Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

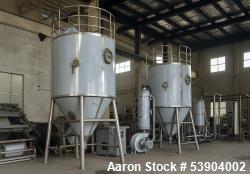

Used NIRO Model MM-XP MOBILE MINOR SPRAY DRYER, Catalyst Spray Dryer, Solvent and Recovery System. Designed to dry Aqueous Feeds. Drying Operation includes: (3) Stages, Atomization of the Feed Liq...

Used NIRO Model MM-XP MOBILE MINOR SPRAY DRYER, Catalyst Spray Dryer, Solvent and Recovery System. Designed to dry Aqueous Feeds. Drying Operation includes: (3) Stages, Atomization of the Feed Liquid into a spray, Contacting the spray with hot air (or Nitrogen) to promote solvent evaporation – Separation of dried product from air (or Nitrogen) in a cyclone. System includes solvent recovery unit for non-Aqueous feeds, (2) atomizing systems, rotary atomizer wheel rated for 33,000 rpm, fountain (2) flow nozzle, water evaporation rate at air rating – 1.7 kg/ hour depending on the temperature, outlet discharge temperature discharge- 150 degrees maximum, 7.5 kw electric heater. Open cycle spray dryer type includes (3) major assemblies. The main dryer system, the electrical control pane and the exhaust gas filter / carbon bed assembly. Main dryer is mounted on a portable frame with electric inlet process gas heater and supply flow control, drying chamber on a pneumatic lift cylinder. Dryer chamber inside diameter – 2.7’ and 2’ cylindrical height (straight side) with a 60 degree conical bottom. Allen Bradley controls. Exhaust gas filter / carbon bed assembly mounted on a portable frame. Watson Marlow peristaltic pump, Model 521CC rated for hazardous operation, (Class 1, Div. 2, Groups C and D). used to control the exit temperature from the Allen Bradley panel. Gear ratio is 1000:1 at 2 to 57 rpm. All stainless steel construction. 316 Stainless contacts, all other is 304 stainless steel. Associated parts, controls, interconnecting piping, etc. if available.

Used NIRO Model MM-XP MOBILE MINOR SPRAY DRYER, Catalyst Spray Dryer, Solvent and Recovery System. Designed to dry Aqueous Feeds. Drying Operation includes: (3) Stages, Atomization of the Feed Liquid into a spray, Contacting the spray with hot air (or Nitrogen) to promote solvent evaporation – Separation of dried product from air (or Nitrogen) in a cyclone. System includes solvent recovery unit for non-Aqueous feeds, (2) atomizing systems, rotary atomizer wheel rated for 33,000 rpm, fountain (2) flow nozzle, water evaporation rate at air rating – 1.7 kg/ hour depending on the temperature, outlet discharge temperature discharge- 150 degrees maximum, 7.5 kw electric heater. Open cycle spray dryer type includes (3) major assemblies. The main dryer system, the electrical control pane and the exhaust gas filter / carbon bed assembly. Main dryer is mounted on a portable frame with electric inlet process gas heater and supply flow control, drying chamber on a pneumatic lift cylinder. Dryer chamber inside diameter – 2.7’ and 2’ cylindrical height (straight side) with a 60 degree conical bottom. Allen Bradley controls. Exhaust gas filter / carbon bed assembly mounted on a portable frame. Watson Marlow peristaltic pump, Model 521CC rated for hazardous operation, (Class 1, Div. 2, Groups C and D). used to control the exit temperature from the Allen Bradley panel. Gear ratio is 1000:1 at 2 to 57 rpm. All stainless steel construction. 316 Stainless contacts, all other is 304 stainless steel. Associated parts, controls, interconnecting piping, etc. if available.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory