Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

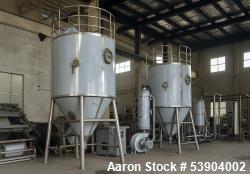

Unused Spray Drying Systems Model 48 Spray Dryer – 69 kg/hr Evaporation Rate

Unused- Spray Drying Systems Spray Dryer, Model 48. 5-69 kg/hour (approx. 11-152 lbs.) evaporation rate (dependent on temperature); 3-39 kg/hour (approx. 6.6-86 lbs.) product rate (dependent on temperature). 4' Diameter x 6' straight side vessel; 13'6" clearance height required; 304 stainless steel contact parts. (1) Pressure nozzle with lance, mounted in the co-current configuration. Factory insulated with seal welded 304 stainless steel cladding from air heater to bottom of dryer cone. Components include: Spray dryer; Gas-fired air heater; Feed pump; Cyclone; Chemical suppression system; Bag filter; System fan; Allen Bradley PLC and HMI. Mounted on 304 stainless steel legs. Approximate 8' x 12' overall footprint. Built 2023. It runs on 460V. For the explosion suppression system, there is an additional requirement of 120V.

The Spray Drying Systems (SDS) Model 48 Spray Dryer is an advanced, versatile spray dryer used in a variety of industries to efficiently convert liquids or slurries into dry powders. Spray drying is a key process for drying materials quickly while maintaining the quality and integrity of the product. The Model 48 is designed to handle small to medium-scale production, making it ideal for research, development, and pilot production applications.

Manufacturers Info:

- Manufacturer: Spray Drying Systems

- Model: 48

- Condition: Unused

- Year Built: 2023

- Construction: 304 Stainless Steel Contact Parts

- Mounting: 304 Stainless Steel Legs

Facts About the Spray Drying Systems Model 48 Spray Dryer:

- High-performance spray dryer designed for industrial-scale drying applications.

- Evaporation rate of 5-69 kg/hour (approx. 11-152 lbs.), dependent on temperature settings.

- Product output rate of 3-39 kg/hour (approx. 6.6-86 lbs.), based on material and temperature.

- 4-foot diameter x 6-foot straight-side vessel, requiring 13'6" clearance height.

- 304 stainless steel contact surfaces, ensuring sanitary and corrosion-resistant operation.

- Pressure nozzle with lance, mounted in a co-current spray drying configuration for efficient drying and particle formation.

- Factory-insulated with seal-welded 304 stainless steel cladding from air heater to bottom of dryer cone, preventing heat loss and enhancing efficiency.

- Gas-fired air heater provides precise temperature control for optimized drying conditions.

- Explosion suppression system for enhanced safety and compliance with industrial regulations.

- Operates on 460V, with an additional 120V requirement for explosion suppression system.

- Mounted on 304 stainless steel legs, offering durability and stability.

Components Included:

- Spray Dryer

- Gas-Fired Air Heater

- Feed Pump

- Cyclone Separator

- Chemical Suppression System

- Bag Filter

- System Fan

- Allen Bradley PLC & HMI for automated control and monitoring

Description:

This unused Spray Drying Systems Model 48 Spray Dryer is a high-capacity, industrial-grade drying system designed for food, pharmaceutical, chemical, and industrial applications. With an evaporation rate of up to 69 kg/hour (152 lbs.), this unit efficiently converts liquid feed into free-flowing powders using a co-current spray drying system.

Built with 304 stainless steel contact parts, this spray dryer is hygienic, corrosion-resistant, and durable. The pressure nozzle with lance enables fine particle atomization, while the gas-fired air heater ensures precise drying conditions.

Equipped with a cyclone separator, bag filter, and explosion suppression system, the system is engineered for safe, efficient operation. The Allen Bradley PLC & HMI provide automated process control, making it ideal for continuous production environments.

Mounted on 304 stainless steel legs, this unit has an overall footprint of approximately 8' x 12' and requires a clearance height of 13'6" for installation.

Specifications:

- Evaporation Rate: 5-69 kg/hour (11-152 lbs.), temperature-dependent

- Product Output Rate: 3-39 kg/hour (6.6-86 lbs.), temperature-dependent

- Chamber Dimensions: 4' Diameter x 6' Straight Side Vessel

- Clearance Height Requirement: 13'6"

- Construction: 304 Stainless Steel Contact Parts

- Spray System: Pressure Nozzle with Lance (Co-Current Configuration)

- Insulation: Seal-Welded 304 Stainless Steel Cladding

- Power Requirements:

- 460V Operation

- 120V for Explosion Suppression System

- Includes:

- Gas-Fired Air Heater

- Feed Pump

- Cyclone Separator

- Chemical Suppression System

- Bag Filter

- System Fan

- Allen Bradley PLC & HMI

- Mounting: 304 Stainless Steel Legs

- Overall Footprint: Approximately 8' x 12'

- Year Built: 2023

Applications:

- Food & Beverage Powder Production

- Pharmaceutical & Nutraceutical Spray Drying

- Chemical & Polymer Powder Processing

- Biotechnology & Bio-Extract Drying

- Dairy & Protein Powder Manufacturing

What Products Would This Be Used For?

- Instant Coffee & Tea Powder

- Dairy Products (Milk, Whey, Protein Powders)

- Flavor & Fragrance Encapsulation

- Pharmaceutical Drug & Herbal Extract Drying

- Specialty Chemicals & Nutraceutical Powders

Key Features of the Spray Drying Systems Model 48:

-

Compact and Efficient Design:

- The Model 48 is compact, making it suitable for laboratory and pilot-scale applications where space is limited.

- Despite its compact size, it is designed to handle significant volumes, offering a balance between capacity and footprint.

-

Advanced Atomization:

- The system is equipped with high-performance atomizers, such as rotary atomizers or pressure nozzles, which break up the liquid feed into fine droplets.

- These fine droplets maximize surface area, improving the evaporation rate and resulting in uniform drying.

-

High Temperature and Control:

- The Model 48 provides precise temperature control, which is crucial for optimizing the drying process and avoiding degradation of temperature-sensitive products.

- The air temperature can be adjusted based on the material being processed, typically in the range of 150–250°C, but can vary depending on the requirements of the application.

-

Particle Size Control:

- One of the main advantages of the SDS Model 48 is its ability to control the particle size and distribution of the final powder.

- The particle size is influenced by parameters such as the atomization pressure, feed rate, and air flow, allowing for customization based on product requirements.

-

Efficient Drying:

- The system utilizes hot air to rapidly evaporate moisture from the liquid feed. This quick evaporation produces dry particles almost instantly.

- The drying process is optimized to reduce the amount of heat sensitive materials exposed to high temperatures, helping maintain the quality of the end product.

-

Versatile Applications:

- The SDS Model 48 Spray Dryer can be used in a wide range of industries, including:

- Pharmaceuticals: Drying active pharmaceutical ingredients (APIs), excipients, and other drug formulations.

- Food and Beverages: Drying ingredients like milk, juices, flavorings, and coffee to produce powdered versions.

- Chemicals and Polymers: For drying various chemical formulations, resins, and polymer products.

- Biotechnology: For drying biological materials such as enzymes, microbial cultures, and vaccines.

- The SDS Model 48 Spray Dryer can be used in a wide range of industries, including:

-

Automated Control System:

- The system is often equipped with an automated control system that allows operators to adjust and monitor critical parameters, such as air temperature, feed rate, and airflow.

- This ensures consistency and precision during production.

-

Product Recovery System:

- The Model 48 typically includes efficient collection systems, such as cyclones or baghouses, to capture the dried powders.

- These recovery systems minimize material loss and help ensure that the drying process remains economically viable.

-

Energy Efficiency:

- The system is designed to be energy-efficient, reducing energy consumption while maintaining effective drying rates.

- Efficient heat recovery options can help minimize operational costs, especially in large-scale production environments.

-

Customizable Features:

- Depending on the application, additional options may be available, such as spray nozzles for different feed types (liquids, slurries, or pastes), different cyclone designs for powder collection, and more.

Benefits:

- Rapid Drying: The spray drying process ensures fast drying times, which is essential for products that need to be processed quickly while retaining their properties.

- High-Quality Powders: The Model 48 produces powders with uniform particle sizes, making it ideal for applications where consistency is key, such as in pharmaceuticals or food products.

- Scalability: While ideal for pilot or small-scale production, the Model 48 is designed with scalability in mind, enabling transition to larger systems if needed.

Applications:

- Pharmaceuticals: Drying of active pharmaceutical ingredients (APIs), excipients, and formulated products. It ensures that products maintain their bioactivity and quality.

- Food Industry: Producing powdered ingredients like milk, instant coffee, and flavors. Spray drying is a common method for creating instant products.

- Chemicals: Spray drying can be used to produce powdered chemicals, detergents, or pigments.

- Cosmetics: For drying materials like fragrances, essential oils, or emulsions into a powder form.

Conclusion:

The Spray Drying Systems Model 48 Spray Dryer is a highly efficient, versatile, and compact solution for producing dry powders from liquids. It is ideal for small to medium-scale operations in a range of industries, including pharmaceuticals, food, chemicals, and more. The ability to control particle size, adjust drying conditions, and ensure consistent quality makes it a valuable tool for both research and production environments.

Ceramic Powders, Ceramics, Chemical Industries, Chemical Powders, Chemical Products, Chemicals, Coffee, Coffee Powder, Coffee, Tea, Dairy Industry, Dairy Powder, Dairy Products, Dry Mixtures, Drying, Flavorings & Spices, Flavors and spices, Food and Beverage, Food Industry, Food Manufacturing, Food Powder, Food Processing, Food Production, Food Products, Organic Chemicals, Pesticides, Powder Production, Powders, Solvent, Solvents, Spice, Spices, Spray Dryer, Tea, Teas

- Spray Drying System

- Spray Dryer Equipment

- Spray Drying Technology

- Powder Production

- Industrial Spray Drying

- Pharmaceutical Spray Dryer

- Food Industry Drying

- Spray Drying for Chemicals

- Industrial Spray Dryer

- High-Capacity Spray Drying System

- Food Powder Processing Dryer

- Used Spray Drying Equipment

- Stainless Steel Spray Dryer

- Unused Spray Drying Systems Model 48 for Sale

- Industrial-Scale Spray Dryer with PLC Control

- High-Efficiency Food & Chemical Powder Spray Dryer

- 69 kg/hr Evaporation Rate Spray Dryer with Explosion Suppression

- Gas-Fired Spray Dryer for Powder Processing

- Unused Spray Drying Systems Model 48 Spray Dryer – 69 kg/hr Evaporation, 304 Stainless Steel

- Large-Scale Food & Pharmaceutical Spray Dryer with Allen Bradley PLC & HMI

- Industrial Spray Drying Equipment with Gas-Fired Heater & Chemical Suppression System

- High-Performance Powder Drying System with 460V Operation & Cyclone Separator

- Energy-Efficient Co-Current Spray Dryer for Dairy, Nutraceutical, & Chemical Processing

Unused- Spray Drying Systems Spray Dryer, Model 48. 5-69 kg/hour (approx. 11-152 lbs.) evaporation rate (dependent on temperature); 3-39 kg/hour (approx. 6.6-86 lbs.) product rate (dependent on temperature). 4' Diameter x 6' straight side vessel; 13'6" clearance height required; 304 stainless steel contact parts. (1) Pressure nozzle with lance, mounted in the co-current configuration. Factory insulated with seal welded 304 stainless steel cladding from air heater to bottom of dryer cone. Components include: Spray dryer; Gas-fired air heater; Feed pump; Cyclone; Chemical suppression system; Bag filter; System fan; Allen Bradley PLC and HMI. Mounted on 304 stainless steel legs. Approximate 8' x 12' overall footprint. Built 2023. It runs on 460V. For the explosion suppression system, there is an additional requirement of 120V.

The Spray Drying Systems (SDS) Model 48 Spray Dryer is an advanced, versatile spray dryer used in a variety of industries to efficiently convert liquids or slurries into dry powders. Spray drying is a key process for drying materials quickly while maintaining the quality and integrity of the product. The Model 48 is designed to handle small to medium-scale production, making it ideal for research, development, and pilot production applications.

Manufacturers Info:

- Manufacturer: Spray Drying Systems

- Model: 48

- Condition: Unused

- Year Built: 2023

- Construction: 304 Stainless Steel Contact Parts

- Mounting: 304 Stainless Steel Legs

Facts About the Spray Drying Systems Model 48 Spray Dryer:

- High-performance spray dryer designed for industrial-scale drying applications.

- Evaporation rate of 5-69 kg/hour (approx. 11-152 lbs.), dependent on temperature settings.

- Product output rate of 3-39 kg/hour (approx. 6.6-86 lbs.), based on material and temperature.

- 4-foot diameter x 6-foot straight-side vessel, requiring 13'6" clearance height.

- 304 stainless steel contact surfaces, ensuring sanitary and corrosion-resistant operation.

- Pressure nozzle with lance, mounted in a co-current spray drying configuration for efficient drying and particle formation.

- Factory-insulated with seal-welded 304 stainless steel cladding from air heater to bottom of dryer cone, preventing heat loss and enhancing efficiency.

- Gas-fired air heater provides precise temperature control for optimized drying conditions.

- Explosion suppression system for enhanced safety and compliance with industrial regulations.

- Operates on 460V, with an additional 120V requirement for explosion suppression system.

- Mounted on 304 stainless steel legs, offering durability and stability.

Components Included:

- Spray Dryer

- Gas-Fired Air Heater

- Feed Pump

- Cyclone Separator

- Chemical Suppression System

- Bag Filter

- System Fan

- Allen Bradley PLC & HMI for automated control and monitoring

Description:

This unused Spray Drying Systems Model 48 Spray Dryer is a high-capacity, industrial-grade drying system designed for food, pharmaceutical, chemical, and industrial applications. With an evaporation rate of up to 69 kg/hour (152 lbs.), this unit efficiently converts liquid feed into free-flowing powders using a co-current spray drying system.

Built with 304 stainless steel contact parts, this spray dryer is hygienic, corrosion-resistant, and durable. The pressure nozzle with lance enables fine particle atomization, while the gas-fired air heater ensures precise drying conditions.

Equipped with a cyclone separator, bag filter, and explosion suppression system, the system is engineered for safe, efficient operation. The Allen Bradley PLC & HMI provide automated process control, making it ideal for continuous production environments.

Mounted on 304 stainless steel legs, this unit has an overall footprint of approximately 8' x 12' and requires a clearance height of 13'6" for installation.

Specifications:

- Evaporation Rate: 5-69 kg/hour (11-152 lbs.), temperature-dependent

- Product Output Rate: 3-39 kg/hour (6.6-86 lbs.), temperature-dependent

- Chamber Dimensions: 4' Diameter x 6' Straight Side Vessel

- Clearance Height Requirement: 13'6"

- Construction: 304 Stainless Steel Contact Parts

- Spray System: Pressure Nozzle with Lance (Co-Current Configuration)

- Insulation: Seal-Welded 304 Stainless Steel Cladding

- Power Requirements:

- 460V Operation

- 120V for Explosion Suppression System

- Includes:

- Gas-Fired Air Heater

- Feed Pump

- Cyclone Separator

- Chemical Suppression System

- Bag Filter

- System Fan

- Allen Bradley PLC & HMI

- Mounting: 304 Stainless Steel Legs

- Overall Footprint: Approximately 8' x 12'

- Year Built: 2023

Applications:

- Food & Beverage Powder Production

- Pharmaceutical & Nutraceutical Spray Drying

- Chemical & Polymer Powder Processing

- Biotechnology & Bio-Extract Drying

- Dairy & Protein Powder Manufacturing

What Products Would This Be Used For?

- Instant Coffee & Tea Powder

- Dairy Products (Milk, Whey, Protein Powders)

- Flavor & Fragrance Encapsulation

- Pharmaceutical Drug & Herbal Extract Drying

- Specialty Chemicals & Nutraceutical Powders

Key Features of the Spray Drying Systems Model 48:

-

Compact and Efficient Design:

- The Model 48 is compact, making it suitable for laboratory and pilot-scale applications where space is limited.

- Despite its compact size, it is designed to handle significant volumes, offering a balance between capacity and footprint.

-

Advanced Atomization:

- The system is equipped with high-performance atomizers, such as rotary atomizers or pressure nozzles, which break up the liquid feed into fine droplets.

- These fine droplets maximize surface area, improving the evaporation rate and resulting in uniform drying.

-

High Temperature and Control:

- The Model 48 provides precise temperature control, which is crucial for optimizing the drying process and avoiding degradation of temperature-sensitive products.

- The air temperature can be adjusted based on the material being processed, typically in the range of 150–250°C, but can vary depending on the requirements of the application.

-

Particle Size Control:

- One of the main advantages of the SDS Model 48 is its ability to control the particle size and distribution of the final powder.

- The particle size is influenced by parameters such as the atomization pressure, feed rate, and air flow, allowing for customization based on product requirements.

-

Efficient Drying:

- The system utilizes hot air to rapidly evaporate moisture from the liquid feed. This quick evaporation produces dry particles almost instantly.

- The drying process is optimized to reduce the amount of heat sensitive materials exposed to high temperatures, helping maintain the quality of the end product.

-

Versatile Applications:

- The SDS Model 48 Spray Dryer can be used in a wide range of industries, including:

- Pharmaceuticals: Drying active pharmaceutical ingredients (APIs), excipients, and other drug formulations.

- Food and Beverages: Drying ingredients like milk, juices, flavorings, and coffee to produce powdered versions.

- Chemicals and Polymers: For drying various chemical formulations, resins, and polymer products.

- Biotechnology: For drying biological materials such as enzymes, microbial cultures, and vaccines.

- The SDS Model 48 Spray Dryer can be used in a wide range of industries, including:

-

Automated Control System:

- The system is often equipped with an automated control system that allows operators to adjust and monitor critical parameters, such as air temperature, feed rate, and airflow.

- This ensures consistency and precision during production.

-

Product Recovery System:

- The Model 48 typically includes efficient collection systems, such as cyclones or baghouses, to capture the dried powders.

- These recovery systems minimize material loss and help ensure that the drying process remains economically viable.

-

Energy Efficiency:

- The system is designed to be energy-efficient, reducing energy consumption while maintaining effective drying rates.

- Efficient heat recovery options can help minimize operational costs, especially in large-scale production environments.

-

Customizable Features:

- Depending on the application, additional options may be available, such as spray nozzles for different feed types (liquids, slurries, or pastes), different cyclone designs for powder collection, and more.

Benefits:

- Rapid Drying: The spray drying process ensures fast drying times, which is essential for products that need to be processed quickly while retaining their properties.

- High-Quality Powders: The Model 48 produces powders with uniform particle sizes, making it ideal for applications where consistency is key, such as in pharmaceuticals or food products.

- Scalability: While ideal for pilot or small-scale production, the Model 48 is designed with scalability in mind, enabling transition to larger systems if needed.

Applications:

- Pharmaceuticals: Drying of active pharmaceutical ingredients (APIs), excipients, and formulated products. It ensures that products maintain their bioactivity and quality.

- Food Industry: Producing powdered ingredients like milk, instant coffee, and flavors. Spray drying is a common method for creating instant products.

- Chemicals: Spray drying can be used to produce powdered chemicals, detergents, or pigments.

- Cosmetics: For drying materials like fragrances, essential oils, or emulsions into a powder form.

Conclusion:

The Spray Drying Systems Model 48 Spray Dryer is a highly efficient, versatile, and compact solution for producing dry powders from liquids. It is ideal for small to medium-scale operations in a range of industries, including pharmaceuticals, food, chemicals, and more. The ability to control particle size, adjust drying conditions, and ensure consistent quality makes it a valuable tool for both research and production environments.

Ceramic Powders, Ceramics, Chemical Industries, Chemical Powders, Chemical Products, Chemicals, Coffee, Coffee Powder, Coffee, Tea, Dairy Industry, Dairy Powder, Dairy Products, Dry Mixtures, Drying, Flavorings & Spices, Flavors and spices, Food and Beverage, Food Industry, Food Manufacturing, Food Powder, Food Processing, Food Production, Food Products, Organic Chemicals, Pesticides, Powder Production, Powders, Solvent, Solvents, Spice, Spices, Spray Dryer, Tea, Teas

- Spray Drying System

- Spray Dryer Equipment

- Spray Drying Technology

- Powder Production

- Industrial Spray Drying

- Pharmaceutical Spray Dryer

- Food Industry Drying

- Spray Drying for Chemicals

- Industrial Spray Dryer

- High-Capacity Spray Drying System

- Food Powder Processing Dryer

- Used Spray Drying Equipment

- Stainless Steel Spray Dryer

- Unused Spray Drying Systems Model 48 for Sale

- Industrial-Scale Spray Dryer with PLC Control

- High-Efficiency Food & Chemical Powder Spray Dryer

- 69 kg/hr Evaporation Rate Spray Dryer with Explosion Suppression

- Gas-Fired Spray Dryer for Powder Processing

- Unused Spray Drying Systems Model 48 Spray Dryer – 69 kg/hr Evaporation, 304 Stainless Steel

- Large-Scale Food & Pharmaceutical Spray Dryer with Allen Bradley PLC & HMI

- Industrial Spray Drying Equipment with Gas-Fired Heater & Chemical Suppression System

- High-Performance Powder Drying System with 460V Operation & Cyclone Separator

- Energy-Efficient Co-Current Spray Dryer for Dairy, Nutraceutical, & Chemical Processing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory