Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

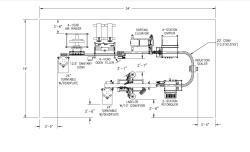

Used Evergreen Liquid Filling Line consisting of: Evergreen Carton Former-Filler-Sealer; MODEL EH-2, with Dual Spout Fitment Attachment, and Electrical Heat Sealing, 230 Volts, 238 AMPS. Serial # 5...

Used Evergreen Liquid Filling Line consisting of: Evergreen Carton Former-Filler-Sealer; MODEL EH-2, with Dual Spout Fitment Attachment, and Electrical Heat Sealing, 230 Volts, 238 AMPS. Serial # 5538R-417R. Built 2011; Hoppman Cap System, with Approx. 10ft. High Cap Elevator with Lower Feed Hopper, and Rotary Cap sorter with Cap Chute. Model FTF 30-2L, Serial # 32017; Deam Corrugated Box Carton Caser, Includes Allen Bradley Panel View 600 PLC Controller, Model 240, Serial #20107; Klockner Palletizer, Mfg. by: Priority One Packaging, Waterloo, ON. Serial # 93-202. Includes Approximately 4.5 ft. Section of 14” Wide Power Roller Conveyor turning 90 degrees east from Incline Conveyor, Approx. 6ft of 14” wide power roller moving east to a 90 degree powered roller curve, through wall, south to a 14” wide Belt Conveyor to the loading platform of the palletizer; Qty. (2) CIRTRONIX Model Ci1000 Ink Jet Carton Code Daters, Serial #’s 0409286B, and 0409286D: Mounted on S/S Table near Outlet Conveyor from Filler;Squid Brand Co-Pilot Model 256 Dual Head Ink Jet Case Coder; Serial # CPT256PI508001; Located on Case Conveyor Line after Caser. Dual Lane S/S Plastic Link Chain Design Carton Conveyor leaves Filler for approx. 3ft .(North Direction), to 90 degree turn for approx. 10ft. (West Direction) to 90 degree turn (South Direction). One “Smart Eye” Pedestal Mount Carton sensor is Located near the 90 degree turn. Dual Plastic Chain Conveyor continues south approx. 15ft. to Drive Unit, then continues Approx. 26ft. to a Lane Transfer Section, where Carton Conveyor changes to 3.25” Flat Table top chain Conveyor. There are 2 Photo Switch Sensors Located at 14 ft. Mark. From the Transfer Section, the Dual Conveyor continues Approx. 10ft. South to 90 degree turn and travels approx. 10ft. east with air pillow carton guides, to a 90 degree turn to Continue North, for Approx. 12ft to receiving area of the top feed Deam Caser.

Used Evergreen Liquid Filling Line consisting of: Evergreen Carton Former-Filler-Sealer; MODEL EH-2, with Dual Spout Fitment Attachment, and Electrical Heat Sealing, 230 Volts, 238 AMPS. Serial # 5538R-417R. Built 2011; Hoppman Cap System, with Approx. 10ft. High Cap Elevator with Lower Feed Hopper, and Rotary Cap sorter with Cap Chute. Model FTF 30-2L, Serial # 32017; Deam Corrugated Box Carton Caser, Includes Allen Bradley Panel View 600 PLC Controller, Model 240, Serial #20107; Klockner Palletizer, Mfg. by: Priority One Packaging, Waterloo, ON. Serial # 93-202. Includes Approximately 4.5 ft. Section of 14” Wide Power Roller Conveyor turning 90 degrees east from Incline Conveyor, Approx. 6ft of 14” wide power roller moving east to a 90 degree powered roller curve, through wall, south to a 14” wide Belt Conveyor to the loading platform of the palletizer; Qty. (2) CIRTRONIX Model Ci1000 Ink Jet Carton Code Daters, Serial #’s 0409286B, and 0409286D: Mounted on S/S Table near Outlet Conveyor from Filler;Squid Brand Co-Pilot Model 256 Dual Head Ink Jet Case Coder; Serial # CPT256PI508001; Located on Case Conveyor Line after Caser. Dual Lane S/S Plastic Link Chain Design Carton Conveyor leaves Filler for approx. 3ft .(North Direction), to 90 degree turn for approx. 10ft. (West Direction) to 90 degree turn (South Direction). One “Smart Eye” Pedestal Mount Carton sensor is Located near the 90 degree turn. Dual Plastic Chain Conveyor continues south approx. 15ft. to Drive Unit, then continues Approx. 26ft. to a Lane Transfer Section, where Carton Conveyor changes to 3.25” Flat Table top chain Conveyor. There are 2 Photo Switch Sensors Located at 14 ft. Mark. From the Transfer Section, the Dual Conveyor continues Approx. 10ft. South to 90 degree turn and travels approx. 10ft. east with air pillow carton guides, to a 90 degree turn to Continue North, for Approx. 12ft to receiving area of the top feed Deam Caser.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory