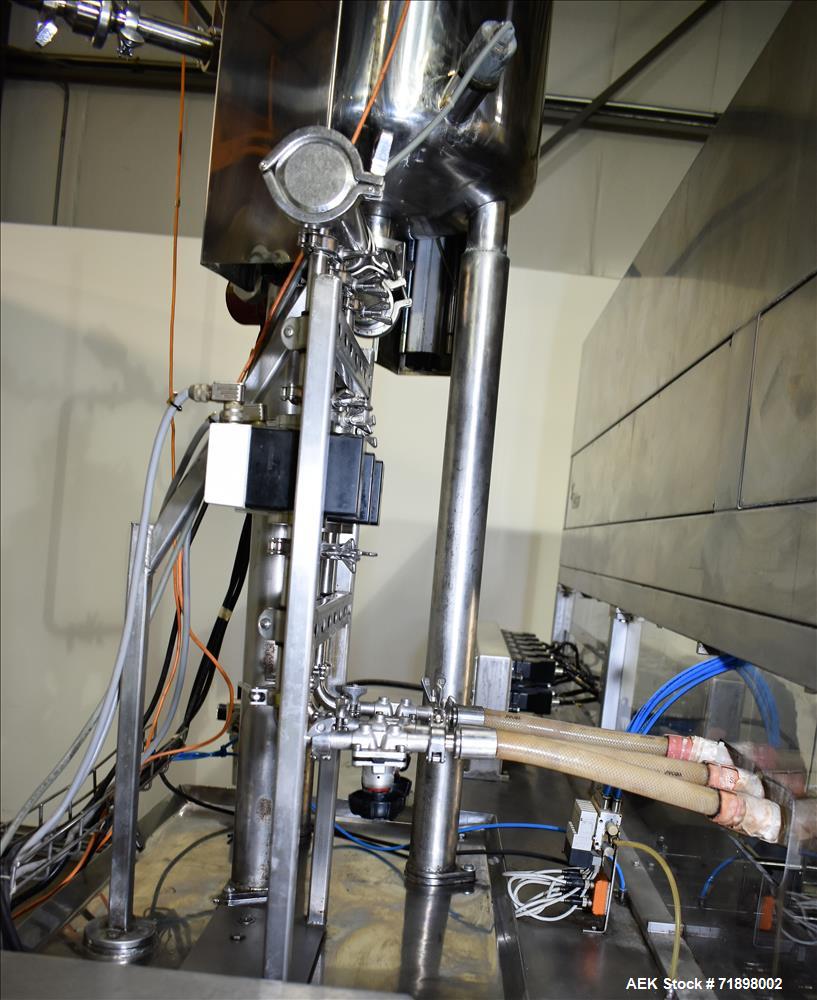

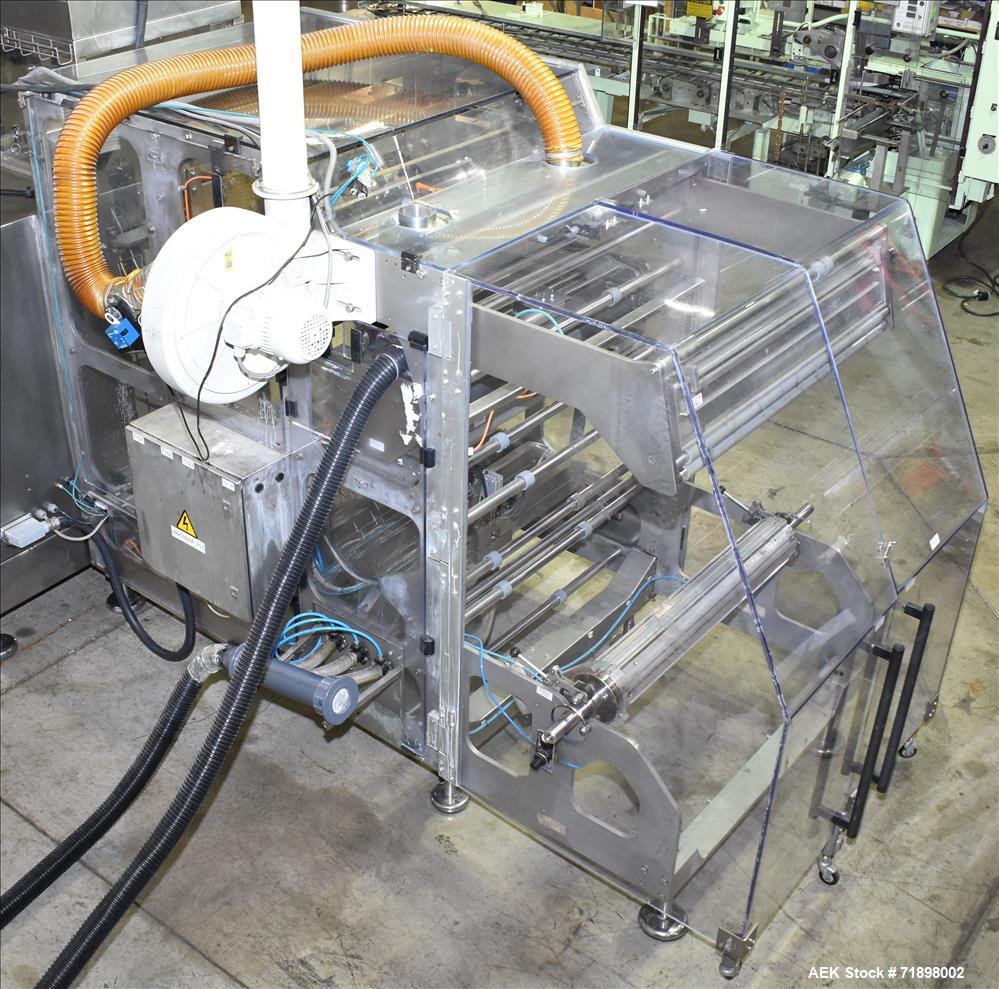

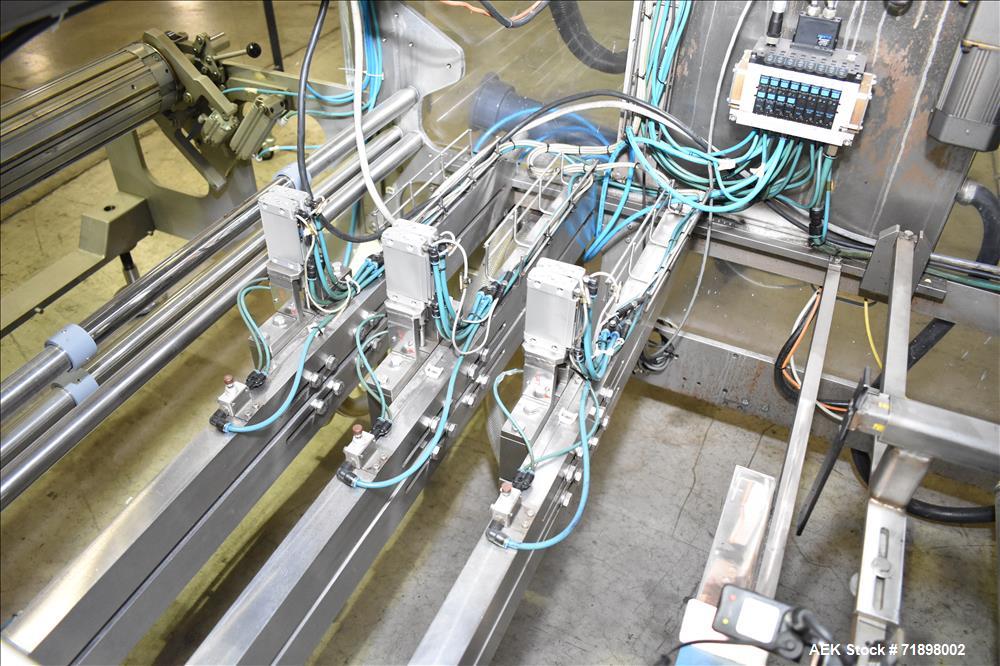

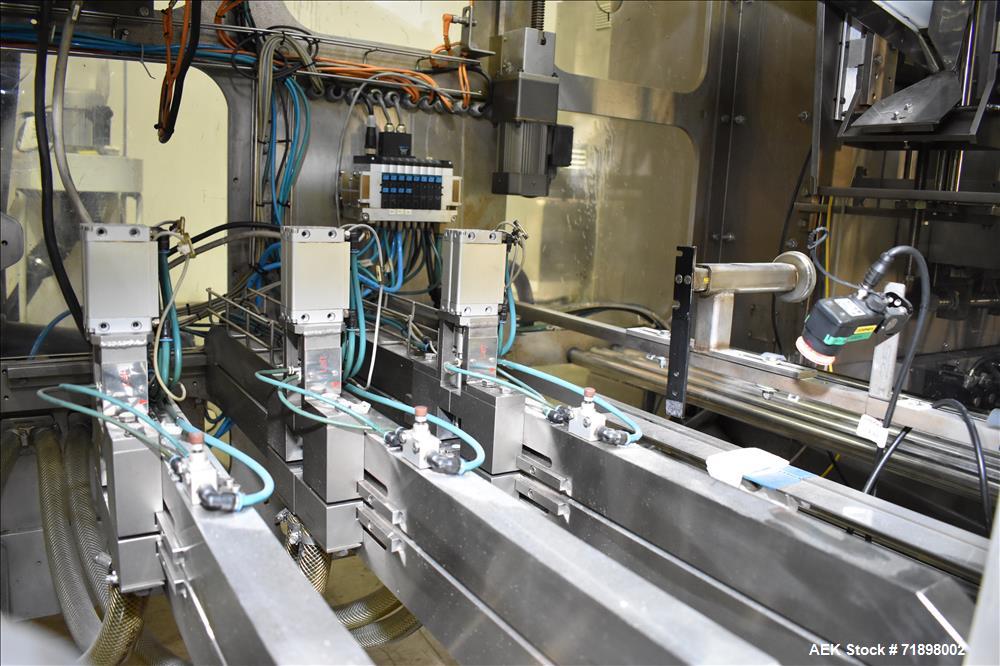

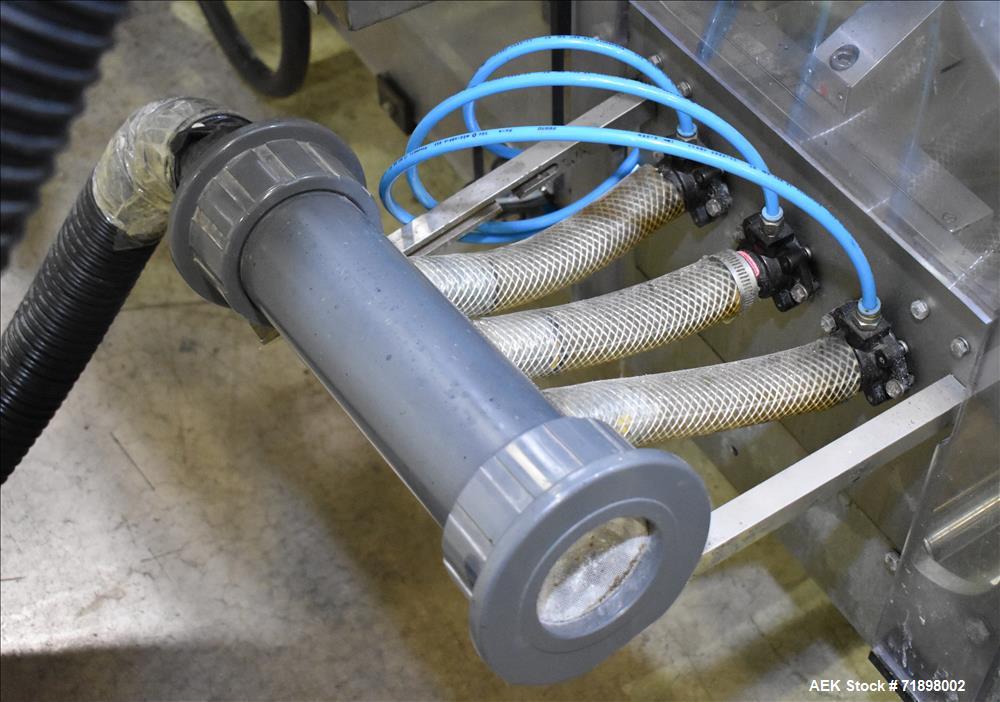

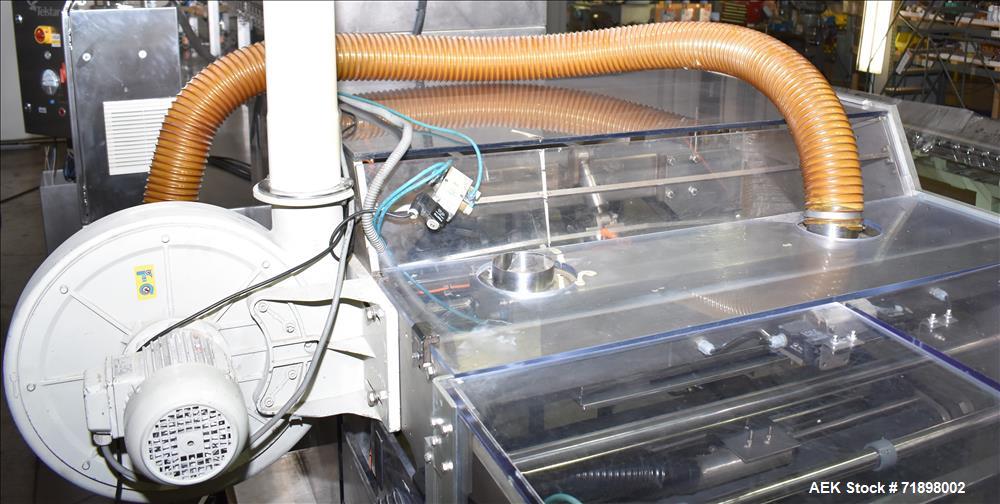

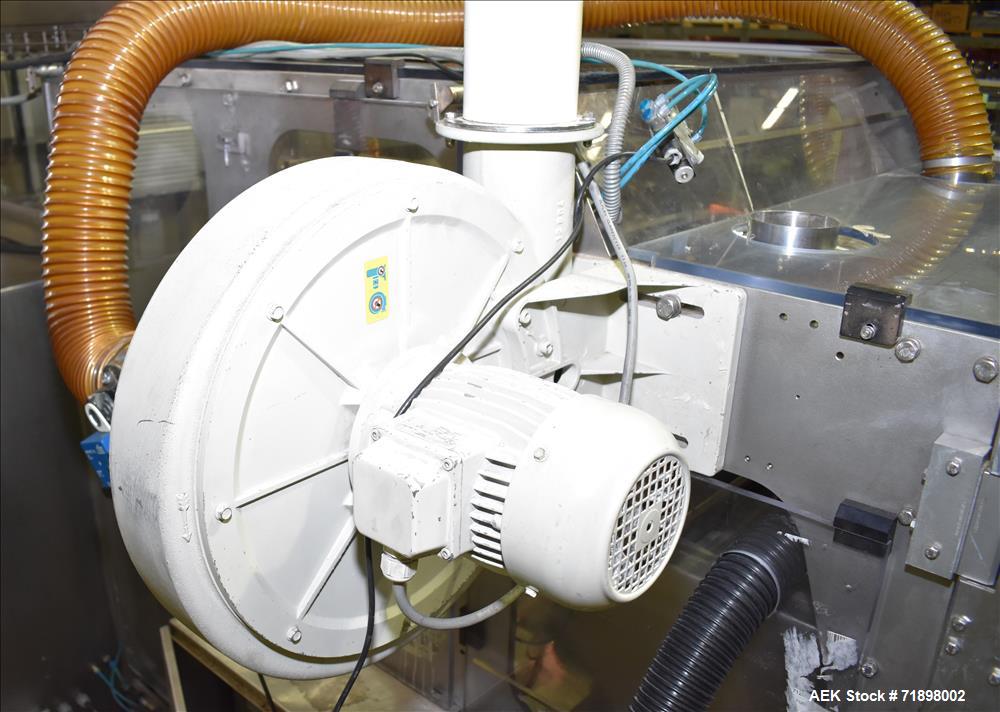

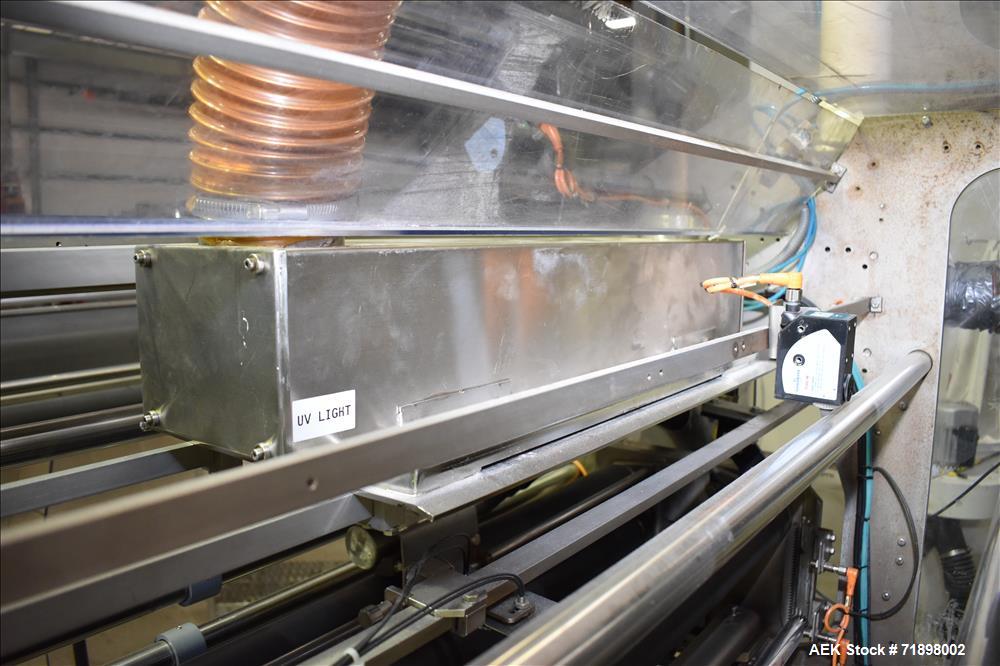

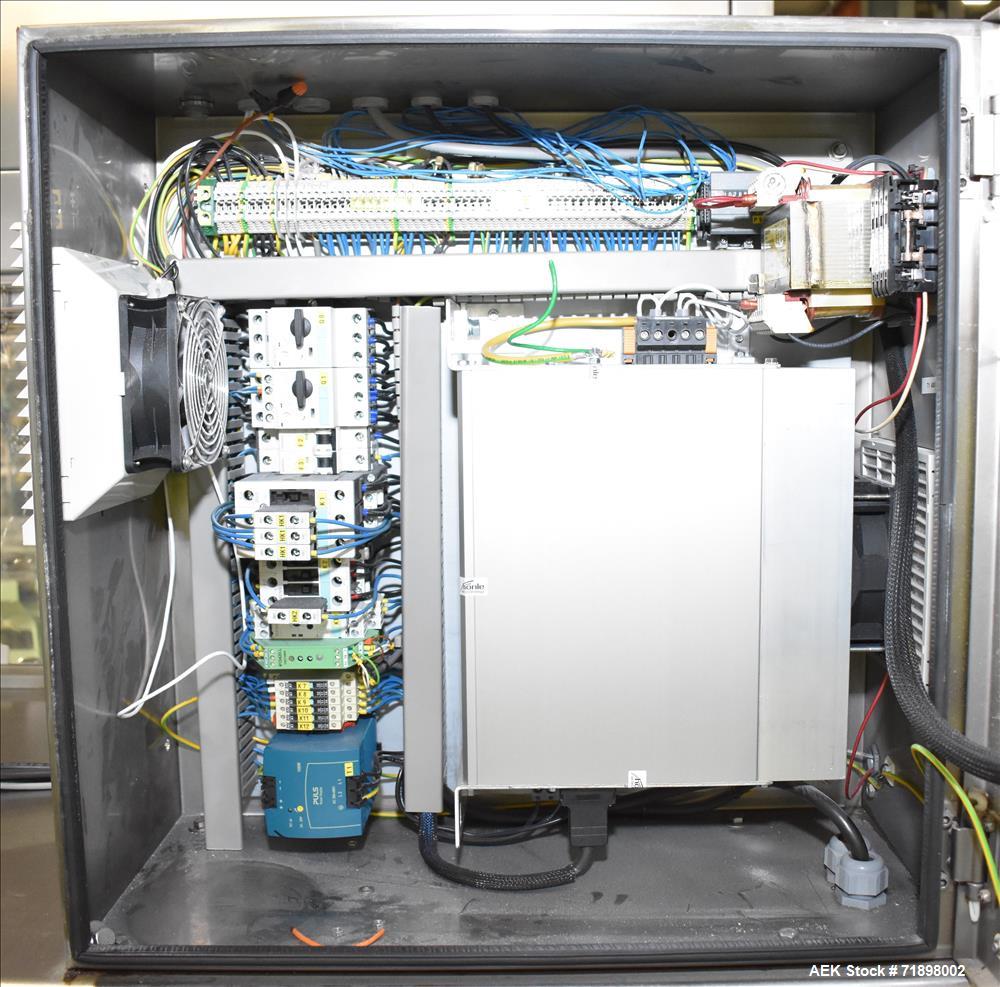

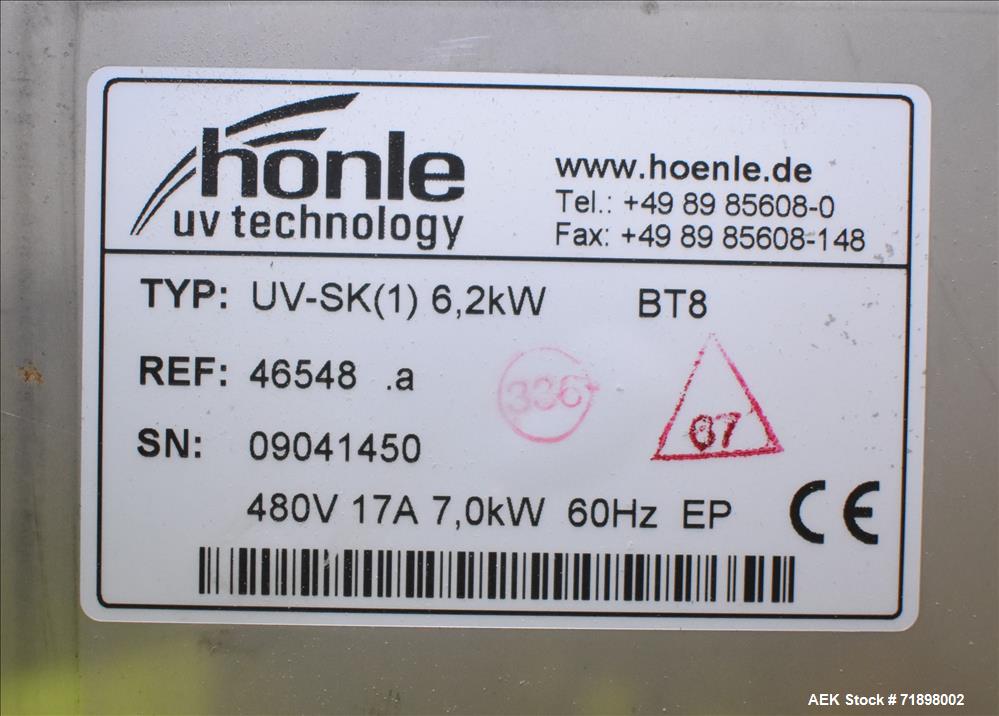

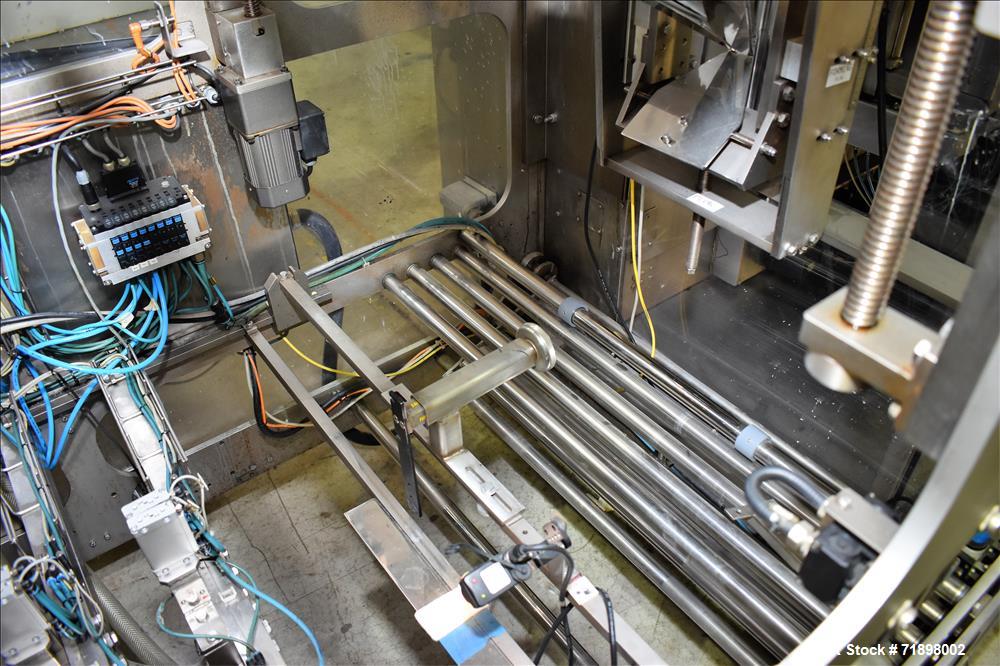

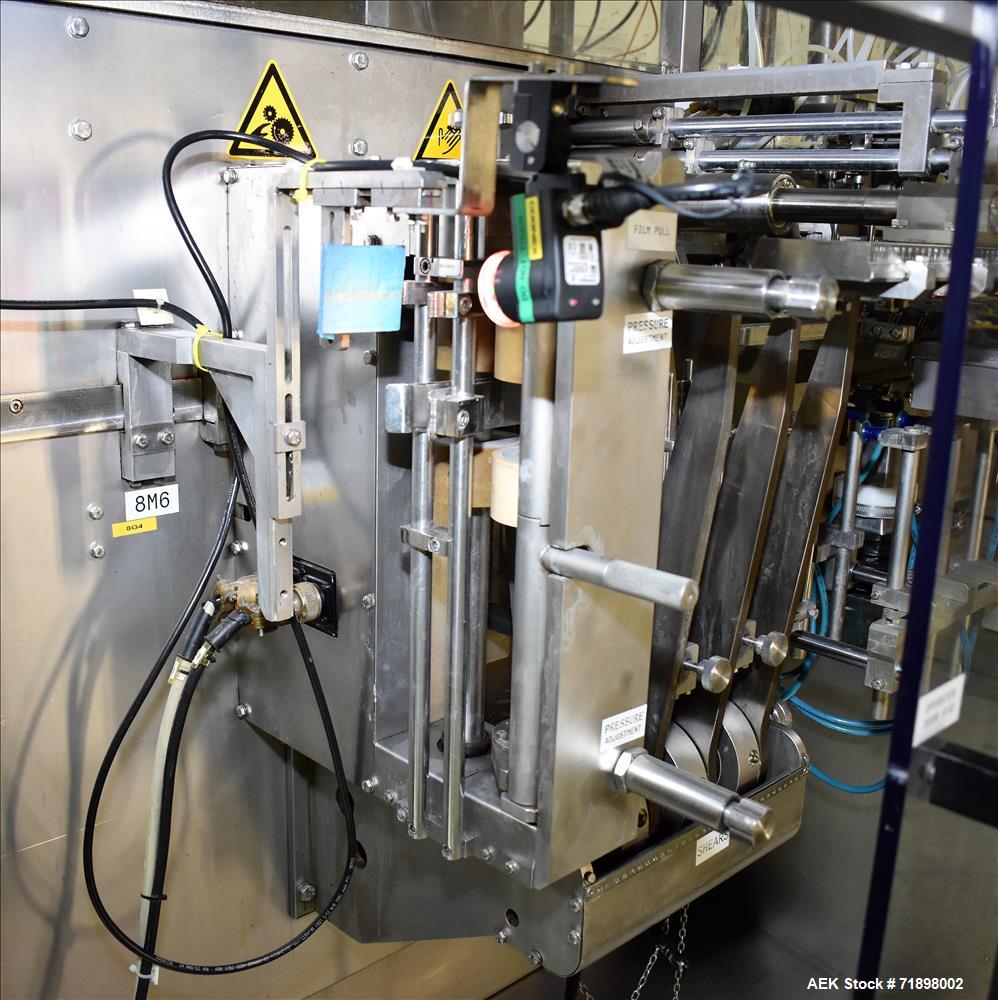

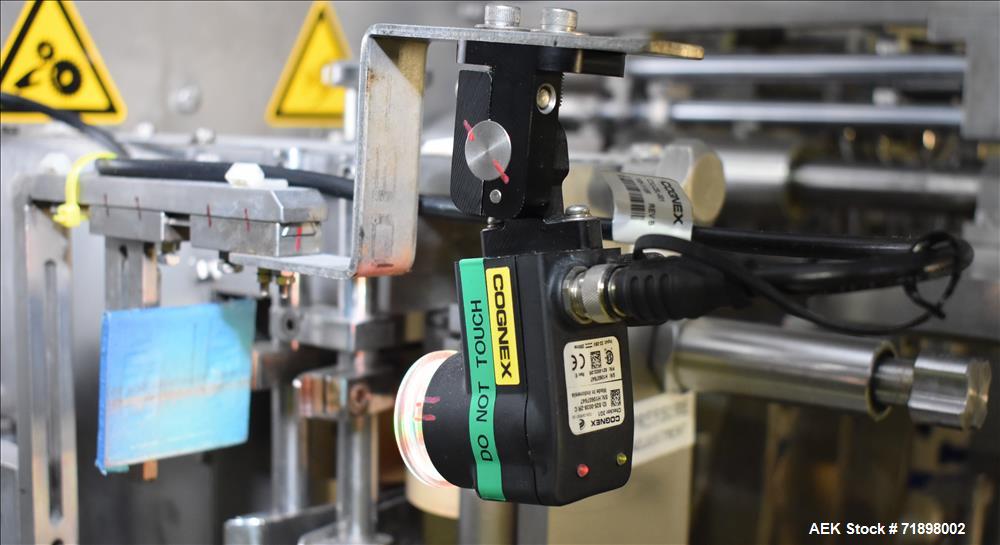

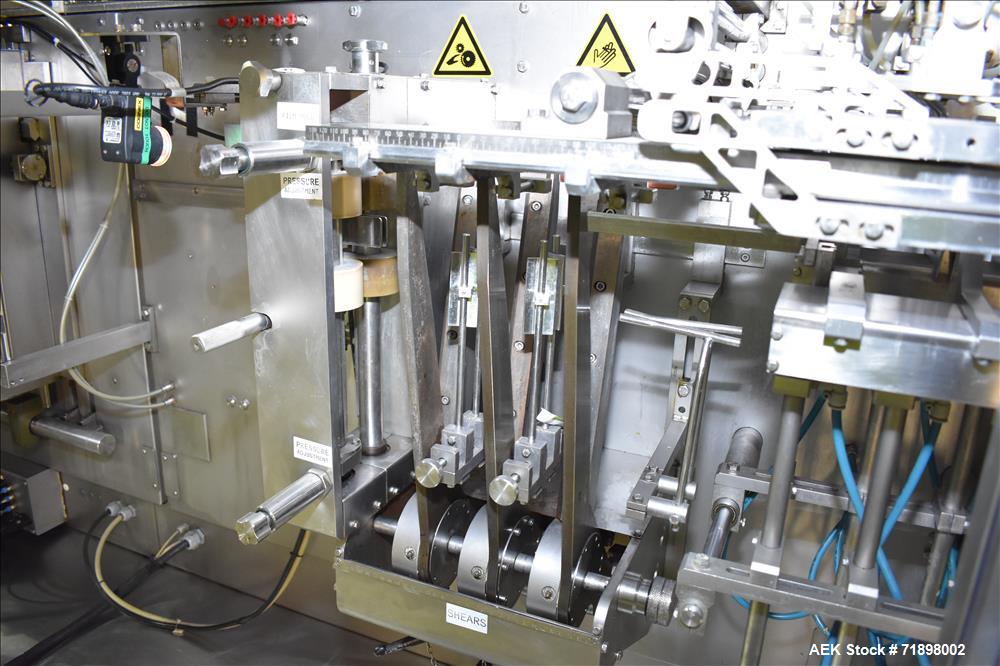

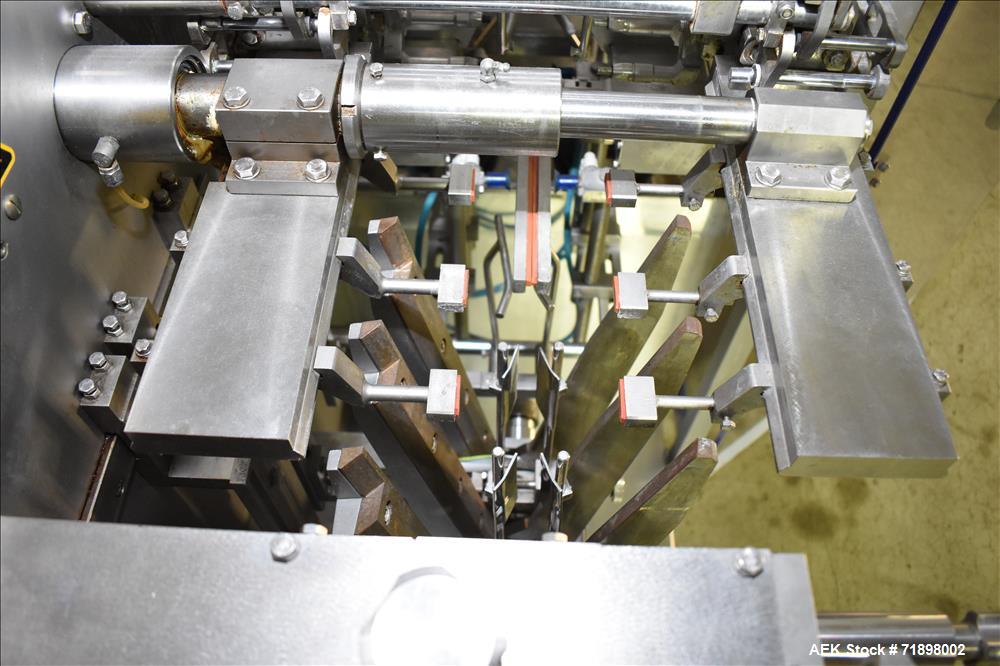

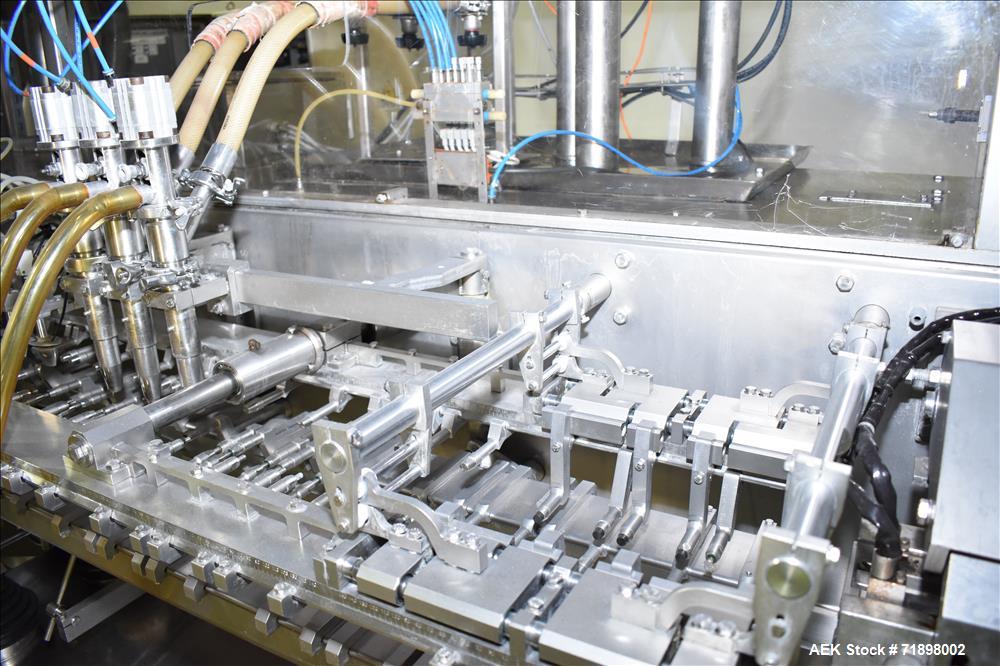

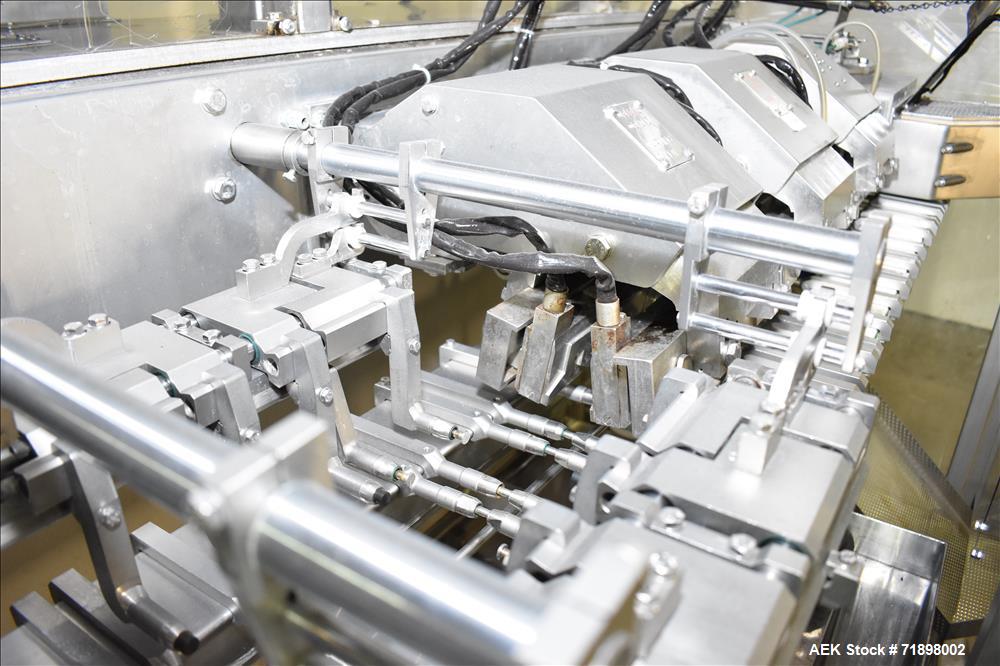

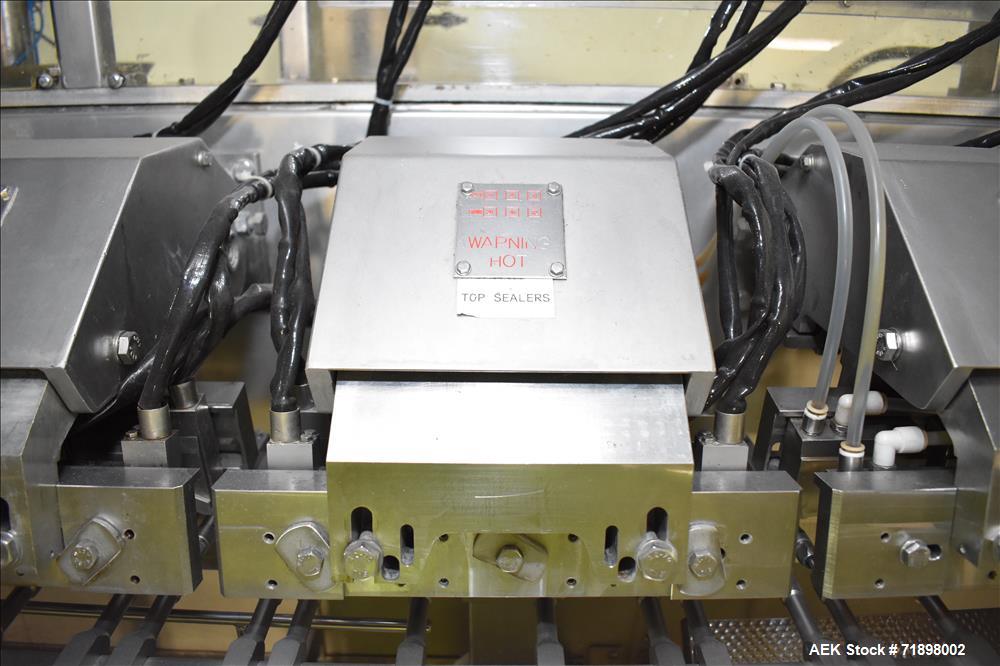

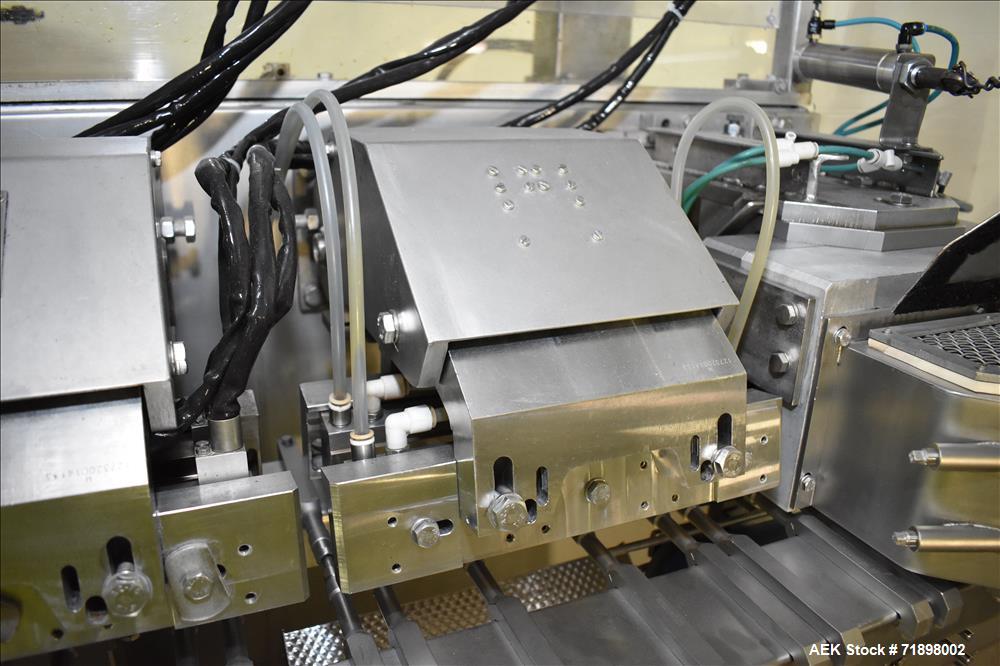

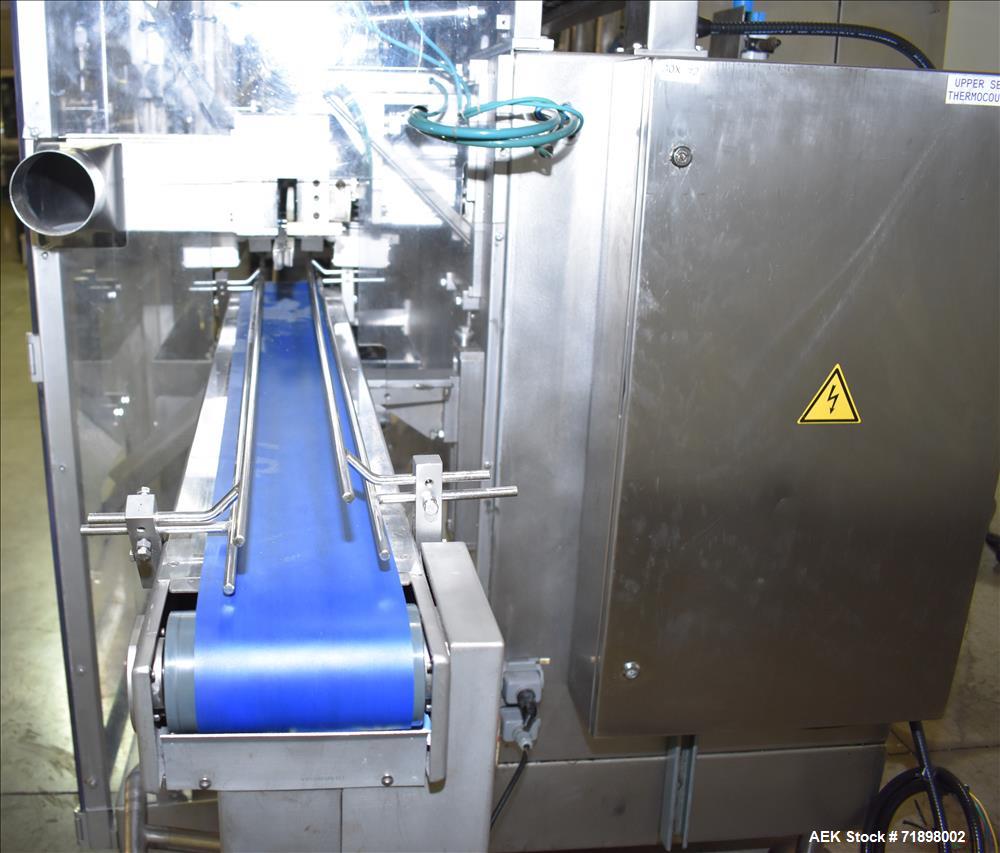

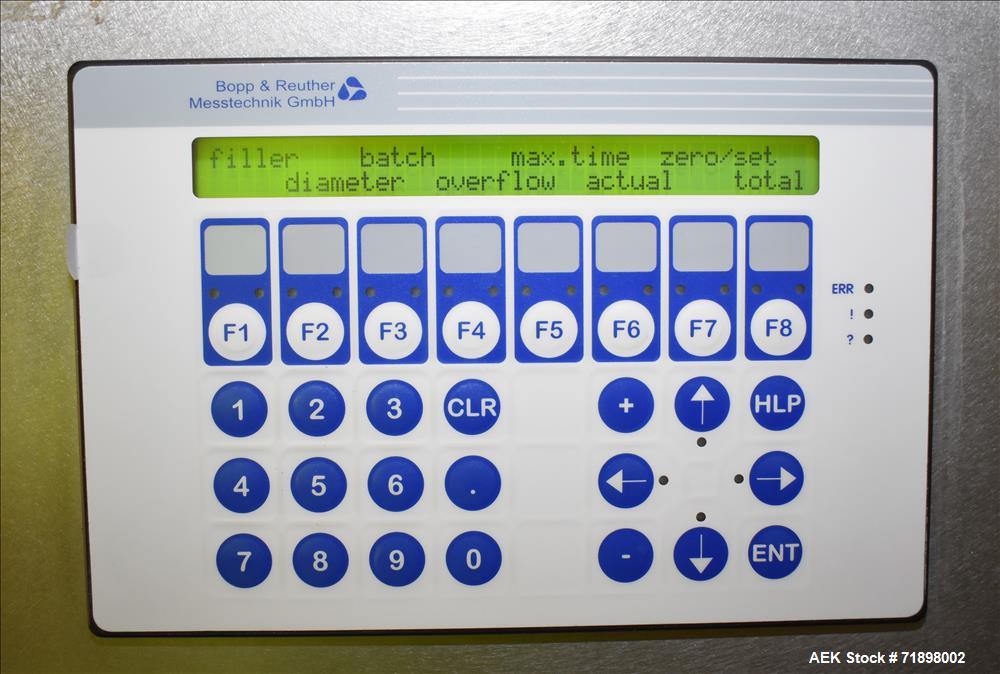

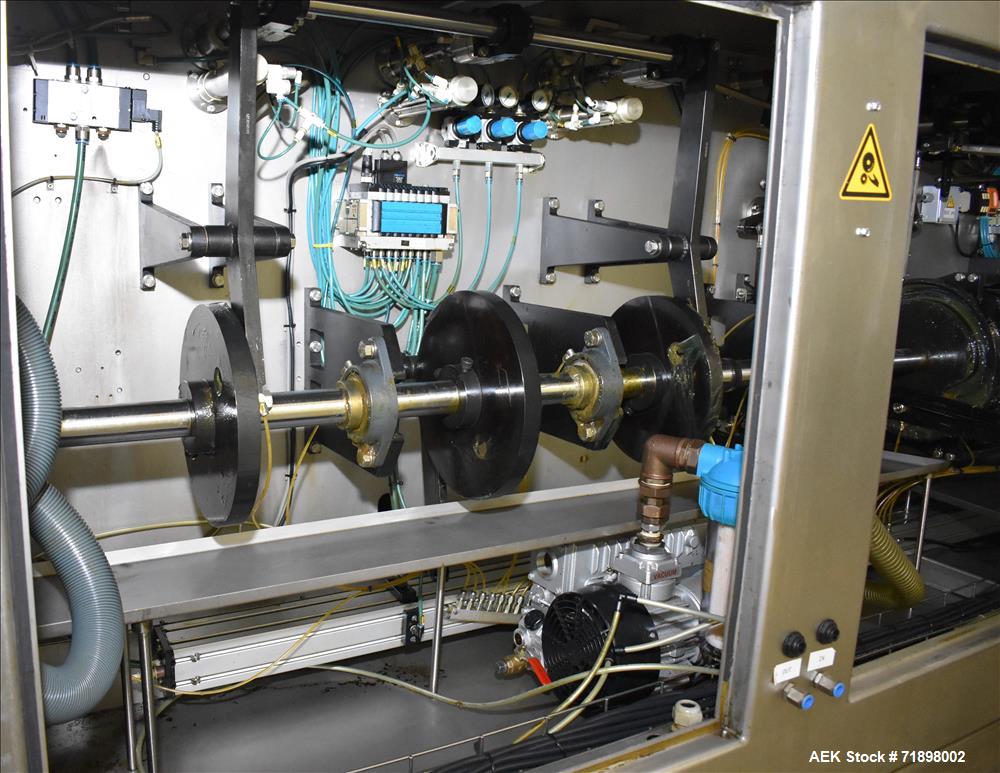

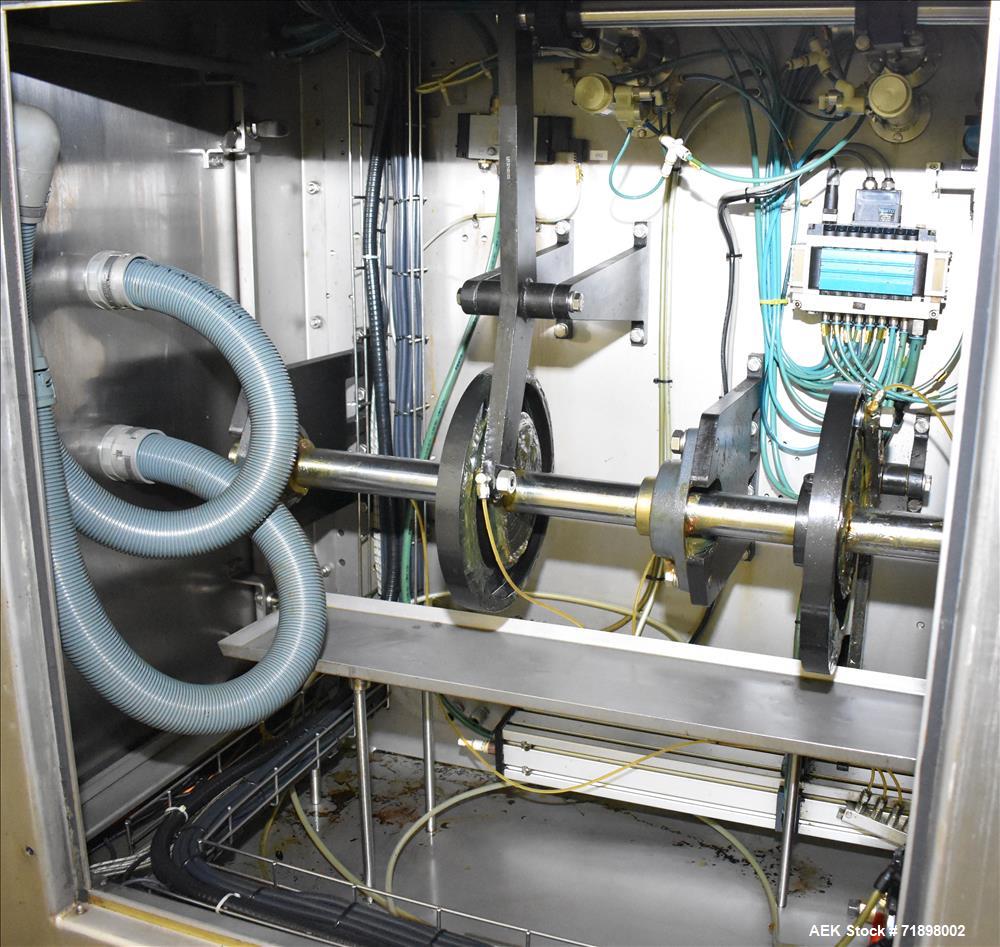

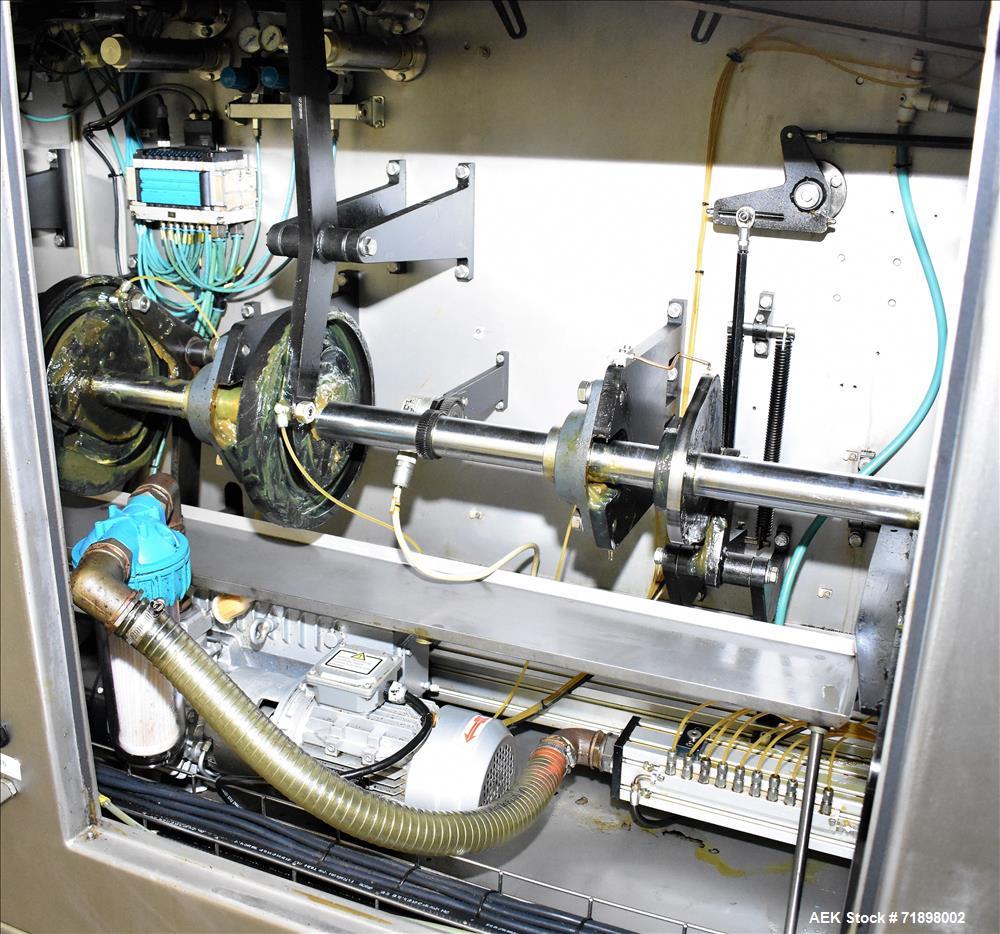

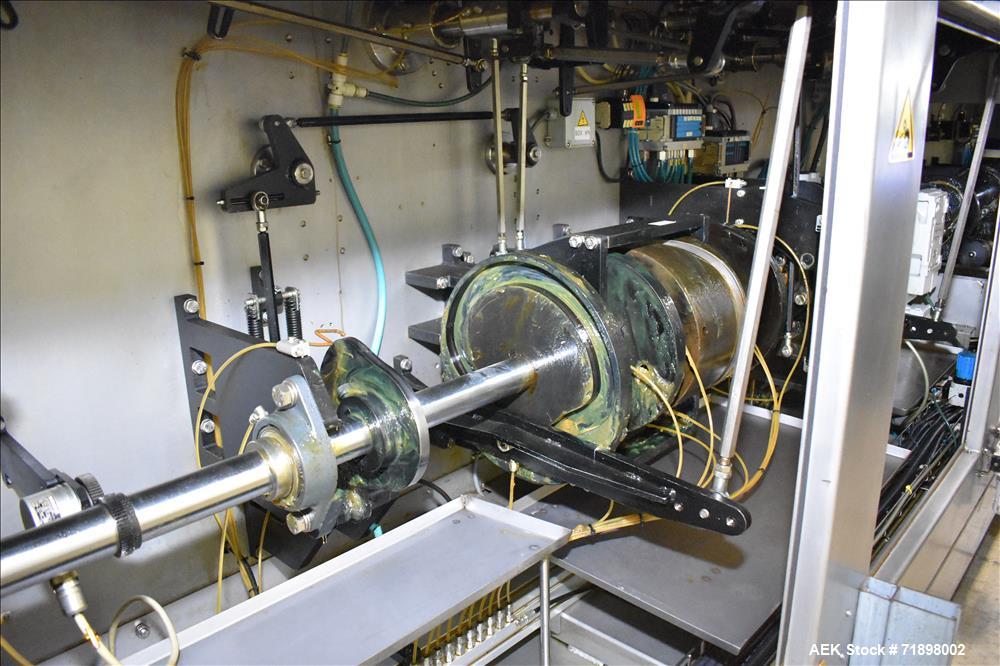

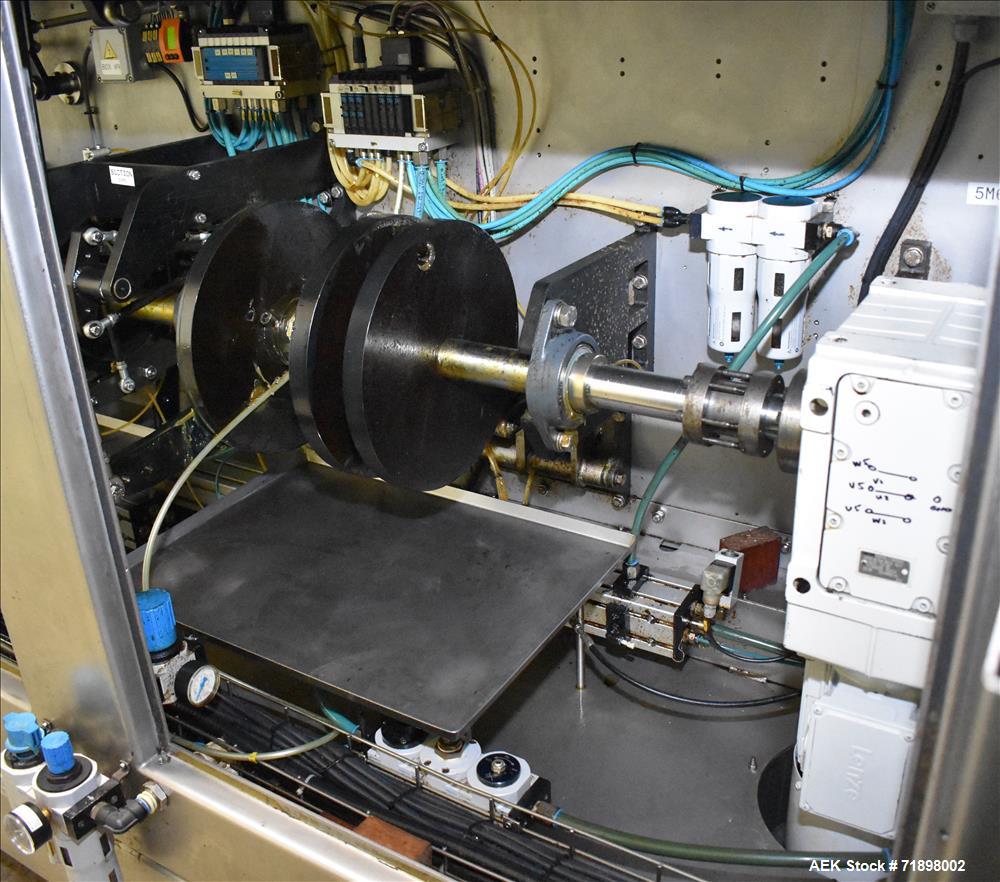

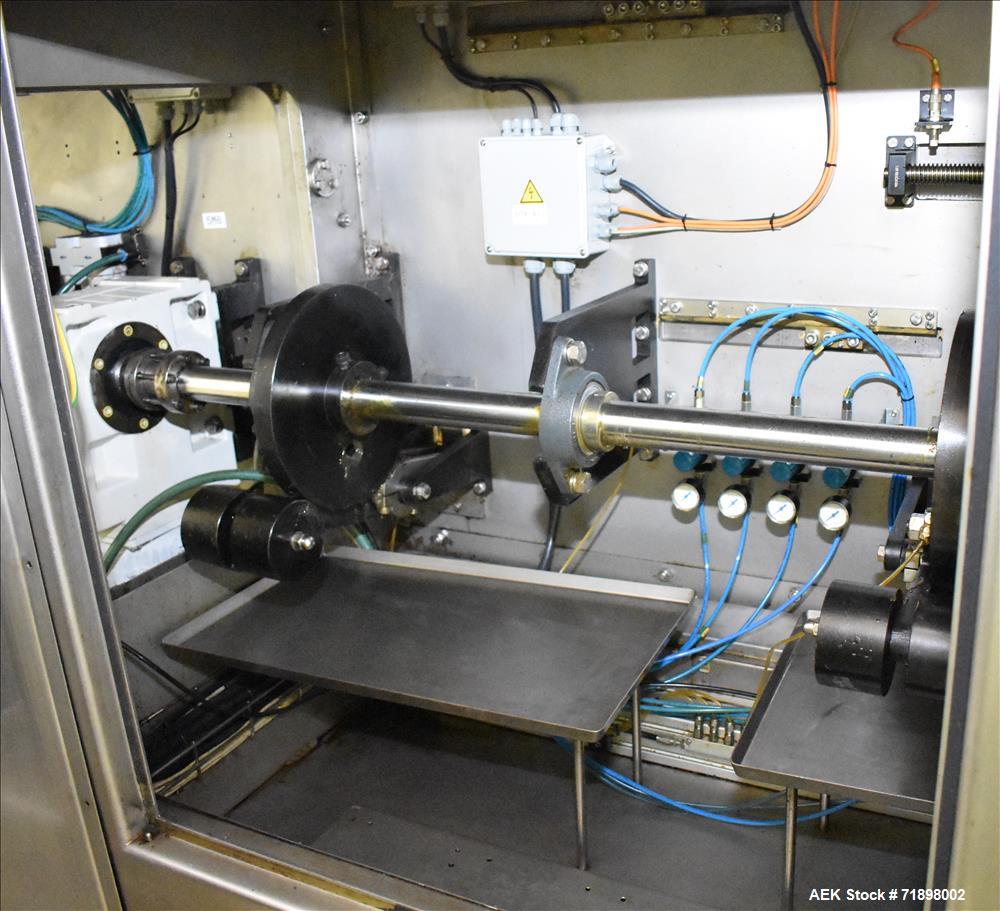

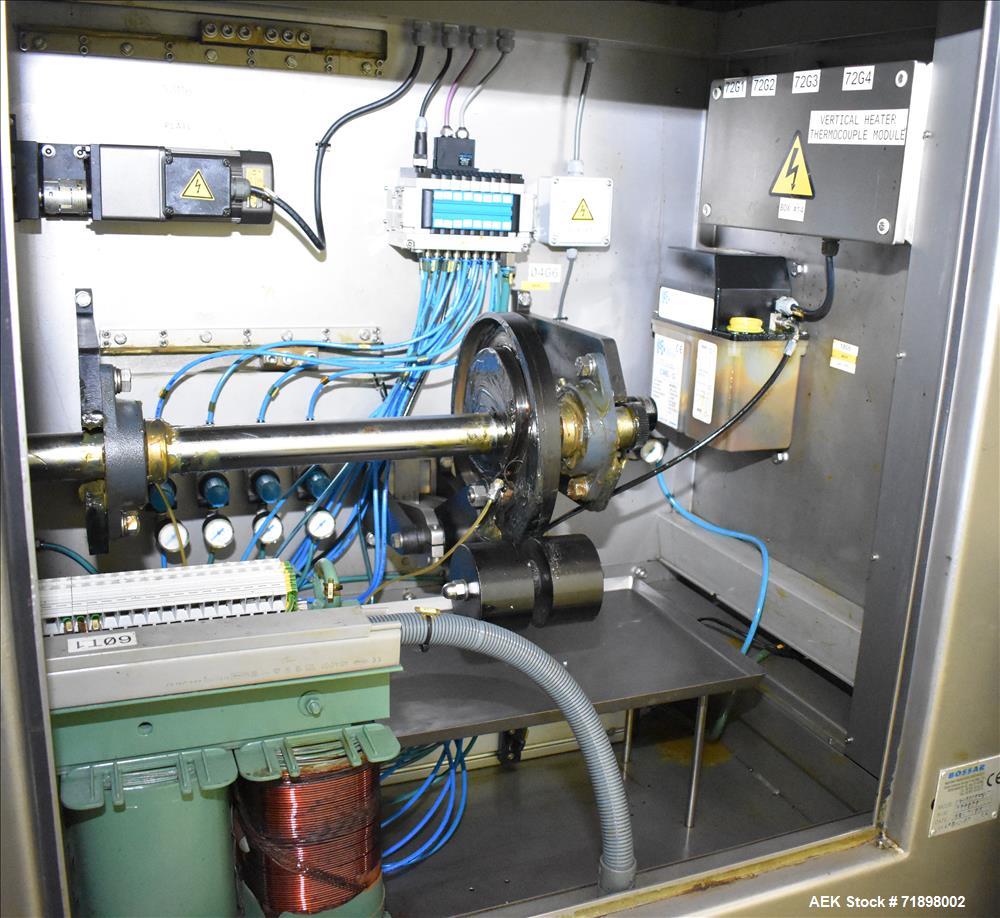

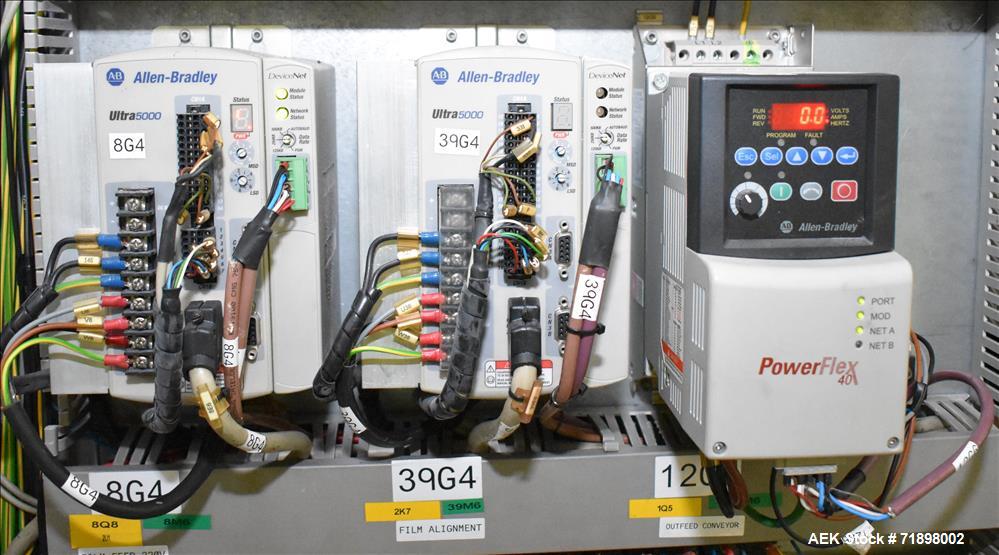

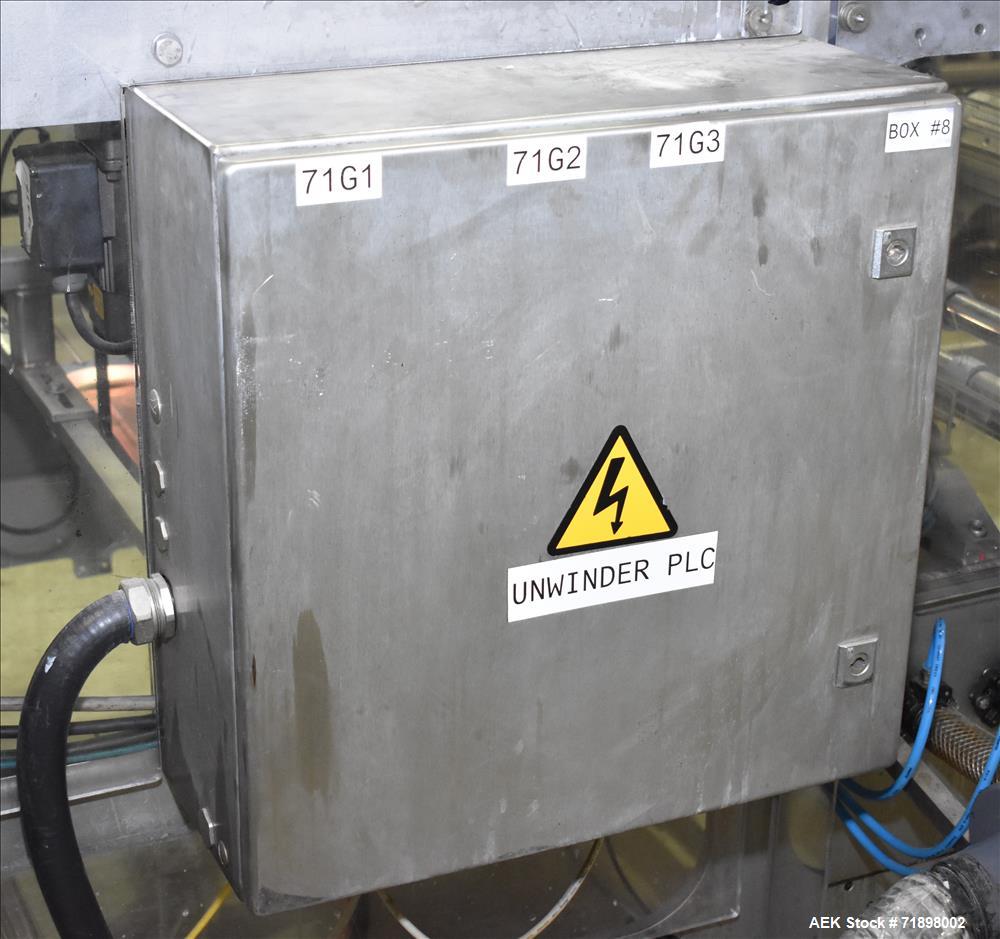

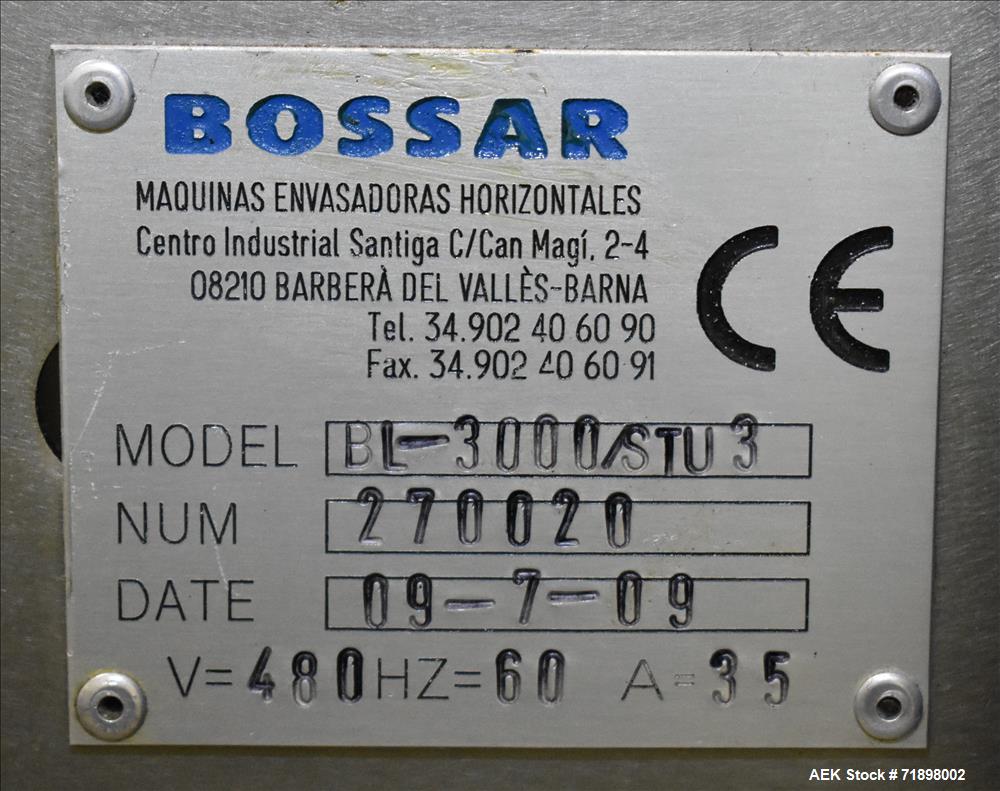

Used Bossar Model BL3000 STU3 Horizontal Form Fill Seal Machine for Liquid Stand Up Pouches with Time Pressure Liquid Filler. Capable of speeds up to 150 ppm. Set up currently for 140mm x 140mm x 42+42mm stu to maximum 230mm x 350mm flat pouch @ speeds of 80 to 100 ppm(per OEM). Has Allen Bradley PLC 5550 Compact Logix PLC and servos ultra 5000 in devicenet. Allen Bradley Panelview 1250 HMI. Form and Fill Horizontal Pouch, Model BL-3000/STU 3, Serial. Has all stainless steel contact parts, top datum line for quick size changes. Film Unwind: Maximum (diameter) 900mm x (width) 850mm. Photo eye registration, no pouch no fill system, film edge alignment, central lubrication system, three magnetic flow meters with heated and jacketed hopper temperature probe and agitation. Three filling nozzles, triplex punch die cut unit. Triplex embosse date coder. Last running a 3 oz (88.7ml) hot fill at 80 degree celcius in a stand up pouch with shape in top seal at 150 ppm. Pouch was 86mm w x 171mm x 47mm bottom gusset. 3/60/480v. LAST RAN ALOE VERA DRINK WITH PULP.

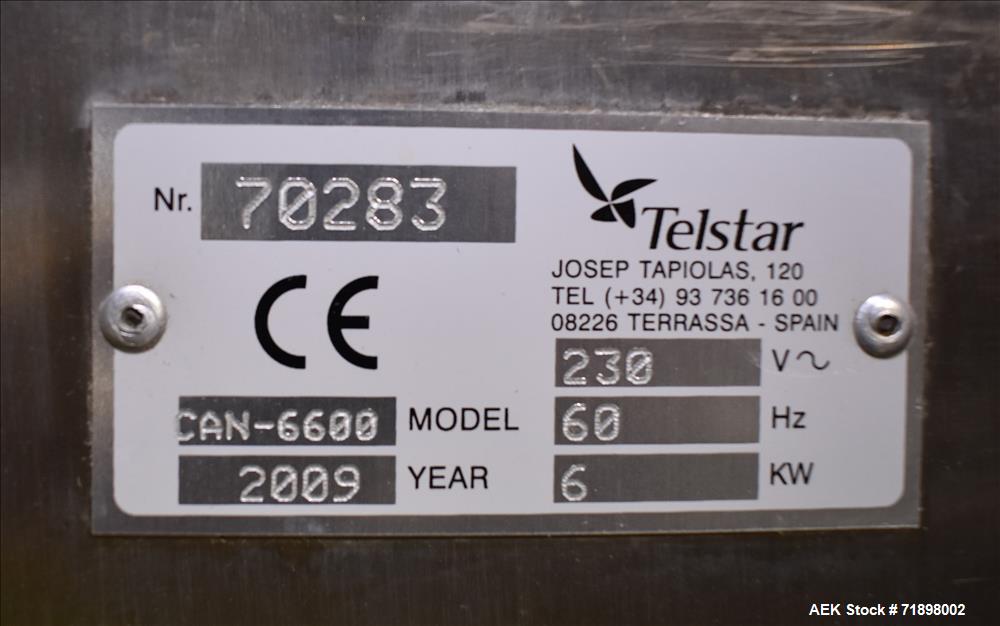

| Manufacturer | BossarBossar |

| Model | BL-3000/ST |

| Serial # | 270020 |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Form & Fill Horizontal - Horizontal PouchForm & Fill Horizontal - Horizontal Pouch |

| Make | Bossar |

| Model Number | BL-3000/ST |

| Serial # | 270020 |

| Speed Range CPM | up to 150 ppm |

| Fill Type | Liquid |

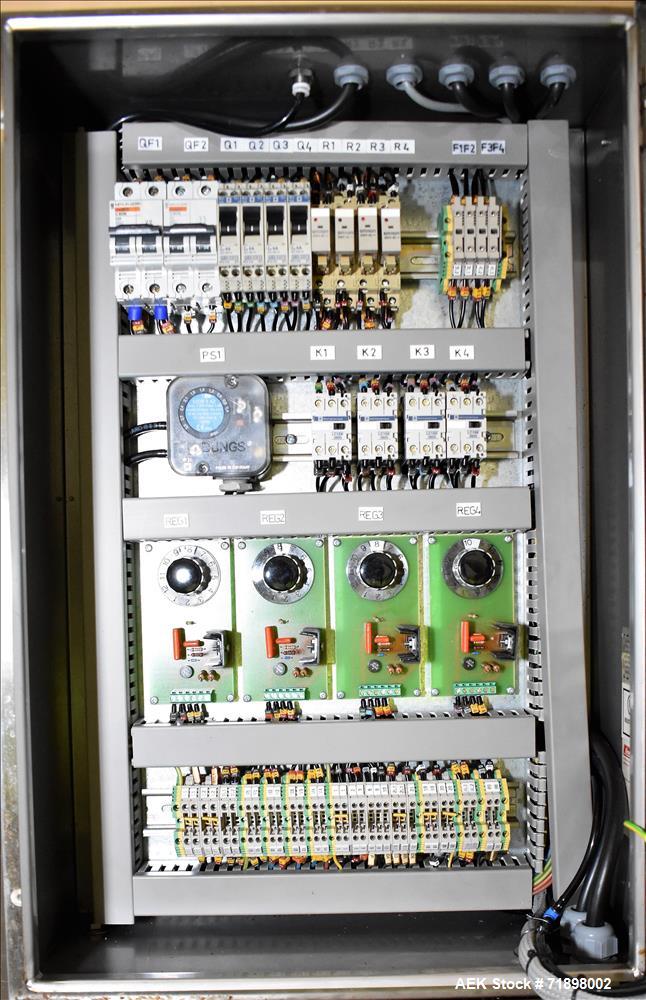

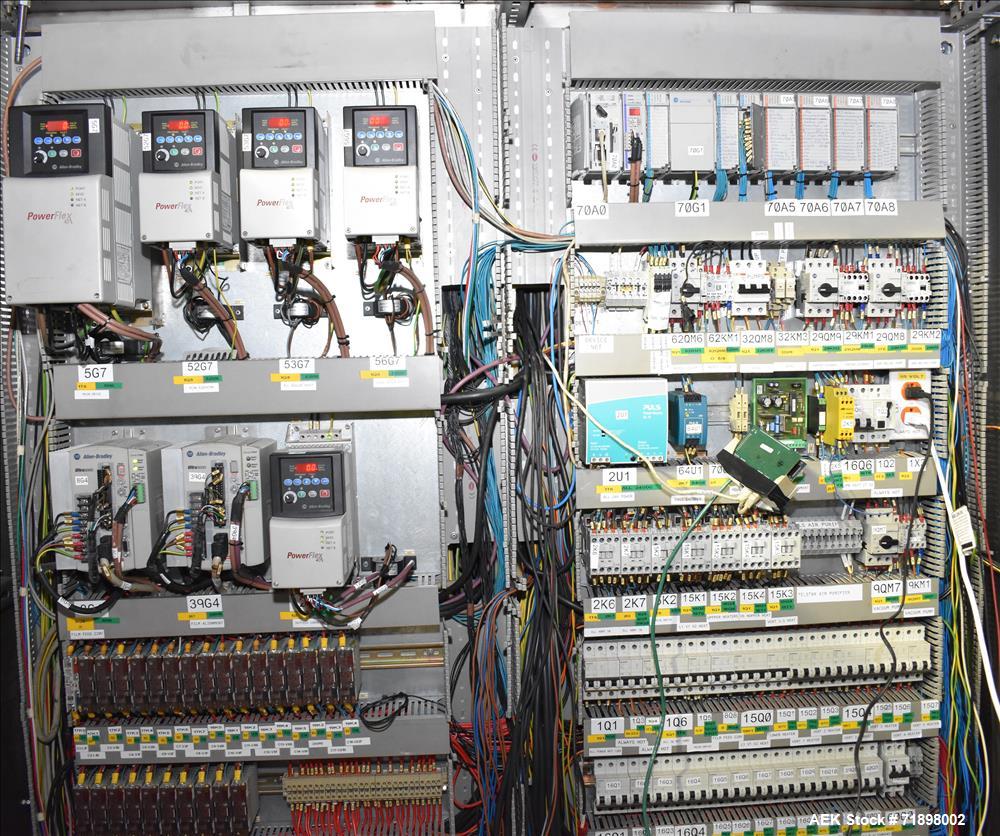

| Make and Model of PLC | Allen Bradley Compact Logix 5550 |

| Make and Model of HMI | Allen-Bradley Panelview 1250 |

| Make and Model of Servo | Allen-Bradley Ultra 5000 Devicenet |

| End Seal Jaw Lines | Vertical |

| Current Voltage | 480 volts |

| OAD (Height) | 112 |

| OAD (Length) | 396" OR 33' FEET |

| OAD (Width) | 171" WITH CONTROL CABINET. |

| Manual | Yes |

| Low Film Sensor | Yes |

| Hole Punch | Yes |

| Year Built | 2009 |

🏭 Manufacturer Info

-

Manufacturer: Bossar Packaging

-

Model: BL3000 / STU3

-

Serial Number: Available (not provided here)

-

Control System:

-

Allen Bradley CompactLogix PLC 5550

-

Allen Bradley Ultra 5000 Servos via DeviceNet

-

Allen Bradley PanelView 1250 HMI

-

-

Condition: Used, excellent working condition

-

Power Requirements: 3 Phase / 60 Hz / 480V

📝 Description

This Used Bossar Model BL3000 STU3 Horizontal Form Fill Seal Machine is a high-performance pouching solution specifically designed for liquid stand-up pouch packaging. Featuring a time-pressure liquid filler, the system supports up to 150 pouches per minute, with reliable Allen Bradley CompactLogix controls, Ultra 5000 servos, and a PanelView 1250 HMI. Built with stainless steel contact parts and engineered for fast changeovers via top datum line alignment, the machine includes three filling nozzles, triplex punch die cutter, triplex embosser/date coder, and photo eye registration.

The system includes three magnetic flow meters, a heated and jacketed hopper with temperature probe and agitation—ideal for hot fill applications. Most recently ran 3 oz aloe vera drink with pulp at 80°C, into an 86mm x 171mm pouch with a 47mm bottom gusset, achieving 150 ppm. Compatible with pouch sizes up to 230mm x 350mm flat.

⚙️ Specifications

-

Model: BL3000 / STU3

-

Type: Horizontal Form Fill Seal (HFFS)

-

Product Type: Liquids – hot fill compatible

-

Speed:

-

Up to 150 pouches per minute (standard)

-

OEM: 80–100 ppm for 230mm x 350mm pouches

-

-

Pouch Sizes:

-

Min: 140mm x 140mm x 42+42mm (STU)

-

Max: 230mm x 350mm (flat)

-

Last ran: 86mm x 171mm with 47mm bottom gusset (3 oz pouch)

-

-

Filling System:

-

Time-pressure liquid filler

-

Heated/jacketed hopper with temperature probe & agitation

-

Three magnetic flow meters

-

Three liquid filling nozzles

-

-

Controls & Automation:

-

Allen Bradley CompactLogix PLC 5550

-

Ultra 5000 servos via DeviceNet

-

PanelView 1250 HMI

-

-

Construction: All stainless steel contact parts

-

Changeover: Top datum line system for fast changeovers

-

Film Handling:

-

Max film diameter: 900mm

-

Max film width: 850mm

-

Film edge alignment, photo eye registration

-

“No pouch, no fill” logic

-

-

Other Features:

-

Triplex punch die cut unit

-

Triplex embosser/date coder

-

Central lubrication system

-

-

Previous Product: 3 oz Aloe Vera Drink with Pulp at 80°C

🧰 Applications

Perfect for:

-

RTD beverages (ready-to-drink drinks)

-

Functional or wellness drinks

-

Fruit juices and aloe vera drinks

-

Energy shots and sports hydration packs

-

Liquid supplements and nutraceuticals

-

Yogurt, kefir, or smoothie-style drinks

-

Baby food purees in pouch format

-

Soups, sauces, and dressings

-

Hot fill food and drink applications

-

Shaped stand-up pouches with die-cut profiles

📦 Commonly Used For (Bulleted)

-

Liquid stand-up pouch production

-

Time-pressure filling with heated hopper

-

Hot-fill beverage pouch packaging

-

Flow-meter controlled liquid dosing

-

Aloe vera and pulp-based drinks

-

RTD beverage pouch manufacturing

-

Triplex liquid nozzle pouching

-

Die-cut stand-up pouches

-

Servo-controlled pouch machine

-

Automated film registration & fill control

Aloe Vera, Body WashPouch Packaging, Conditioner Pouch Packaging, Dish SoapPouch Packaging, Hand Soap Packaging, Shampoo Pouch Packaging, Skin Care Products

- Bossar BL3000 Liquid Stand up pouch machine

- Bossar Model BL-3000 Horizontal Doy Pack Pouch Machine

- Bossar BL-3000 Drinkable Aloe Pouch Machine

- Horizontal Form Fill Seal Liquid Pouch Machine

- Liquid Stand Up Pouches

- Aloe Vera Drink with Pulp

- Food Industry

- Drinkable Stand Up Pouch Machine

-

Bossar BL3000

-

pouch filler

-

HFFS machine

-

stand-up pouch

-

liquid filler

-

hot fill pouch

-

time pressure filler

-

servo pouch machine

-

flow meter filler

-

PanelView HMI

-

Bossar STU3 horizontal pouch machine

-

hot fill pouch packaging machine

-

servo-driven pouch filling equipment

-

stand-up pouch form fill seal

-

aloe vera drink pouch filler

-

pouch machine with magnetic flow meters

-

stainless steel liquid pouch filler

-

used Bossar form fill machine

-

triplex die-cut pouch machine

-

PanelView controlled pouch system

-

used Bossar BL3000 STU3 horizontal pouch filling machine for liquids

-

stand-up pouch form fill and seal machine with time-pressure filling

-

hot fill pouch packaging equipment with jacketed hopper and agitation

-

servo-driven horizontal pouch machine with Allen Bradley control system

-

Bossar machine for aloe vera drink with pulp in shaped pouch

-

flow meter-controlled pouch filler for beverages and sauces

-

high-speed pouch filler with triple nozzle and triplex die cutter

-

stainless steel pouch filler for RTD drink and functional beverages

-

automated film handling with print registration and no-fill logic

-

used form fill seal machine for hot fill food and beverage packaging

-

liquid pouch machine

-

hot fill filler

-

Bossar pouch machine

-

used form fill seal

-

magnetic flow meter filler

-

stand-up pouch line

-

servo liquid filler

-

hot fill packaging system

-

aloe drink pouch machine

-

pouch die-cut unit

-

buy Bossar pouch machine

-

sell used liquid filler

-

hot fill pouch machine for sale

-

purchase FFS beverage line

-

used horizontal pouch filler

-

buy RTD drink filler

-

servo-controlled pouch filler

-

Bossar hot fill machine

-

sell used food pouch equipment

-

pouch filler with flow meters

Used Bossar Model BL3000 STU3 Horizontal Form Fill Seal Machine for Liquid Stand Up Pouches with Time Pressure Liquid Filler. Capable of speeds up to 150 ppm. Set up currently for 140mm x 140mm x 42+42mm stu to maximum 230mm x 350mm flat pouch @ speeds of 80 to 100 ppm(per OEM). Has Allen Bradley PLC 5550 Compact Logix PLC and servos ultra 5000 in devicenet. Allen Bradley Panelview 1250 HMI. Form and Fill Horizontal Pouch, Model BL-3000/STU 3, Serial. Has all stainless steel contact parts, top datum line for quick size changes. Film Unwind: Maximum (diameter) 900mm x (width) 850mm. Photo eye registration, no pouch no fill system, film edge alignment, central lubrication system, three magnetic flow meters with heated and jacketed hopper temperature probe and agitation. Three filling nozzles, triplex punch die cut unit. Triplex embosse date coder. Last running a 3 oz (88.7ml) hot fill at 80 degree celcius in a stand up pouch with shape in top seal at 150 ppm. Pouch was 86mm w x 171mm x 47mm bottom gusset. 3/60/480v. LAST RAN ALOE VERA DRINK WITH PULP.

🏭 Manufacturer Info

-

Manufacturer: Bossar Packaging

-

Model: BL3000 / STU3

-

Serial Number: Available (not provided here)

-

Control System:

-

Allen Bradley CompactLogix PLC 5550

-

Allen Bradley Ultra 5000 Servos via DeviceNet

-

Allen Bradley PanelView 1250 HMI

-

-

Condition: Used, excellent working condition

-

Power Requirements: 3 Phase / 60 Hz / 480V

📝 Description

This Used Bossar Model BL3000 STU3 Horizontal Form Fill Seal Machine is a high-performance pouching solution specifically designed for liquid stand-up pouch packaging. Featuring a time-pressure liquid filler, the system supports up to 150 pouches per minute, with reliable Allen Bradley CompactLogix controls, Ultra 5000 servos, and a PanelView 1250 HMI. Built with stainless steel contact parts and engineered for fast changeovers via top datum line alignment, the machine includes three filling nozzles, triplex punch die cutter, triplex embosser/date coder, and photo eye registration.

The system includes three magnetic flow meters, a heated and jacketed hopper with temperature probe and agitation—ideal for hot fill applications. Most recently ran 3 oz aloe vera drink with pulp at 80°C, into an 86mm x 171mm pouch with a 47mm bottom gusset, achieving 150 ppm. Compatible with pouch sizes up to 230mm x 350mm flat.

⚙️ Specifications

-

Model: BL3000 / STU3

-

Type: Horizontal Form Fill Seal (HFFS)

-

Product Type: Liquids – hot fill compatible

-

Speed:

-

Up to 150 pouches per minute (standard)

-

OEM: 80–100 ppm for 230mm x 350mm pouches

-

-

Pouch Sizes:

-

Min: 140mm x 140mm x 42+42mm (STU)

-

Max: 230mm x 350mm (flat)

-

Last ran: 86mm x 171mm with 47mm bottom gusset (3 oz pouch)

-

-

Filling System:

-

Time-pressure liquid filler

-

Heated/jacketed hopper with temperature probe & agitation

-

Three magnetic flow meters

-

Three liquid filling nozzles

-

-

Controls & Automation:

-

Allen Bradley CompactLogix PLC 5550

-

Ultra 5000 servos via DeviceNet

-

PanelView 1250 HMI

-

-

Construction: All stainless steel contact parts

-

Changeover: Top datum line system for fast changeovers

-

Film Handling:

-

Max film diameter: 900mm

-

Max film width: 850mm

-

Film edge alignment, photo eye registration

-

“No pouch, no fill” logic

-

-

Other Features:

-

Triplex punch die cut unit

-

Triplex embosser/date coder

-

Central lubrication system

-

-

Previous Product: 3 oz Aloe Vera Drink with Pulp at 80°C

🧰 Applications

Perfect for:

-

RTD beverages (ready-to-drink drinks)

-

Functional or wellness drinks

-

Fruit juices and aloe vera drinks

-

Energy shots and sports hydration packs

-

Liquid supplements and nutraceuticals

-

Yogurt, kefir, or smoothie-style drinks

-

Baby food purees in pouch format

-

Soups, sauces, and dressings

-

Hot fill food and drink applications

-

Shaped stand-up pouches with die-cut profiles

📦 Commonly Used For (Bulleted)

-

Liquid stand-up pouch production

-

Time-pressure filling with heated hopper

-

Hot-fill beverage pouch packaging

-

Flow-meter controlled liquid dosing

-

Aloe vera and pulp-based drinks

-

RTD beverage pouch manufacturing

-

Triplex liquid nozzle pouching

-

Die-cut stand-up pouches

-

Servo-controlled pouch machine

-

Automated film registration & fill control

Aloe Vera, Body WashPouch Packaging, Conditioner Pouch Packaging, Dish SoapPouch Packaging, Hand Soap Packaging, Shampoo Pouch Packaging, Skin Care Products

| Manufacturer | Bossar |

| Model | BL-3000/ST |

| Serial # | 270020 |

| Category | Packaging Equipment |

| Subcategory | Form & Fill Horizontal - Horizontal Pouch |

| Make | Bossar |

| Model Number | BL-3000/ST |

| Serial # | 270020 |

| Speed Range CPM | up to 150 ppm |

| Fill Type | Liquid |

| Make and Model of PLC | Allen Bradley Compact Logix 5550 |

| Make and Model of HMI | Allen-Bradley Panelview 1250 |

| Make and Model of Servo | Allen-Bradley Ultra 5000 Devicenet |

| End Seal Jaw Lines | Vertical |

| Current Voltage | 480 volts |

| OAD (Height) | 112 |

| OAD (Length) | 396" OR 33' FEET |

| OAD (Width) | 171" WITH CONTROL CABINET. |

| Manual | Yes |

| Low Film Sensor | Yes |

| Hole Punch | Yes |

| Year Built | 2009 |

- Bossar BL3000 Liquid Stand up pouch machine

- Bossar Model BL-3000 Horizontal Doy Pack Pouch Machine

- Bossar BL-3000 Drinkable Aloe Pouch Machine

- Horizontal Form Fill Seal Liquid Pouch Machine

- Liquid Stand Up Pouches

- Aloe Vera Drink with Pulp

- Food Industry

- Drinkable Stand Up Pouch Machine

-

Bossar BL3000

-

pouch filler

-

HFFS machine

-

stand-up pouch

-

liquid filler

-

hot fill pouch

-

time pressure filler

-

servo pouch machine

-

flow meter filler

-

PanelView HMI

-

Bossar STU3 horizontal pouch machine

-

hot fill pouch packaging machine

-

servo-driven pouch filling equipment

-

stand-up pouch form fill seal

-

aloe vera drink pouch filler

-

pouch machine with magnetic flow meters

-

stainless steel liquid pouch filler

-

used Bossar form fill machine

-

triplex die-cut pouch machine

-

PanelView controlled pouch system

-

used Bossar BL3000 STU3 horizontal pouch filling machine for liquids

-

stand-up pouch form fill and seal machine with time-pressure filling

-

hot fill pouch packaging equipment with jacketed hopper and agitation

-

servo-driven horizontal pouch machine with Allen Bradley control system

-

Bossar machine for aloe vera drink with pulp in shaped pouch

-

flow meter-controlled pouch filler for beverages and sauces

-

high-speed pouch filler with triple nozzle and triplex die cutter

-

stainless steel pouch filler for RTD drink and functional beverages

-

automated film handling with print registration and no-fill logic

-

used form fill seal machine for hot fill food and beverage packaging

-

liquid pouch machine

-

hot fill filler

-

Bossar pouch machine

-

used form fill seal

-

magnetic flow meter filler

-

stand-up pouch line

-

servo liquid filler

-

hot fill packaging system

-

aloe drink pouch machine

-

pouch die-cut unit

-

buy Bossar pouch machine

-

sell used liquid filler

-

hot fill pouch machine for sale

-

purchase FFS beverage line

-

used horizontal pouch filler

-

buy RTD drink filler

-

servo-controlled pouch filler

-

Bossar hot fill machine

-

sell used food pouch equipment

-

pouch filler with flow meters

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory

.jpg)

.jpg)

.jpg)