Process & Packaging Equipment Liquidations In Progress

When a manufacturing facility decides to stop production, often times liquidating the process equipment becomes a difficult undertaking. Expanding on Aaron Equipment Company's 80+ years of experience in packaging and processing equipment sales, we have made businesses that are closing their doors and must vacate their premises on short notice a corporate focus. We also do not allow last-minute desperation to stand in the way of your getting the best cash value for your machinery and equipment.

In fact, when you partner with us in liquidating your equipment, our aim is two fold: (1) We help maximize your Return on Investment (ROI) and (2) We minimize the time in which that ROI occurs. How do we accomplish these goals? Thanks to our long standing track record of buying and selling equipment world wide, we have developed one of the largest detailed customer databases in the industry. As a result, we can leverage both our reputation and experience with both buyers and sellers across a wide range of industries to create tailored asset disposition programs for any company, even on the shortest of notice, regardless of size or number of assets requiring liquidation.

For reliability, speed and superior results, entrust your asset liquidation with the company that equipment and machinery owners have been turning to for more than three-quarters of a century.

Cryogenic storage tanks for sale includes both liquid oxygen and liquid nitrogen options. Cryogenic tanks range in sizes from 1,600 to 50,000 gallons.

Read More ...

Location: California

Used- Joule Thomson Effect, LNG Liquid Natural Gas Extraction and Fractionation Plant

Read More ...

Location: PENNSYLVANIA

Location: Multiple Locations

Candy, Confectionary, Bakery and Food Equipment Liquidation

Read More ...

Location: Multiple Locations

Pharmaceutical / Chemical Processing / Essential Oil Extraction Plant Assets Including Assorted Tanks, Boilers & Chillers, Pumps & Compressors, Dryers, Heat Exchangers, Decanter Centrifuge, Filter Press, and Much More!

Read More ...

Location: Quebec, Canada

Surplus Equipment for the Infant Formula Process

Read More ...

Location:

Nitric Acid Plants and Support Equipment For Sale

Read More ...

Location: Multiple Locations

Surplus Equipment previously used on food Ingredients, Enzymes and Biobased Technologies.

Read More ...

Location: Peoria, IL

During COVID 19, there has been an increased demand for manufacturing retail food products and would like Aaron Equipment and AEK Packaging to be “Your source for food packaging and processing equipment”

Read More ...

Location: Multiple Locations

Location: Ohio

Location: Battle Creek, MI

Location: Belvidere, IL

Recently acquired biofuels - ethanol demonstration pilot plant and we are currently liquidating the assets

Read More ...

Location: Visalia, CA

Consisting of Dispersion Mixers and Sand Media Mills

Read More ...

Location: California

More than 90 tanks ranging in size from 75 Liters to 500 Liters

Read More ...

Location: Belvidere, IL

Consisting of: Dedert Evaporator, Single Effect, Stainless steel. (2) Fluid Quip Mill, Stainless steel, 600 HP. Mason Steel Tank, Approximately 2,500 Gallons. (5) Lochmen Filters, Model RJWCD 92/1200/44 DC. Stainless steel. Alfa Laval Plate Heat Exchanger, 4,604 sqft. Stainless steel. Alfa Laval Plate Heat Exchanger, 659 sqft. Stainless steel.Tank, Approximately 12,000 gallon, Stainless steel. (2) Velo Polishing Filter, Model CFV035, Stainless steel.

Read More ...

Location: Stockton, California

Check out our list of "Unused" Heat Exchangers below. Various Sizes and Materials to choose from.

Read More ...

Location: Bensenville, IL

Bring all reasonable offers, the owner is looking to free up space!

Read More ...

Location: Kankakee, IL

Aaron Equipment Company is over stocked with numerous models of Desludger Disc, Disc Batch, Decanter and Misc. Centrifuges. This provides you with the opportunity to acquire a centrifuge at a tremendously reduced price! This inventory reduction sale is a limited time opportunity on the centrifuges listed on the following pages.

Read More ...

Location: Illinois

View our entire list of complete plants available in Europe.

Read More ...

Location: Multiple Locations

Click here to view recent tanks added to our inventory. Contact an Aaron Sales Pro for more info on our tanks and to request a price quote.

Read More ...

Location: Multiple Locations

Location: Multiple Locations

Location: New Jersey

New- Paul O. Abbe Model RB Ribbon Blenders In Stock!

Read More ...

Location:

Complete Lignocellulosic Biomass Processing Plant Available as Turnkey/Going-Concern, Real Estate also available.

Read More ...

Location: Kearney, Nebraska

Used-Plant Closure Due to Lease Expiration - COGEN Facility. Featuring: (3) 2005 Cummins 1100GQMA-QSV8 1.1MW 2005 Cummins QSV19 334 kW Natural Gas Fired Reciprocating Generators Cummins

Read More ...

Location: Call For Details

6 Available: Used- CSC Les Constructions Soudees Du Coteau, Holding Tank. 26,980 Gallon, 316 Stainless Steel, Vertical. Cone Top,

Location:

Used- Criveller Ganimede Fermentation Tanks, 5.5 Ton and 7 Ton Capacity available.

Location: New York

Kraft Heinz Wet Mix Cheese Floor @ MDG Auction Showroom v2.0 – Most Major Items Immediately Available Prior to Auction

Location: Monroeville, PA

“Everything must go to make room for expansion!

Location: Ontario, Canada

Unused / Uninstalled - Clayton Industries Model EOG-404-1 Steam Generator. 400HP. Equivalent steam output 13,800 pph. Design pressure 150 psig. Operating pressure 75-125 psig. Fuel: natural gas or diesel #2 light oil. Monotube heating coil with integral burner base. Steam separator (ASME stamped) with safety relief valves. Serial# 25716, with E404/504 Water Pump. Inspected by Clayton Industries.

Location: New Jersey

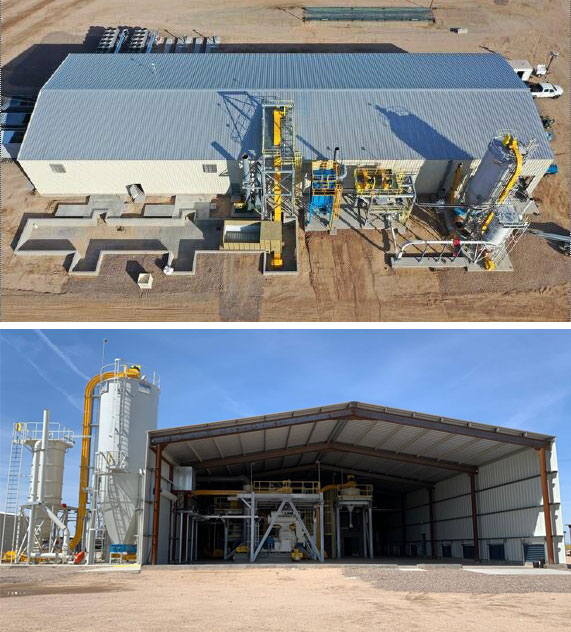

Used – Next Generation, Advantaged Renewable Energy Plant consisting of; 3 MMGY Renewable Diesel Production Facility and 2 MMGY Biodiesel Production Facility. Renewable Diesel Facility Produces 3%-5% Naphtha, and 5%-10% Propane and meets ASTM D975 Standard. Biodiesel Facility Produces 82.8% Biodiesel Yield from Corn Oil Feedstock, Fats, Oils and Greases (FOG), and meets ASTM D6751 Standard.

Location: Sedgwick, Kansas

Used-Complete 300TPD Nitrogen Liquefaction Plant. Includes: Gaseous Nitrogen Plant / N2 rated @ 250,000 SCFH (standard cuft / hour) Includes: Reversing Gaseous Nitrogen Plant rate @ 100,000 SCFH and 300TPD Nitrogen Liquefier. Serious inquiries. Located in Strathmore, Alberta, Canada. Please request technical data from an Aaron Equipment representative.

Location: Calgary, Alberta Canada

Used- C02 Plant, 165 tpd. Serious inquiries. Located in Empress, Alberta, Canada. Please request technical data from an Aaron Equipment representative.

Location: Calgary, Alberta Canada

Used- C02 Plant, 320 tpd. Serious inquiries. Located in Elmworth, Alberta, Canada. Please request technical data from an Aaron Equipment representative.

Location: Calgary, Alberta Canada

Used- C02 Dehydration and Liquefaction Plant. Rated 295 MTPD. Built to operate through temperatures ranging from -40 to +95 degrees F. 720 tonnes of on-site storage capacity (2 vessels). Fully automated 3-rack loading system. Commissioned late August 2009.

Location: Saskatchewan, Canada

.jpg)

Location: Kawaihae, HI

Carbon Steel Tanks ranging from 1000 gallons to 10,000

Location: Illinois

Used-Cannabis Drying Facility consisting of the following: Metering Bin. 6' wide x Approximately 20' long x 9' High.

Location: Arizona

Surplus to Ongoing Operations of Western Reserve Water Systems, Inc.

Location: Cleveland, OH

SURPLUS DUE TO PLANT CAPACITY UPGRADES – 4 Lines Available. Total Equipment Capacity rated at 600,000 TPY

Location: Arkansas

80 Items Available...Including Ozone Generators, Sheed Coating Printers, Custom Dryer Box Systems, Unused Rubber Belt Conveyors, Unused Hemp Robotics Cannons, Unused Heating Units and Much More!

Location: United States

Consiting of (1) Double Cone Dryer, (1) Stainless Steel Kettle / Tank, and (2) Markem Ink Jet Coders.

Location: Florida

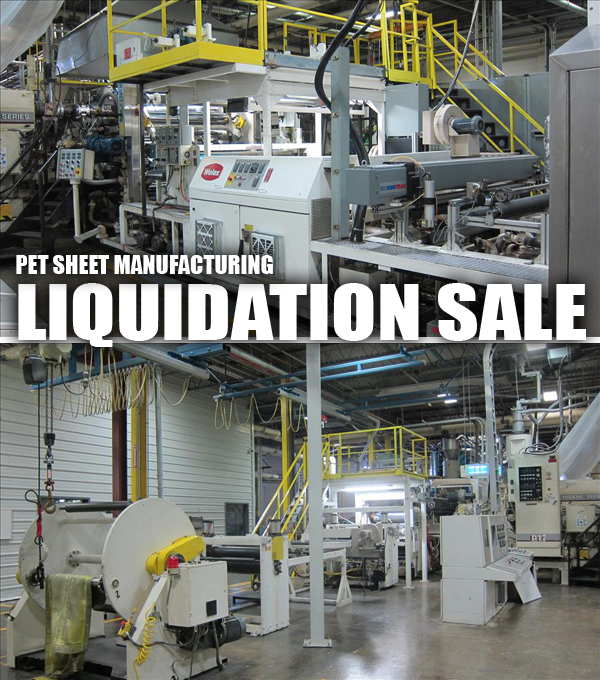

Complete Plant for Sale: PET Sheet Manufacturing Equipment

Location: Illinois

Used- Complete Bio-Refinery. Biological Safety Level 1 (BSL-1). Fermentation based manufacturing plant which is capable of producing various bio-chemicals by fermentation processes or possibly catalytic or enzymatic.

Location: Lake Providence, LA

Process and Packaging equipment consisting of:Blanchers/Cookers, Air Compressors, Belt and Vibratory Conveyors, Freeze Tunnels, Heat Exchangers, Pumps, Screeners, Tanks and more.

Location: Salem, Oregon

Consisting of (10) 1980 sq. ft. and (18) 2454 sq. ft. Spiral Heat Exchangers

Location: Alberta, Canada

The plant was a former Biofuels business that was a joint venture between BP and Verenium. The plant was built to validate various technology platforms to apply to all types of biofuel business segments. Original cost of 98 million dollars. Located in Jennings, LA on over 40 acres including facilities.

Location: Jennings, LA

10,000,000 gallons per year from soybean oil. Plant also ran corn oil tests at 4,000,000 gallons per year.

Location: Clinton, Iowa

Location:

Surplus Equipment used to Manufacture ABS (Acrylonitrile Butadiene Styrene) including: Volumetric Screw Feeders, Stainkless Steel Screw Feeders, Banbury Mixers, Single Screw Dump Extruders, Two Roll Mills and More...

Location: Ottawa, IL

Biochemical Plant Liquidation. Stainless steel Reactors and Heat Exchangers (Not used on penicillin or cephalosporin)

Location: Indiana

Surplus Equipment to the Continuing Operations of Midwestern Pet Foods consisting of: Paddle Blenders, Ribbon Blenders, Mixers, Hammer Mills, Shredders, Kettles, Generator, Case Erectors, Case Packers, Box Tapers, Tray Formers, Fillers, Conveyors, Storevetors, Feeders, Bins and more!

Location: Monmouth, Illinois

Location: Farmington Hills, MI

Location:

Location:

Location:

Location:

Location:

Surplus assets to the ongoing operations of Little Lady Foods. Primarliy in production of frozen pizza, frozen sandwiches, frozen pizza bread.

Location: Bensenville, IL / Belvidere, IL

Featuring: 1,000's of Lots of Chemical Processing and Plant Support Equipment, including 100s of Stainless Steel Tanks

Location: Bensenville, IL

A world leading pharmaceutical company. Available packaging equipment including fillers, bundlers, blister cartoners, tray packers, blister card equipment, wrappers and more...

Location:

Location:

(Not used on penicillin or cephalosporin)

Location: Indiana

Coating Pans, Twin Shell V-Blenders, Stainless Steel Bins, Fette Rotary Tablet Presses, Fluid Bed Dryers, Granulating Mixers, Tablet Coaters, and much more...

Location:

Location: Ada, Michigan

Stainless Steel Reactors from Bio-chemical Plant for Sale

Location: Memphis, TN

Including: Ribbon Blenders, Heat Exchangers, Vibratory Shakers, Conveyors, American Can Closing Machines, Solbern Fillers, Centrifugal and Positive Displacement Pumps, continuous Retorts, Stainless Steel Tanks and more.

Location: Oregon

Aaron Equipment Company in conjunction with Earl Corporate Advisors, LLC (“Earl”) is selling the assets and business of a consumer dental products company.The Company manufactures flosses and creams for global consumer health care businesses.

Location: Stafford, TX

Potato Chip Manufacturing Facility for Sale. Highlighted Equipment Below. Call Your Aaron Equipment Sales Rep for a Complete List of Additional Machinery.

Location: Minnesota

Location: Belvidere, IL

Plow Mixers Ready for Immediate Delivery

Location: Multiple Locations

![Image[1].jpg](https://www.aaronequipment.com/images/LiquidationImages/Image[1].jpg)