Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Unused Oden Servo/Fill Positive Displacement Filling Line – Complete Turnkey Packaging System (Never In Production)

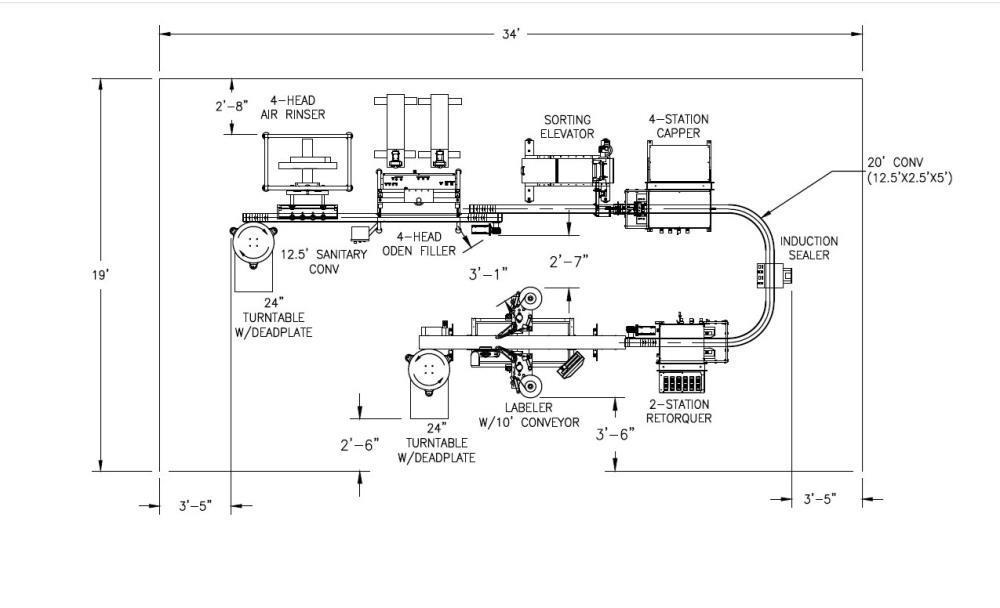

Unused Oden Servo/Fill Positive Displacement Filling Line. Line consists of an E-Pak 24" diameter stainless steel feed turntable, in an E-Pak 12.5" L sanitary rinser conveyor with E-Pak 4 head air rinser, into Oden Servo/Fill 2 Head Sanitary Gear Pump Filler (Expandable Option Ordered For 4 Pumps) With Gen 6 Proface HMI, 316 SS Contact Parts, Bottom Up / Diving Type Filling Nozzles, E-Pak 12.5' Long Sanitary Rinser/Filler Conveyor, E-Pak Automatic 4 Station, 8 Quill Capper, E-Pak Curved Sanitary Capper Conveyor, Enercon Super Seal Induciton Sealer, E-Pak Automatic 2-Station, 4-Quill Retorquer/Cap Tightener, NITAModel XP200 Front and Back Pressure Sensitive Front and Back and Wrapround Labeler with Top Hold Down Belt, Bottle Infeed Spacer Wheel and Aligner, Wrap Belt for Wrap Application, Integral 10 Ft. L Conveyor, 7" Tall Label Option Video Jet Automatic Small Character Ink Jet Printer Model #1520, E-Pak 24" Accumulation Turntable Line was purchased new in 2016 and never ran production.

| Manufacturer | OdenOden |

| Model | Proface Gear Pump |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Complete Packaging Line - Liquid - PasteComplete Packaging Line - Liquid - Paste |

Manufacturer Information

-

Primary Filler Manufacturer: Oden Machinery

-

Filler Type: Servo/Fill Positive Displacement Gear Pump Filler

-

HMI: Gen 6 Proface

-

Contact Parts: 316 Stainless Steel

-

Line Year: Purchased New in 2016

-

Condition: Unused – Never Ran Production

Description

This Unused Oden Servo/Fill Positive Displacement Filling Line is a fully integrated, sanitary, turnkey liquid packaging system purchased new in 2016 and never placed into production. Designed for high-accuracy filling of liquids ranging from thin to viscous products, the line incorporates premium OEM components for rinsing, filling, capping, induction sealing, labeling, coding, and accumulation.

The heart of the system is an Oden 2-Head Servo/Fill Sanitary Gear Pump Filler, expandable to 4 pumps, featuring 316 stainless steel contact parts, bottom-up/diving fill nozzles, and a Gen 6 Proface HMI for precision control and repeatability.

The line includes E-Pak conveyors and packaging equipment, an Enercon Super Seal induction sealer, NITA XP200 pressure sensitive labeler, and a Videojet 1520 inkjet coder, creating a complete infeed-to-accumulation solution ready for integration.

Ideal for food, beverage, pharmaceutical, cosmetic, and chemical liquid packaging applications requiring sanitary design and fill accuracy.

Line Components

Infeed & Rinsing

-

E-Pak 24" Diameter Stainless Steel Feed Turntable

-

E-Pak 12.5' Sanitary Rinser Conveyor

-

E-Pak 4-Head Air Rinser

Filling System

-

Oden Servo/Fill 2-Head Sanitary Gear Pump Filler

-

Expandable to 4 pumps (option ordered)

-

316 SS contact parts

-

Bottom-up / diving nozzles

-

Gen 6 Proface HMI

-

Capping & Sealing

-

E-Pak Automatic 4-Station, 8-Quill Capper

-

E-Pak Curved Sanitary Capper Conveyor

-

Enercon Super Seal Induction Sealer

-

E-Pak Automatic 2-Station, 4-Quill Retorquer/Cap Tightener

Labeling & Coding

-

NITA XP200 Labeler

-

Front & back pressure sensitive

-

Wraparound capability

-

Top hold-down belt

-

Bottle infeed spacer wheel & aligner

-

Wrap belt application

-

Integral 10’ conveyor

-

7” tall label option

-

-

Videojet Model 1520 Inkjet Printer

-

Automatic small character coding

-

Discharge

-

E-Pak 24" Accumulation Turntable

Applications

-

Food and beverage bottling

-

Pharmaceutical liquid filling

-

Cosmetic and personal care packaging

-

Chemical liquid packaging

-

Nutraceutical production

What Might This Be Used For

This turnkey filling line is designed for accurate sanitary filling, capping, sealing, labeling, and coding of liquid products in bottles or containers, particularly in regulated or high-precision environments.

Products This Equipment Is Used For

-

Sauces and dressings

-

Syrups

-

Oils

-

Cleaning solutions

-

Hand sanitizers

-

Cosmetic lotions

-

Liquid supplements

-

Pharmaceuticals

-

Industrial chemicals

-

Specialty liquids

-

Filling line

-

Oden filler

-

Servo filler

-

Gear pump filler

-

Bottling line

-

Liquid filling line

-

Used filling line

-

Packaging line

-

Turnkey filling system

-

Sanitary filler

-

Filling line

-

Oden filler

-

Servo filler

-

Gear pump filler

-

Bottling line

-

Liquid filling line

-

Used filling line

-

Packaging line

-

Turnkey filling system

-

Sanitary filler

-

Unused Oden Servo Fill line

-

Positive displacement filling line

-

Sanitary gear pump filler

-

Complete liquid bottling line

-

Automatic filling and capping line

-

Food grade liquid packaging line

-

4 head expandable filler

-

Enercon induction sealer line

-

NITA XP200 labeling system

-

Servo driven liquid filler

-

Buy Oden filling line

-

Unused liquid bottling line for sale

-

Purchase servo gear pump filler

-

Buy turnkey liquid packaging system

-

Automatic filling and capping line price

-

Sanitary liquid filling line supplier

-

Complete bottling line for sale

-

Food grade liquid packaging equipment

-

Expandable servo filler

-

Industrial filling line 2016

-

Buy Oden filling line

-

Unused liquid bottling line for sale

-

Purchase servo gear pump filler

-

Buy turnkey liquid packaging system

-

Automatic filling and capping line price

-

Sanitary liquid filling line supplier

-

Complete bottling line for sale

-

Food grade liquid packaging equipment

-

Expandable servo filler

-

Industrial filling line 2016

Unused Oden Servo/Fill Positive Displacement Filling Line. Line consists of an E-Pak 24" diameter stainless steel feed turntable, in an E-Pak 12.5" L sanitary rinser conveyor with E-Pak 4 head air rinser, into Oden Servo/Fill 2 Head Sanitary Gear Pump Filler (Expandable Option Ordered For 4 Pumps) With Gen 6 Proface HMI, 316 SS Contact Parts, Bottom Up / Diving Type Filling Nozzles, E-Pak 12.5' Long Sanitary Rinser/Filler Conveyor, E-Pak Automatic 4 Station, 8 Quill Capper, E-Pak Curved Sanitary Capper Conveyor, Enercon Super Seal Induciton Sealer, E-Pak Automatic 2-Station, 4-Quill Retorquer/Cap Tightener, NITAModel XP200 Front and Back Pressure Sensitive Front and Back and Wrapround Labeler with Top Hold Down Belt, Bottle Infeed Spacer Wheel and Aligner, Wrap Belt for Wrap Application, Integral 10 Ft. L Conveyor, 7" Tall Label Option Video Jet Automatic Small Character Ink Jet Printer Model #1520, E-Pak 24" Accumulation Turntable Line was purchased new in 2016 and never ran production.

Manufacturer Information

-

Primary Filler Manufacturer: Oden Machinery

-

Filler Type: Servo/Fill Positive Displacement Gear Pump Filler

-

HMI: Gen 6 Proface

-

Contact Parts: 316 Stainless Steel

-

Line Year: Purchased New in 2016

-

Condition: Unused – Never Ran Production

Description

This Unused Oden Servo/Fill Positive Displacement Filling Line is a fully integrated, sanitary, turnkey liquid packaging system purchased new in 2016 and never placed into production. Designed for high-accuracy filling of liquids ranging from thin to viscous products, the line incorporates premium OEM components for rinsing, filling, capping, induction sealing, labeling, coding, and accumulation.

The heart of the system is an Oden 2-Head Servo/Fill Sanitary Gear Pump Filler, expandable to 4 pumps, featuring 316 stainless steel contact parts, bottom-up/diving fill nozzles, and a Gen 6 Proface HMI for precision control and repeatability.

The line includes E-Pak conveyors and packaging equipment, an Enercon Super Seal induction sealer, NITA XP200 pressure sensitive labeler, and a Videojet 1520 inkjet coder, creating a complete infeed-to-accumulation solution ready for integration.

Ideal for food, beverage, pharmaceutical, cosmetic, and chemical liquid packaging applications requiring sanitary design and fill accuracy.

Line Components

Infeed & Rinsing

-

E-Pak 24" Diameter Stainless Steel Feed Turntable

-

E-Pak 12.5' Sanitary Rinser Conveyor

-

E-Pak 4-Head Air Rinser

Filling System

-

Oden Servo/Fill 2-Head Sanitary Gear Pump Filler

-

Expandable to 4 pumps (option ordered)

-

316 SS contact parts

-

Bottom-up / diving nozzles

-

Gen 6 Proface HMI

-

Capping & Sealing

-

E-Pak Automatic 4-Station, 8-Quill Capper

-

E-Pak Curved Sanitary Capper Conveyor

-

Enercon Super Seal Induction Sealer

-

E-Pak Automatic 2-Station, 4-Quill Retorquer/Cap Tightener

Labeling & Coding

-

NITA XP200 Labeler

-

Front & back pressure sensitive

-

Wraparound capability

-

Top hold-down belt

-

Bottle infeed spacer wheel & aligner

-

Wrap belt application

-

Integral 10’ conveyor

-

7” tall label option

-

-

Videojet Model 1520 Inkjet Printer

-

Automatic small character coding

-

Discharge

-

E-Pak 24" Accumulation Turntable

Applications

-

Food and beverage bottling

-

Pharmaceutical liquid filling

-

Cosmetic and personal care packaging

-

Chemical liquid packaging

-

Nutraceutical production

What Might This Be Used For

This turnkey filling line is designed for accurate sanitary filling, capping, sealing, labeling, and coding of liquid products in bottles or containers, particularly in regulated or high-precision environments.

Products This Equipment Is Used For

-

Sauces and dressings

-

Syrups

-

Oils

-

Cleaning solutions

-

Hand sanitizers

-

Cosmetic lotions

-

Liquid supplements

-

Pharmaceuticals

-

Industrial chemicals

-

Specialty liquids

| Manufacturer | Oden |

| Model | Proface Gear Pump |

| Category | Packaging Equipment |

| Subcategory | Complete Packaging Line - Liquid - Paste |

-

Filling line

-

Oden filler

-

Servo filler

-

Gear pump filler

-

Bottling line

-

Liquid filling line

-

Used filling line

-

Packaging line

-

Turnkey filling system

-

Sanitary filler

-

Filling line

-

Oden filler

-

Servo filler

-

Gear pump filler

-

Bottling line

-

Liquid filling line

-

Used filling line

-

Packaging line

-

Turnkey filling system

-

Sanitary filler

-

Unused Oden Servo Fill line

-

Positive displacement filling line

-

Sanitary gear pump filler

-

Complete liquid bottling line

-

Automatic filling and capping line

-

Food grade liquid packaging line

-

4 head expandable filler

-

Enercon induction sealer line

-

NITA XP200 labeling system

-

Servo driven liquid filler

-

Buy Oden filling line

-

Unused liquid bottling line for sale

-

Purchase servo gear pump filler

-

Buy turnkey liquid packaging system

-

Automatic filling and capping line price

-

Sanitary liquid filling line supplier

-

Complete bottling line for sale

-

Food grade liquid packaging equipment

-

Expandable servo filler

-

Industrial filling line 2016

-

Buy Oden filling line

-

Unused liquid bottling line for sale

-

Purchase servo gear pump filler

-

Buy turnkey liquid packaging system

-

Automatic filling and capping line price

-

Sanitary liquid filling line supplier

-

Complete bottling line for sale

-

Food grade liquid packaging equipment

-

Expandable servo filler

-

Industrial filling line 2016

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory