Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used GEA Niro A/S Production Minor FSD Fluidized Spray Dryer.

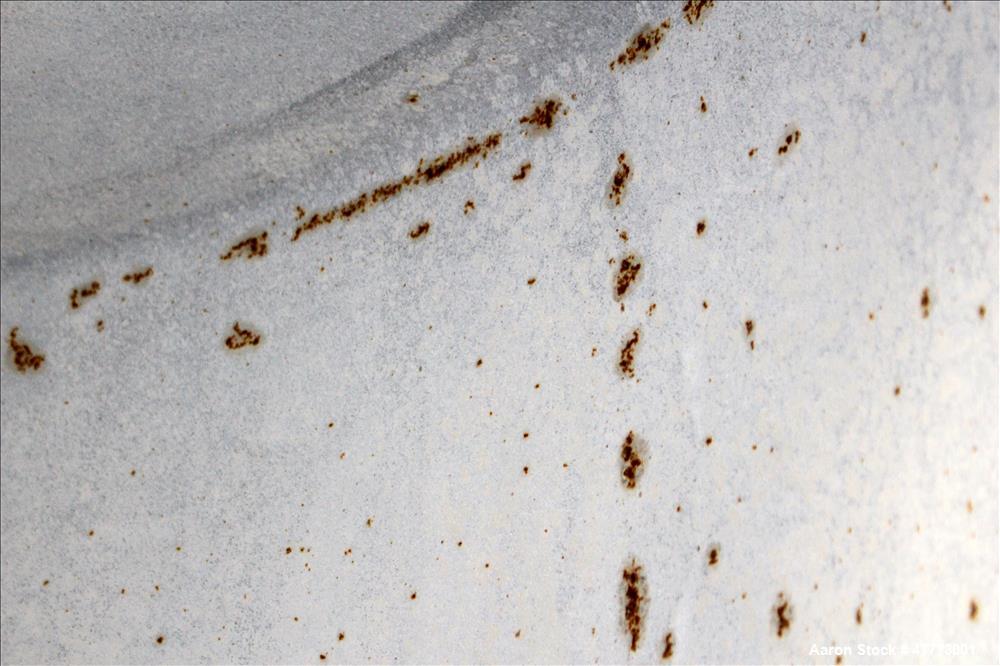

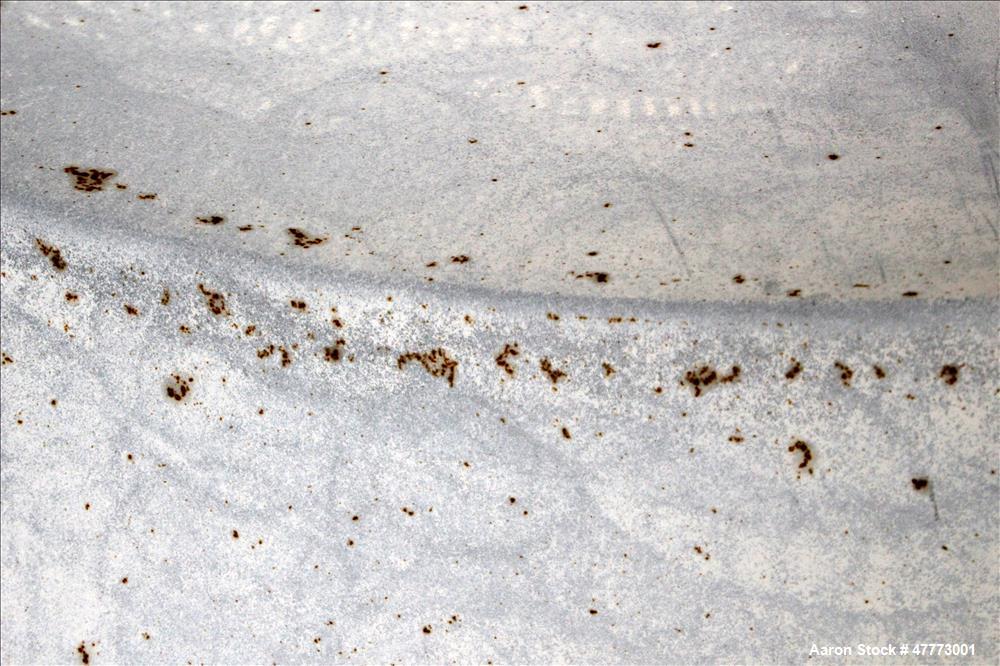

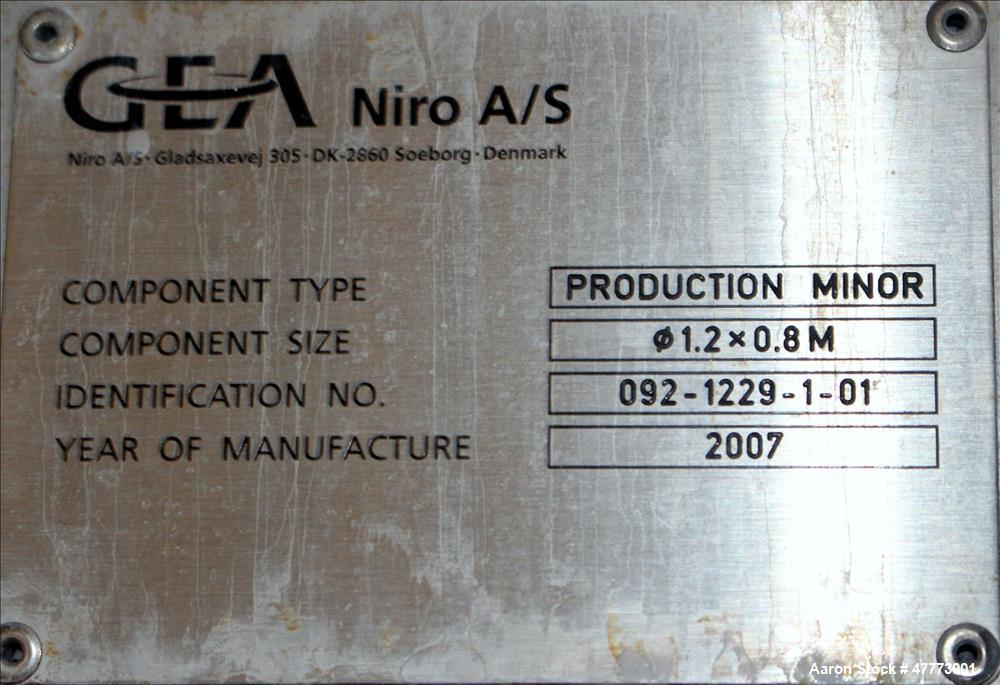

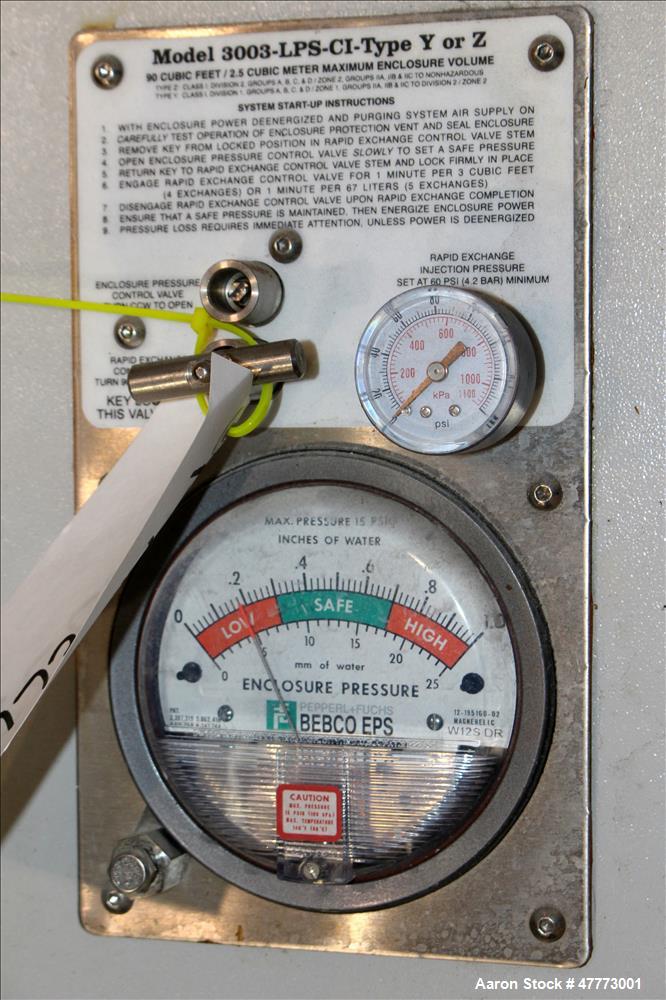

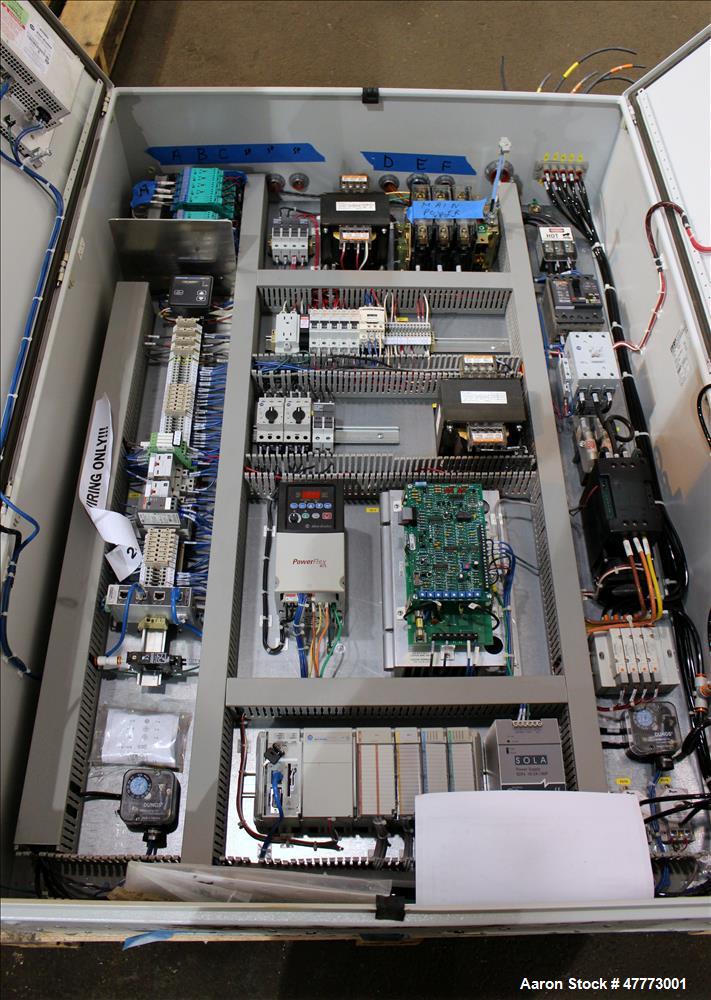

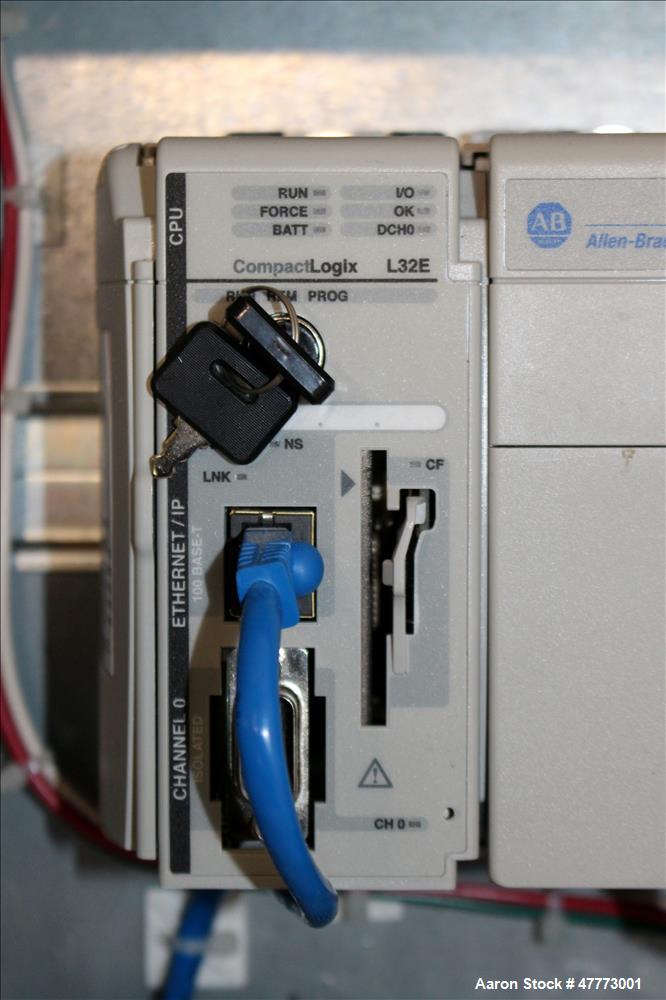

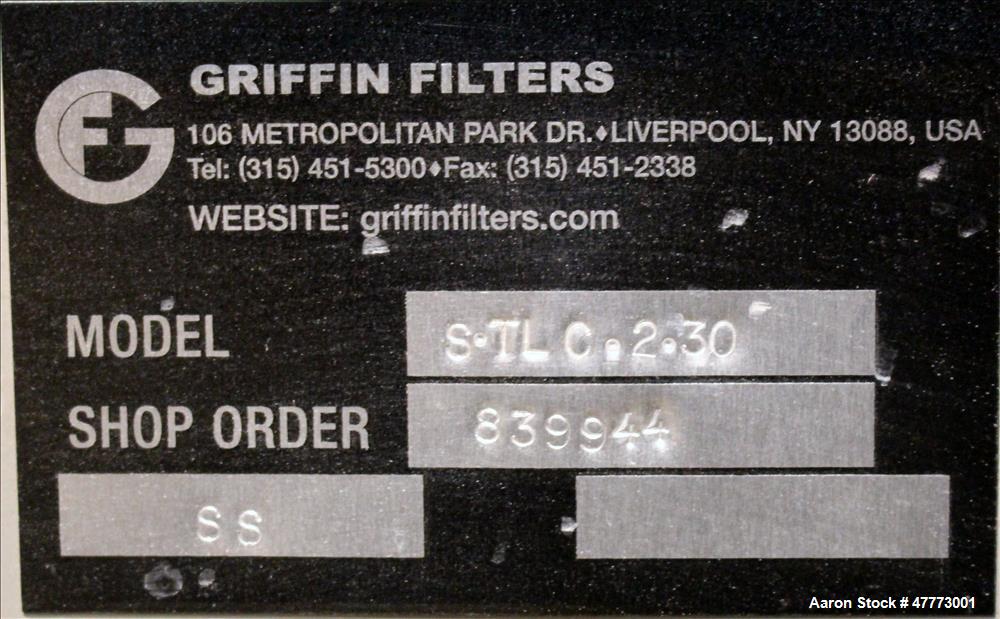

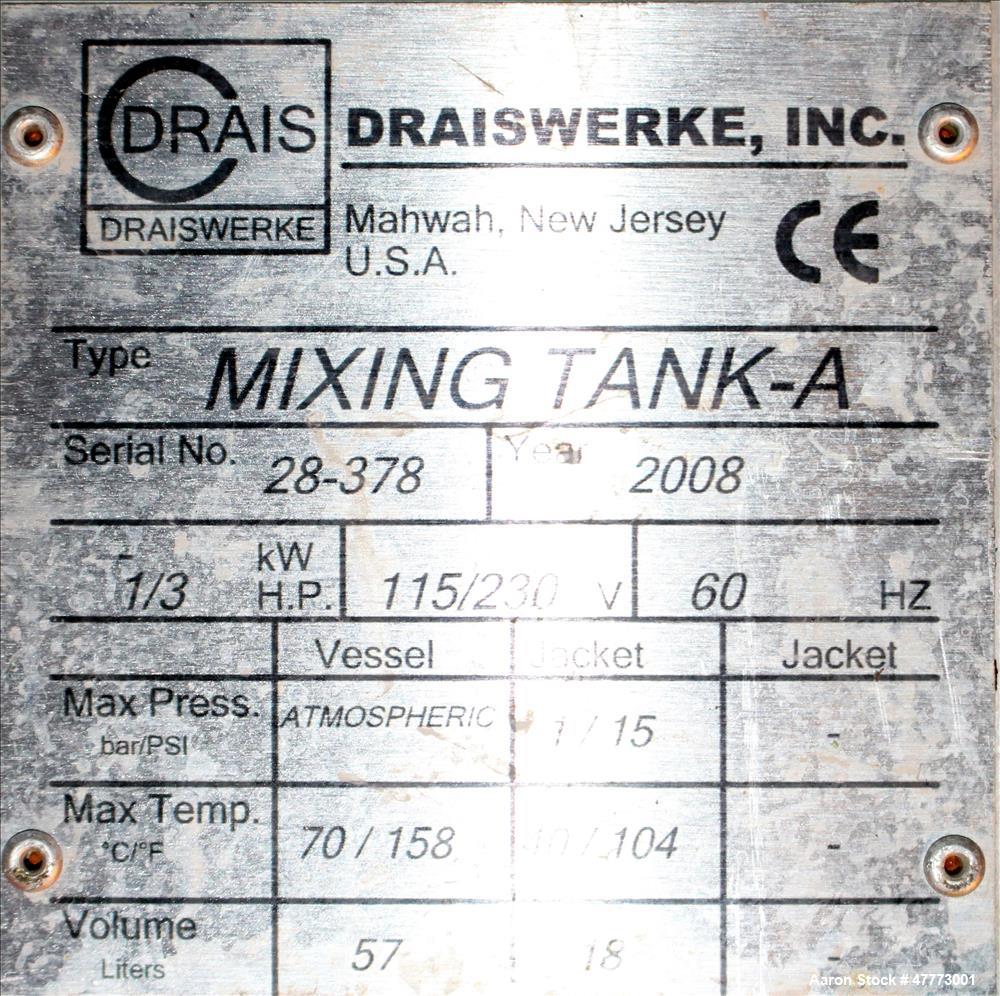

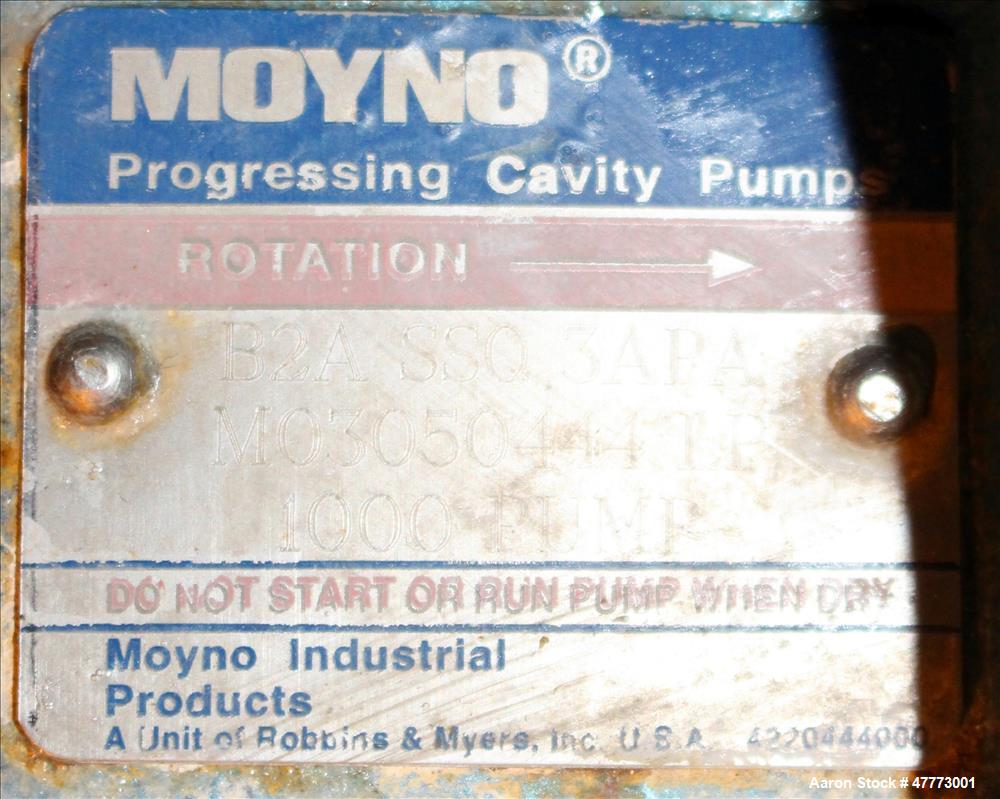

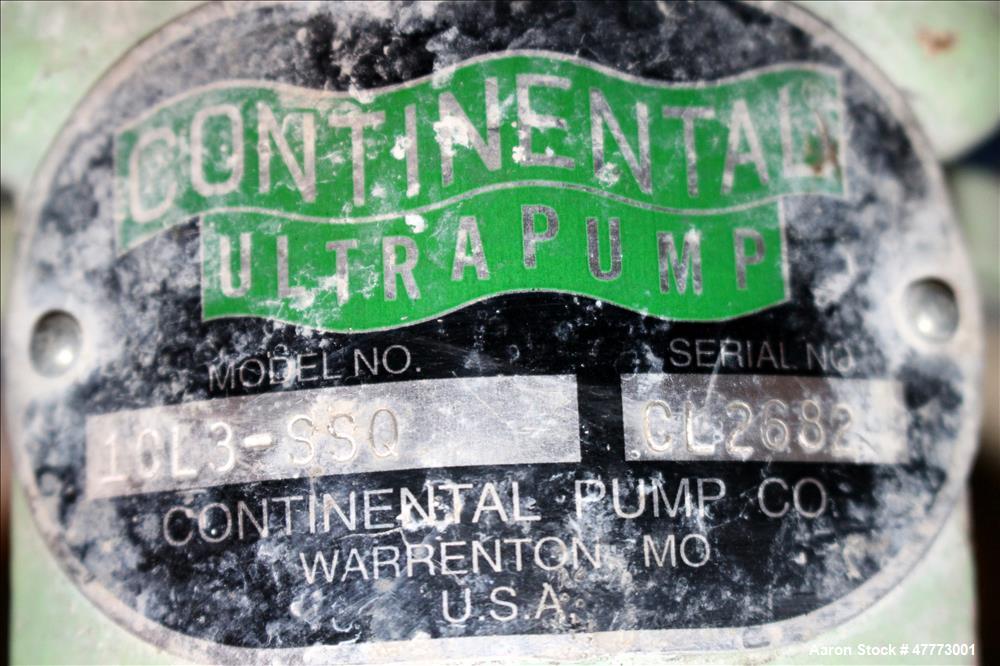

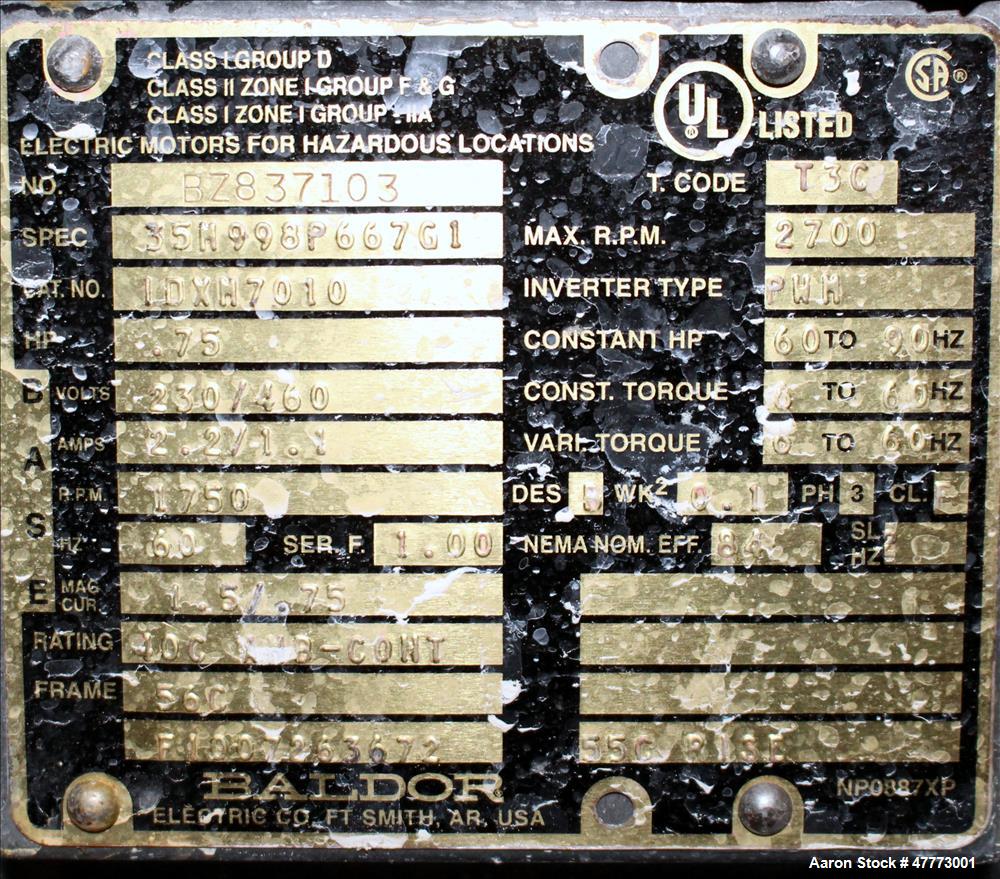

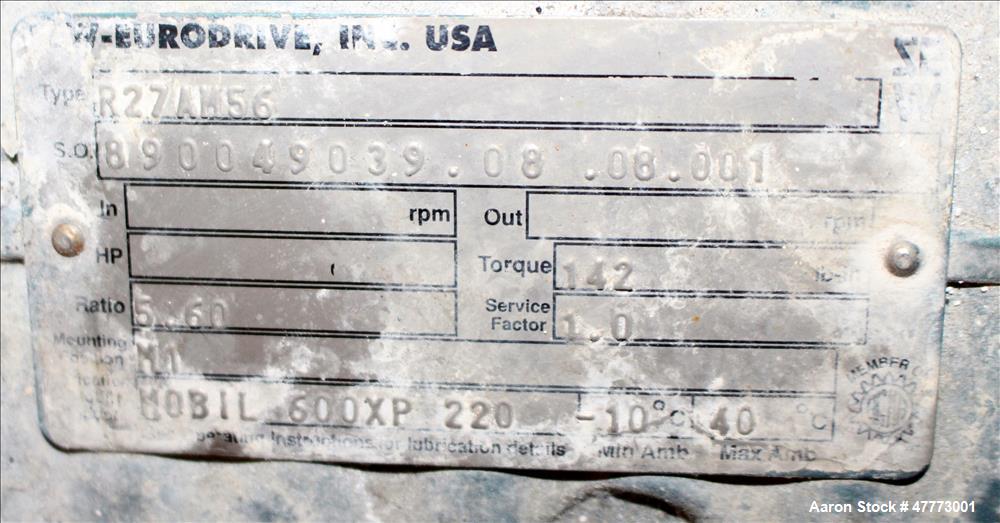

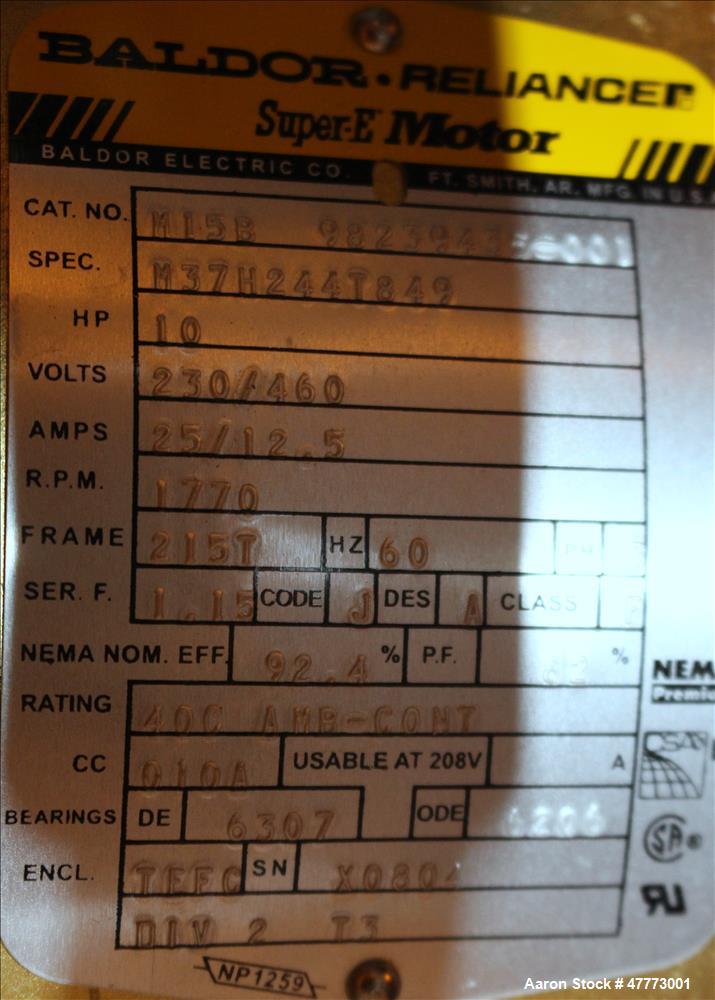

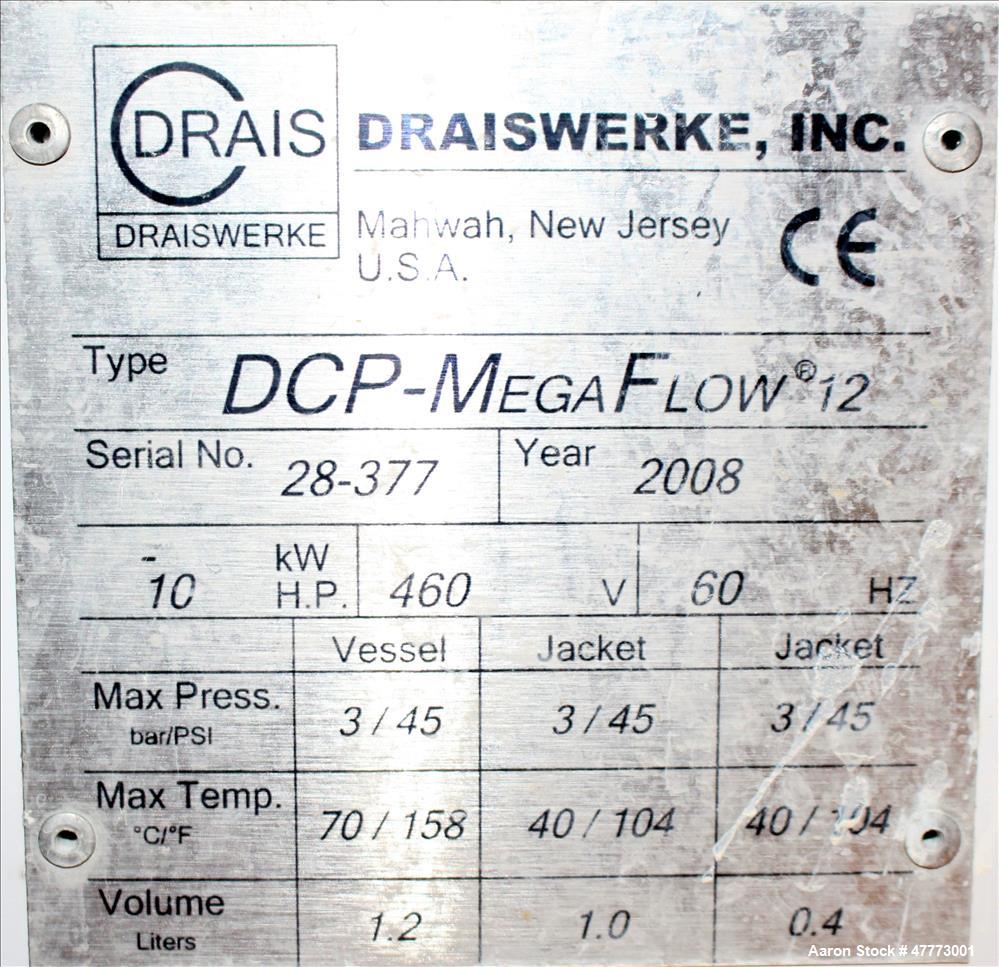

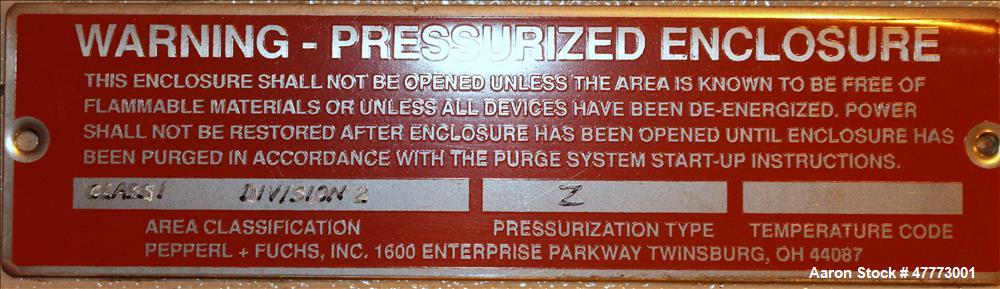

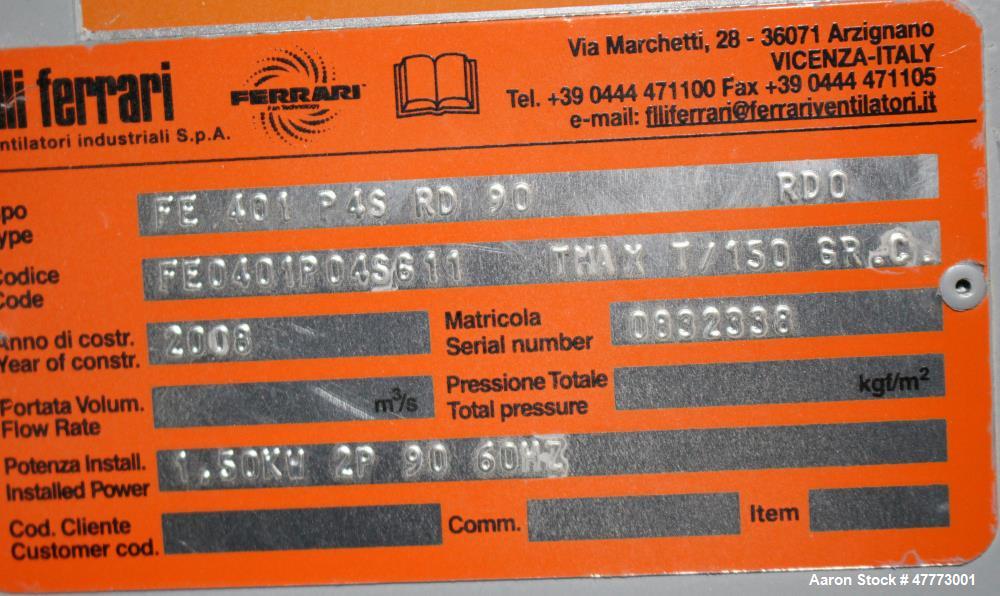

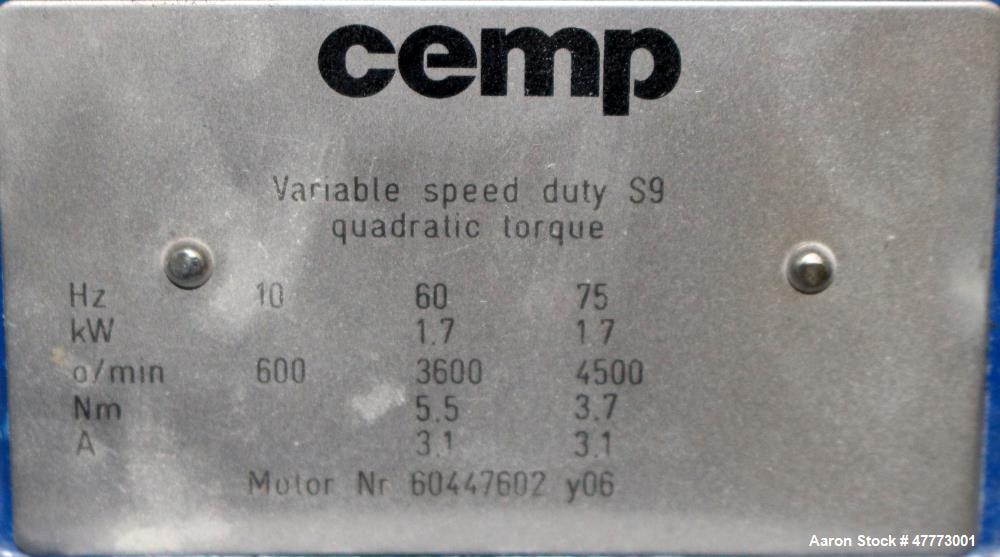

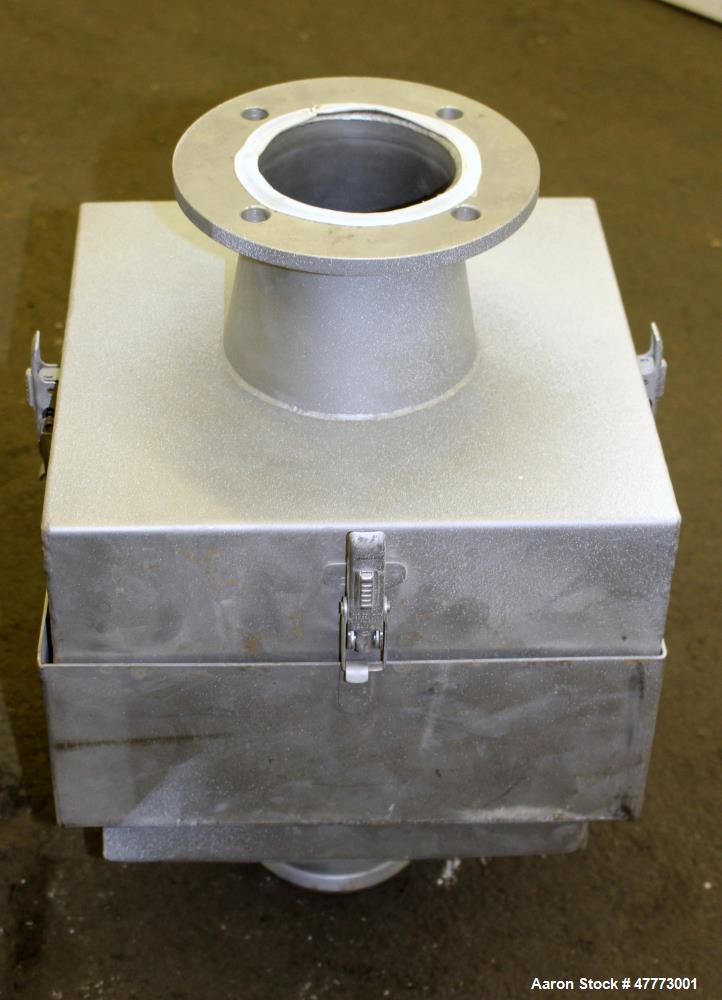

Used GEA Niro A/S Production Minor Spray Dryer, Size 1.2 x 0.8 M, Serial# 092-1229-1-01, Built 2007, 316 Stainless Steel. Drying capacity up to 35 kg/h water evaporation. Chamber measures approximate 48" diameter x 32" straight side x 36" coned bottom. 2 Fluid nozzle fountain configuration. Electric heater 36kw maximum, inlet temperature 360 degree C, 180 degree C air outlet. Ambient pressure, drying air flow up to 400 cubic meter an hour, slurry feed up to 60 liters an hour. Class 1, Division II electrical classification. Includes collection jars, 300 CHE cyclone, (1) Moyno series 1000 progressive cavity pump, model B2A-SSQ-3APA, serial# M03050444LP, driven by a 1/2hp, 180 volt, 1750 rpm XP DC gear motor, ratio 28.37 to 1 with plastic feed hopper, (1) control panel with an Allen-Bradley PanelView Plus 1000, CompactLogix L32E controller, (1) Griffin Filter 304 stainless steel cartridge type dust collector, model S-TLC-2-30, serial # 839944, approximate 232 square feet filter area, (1) Drais Draisewerke Perl Mill, Model DCP-MegaFlow 12, Serial# 28-377, Built 2008. Material of rotor with pins & stator outer & inner cylinders is Dusaresist, agitator pins are Tungsten Carbide. Grinding vessel volume net 1.2 liters, rated 3 bar (45 psi) at 70 degrees C. (158 degrees F). Jacket rated 3 bar (45 psi) at 40 degrees C. (104 degrees F). Hydraulic hand pump chamber raise, and lower. Driven by a 10hp, 3/60/230/460 volt, 1770 rpm motor. Includes (1) Drais Draisewerke jacketed mixing tank, serial# 28-378, 15 gallon, 316 stainless steel. Jacket rated 1 bar (15 psi) at 40 degrees C. (104 degrees F.) with a Lightnin agitator, model X1P50, serial# 1770397, shaft and blade driven by a 1/2hp, 90 volt, 1750 rpm DC motor with a Baldor DC drive, (1) Drais Draisewerke jacketed mixing tank, serial# 28-370, 15 gallon, 316 stainless steel. Jacket rated 1 bar (15 psi) at 40 degrees C. (104 degrees F.) with a Lightnin agitator, model X1P50, serial# 1770641, shaft and blade driven by a 1/2hp, 90 volt, 1750 rpm DC motor with a Baldor DC drive, (1) Continental Progressing Cavity Ultrapump, model 1CL3-SSQ, serial# CL2682. Driven by a 3/4hp, 3/60/230/460 volt, 1750 rpm XP gear motor, ratio 5.60 to 1, with a plastic feed hopper. (1) Drais Draisewerke control panel with (2) ABB drives, Allen-Bradley SLC 5/03 CPU controller, and an Automation Direct panel. (1) Larox Laboratory Pressure Filter, Model PF 0.1 H2, Serial# T0239, Built 2009, Approximate 0.1 Square Meter. (1) Filter plate approximate 14-1/8" diameter. Includes a 90 liter plastic slurry tank with 0.30kw agitator and PowerFlex drive, mounted on casters, (1) SPX Power Team air hydraulic pump, (1) SC Hydraulic Engineering air driven liquid pump, model 10-4000W003, ratio 5 to 1, serial# 1107509, with a pressing water tank, (1) Wilden plastic diaphragm pump, model P2/PKPPP/NES/NE/PBN/0404, serial# 0020904027, built 2009, (1) Wilden plastic diaphragm pump, model P1/PPPPP/BNS/BN/KBN, serial# 0020883393, built 2008. (1) Ferrari Blower driven by 1.7kW motor. Miscellaneous piping and valves. Mounted on a frame with casters.

Used GEA Niro A/S Production Minor Spray Dryer, Size 1.2 x 0.8 M, Serial# 092-1229-1-01, Built 2007, 316 Stainless Steel. Drying capacity up to 35 kg/h water evaporation. Chamber measures approximate 48" diameter x 32" straight side x 36" coned bottom. 2 Fluid nozzle fountain configuration. Electric heater 36kw maximum, inlet temperature 360 degree C, 180 degree C air outlet. Ambient pressure, drying air flow up to 400 cubic meter an hour, slurry feed up to 60 liters an hour. Class 1, Division II electrical classification. Includes collection jars, 300 CHE cyclone, (1) Moyno series 1000 progressive cavity pump, model B2A-SSQ-3APA, serial# M03050444LP, driven by a 1/2hp, 180 volt, 1750 rpm XP DC gear motor, ratio 28.37 to 1 with plastic feed hopper, (1) control panel with an Allen-Bradley PanelView Plus 1000, CompactLogix L32E controller, (1) Griffin Filter 304 stainless steel cartridge type dust collector, model S-TLC-2-30, serial # 839944, approximate 232 square feet filter area, (1) Drais Draisewerke Perl Mill, Model DCP-MegaFlow 12, Serial# 28-377, Built 2008. Material of rotor with pins & stator outer & inner cylinders is Dusaresist, agitator pins are Tungsten Carbide. Grinding vessel volume net 1.2 liters, rated 3 bar (45 psi) at 70 degrees C. (158 degrees F). Jacket rated 3 bar (45 psi) at 40 degrees C. (104 degrees F). Hydraulic hand pump chamber raise, and lower. Driven by a 10hp, 3/60/230/460 volt, 1770 rpm motor. Includes (1) Drais Draisewerke jacketed mixing tank, serial# 28-378, 15 gallon, 316 stainless steel. Jacket rated 1 bar (15 psi) at 40 degrees C. (104 degrees F.) with a Lightnin agitator, model X1P50, serial# 1770397, shaft and blade driven by a 1/2hp, 90 volt, 1750 rpm DC motor with a Baldor DC drive, (1) Drais Draisewerke jacketed mixing tank, serial# 28-370, 15 gallon, 316 stainless steel. Jacket rated 1 bar (15 psi) at 40 degrees C. (104 degrees F.) with a Lightnin agitator, model X1P50, serial# 1770641, shaft and blade driven by a 1/2hp, 90 volt, 1750 rpm DC motor with a Baldor DC drive, (1) Continental Progressing Cavity Ultrapump, model 1CL3-SSQ, serial# CL2682. Driven by a 3/4hp, 3/60/230/460 volt, 1750 rpm XP gear motor, ratio 5.60 to 1, with a plastic feed hopper. (1) Drais Draisewerke control panel with (2) ABB drives, Allen-Bradley SLC 5/03 CPU controller, and an Automation Direct panel. (1) Larox Laboratory Pressure Filter, Model PF 0.1 H2, Serial# T0239, Built 2009, Approximate 0.1 Square Meter. (1) Filter plate approximate 14-1/8" diameter. Includes a 90 liter plastic slurry tank with 0.30kw agitator and PowerFlex drive, mounted on casters, (1) SPX Power Team air hydraulic pump, (1) SC Hydraulic Engineering air driven liquid pump, model 10-4000W003, ratio 5 to 1, serial# 1107509, with a pressing water tank, (1) Wilden plastic diaphragm pump, model P2/PKPPP/NES/NE/PBN/0404, serial# 0020904027, built 2009, (1) Wilden plastic diaphragm pump, model P1/PPPPP/BNS/BN/KBN, serial# 0020883393, built 2008. (1) Ferrari Blower driven by 1.7kW motor. Miscellaneous piping and valves. Mounted on a frame with casters.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory