Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

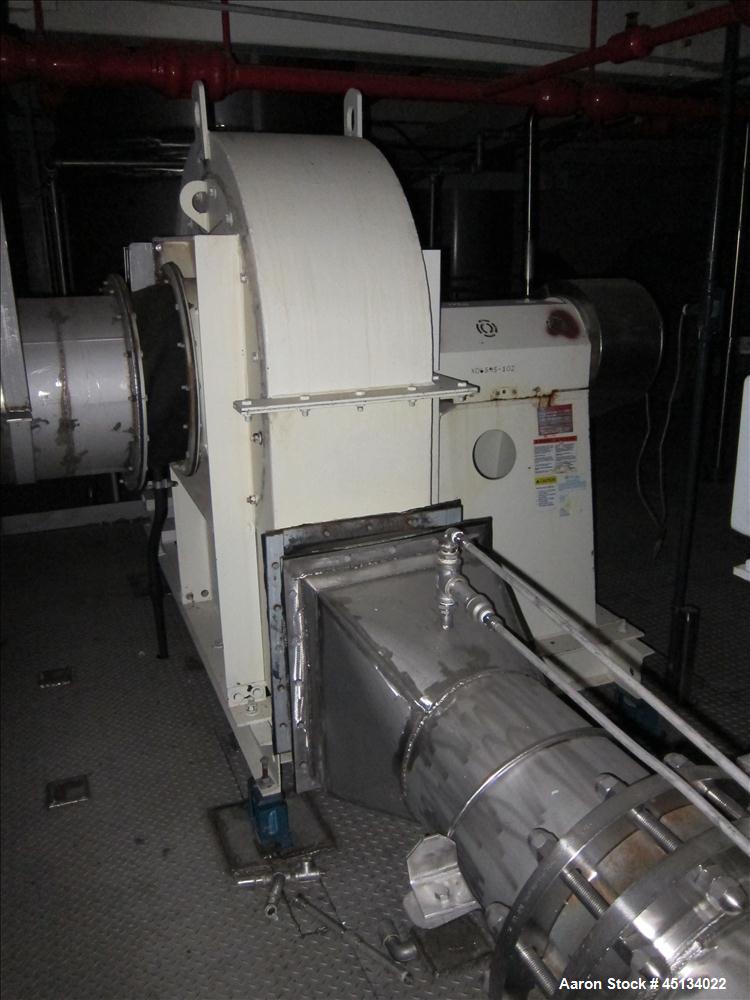

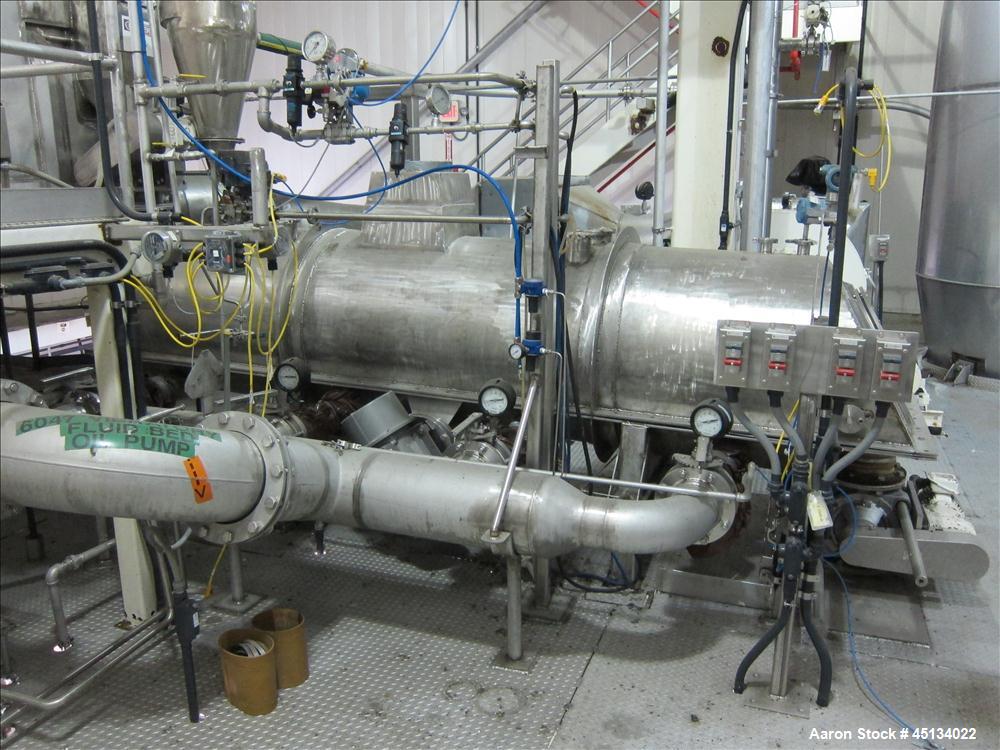

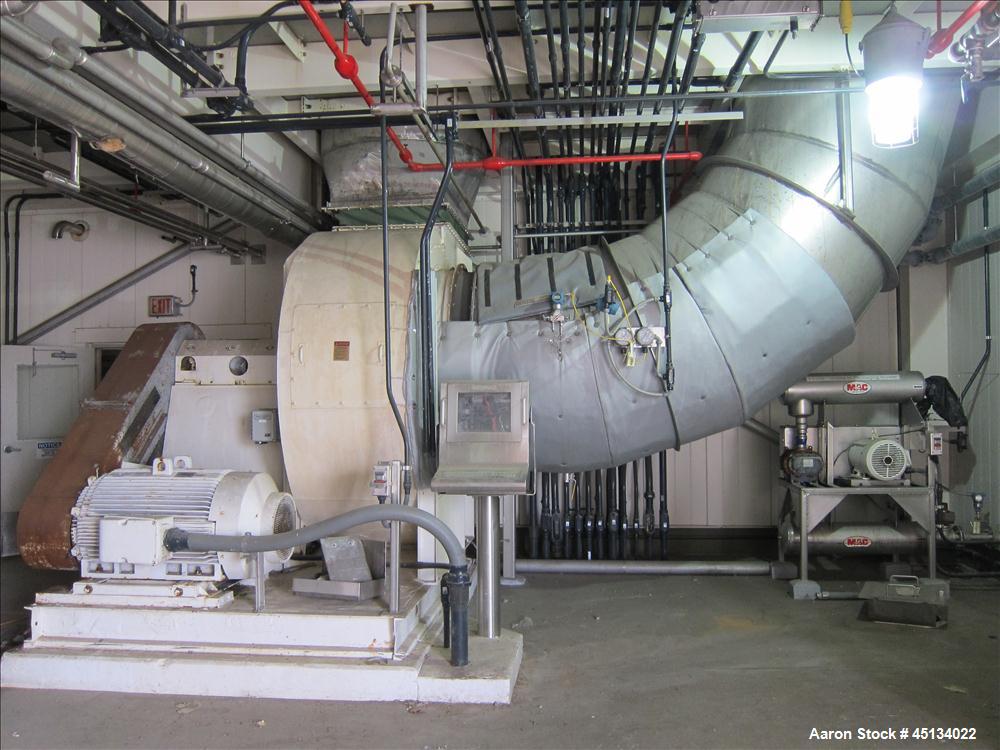

Used Niro Spray Tower Dryer. Originally designed for 12,500 pounds / hour of water evaporation. The dryer capacity was increased to 15,000 pounds / hour at 65,000 SCFM of air flow. The Dryer is constructed of 316 L Stainless Steel. The dryer is a Standard Tall Form Dryer equipped with an integral static Fluid Bed Dryer and external Vibratory Fluid Bed Cooler. Both beds have heaters and the VFB also had a Cooler. The Dryer was equipped with fines return and agglomeration capabilities as an opti

Used Niro Spray Tower Dryer. Originally designed for 12,500 pounds / hour of water evaporation. The dryer capacity was increased to 15,000 pounds / hour at 65,000 SCFM of air flow. The Dryer is constructed of 316 L Stainless Steel. The dryer is a Standard Tall Form Dryer equipped with an integral static Fluid Bed Dryer and external Vibratory Fluid Bed Cooler. Both beds have heaters and the VFB also had a Cooler. The Dryer was equipped with fines return and agglomeration capabilities as an option. It is currently configured without Fines return. Primary cyclone followed by a Dust Collector. Both the burners for the fiber and spray dryer were maximum 30 MMBTU / hour. The Kst of Soy Isolate is 119, so the dryer, cyclone and dust collector all were equipped with explosion panels. The system is equipped with a CIP system with the exception of the dust collector. The feed system was designed for 33 GPM with two high pressure pumps capable of 10,000 psi feed. (The pump is not be included). No controls are included.

Manufacturer Information:

- Brand: Niro

- Type: Spray Tower Dryer

- Capacity: Originally 12,500 lbs/hr, increased to 15,000 lbs/hr

- Airflow: 65,000 SCFM

- Material: 316L Stainless Steel

Description:

The Niro Spray Tower Dryer is a high-performance industrial drying system, designed for large-scale spray drying applications in the food, dairy, pharmaceutical, and chemical industries.

Constructed of 316L stainless steel, this tall-form spray dryer is equipped with:

- Integral Static Fluid Bed Dryer for enhanced drying efficiency

- External Vibratory Fluid Bed Cooler with both heating and cooling functions

- Fines Return & Agglomeration Capabilities (currently configured without fines return)

- Primary Cyclone & Dust Collector for effective particulate separation

- Explosion Panels for safety, rated for Kst of Soy Isolate (119)

- Burners Rated at 30 MMBTU/hr for both the fiber and spray dryer

- CIP System (Clean-In-Place) (excluding dust collector)

- Feed System: Designed for 33 GPM with two high-pressure pumps capable of 10,000 psi

This high-efficiency drying system is ideal for processing dairy, protein powders, pharmaceuticals, and specialty chemicals.

Key Features:

- 15,000 lbs/hr Water Evaporation Capacity

- Tall-Form Spray Dryer with Integrated Fluid Bed System

- Vibratory Fluid Bed Cooler with Heating & Cooling Functions

- Primary Cyclone & Dust Collector for Effective Powder Collection

- Explosion Panels for Enhanced Safety (Kst of Soy Isolate: 119)

- 30 MMBTU/hr Burners for Fiber & Spray Dryer

- CIP System for Easy Cleaning (Excluding Dust Collector)

- High-Pressure Feed System with Two Pumps (10,000 psi Capable)

- Ideal for Dairy, Food, Pharmaceutical, and Chemical Processing

Specifications:

- Machine Type: Spray Tower Dryer

- Brand: Niro

- Material: 316L Stainless Steel

- Water Evaporation Capacity: 15,000 lbs/hr

- Airflow Capacity: 65,000 SCFM

- Dryer Type: Tall Form

- Integrated Features: Static Fluid Bed Dryer & Vibratory Fluid Bed Cooler

- Fines Return & Agglomeration: Available (not currently configured)

- Burners: 30 MMBTU/hr for Fiber & Spray Dryer

- Explosion Rating: Kst of Soy Isolate = 119

- Primary Cyclone & Dust Collector: Equipped with Explosion Panels

- CIP System: Yes (excluding dust collector)

- Feed System: 33 GPM with Two 10,000 psi Pumps

Applications:

- Dairy Industry: Drying milk powders, whey, and protein concentrates

- Food Processing: Spray drying of soy isolates, starches, and flavorings

- Pharmaceuticals: Drying of active ingredients, excipients, and supplements

- Chemical Industry: Processing of specialty powders, detergents, and pigments

- Nutritional Supplements: Spray drying of high-value protein and health powders

What Products Would This Be Used For?

- Whey protein and milk powders

- Soy protein isolates and plant-based powders

- Powdered food additives and flavoring agents

- Pharmaceutical powders and active ingredients

- Specialty chemicals, pigments, and detergents

- Niro Spray Tower Dryer

- Used industrial spray dryer

- High-capacity drying system

- 15,000 lbs/hr spray dryer

- 316L stainless steel spray dryer

- Vibratory fluid bed dryer

- Industrial powder drying system

- Food-grade spray drying equipment

- CIP system spray dryer

- Explosion-proof spray dryer

- Used Niro Spray Tower Dryer with 15,000 lbs/hr evaporation capacity

- Pre-owned tall-form spray dryer with integrated fluid bed system

- Industrial 316L stainless steel spray drying system for food and dairy

- High-efficiency powder drying system with cyclone and dust collector

- Used Niro spray dryer with vibratory fluid bed cooler and agglomeration options

- Explosion-proof spray drying system for pharmaceutical and chemical industries

- Large-scale protein powder drying system with CIP cleaning capabilities

- Pre-owned Niro industrial spray dryer for milk and whey protein processing

- High-capacity food and beverage spray drying system with dust collector

- Used spray drying equipment for sale with fluid bed dryer integration

- Used Niro Spray Tower Dryer with 15,000 lbs/hr evaporation rate and fluid bed cooler

- Buy a pre-owned industrial spray dryer with high-pressure feed system and CIP cleaning

- High-efficiency Niro spray drying system with 65,000 SCFM airflow and explosion panels

- Used 316L stainless steel spray dryer with cyclone, dust collector, and fines return

- Large-scale food and dairy spray drying system with integrated fluid bed drying

- Cost-effective used spray dryer for pharmaceutical and chemical powder processing

- Pre-owned Niro powder drying system with 30 MMBTU/hr burners and safety panels

- Industrial spray drying machine for whey, soy protein, and nutritional powders

- Used high-pressure spray drying system with 10,000 psi feed pumps

- Buy a used Niro spray dryer with vibratory fluid bed cooler and CIP system

- Used Niro Spray Dryer for sale

- Buy used industrial spray drying equipment

- High-performance food-grade spray dryer

- Pre-owned tall-form spray dryer pricing

- Used Niro powder drying system availability

- Industrial spray dryer with fluid bed cooling

- Reliable used spray drying system for chemicals and pharmaceuticals

- Cost-effective used spray dryer for dairy and nutritional products

- Explosion-proof spray drying machine for food processing

- Used spray drying equipment with cyclone and dust collector

- Buy used Niro Spray Tower Dryer

- Sell industrial spray drying equipment

- Used spray drying system for sale

- Where to buy large-scale powder drying machines

- Best spray dryer for food and pharmaceutical applications

- Affordable used industrial drying system pricing

- Used Niro spray dryer availability for sale

- Buy pre-owned high-capacity spray drying system

- Reliable used spray dryer with fluid bed and dust collector

- Used industrial spray drying machine with explosion panels

- Used Industrial Equipment

- Used Industrial Machinery

- Used Process Equipment

- Used Process Machinery

- Used Spray Dryer

- Spray Dryer

- Niro

- Niro Spray Dryer

- Industrial Spray Dryer

- Fluid Bed Dryer

- Used Fluid Bed Dryer

- Aaron Equipment

Used Niro Spray Tower Dryer. Originally designed for 12,500 pounds / hour of water evaporation. The dryer capacity was increased to 15,000 pounds / hour at 65,000 SCFM of air flow. The Dryer is constructed of 316 L Stainless Steel. The dryer is a Standard Tall Form Dryer equipped with an integral static Fluid Bed Dryer and external Vibratory Fluid Bed Cooler. Both beds have heaters and the VFB also had a Cooler. The Dryer was equipped with fines return and agglomeration capabilities as an option. It is currently configured without Fines return. Primary cyclone followed by a Dust Collector. Both the burners for the fiber and spray dryer were maximum 30 MMBTU / hour. The Kst of Soy Isolate is 119, so the dryer, cyclone and dust collector all were equipped with explosion panels. The system is equipped with a CIP system with the exception of the dust collector. The feed system was designed for 33 GPM with two high pressure pumps capable of 10,000 psi feed. (The pump is not be included). No controls are included.

Manufacturer Information:

- Brand: Niro

- Type: Spray Tower Dryer

- Capacity: Originally 12,500 lbs/hr, increased to 15,000 lbs/hr

- Airflow: 65,000 SCFM

- Material: 316L Stainless Steel

Description:

The Niro Spray Tower Dryer is a high-performance industrial drying system, designed for large-scale spray drying applications in the food, dairy, pharmaceutical, and chemical industries.

Constructed of 316L stainless steel, this tall-form spray dryer is equipped with:

- Integral Static Fluid Bed Dryer for enhanced drying efficiency

- External Vibratory Fluid Bed Cooler with both heating and cooling functions

- Fines Return & Agglomeration Capabilities (currently configured without fines return)

- Primary Cyclone & Dust Collector for effective particulate separation

- Explosion Panels for safety, rated for Kst of Soy Isolate (119)

- Burners Rated at 30 MMBTU/hr for both the fiber and spray dryer

- CIP System (Clean-In-Place) (excluding dust collector)

- Feed System: Designed for 33 GPM with two high-pressure pumps capable of 10,000 psi

This high-efficiency drying system is ideal for processing dairy, protein powders, pharmaceuticals, and specialty chemicals.

Key Features:

- 15,000 lbs/hr Water Evaporation Capacity

- Tall-Form Spray Dryer with Integrated Fluid Bed System

- Vibratory Fluid Bed Cooler with Heating & Cooling Functions

- Primary Cyclone & Dust Collector for Effective Powder Collection

- Explosion Panels for Enhanced Safety (Kst of Soy Isolate: 119)

- 30 MMBTU/hr Burners for Fiber & Spray Dryer

- CIP System for Easy Cleaning (Excluding Dust Collector)

- High-Pressure Feed System with Two Pumps (10,000 psi Capable)

- Ideal for Dairy, Food, Pharmaceutical, and Chemical Processing

Specifications:

- Machine Type: Spray Tower Dryer

- Brand: Niro

- Material: 316L Stainless Steel

- Water Evaporation Capacity: 15,000 lbs/hr

- Airflow Capacity: 65,000 SCFM

- Dryer Type: Tall Form

- Integrated Features: Static Fluid Bed Dryer & Vibratory Fluid Bed Cooler

- Fines Return & Agglomeration: Available (not currently configured)

- Burners: 30 MMBTU/hr for Fiber & Spray Dryer

- Explosion Rating: Kst of Soy Isolate = 119

- Primary Cyclone & Dust Collector: Equipped with Explosion Panels

- CIP System: Yes (excluding dust collector)

- Feed System: 33 GPM with Two 10,000 psi Pumps

Applications:

- Dairy Industry: Drying milk powders, whey, and protein concentrates

- Food Processing: Spray drying of soy isolates, starches, and flavorings

- Pharmaceuticals: Drying of active ingredients, excipients, and supplements

- Chemical Industry: Processing of specialty powders, detergents, and pigments

- Nutritional Supplements: Spray drying of high-value protein and health powders

What Products Would This Be Used For?

- Whey protein and milk powders

- Soy protein isolates and plant-based powders

- Powdered food additives and flavoring agents

- Pharmaceutical powders and active ingredients

- Specialty chemicals, pigments, and detergents

- Niro Spray Tower Dryer

- Used industrial spray dryer

- High-capacity drying system

- 15,000 lbs/hr spray dryer

- 316L stainless steel spray dryer

- Vibratory fluid bed dryer

- Industrial powder drying system

- Food-grade spray drying equipment

- CIP system spray dryer

- Explosion-proof spray dryer

- Used Niro Spray Tower Dryer with 15,000 lbs/hr evaporation capacity

- Pre-owned tall-form spray dryer with integrated fluid bed system

- Industrial 316L stainless steel spray drying system for food and dairy

- High-efficiency powder drying system with cyclone and dust collector

- Used Niro spray dryer with vibratory fluid bed cooler and agglomeration options

- Explosion-proof spray drying system for pharmaceutical and chemical industries

- Large-scale protein powder drying system with CIP cleaning capabilities

- Pre-owned Niro industrial spray dryer for milk and whey protein processing

- High-capacity food and beverage spray drying system with dust collector

- Used spray drying equipment for sale with fluid bed dryer integration

- Used Niro Spray Tower Dryer with 15,000 lbs/hr evaporation rate and fluid bed cooler

- Buy a pre-owned industrial spray dryer with high-pressure feed system and CIP cleaning

- High-efficiency Niro spray drying system with 65,000 SCFM airflow and explosion panels

- Used 316L stainless steel spray dryer with cyclone, dust collector, and fines return

- Large-scale food and dairy spray drying system with integrated fluid bed drying

- Cost-effective used spray dryer for pharmaceutical and chemical powder processing

- Pre-owned Niro powder drying system with 30 MMBTU/hr burners and safety panels

- Industrial spray drying machine for whey, soy protein, and nutritional powders

- Used high-pressure spray drying system with 10,000 psi feed pumps

- Buy a used Niro spray dryer with vibratory fluid bed cooler and CIP system

- Used Niro Spray Dryer for sale

- Buy used industrial spray drying equipment

- High-performance food-grade spray dryer

- Pre-owned tall-form spray dryer pricing

- Used Niro powder drying system availability

- Industrial spray dryer with fluid bed cooling

- Reliable used spray drying system for chemicals and pharmaceuticals

- Cost-effective used spray dryer for dairy and nutritional products

- Explosion-proof spray drying machine for food processing

- Used spray drying equipment with cyclone and dust collector

- Buy used Niro Spray Tower Dryer

- Sell industrial spray drying equipment

- Used spray drying system for sale

- Where to buy large-scale powder drying machines

- Best spray dryer for food and pharmaceutical applications

- Affordable used industrial drying system pricing

- Used Niro spray dryer availability for sale

- Buy pre-owned high-capacity spray drying system

- Reliable used spray dryer with fluid bed and dust collector

- Used industrial spray drying machine with explosion panels

- Used Industrial Equipment

- Used Industrial Machinery

- Used Process Equipment

- Used Process Machinery

- Used Spray Dryer

- Spray Dryer

- Niro

- Niro Spray Dryer

- Industrial Spray Dryer

- Fluid Bed Dryer

- Used Fluid Bed Dryer

- Aaron Equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory