Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

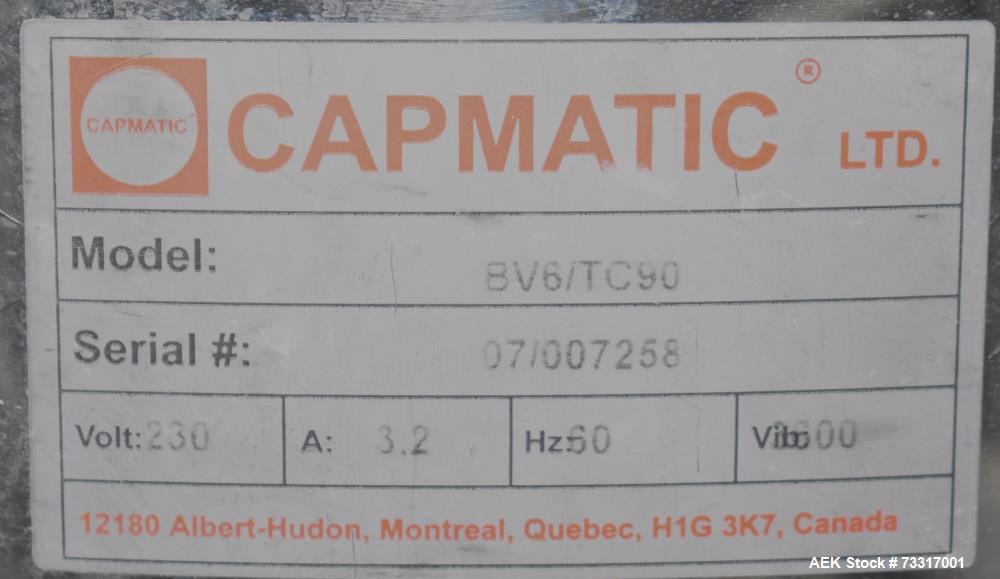

Used Capmatic Intrepid Model 4A/X-PP-222 Monoblock Filler, Plugger & Capper – 60 CPM Capacity

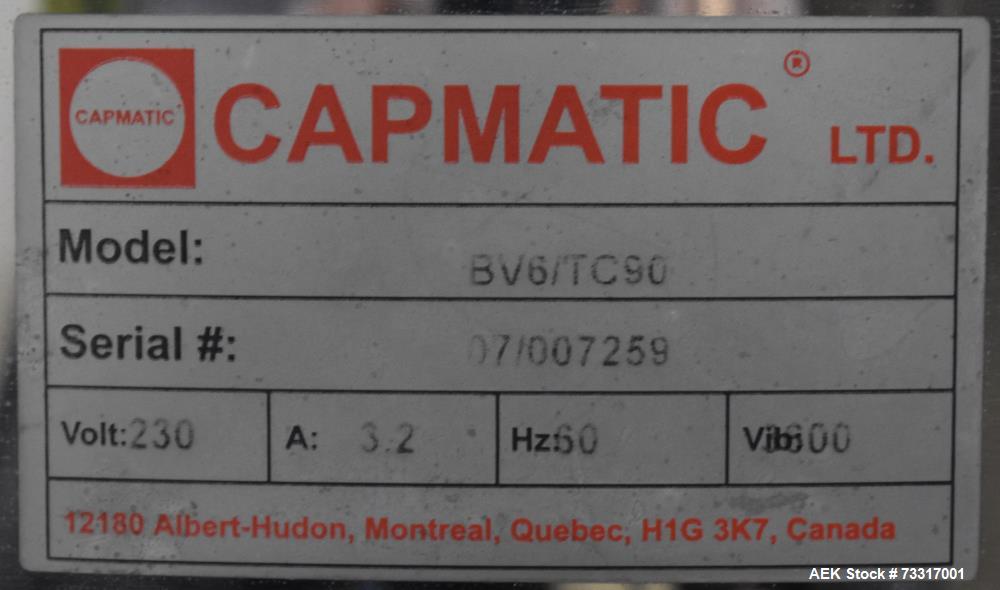

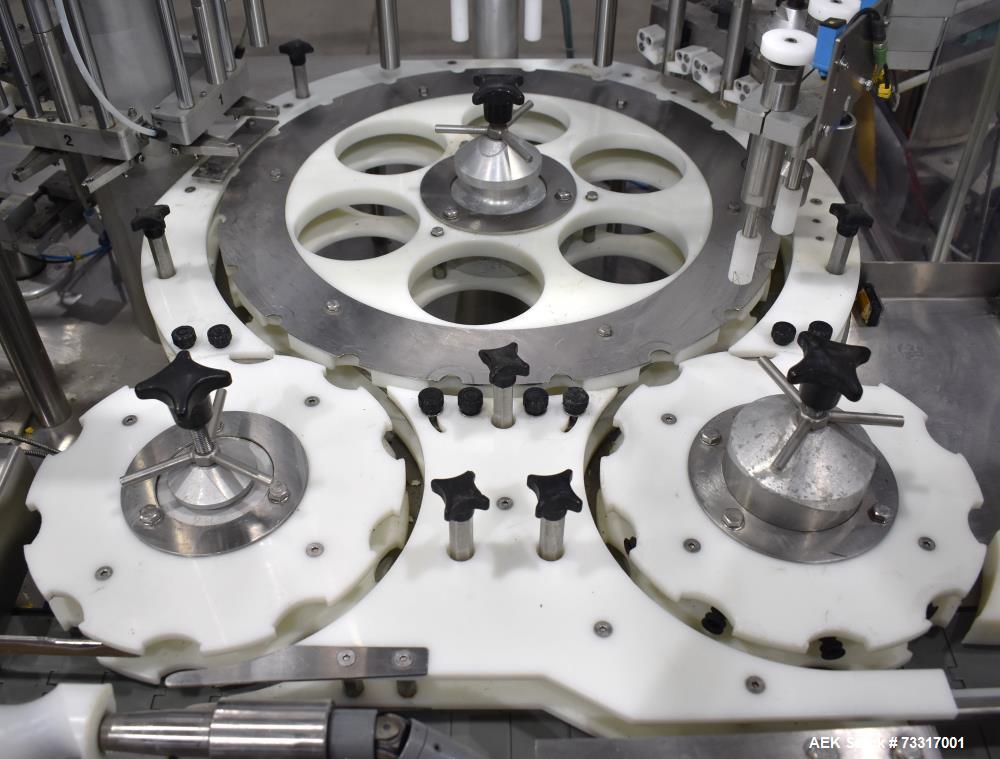

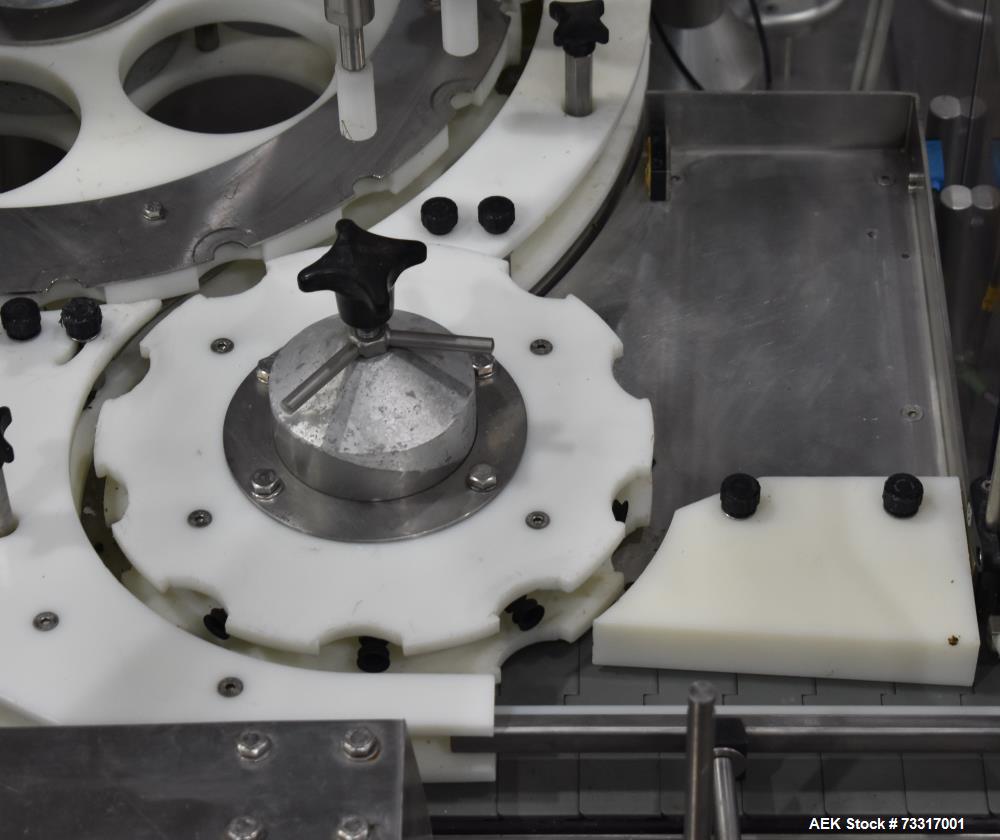

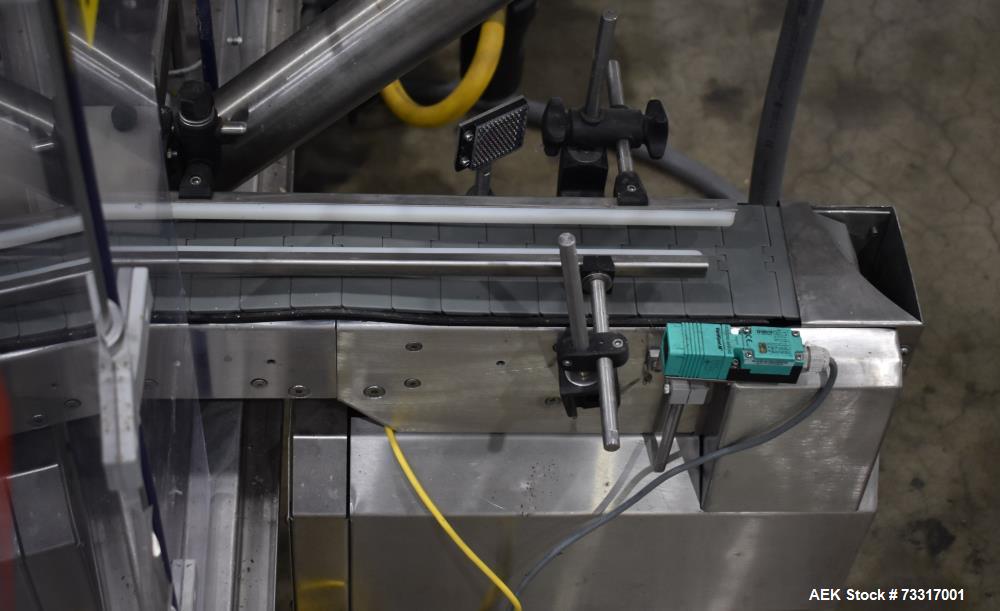

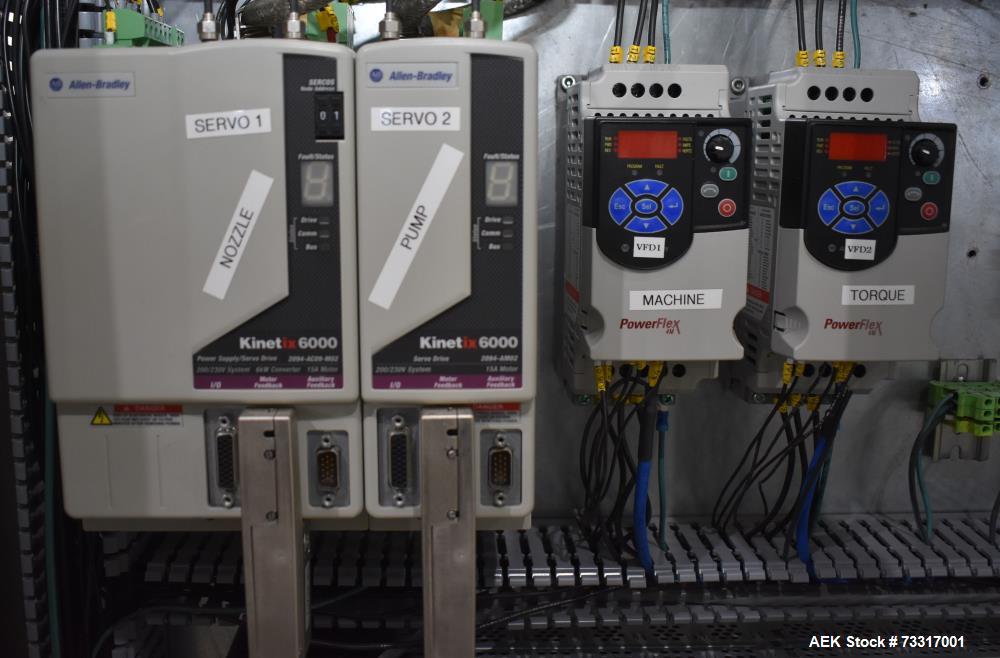

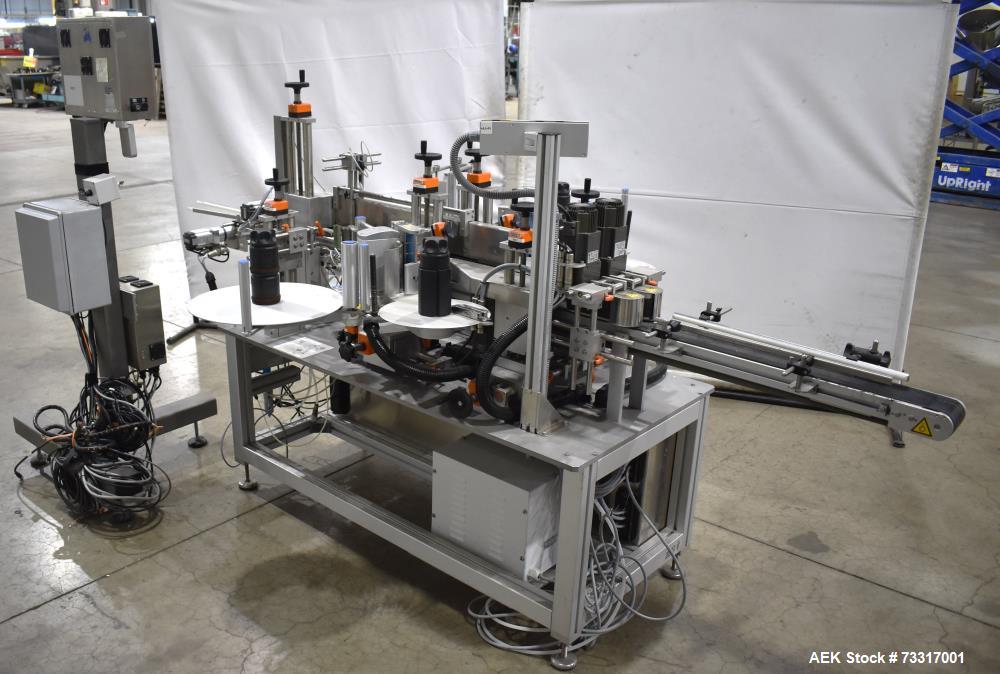

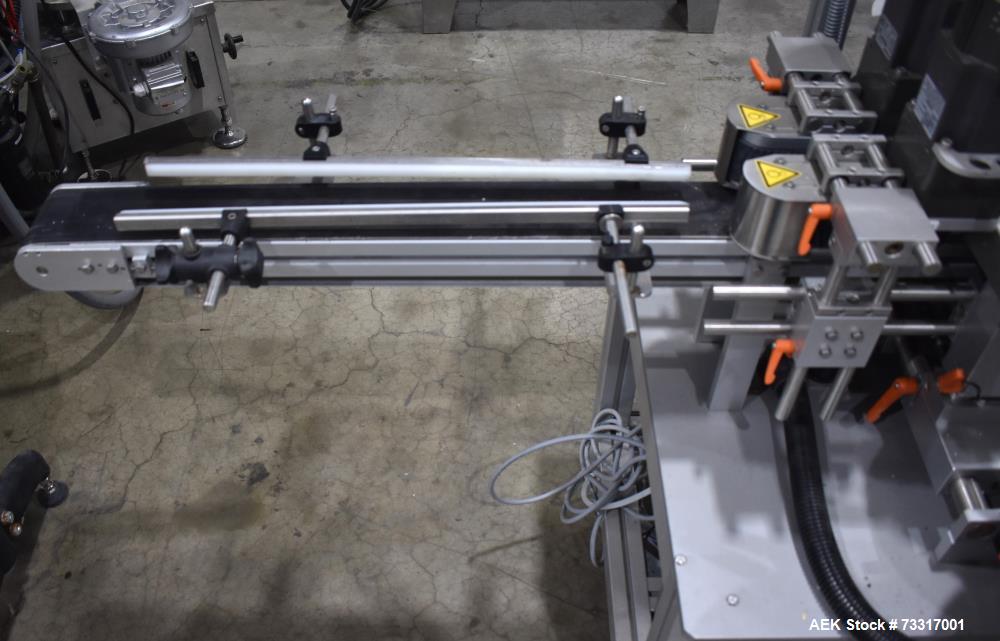

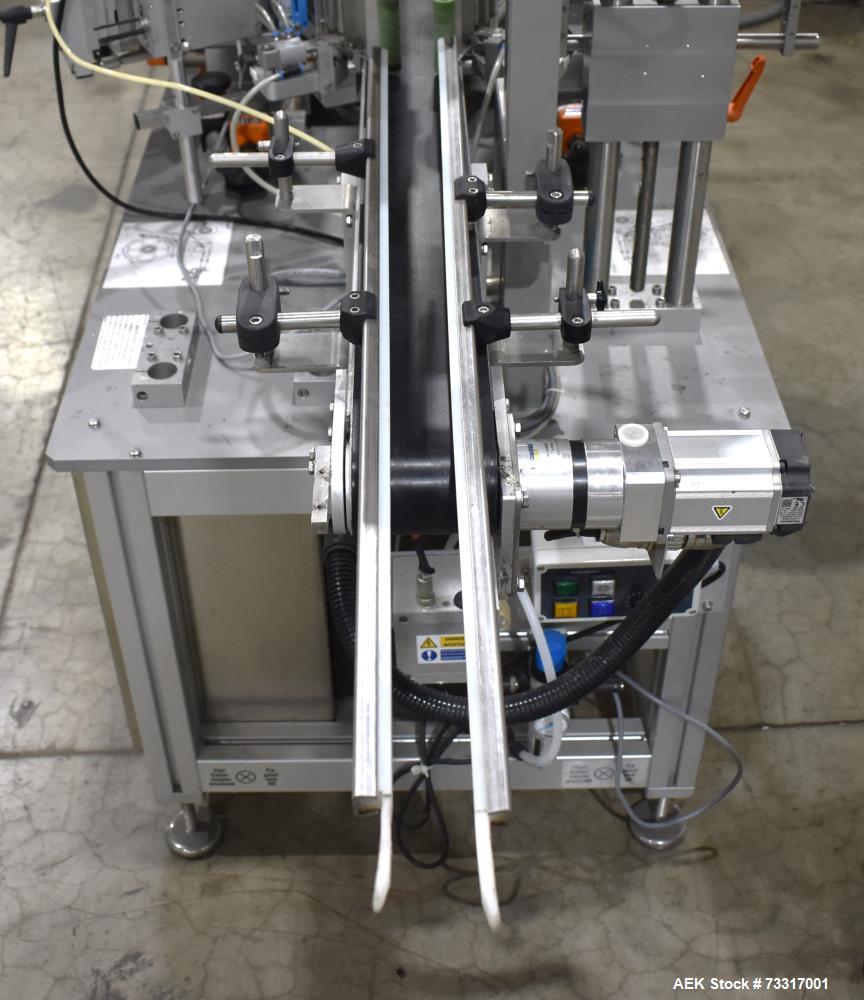

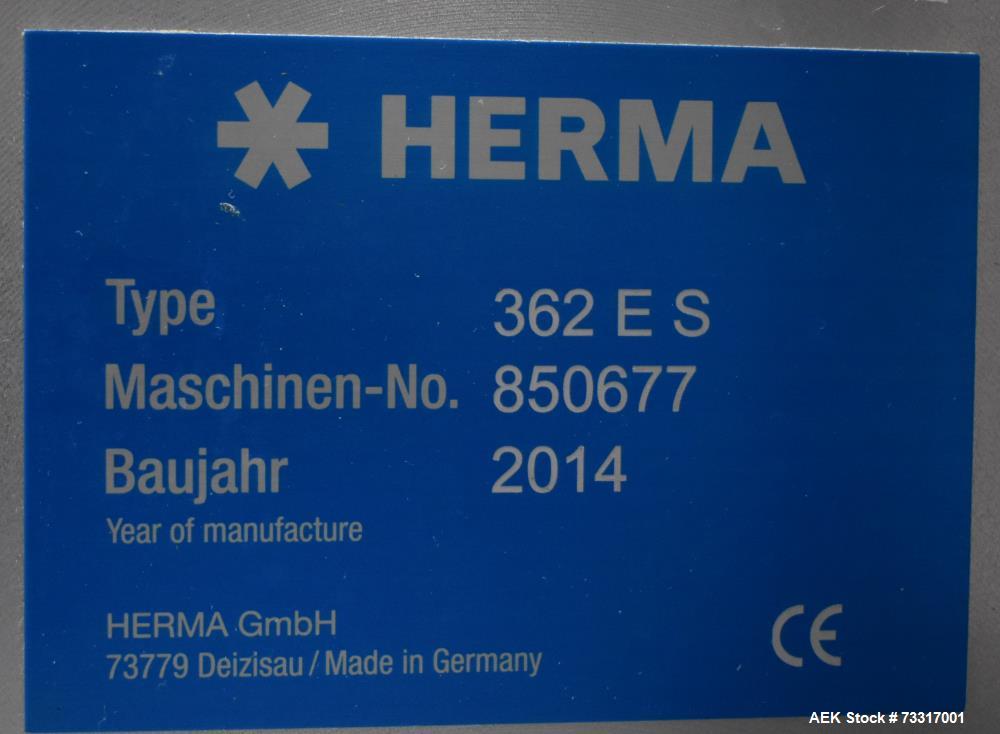

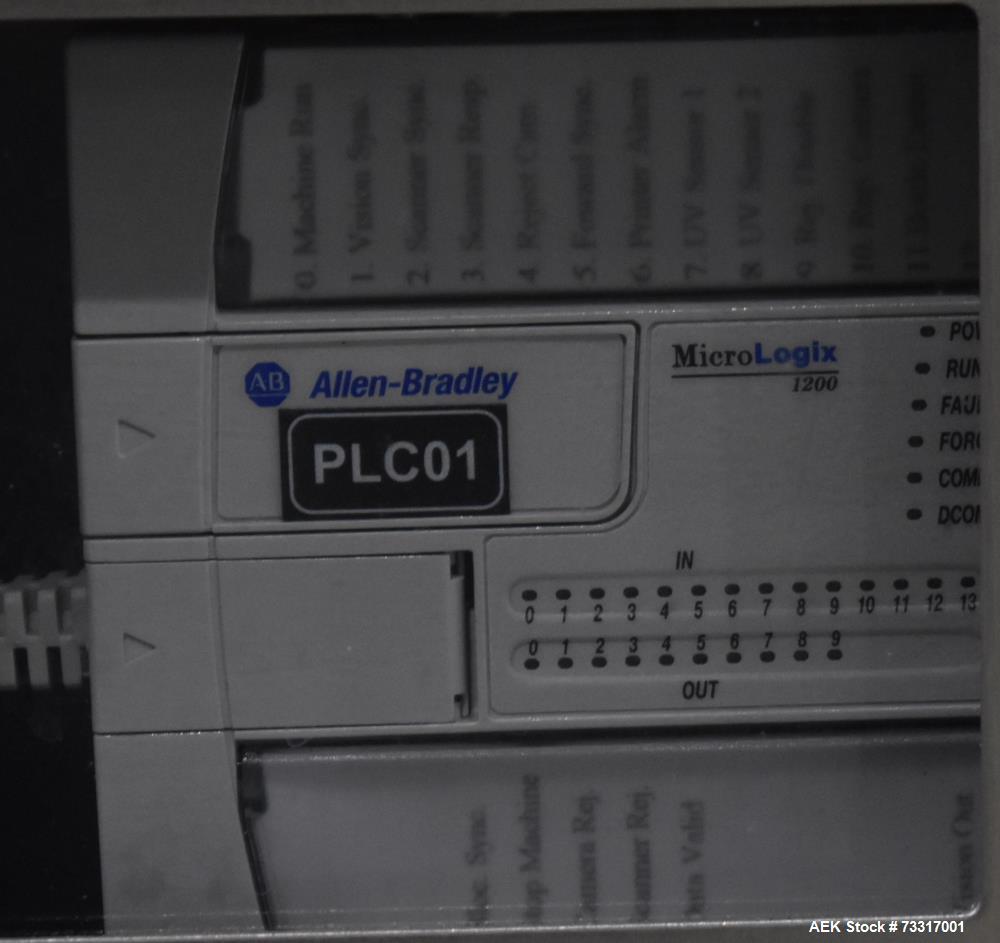

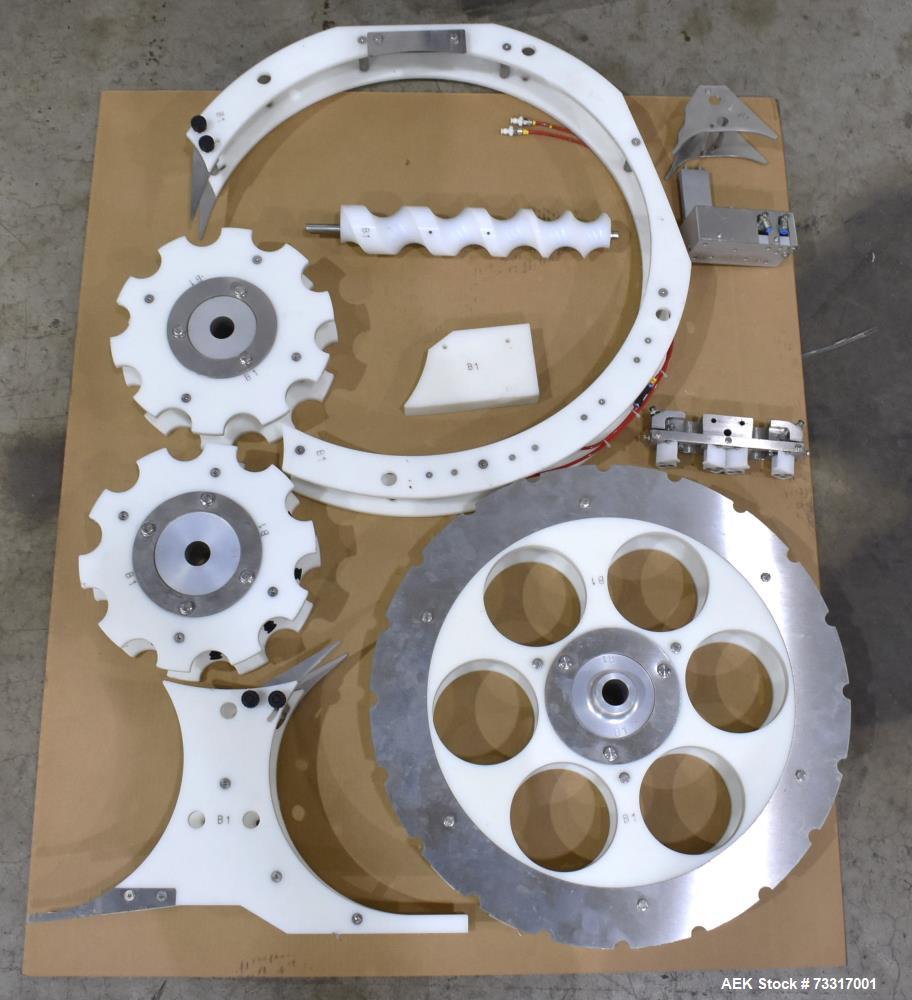

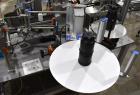

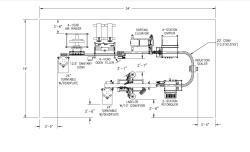

Used Capmatic Intrepid Model 4A/X-PP-222 Monoblock Filler, Plugger and Capper. Capable of speeds up to 60 Cpm (Depending on application). Consists of a Palace Model D18-SPB/HS 15 Bulk bottle unscrambler with inonized air cleaner and bulk bottle elevator. Capmatic Intrepid monoblock filler plugger and capper with assorted changeparts, Allen Bradley Panelview HMI, Allen Bradley ControlLogix 5560M03SE PLC, Kinetix 6000 servo drives. Herma Model 362 E S Front and Back pressure sentive labeler with Allen hot stamp date coder, top hold down, Lixis mode PVS vison system. Last running oval nasal spray bottles.

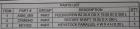

| Manufacturer | CapmaticCapmatic |

| Model | 4A/X-PP-22 |

| Serial # | IN08071512 |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Complete Packaging Line - Liquid - PasteComplete Packaging Line - Liquid - Paste |

The Capmatic Intrepid Model 4A/X-PP-222 is a high-speed monoblock filling, plugging, and capping system, designed for efficient and precise liquid packaging. This integrated packaging line is capable of speeds up to 60 containers per minute (CPM) (depending on application), making it ideal for pharmaceutical, cosmetic, and personal care industries.

This system includes:

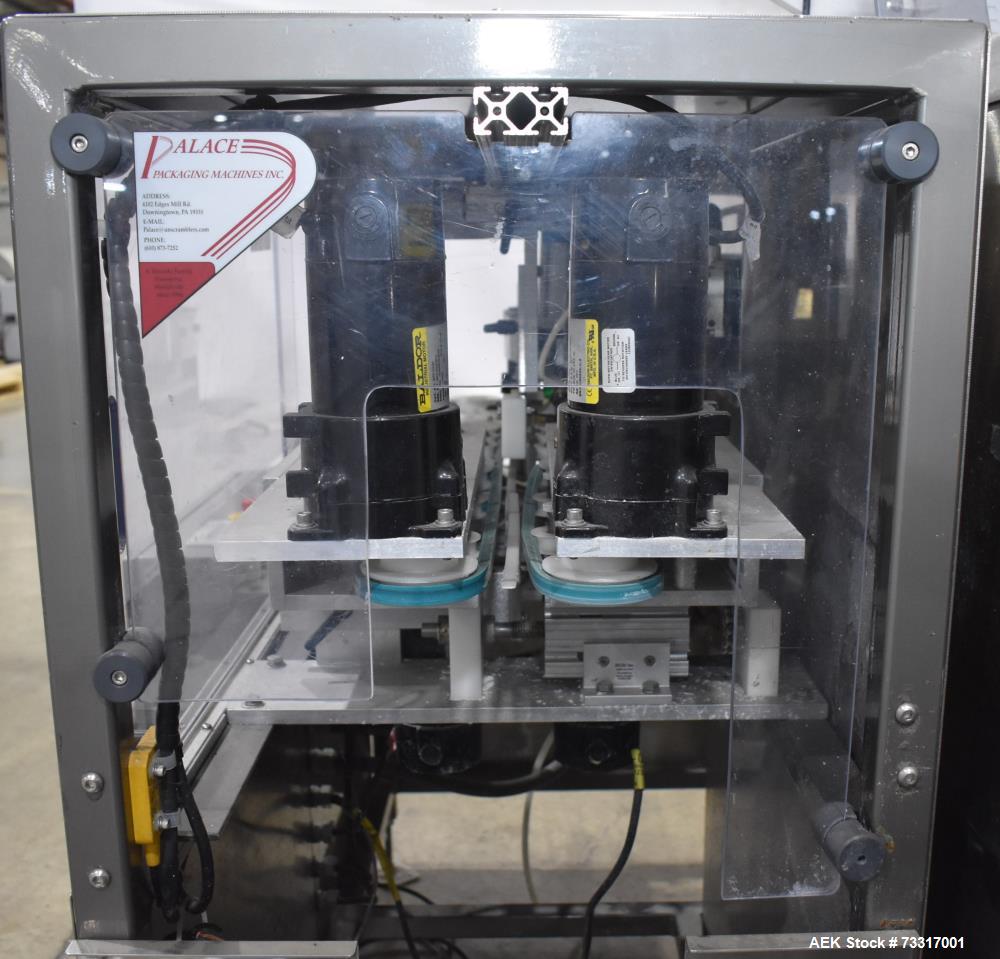

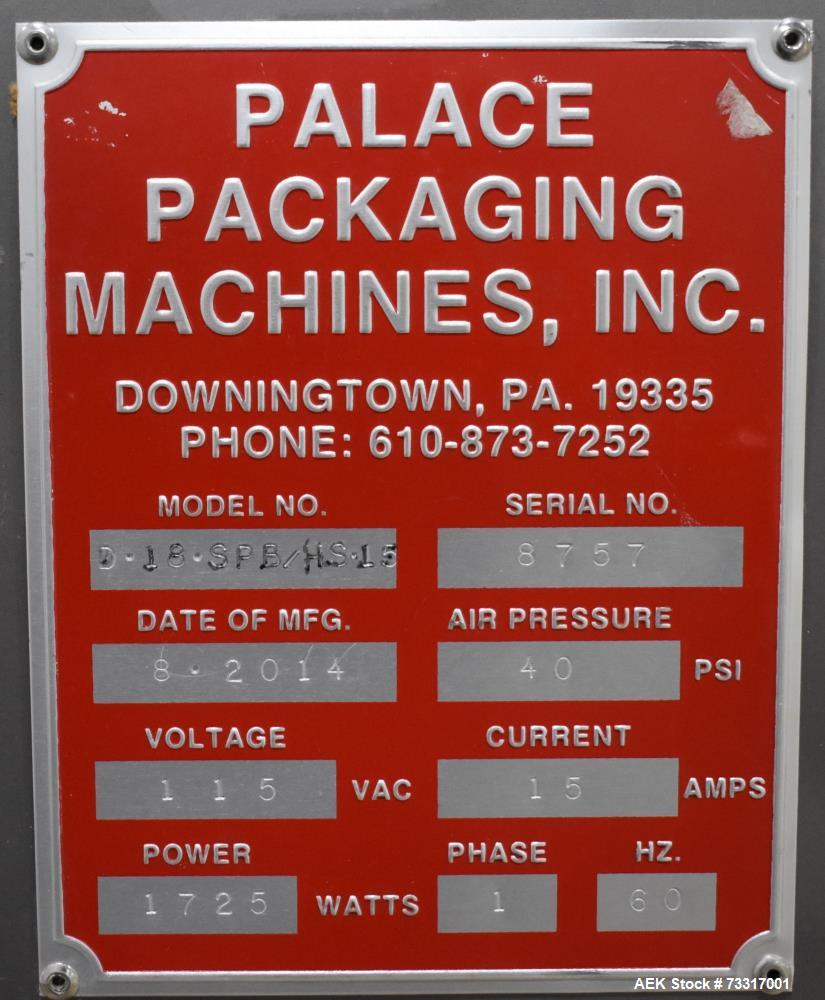

- Palace Model D18-SPB/HS-15 Bulk Bottle Unscrambler with Ionized Air Cleaner & Bulk Bottle Elevator, ensuring clean and properly oriented bottles enter the filling process.

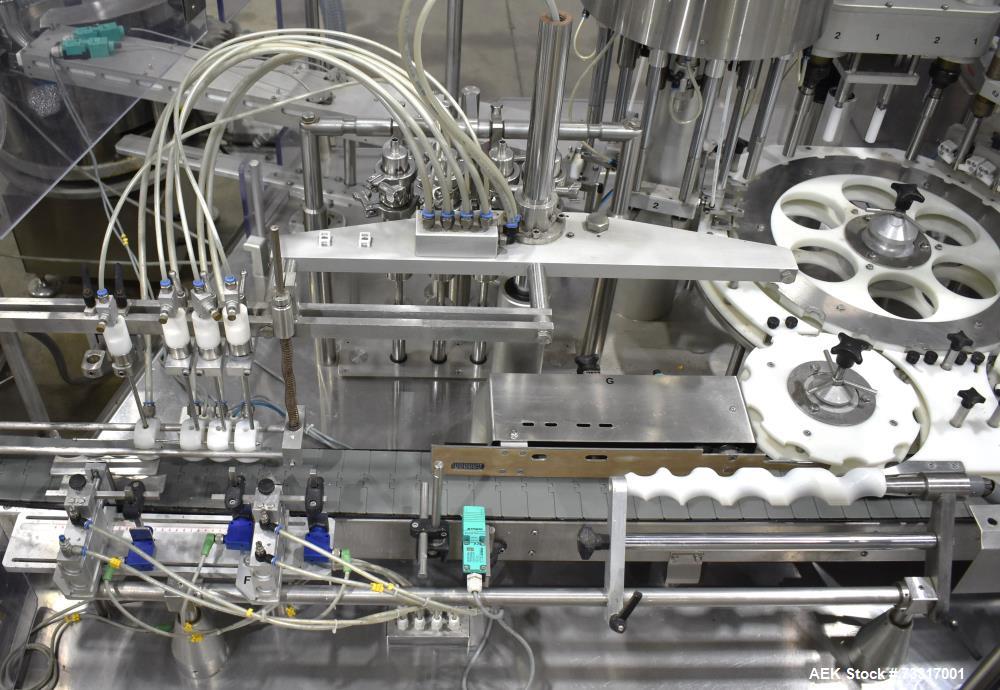

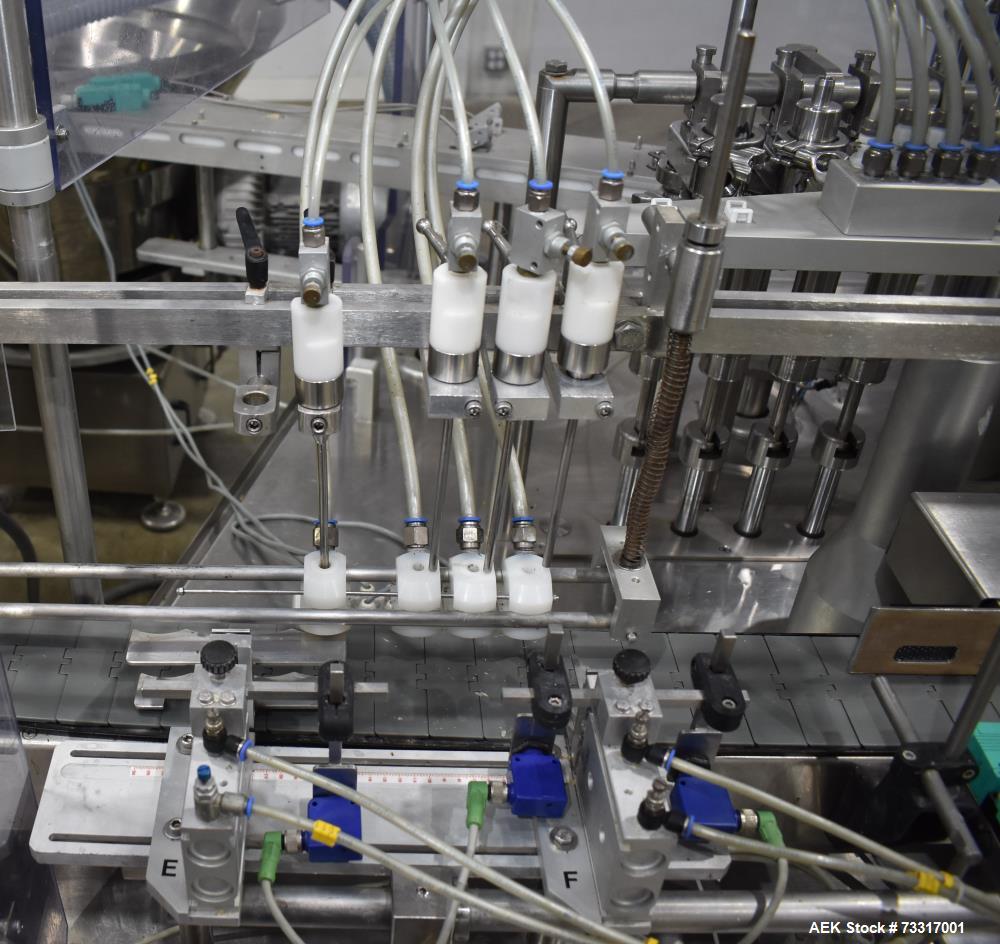

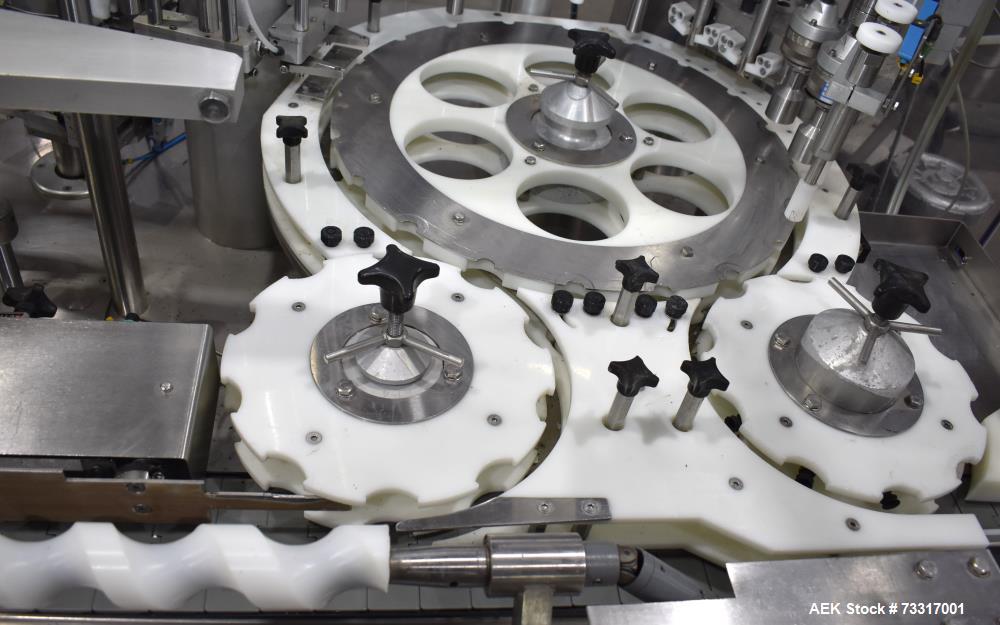

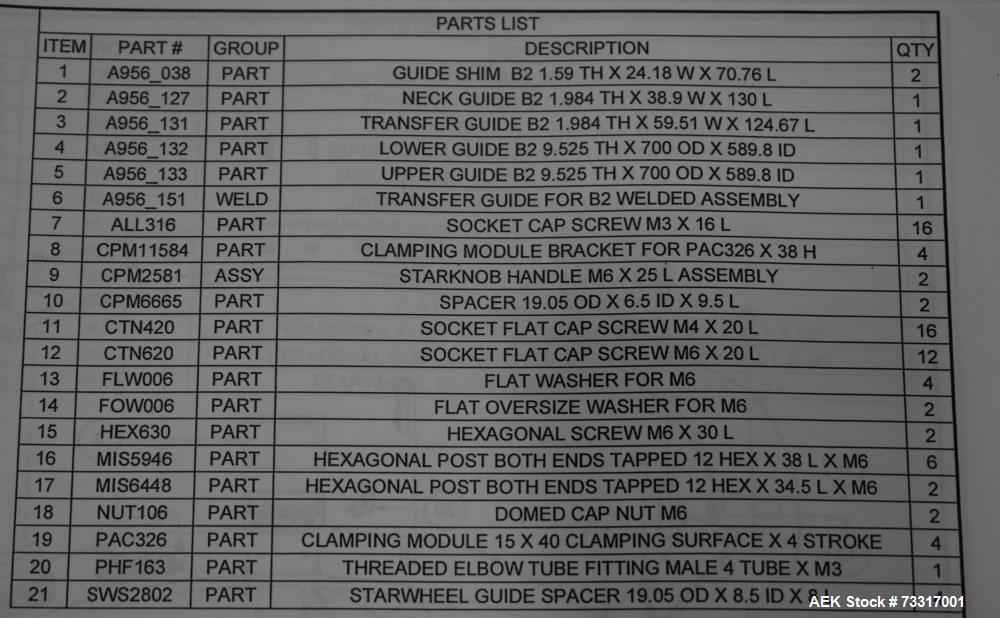

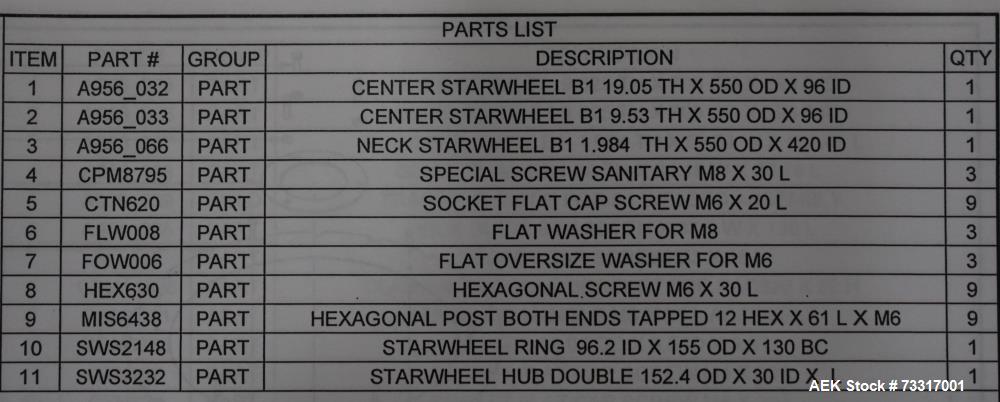

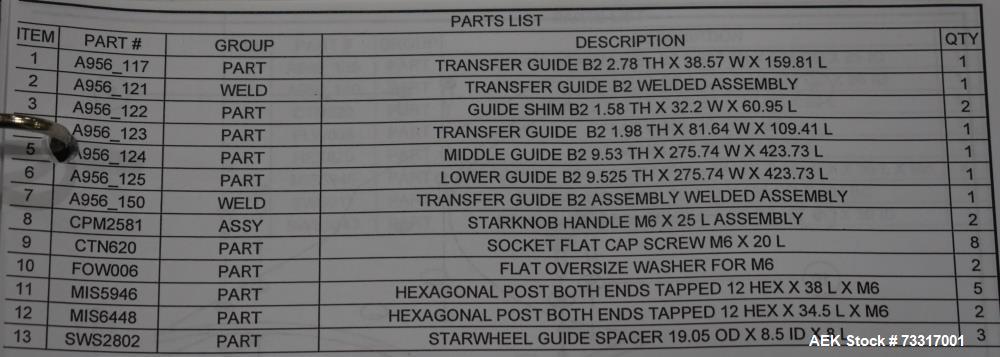

- Capmatic Intrepid Monoblock Filler, Plugger & Capper, complete with assorted changeparts for different bottle sizes and closures.

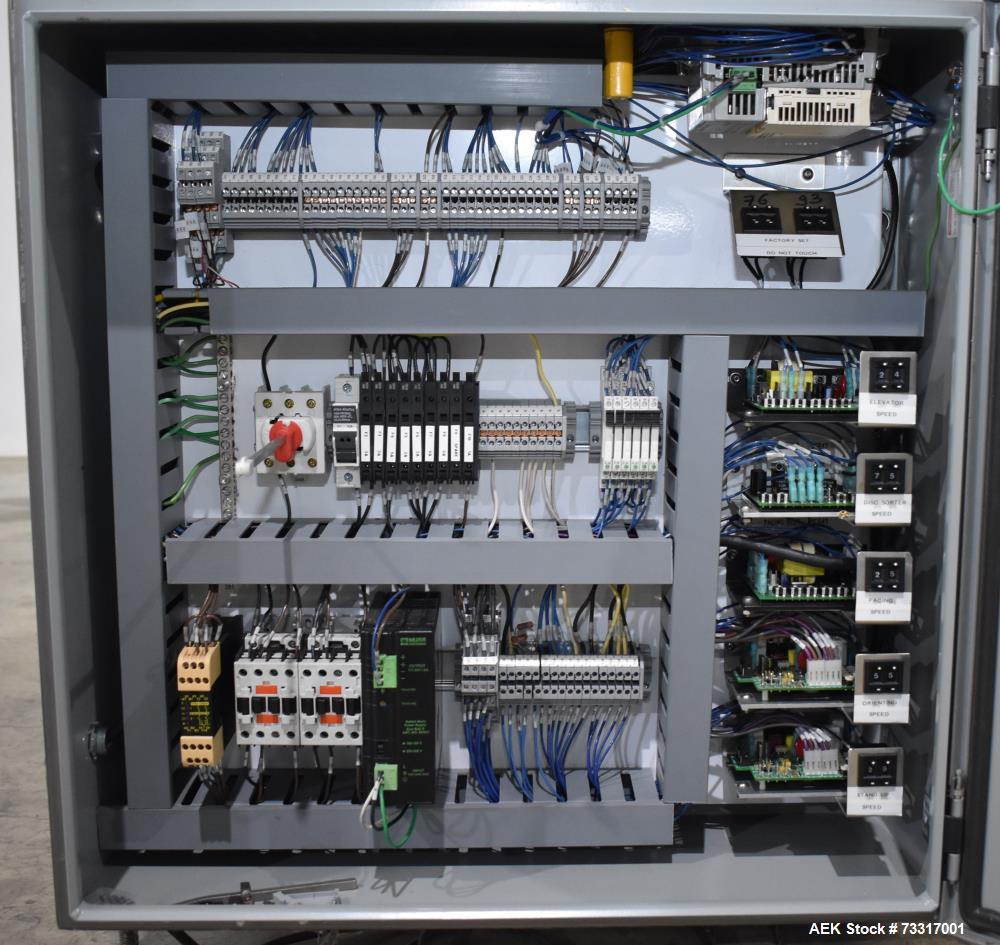

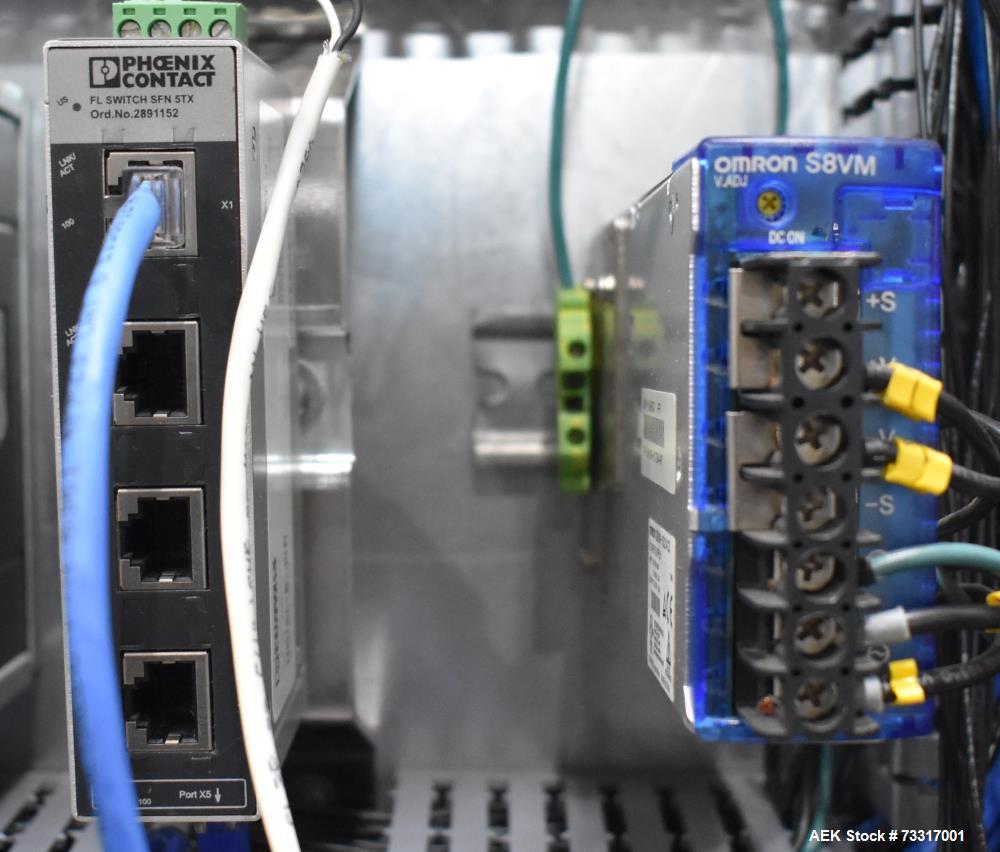

- Allen Bradley Automation Controls, featuring:

- Allen Bradley PanelView HMI for user-friendly interface

- Allen Bradley ControlLogix 5560M03SE PLC for precise automation

- Kinetix 6000 Servo Drives for high-speed and efficient motion control

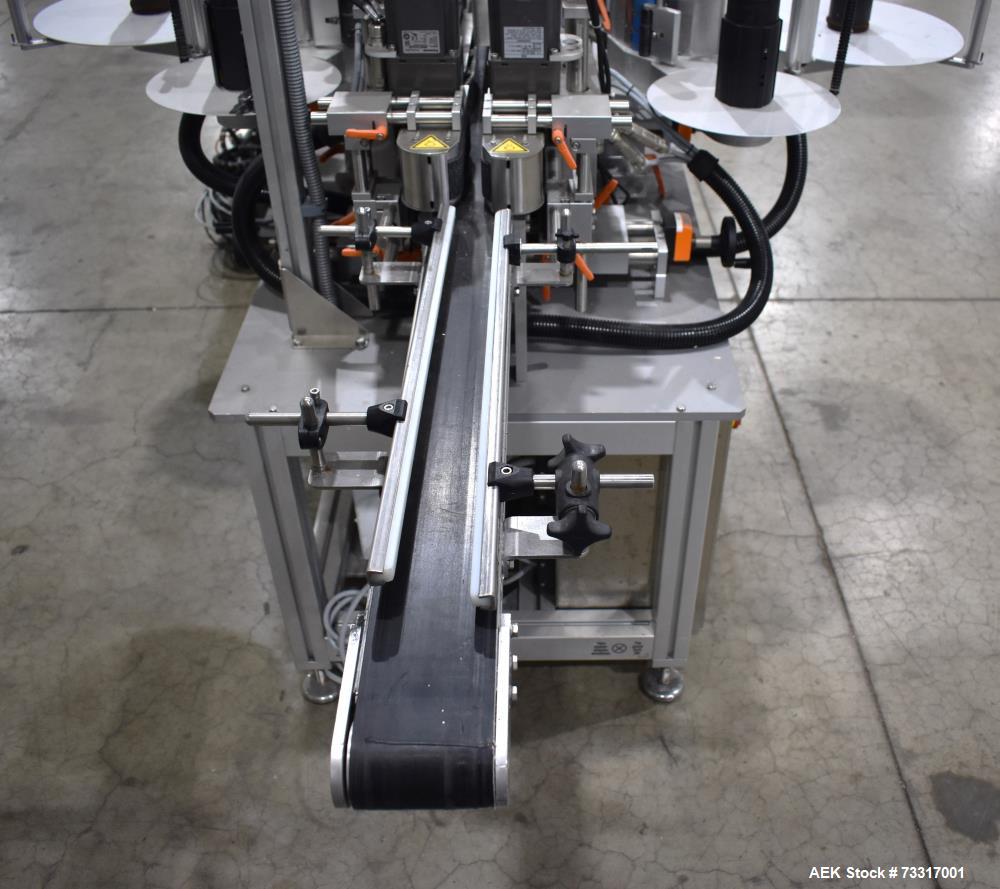

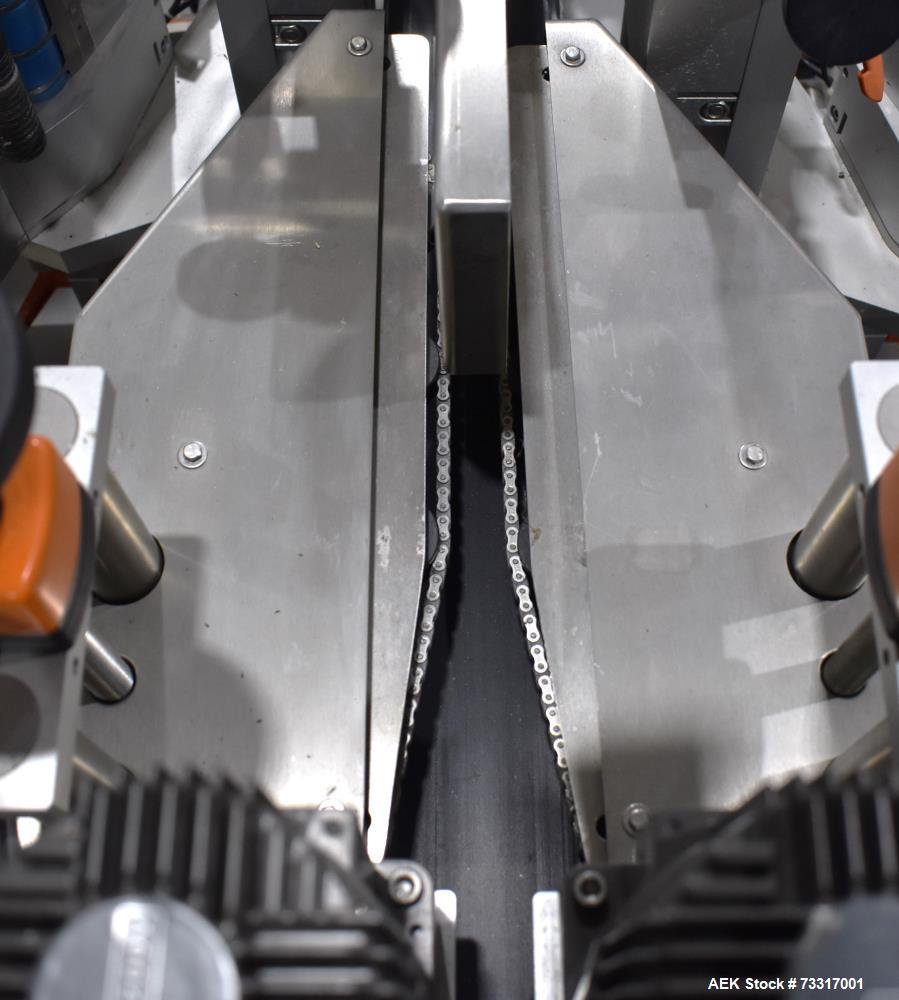

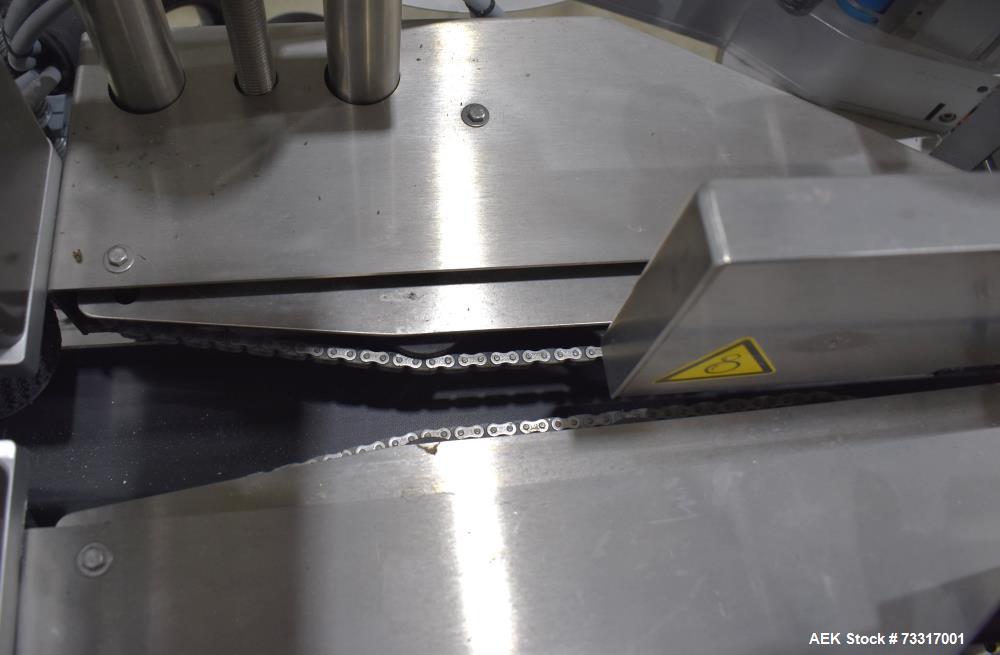

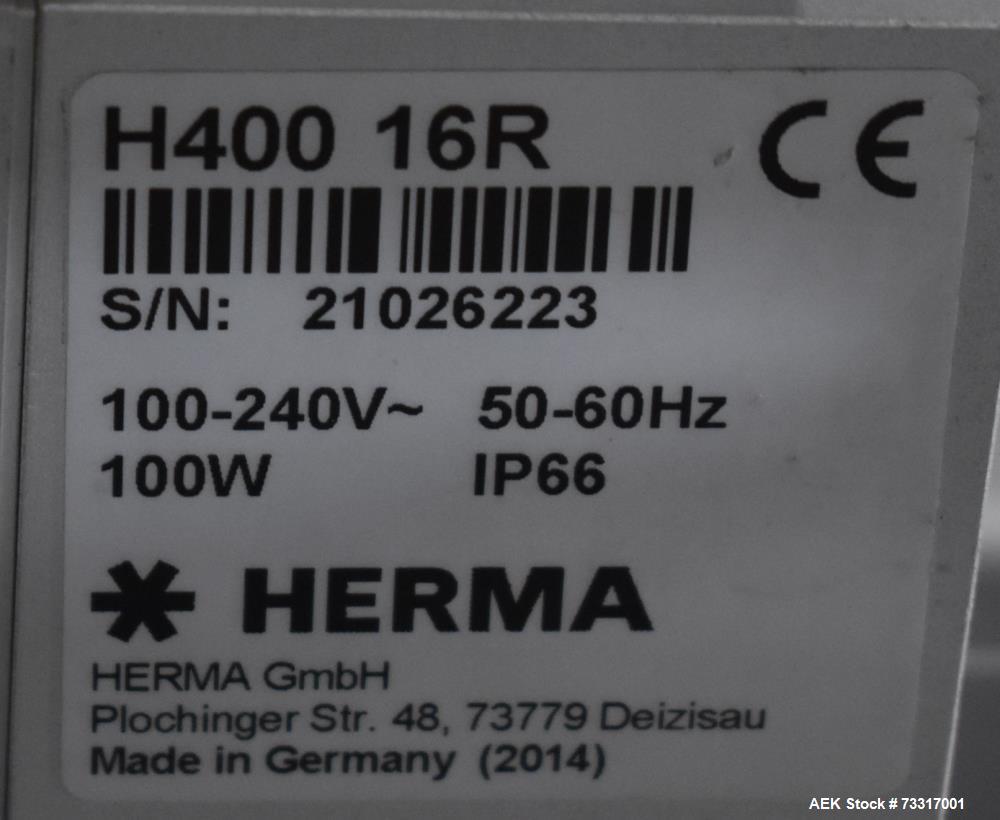

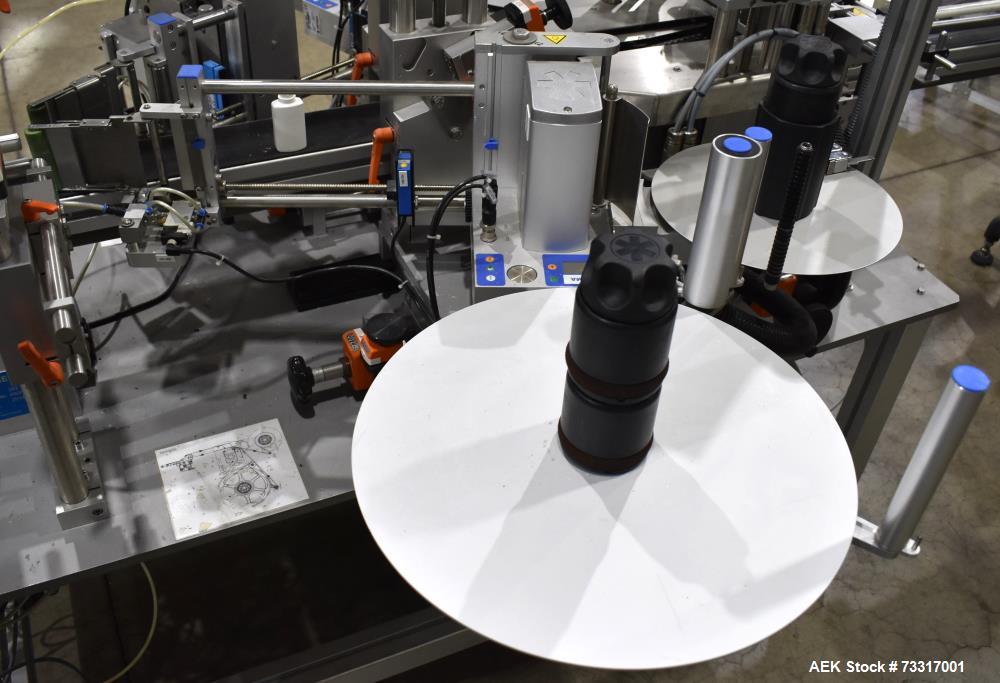

- Herma Model 362ES Front & Back Pressure-Sensitive Labeler, which includes:

- Allen Hot Stamp Date Coder for batch printing

- Top Hold Down System for label application accuracy

- Lixis Model PVS Vision System with Cognex Cameras for no-label detection, expiration verification, and batch tracking

This fully integrated packaging system was last running oval nasal spray bottles, making it ideal for similar bottle shapes and pharmaceutical packaging applications.

Specifications

- Manufacturer: Capmatic

- Model: Intrepid 4A/X-PP-222

- Machine Type: Monoblock Filler, Plugger & Capper

- Speed: Up to 60 CPM (depending on bottle size & application)

- Bottle Handling System:

- Palace D18-SPB/HS-15 Bulk Bottle Unscrambler

- Ionized Air Cleaner & Bulk Bottle Elevator

- Filling, Plugging & Capping System:

- Capmatic Intrepid Monoblock

- Assorted Change Parts for various bottle sizes

- Automation & Controls:

- Allen Bradley PanelView HMI

- Allen Bradley ControlLogix 5560M03SE PLC

- Kinetix 6000 Servo Drives

- Labeling & Inspection System:

- Herma Model 362ES Front & Back Pressure-Sensitive Labeler

- Allen Hot Stamp Date Coder

- Top Hold Down System for stable labeling

- Lixis Model PVS Vision System (with Cognex Cameras for no-label detection, expiration verification, and batch tracking)

- Last Used For: Oval Nasal Spray Bottles

Applications

The Capmatic Intrepid Monoblock System is designed for high-precision liquid filling, plugging, and capping, making it an excellent choice for pharmaceutical, cosmetic, and personal care packaging lines.

Industries & Product Applications:

- Pharmaceuticals & Medical Devices: Nasal sprays, eye drops, liquid medications, sterile solutions.

- Personal Care & Cosmetics: Serums, lotions, essential oils, and cosmetic liquids.

- Nutraceuticals & Health Supplements: Liquid vitamins, herbal extracts, and dietary supplements.

- Specialty Chemicals: Small-volume liquid chemical packaging.

This monoblock filling system ensures precise dosing, accurate labeling, and compliance with quality control standards, making it ideal for GMP and FDA-regulated industries.

Dietary Supplements, Essential Oil, Eye Care, Eye Drops, Herbal Extracts, Liquid Medications, Lotions, Lotions and Creams, Nasal Spray, Personal Care, Sterile, Sterile Solutions, Vitamins

- Used Capmatic Intrepid monoblock filler plugger capper

- High-speed pharmaceutical packaging system

- Automatic filling, plugging, and capping machine

- Used bottle filling and labeling line for sale

- Integrated packaging solution with vision system

- Buy used Capmatic Intrepid monoblock filling, plugging, and capping machine

- High-speed liquid filling machine with automatic bottle unscrambler

- Used pharmaceutical monoblock filler with Allen Bradley PLC controls

- Best automatic capping and labeling system for nasal spray bottles

- Industrial bottle filling and capping machine with servo drive control

- Fully automated pharmaceutical liquid packaging machine for sale

Used Capmatic Intrepid Model 4A/X-PP-222 Monoblock Filler, Plugger and Capper. Capable of speeds up to 60 Cpm (Depending on application). Consists of a Palace Model D18-SPB/HS 15 Bulk bottle unscrambler with inonized air cleaner and bulk bottle elevator. Capmatic Intrepid monoblock filler plugger and capper with assorted changeparts, Allen Bradley Panelview HMI, Allen Bradley ControlLogix 5560M03SE PLC, Kinetix 6000 servo drives. Herma Model 362 E S Front and Back pressure sentive labeler with Allen hot stamp date coder, top hold down, Lixis mode PVS vison system. Last running oval nasal spray bottles.

The Capmatic Intrepid Model 4A/X-PP-222 is a high-speed monoblock filling, plugging, and capping system, designed for efficient and precise liquid packaging. This integrated packaging line is capable of speeds up to 60 containers per minute (CPM) (depending on application), making it ideal for pharmaceutical, cosmetic, and personal care industries.

This system includes:

- Palace Model D18-SPB/HS-15 Bulk Bottle Unscrambler with Ionized Air Cleaner & Bulk Bottle Elevator, ensuring clean and properly oriented bottles enter the filling process.

- Capmatic Intrepid Monoblock Filler, Plugger & Capper, complete with assorted changeparts for different bottle sizes and closures.

- Allen Bradley Automation Controls, featuring:

- Allen Bradley PanelView HMI for user-friendly interface

- Allen Bradley ControlLogix 5560M03SE PLC for precise automation

- Kinetix 6000 Servo Drives for high-speed and efficient motion control

- Herma Model 362ES Front & Back Pressure-Sensitive Labeler, which includes:

- Allen Hot Stamp Date Coder for batch printing

- Top Hold Down System for label application accuracy

- Lixis Model PVS Vision System with Cognex Cameras for no-label detection, expiration verification, and batch tracking

This fully integrated packaging system was last running oval nasal spray bottles, making it ideal for similar bottle shapes and pharmaceutical packaging applications.

Specifications

- Manufacturer: Capmatic

- Model: Intrepid 4A/X-PP-222

- Machine Type: Monoblock Filler, Plugger & Capper

- Speed: Up to 60 CPM (depending on bottle size & application)

- Bottle Handling System:

- Palace D18-SPB/HS-15 Bulk Bottle Unscrambler

- Ionized Air Cleaner & Bulk Bottle Elevator

- Filling, Plugging & Capping System:

- Capmatic Intrepid Monoblock

- Assorted Change Parts for various bottle sizes

- Automation & Controls:

- Allen Bradley PanelView HMI

- Allen Bradley ControlLogix 5560M03SE PLC

- Kinetix 6000 Servo Drives

- Labeling & Inspection System:

- Herma Model 362ES Front & Back Pressure-Sensitive Labeler

- Allen Hot Stamp Date Coder

- Top Hold Down System for stable labeling

- Lixis Model PVS Vision System (with Cognex Cameras for no-label detection, expiration verification, and batch tracking)

- Last Used For: Oval Nasal Spray Bottles

Applications

The Capmatic Intrepid Monoblock System is designed for high-precision liquid filling, plugging, and capping, making it an excellent choice for pharmaceutical, cosmetic, and personal care packaging lines.

Industries & Product Applications:

- Pharmaceuticals & Medical Devices: Nasal sprays, eye drops, liquid medications, sterile solutions.

- Personal Care & Cosmetics: Serums, lotions, essential oils, and cosmetic liquids.

- Nutraceuticals & Health Supplements: Liquid vitamins, herbal extracts, and dietary supplements.

- Specialty Chemicals: Small-volume liquid chemical packaging.

This monoblock filling system ensures precise dosing, accurate labeling, and compliance with quality control standards, making it ideal for GMP and FDA-regulated industries.

Dietary Supplements, Essential Oil, Eye Care, Eye Drops, Herbal Extracts, Liquid Medications, Lotions, Lotions and Creams, Nasal Spray, Personal Care, Sterile, Sterile Solutions, Vitamins

| Manufacturer | Capmatic |

| Model | 4A/X-PP-22 |

| Serial # | IN08071512 |

| Category | Packaging Equipment |

| Subcategory | Complete Packaging Line - Liquid - Paste |

- Used Capmatic Intrepid monoblock filler plugger capper

- High-speed pharmaceutical packaging system

- Automatic filling, plugging, and capping machine

- Used bottle filling and labeling line for sale

- Integrated packaging solution with vision system

- Buy used Capmatic Intrepid monoblock filling, plugging, and capping machine

- High-speed liquid filling machine with automatic bottle unscrambler

- Used pharmaceutical monoblock filler with Allen Bradley PLC controls

- Best automatic capping and labeling system for nasal spray bottles

- Industrial bottle filling and capping machine with servo drive control

- Fully automated pharmaceutical liquid packaging machine for sale

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory