Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

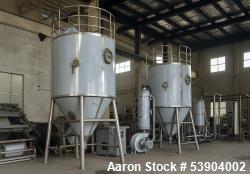

Used Niro spray tower/spray dryer. 23' diameter x 41' tall, 304 stainless steel construction. Main chamber is double walled and insulated. Unit has a fluid bed unit with three steam coil heater units...

Used Niro spray tower/spray dryer. 23' diameter x 41' tall, 304 stainless steel construction. Main chamber is double walled and insulated. Unit has a fluid bed unit with three steam coil heater units and one cooling coil unit. The fluid bed has one cyclone section included. Stated evaporation rate was 2,500 pounds water per hour, an additional 300 is fluid bed used for drying. Dryer has two scrubbers for discharge air. Some valves and piping are included as well as some platforms. Utility requirements for system: 16,000 lb/hour steam @ 125 psi; 400 gpm domestic water; 100 gpm chilled water @ 38 F - 40 tons cooling; 400 scfm compressed air @ 125 psig; 2,500 cfh natural gas @ 2 psig; 100 gpm @ 40 psi for fire suppression (water); 750 kva @ 3/60/480V electrical. Control panel and motor control. Year 1984.

Used Niro spray tower/spray dryer. 23' diameter x 41' tall, 304 stainless steel construction. Main chamber is double walled and insulated. Unit has a fluid bed unit with three steam coil heater units and one cooling coil unit. The fluid bed has one cyclone section included. Stated evaporation rate was 2,500 pounds water per hour, an additional 300 is fluid bed used for drying. Dryer has two scrubbers for discharge air. Some valves and piping are included as well as some platforms. Utility requirements for system: 16,000 lb/hour steam @ 125 psi; 400 gpm domestic water; 100 gpm chilled water @ 38 F - 40 tons cooling; 400 scfm compressed air @ 125 psig; 2,500 cfh natural gas @ 2 psig; 100 gpm @ 40 psi for fire suppression (water); 750 kva @ 3/60/480V electrical. Control panel and motor control. Year 1984.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory