Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

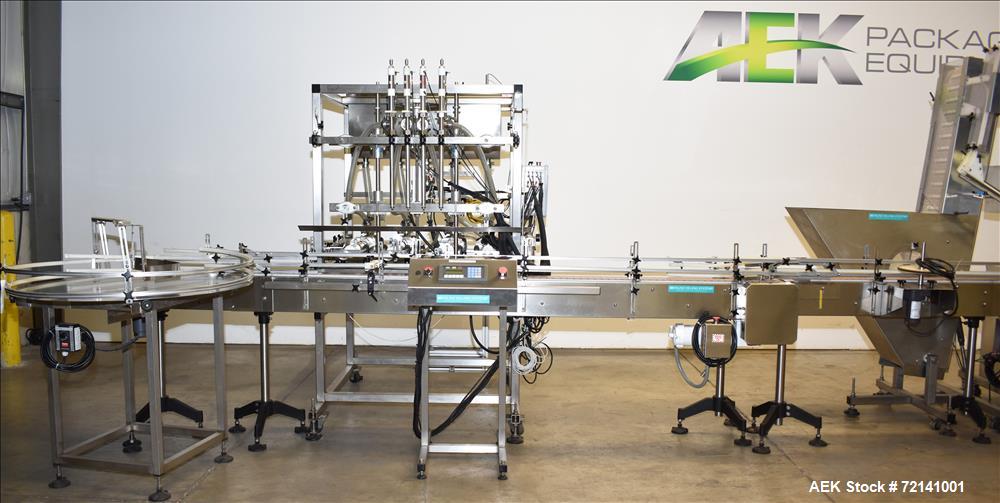

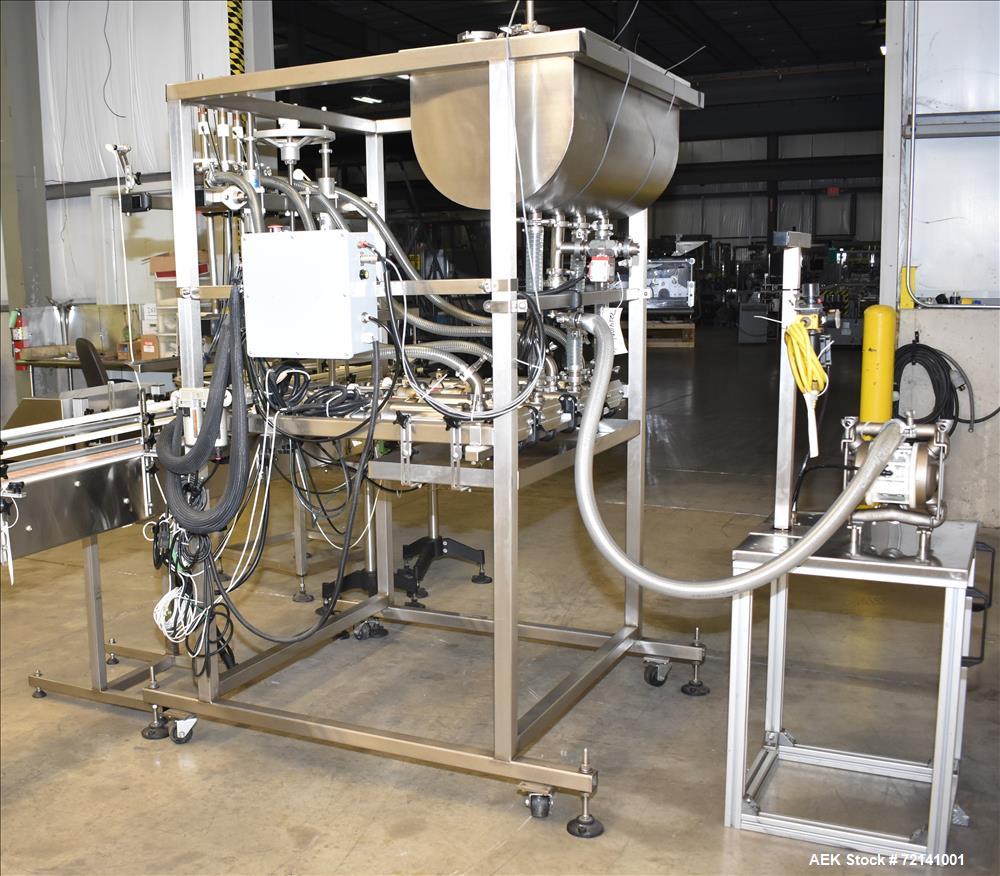

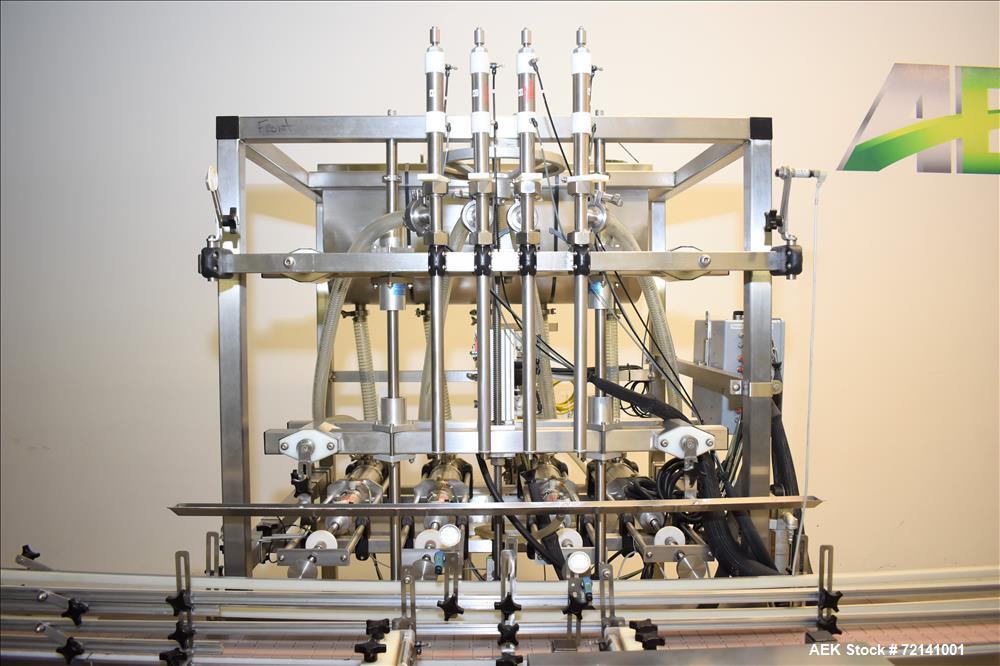

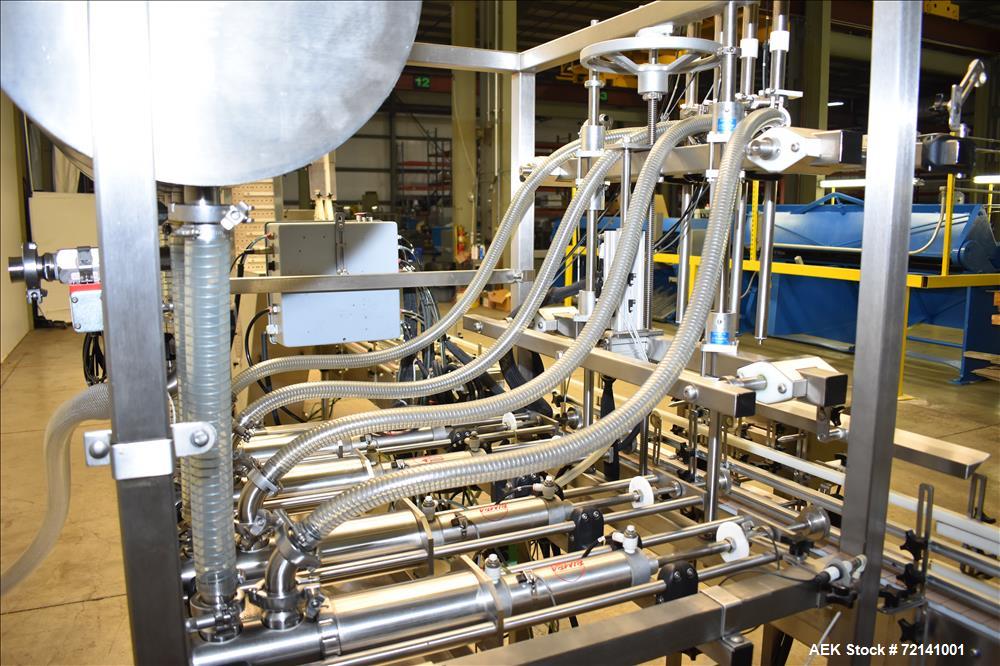

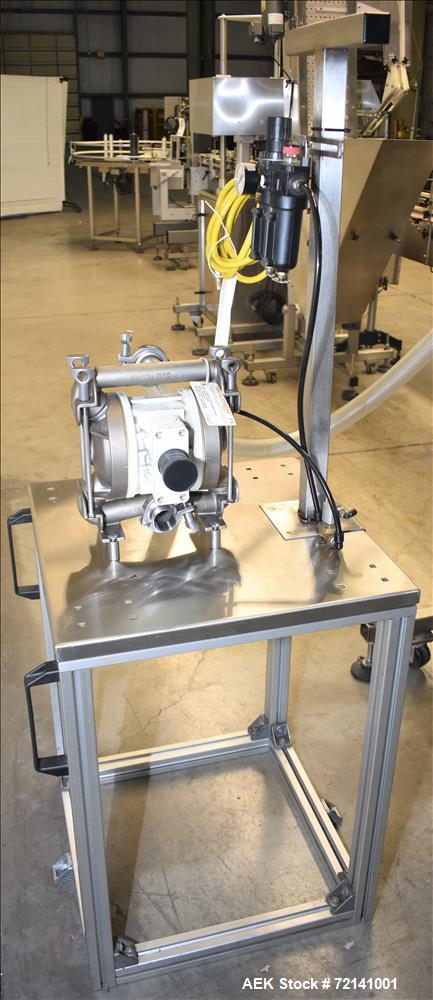

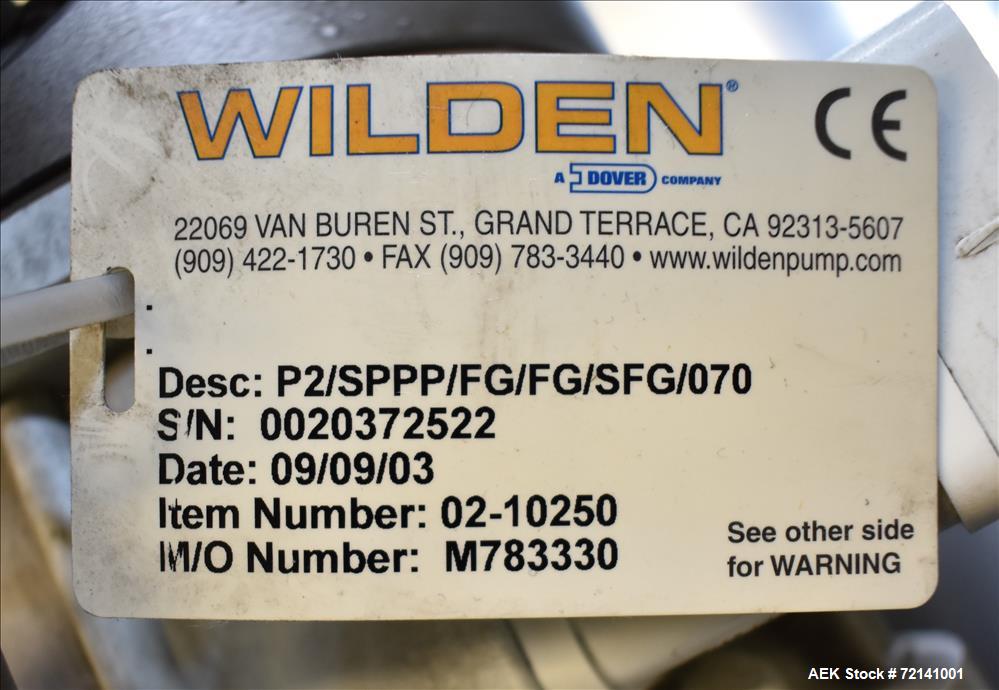

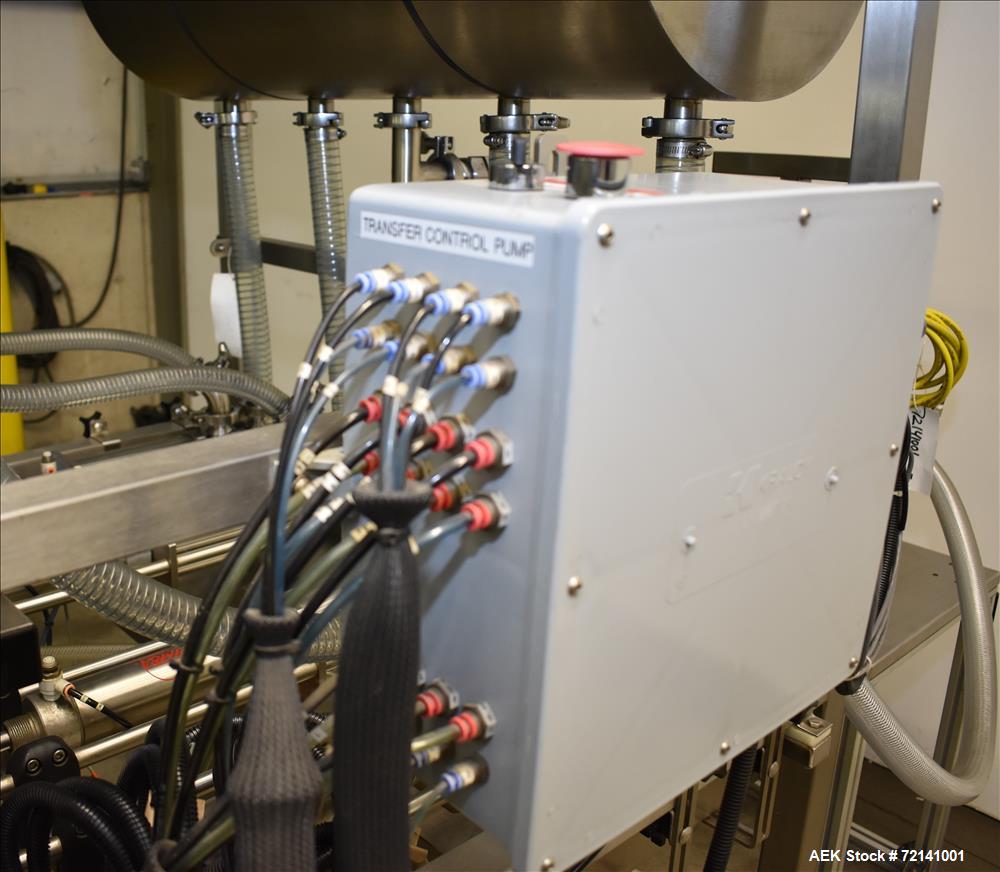

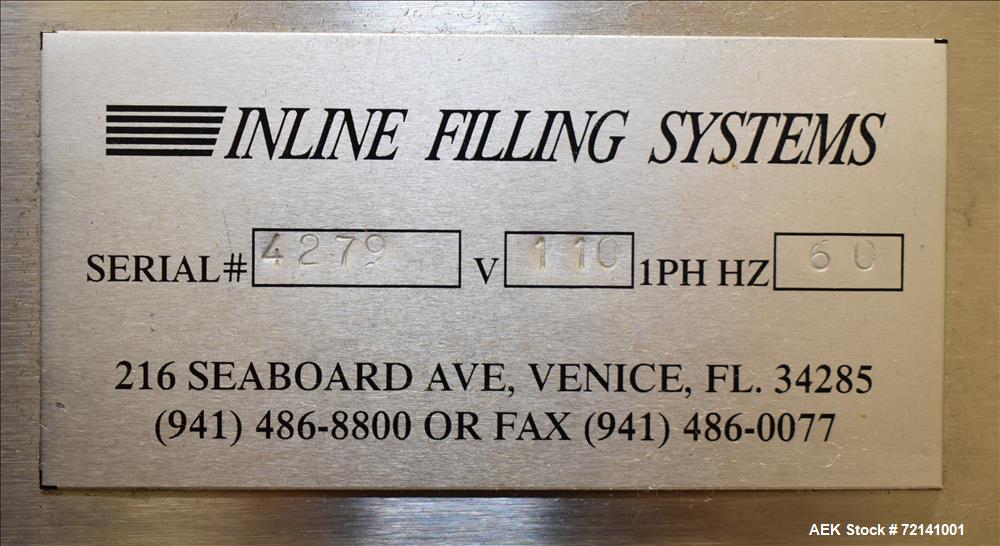

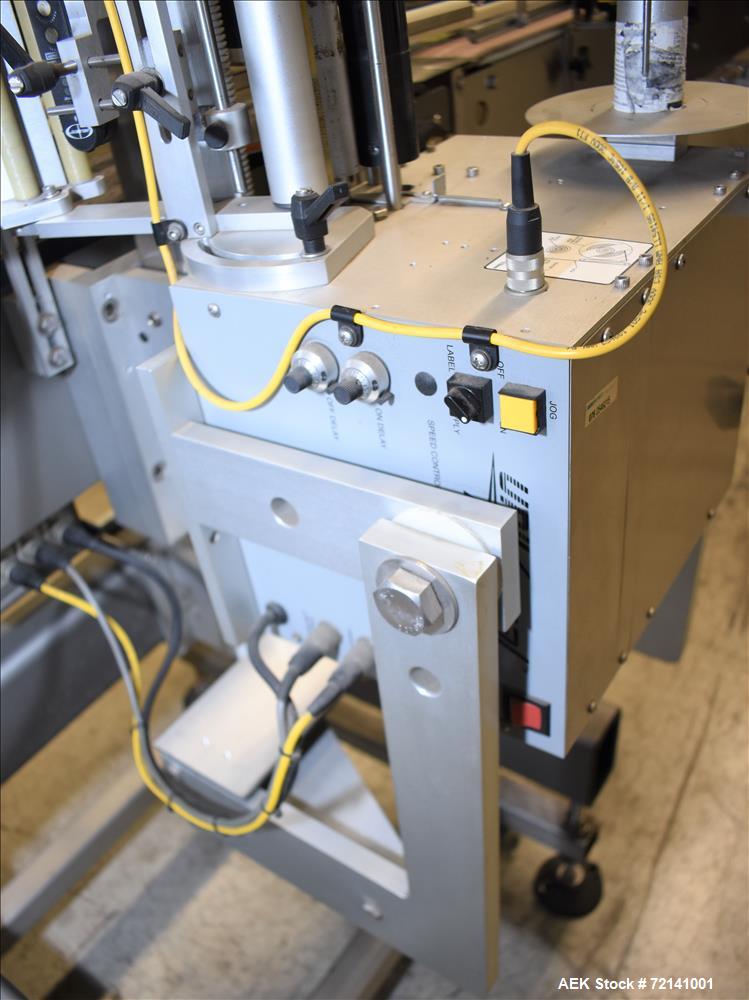

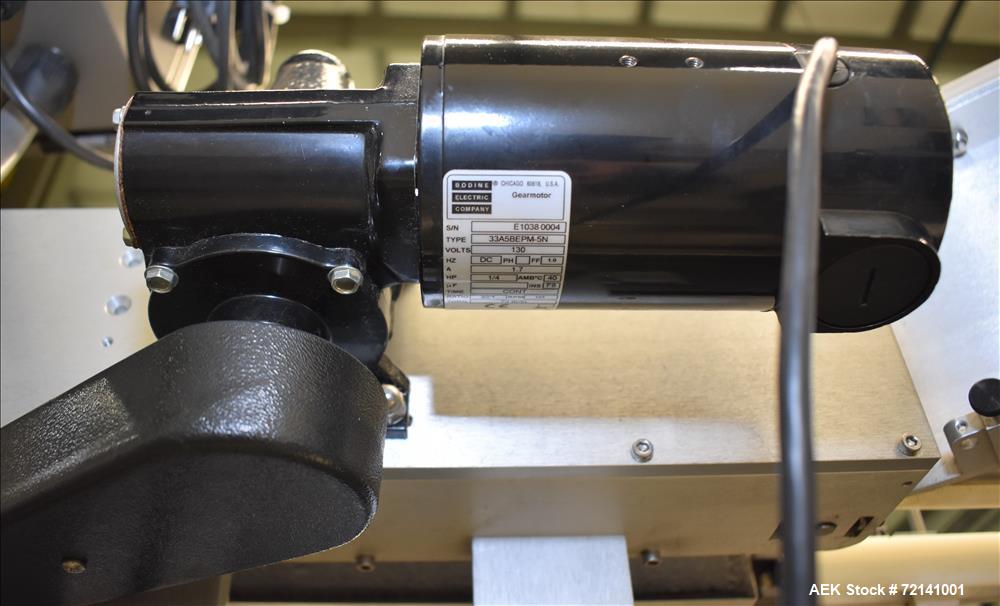

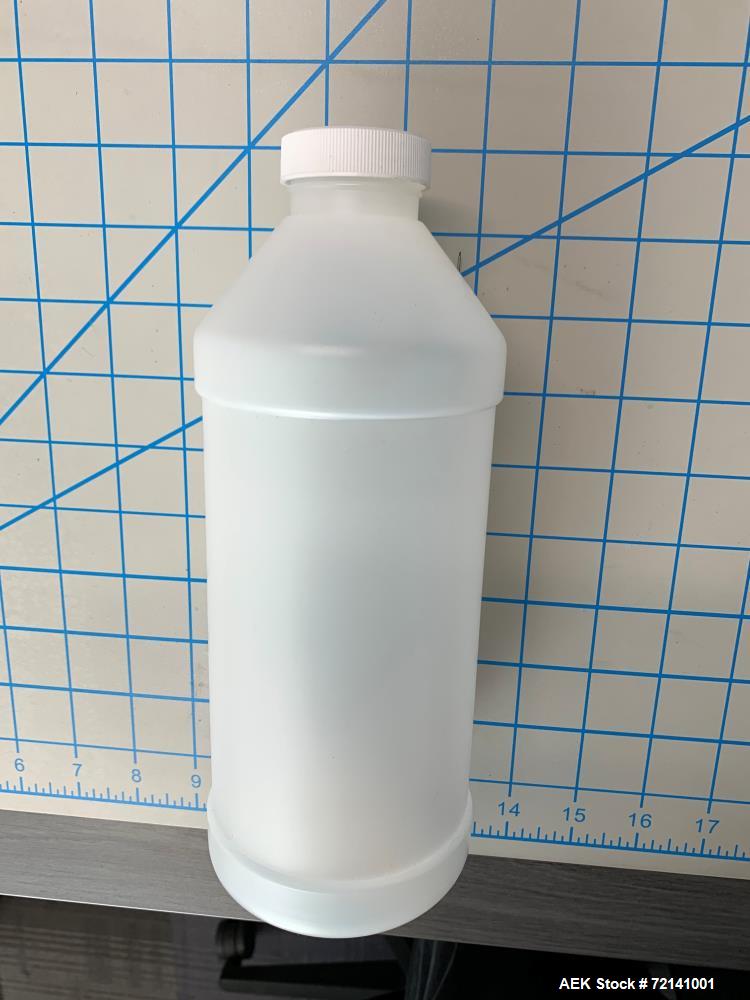

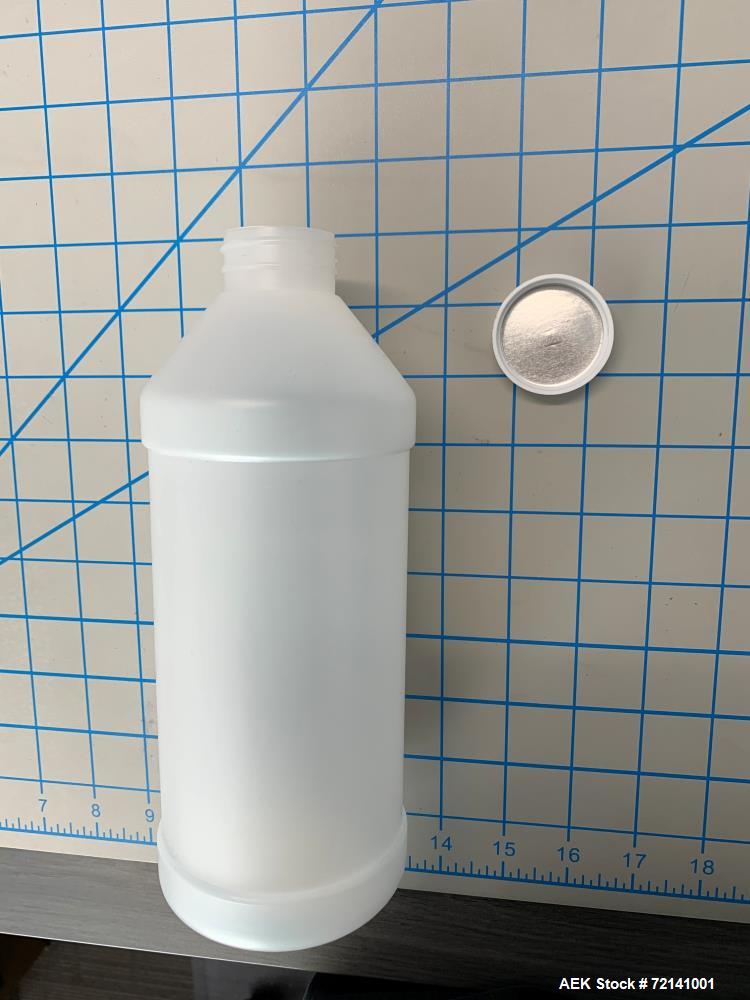

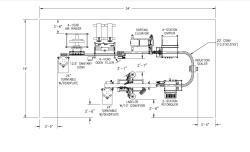

Used Inline Filling Systems Complete Positive Displacement Piston Filling Line.

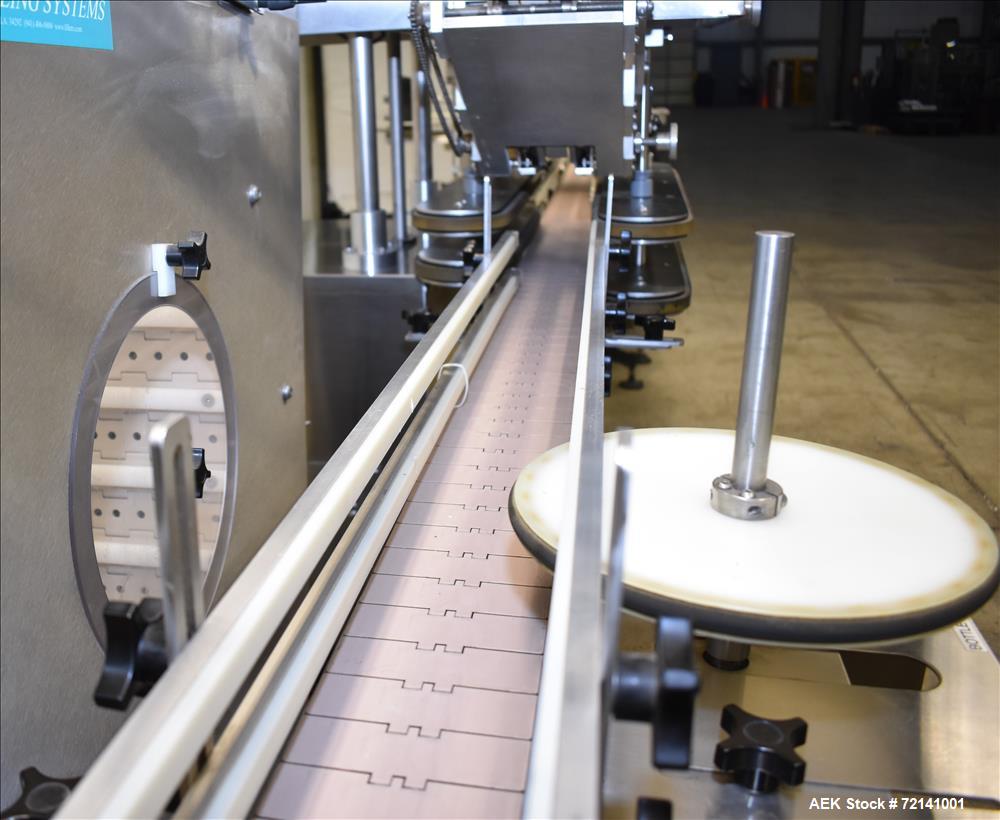

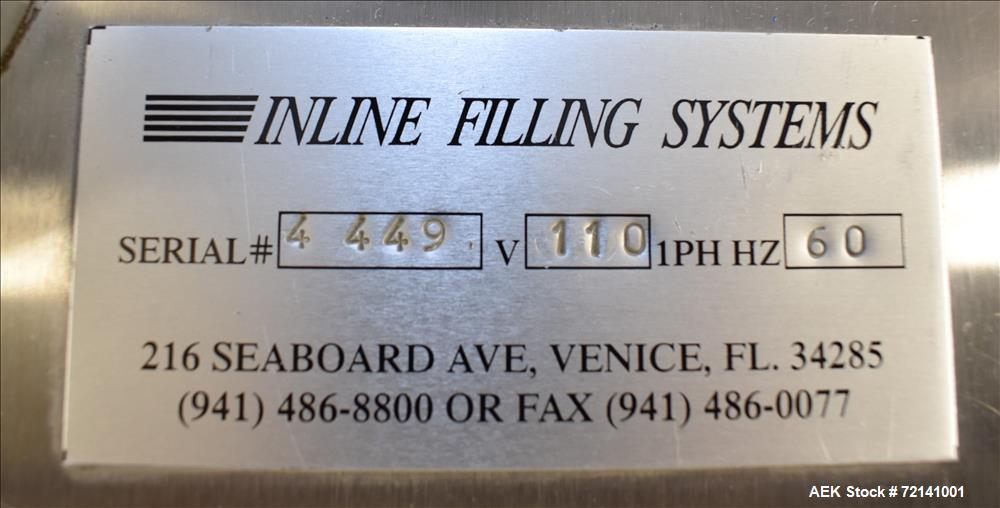

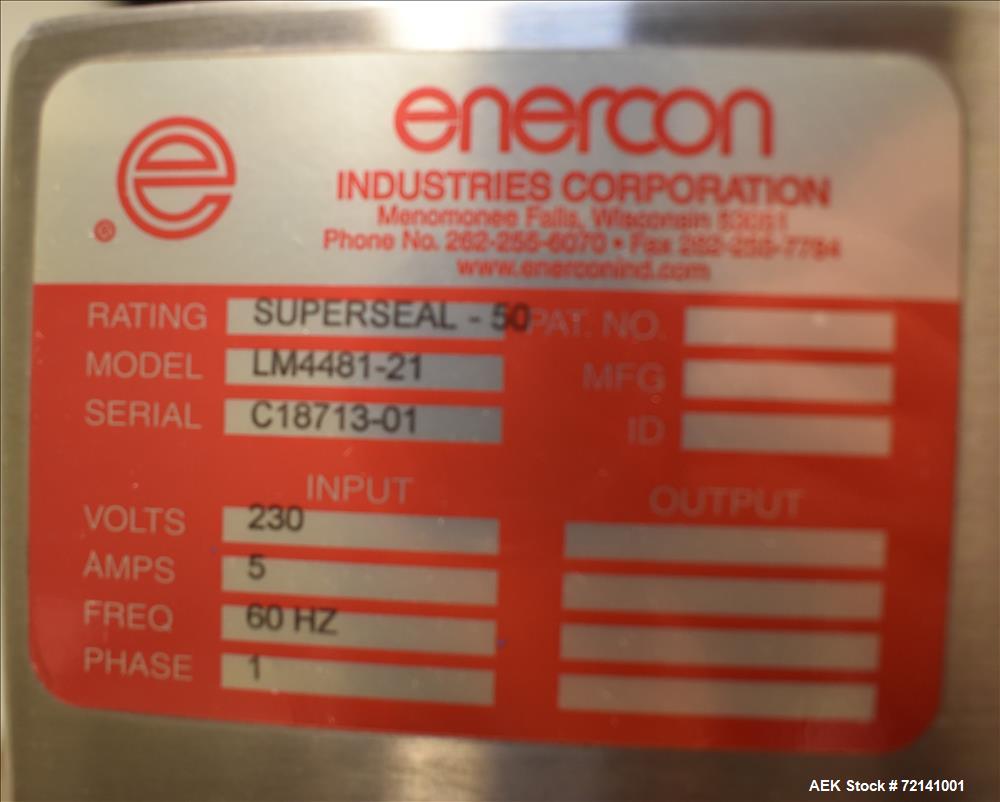

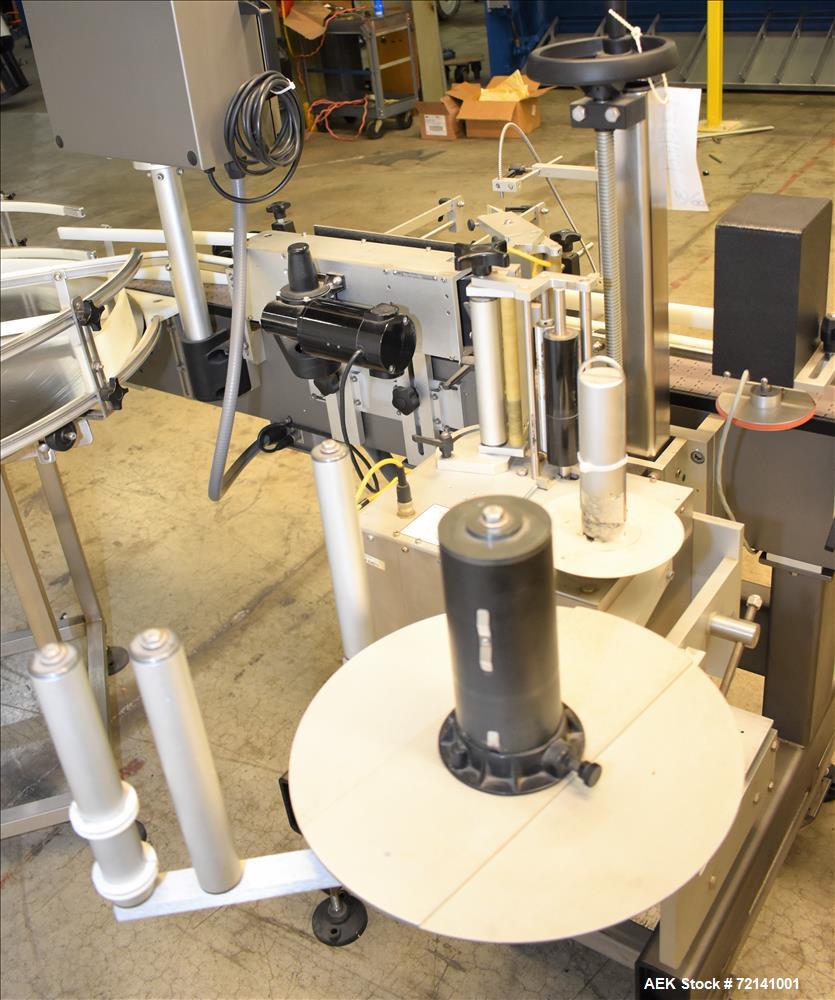

Used Inline Filling Systems Positive Displacement Piston Filling Line. Consisting of: Inline Filling 46" diameter rotary stainless steel feed disc, Inline Filling 4 head piston filler with 1" diameter positive shut off nozzles, drip tray, 32 oz pistons, with pin indexing of container, Inline Filling Systems belt style capper with dual belt container grippers and cleated belt cap elevator and sorter, Enercon air cooled tamper evident induction sealer, Universal Mfg wraparound pressure sensitive labeler with 6" high label unwind and 16" long wrap belt, and Inline Filling System 46" diameter stainless steel accumulation disc. Filler/ capper/ induction sealer utilize 4-1/2" wide x 26' long table top chain conveyors with transfer to labeler 6" wide x 6' long conveyor, for total line length of 32'. Inline Systems mfg machinery uses 1/60/115, Enercon uses 1/60/230. Universal Labeler uses 1/60/115, 90 psi compressed air required. Last filling Polydimythylsilozane based product.

Used Inline Filling Systems Positive Displacement Piston Filling Line. Consisting of: Inline Filling 46" diameter rotary stainless steel feed disc, Inline Filling 4 head piston filler with 1" diameter positive shut off nozzles, drip tray, 32 oz pistons, with pin indexing of container, Inline Filling Systems belt style capper with dual belt container grippers and cleated belt cap elevator and sorter, Enercon air cooled tamper evident induction sealer, Universal Mfg wraparound pressure sensitive labeler with 6" high label unwind and 16" long wrap belt, and Inline Filling System 46" diameter stainless steel accumulation disc. Filler/ capper/ induction sealer utilize 4-1/2" wide x 26' long table top chain conveyors with transfer to labeler 6" wide x 6' long conveyor, for total line length of 32'. Inline Systems mfg machinery uses 1/60/115, Enercon uses 1/60/230. Universal Labeler uses 1/60/115, 90 psi compressed air required. Last filling Polydimythylsilozane based product.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory