Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

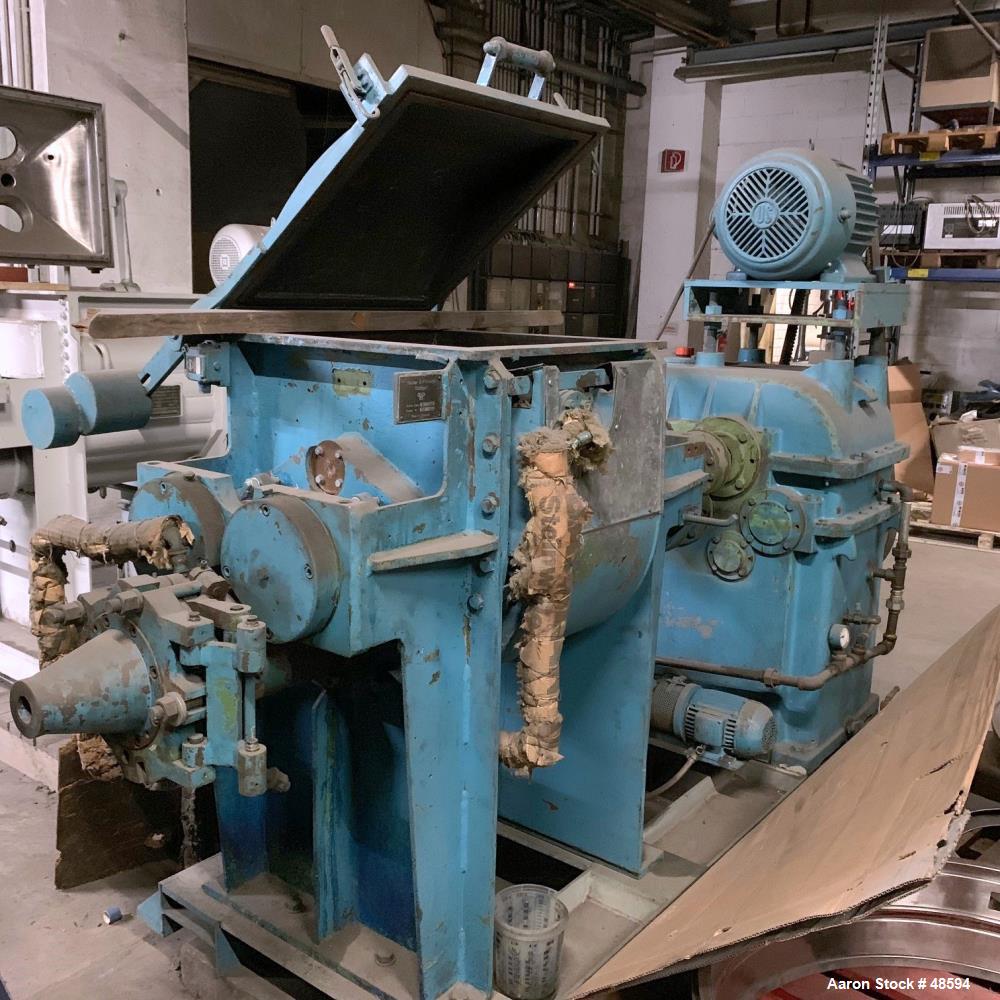

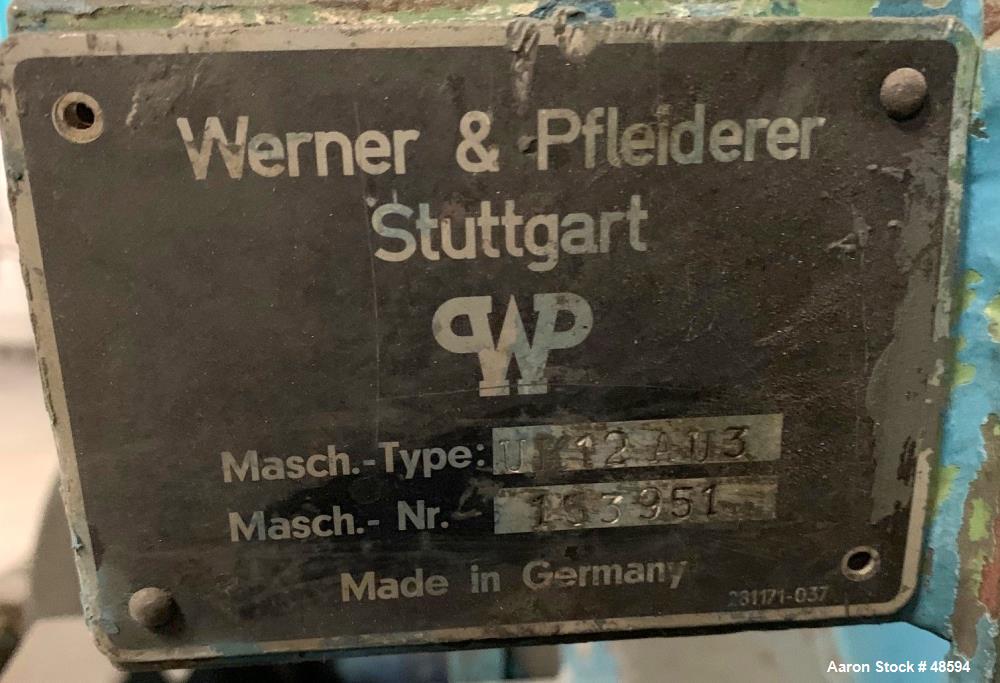

Used Werner & Pfleiderer Mixer/Extruder – Type UK12-AU3, 21 Gallon Capacity, Carbon Steel

Used Werner & Pfleiderer Mixer/Extruder, Type UK12-AU3. 21 Gallon (80 liter) working capacity, 29.1 gallon (110 liter) total capacity. Material of construction is carbon steel on product contact parts. 20-1/2" (530 mm) long x 20-1/2" (530 mm) width x 19-1/2" (500 mm) deep jacketed bowl. Jacket estimated rated for 75 psi (5 bar). Sigma style blades with a speed of 17/21 RPM. Tangential. 6" (150 mm) dia. screw shafts. Standard packing glands. Counter balanced top cover. Screw product discharge. Belt driven thru gearbox by a 22.5HP/15 kw-380V/50cycle/3Ph-1475 RPM motor. Safety belt cover. Screw product discharge by a 11.25HP/7.5Kw-380volt/50cycle/3Ph motor. Frame mounted. Overall dimensions: 85" (2600 mm) long x 52" (1600 mm) width x 5.9" (1800 mm) high. Weight 3 tonnes. Serial # 193951. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

| Manufacturer | Werner & PfleidererWerner & Pfleiderer |

| Model | UK12-AU3 |

| Serial # | 153951 |

| Category | MixersMixers |

| Subcategory | Double Arm Mixer ExtrudersDouble Arm Mixer Extruders |

Manufacturer Information:

- Brand: Werner & Pfleiderer

- Type: Mixer/Extruder

- Model: UK12-AU3

- Material: Carbon Steel (Product Contact Parts)

- Serial #: 193951

Description:

This used Werner & Pfleiderer Mixer/Extruder (Type UK12-AU3) is a high-performance mixing and extrusion system, designed for heavy-duty industrial applications, including rubber, plastic, chemical, and food processing.

With a 21-gallon (80-liter) working capacity and a 29.1-gallon (110-liter) total capacity, this unit features a jacketed mixing bowl (20.5" x 20.5" x 19.5"), estimated rated for 75 psi (5 bar), providing efficient heating or cooling during processing.

The sigma-style blades operate at 17/21 RPM, ensuring thorough mixing and kneading of high-viscosity materials. The tangential blade configuration enhances material shearing and blending, making it suitable for high-consistency applications.

This machine includes a 6” (150mm) diameter screw discharge system, belt-driven through a gearbox, powered by a 22.5 HP (15 kW), 380V, 50 Hz, 3-phase motor operating at 1475 RPM. The screw discharge mechanism is driven by an 11.25 HP (7.5 kW), 380V, 50 Hz, 3-phase motor, ensuring efficient material output.

Mounted on a sturdy frame, this 3-ton mixer/extruder is built for durability and high-throughput processing.

Key Features:

- 21-Gallon (80L) Working Capacity | 29.1-Gallon (110L) Total Capacity

- Carbon Steel Construction for Heavy-Duty Industrial Use

- Jacketed Mixing Bowl (75 PSI Rated) for Heating & Cooling Applications

- Sigma-Style Tangential Blades Operating at 17/21 RPM for High-Viscosity Mixing

- 6” (150mm) Diameter Screw Shafts for Product Discharge

- 22.5 HP (15 kW) Main Motor | 11.25 HP (7.5 kW) Screw Discharge Motor

- Belt-Driven Through Gearbox for Smooth Operation

- Counterbalanced Top Cover for Safe & Easy Access

- Frame-Mounted Design for Stability & Heavy-Duty Performance

- Overall Dimensions: 85" (2600mm) L x 52" (1600mm) W x 5.9' (1800mm) H

- Total Weight: 3 Tonnes

- Serial #: 193951

Specifications:

- Model: UK12-AU3

- Material: Carbon Steel (Product Contact Parts)

- Working Capacity: 21 Gallons (80 Liters)

- Total Capacity: 29.1 Gallons (110 Liters)

- Bowl Dimensions: 20.5” L x 20.5” W x 19.5” D

- Jacket Pressure Rating: 75 PSI (5 Bar) (Estimated)

- Blade Type: Sigma-Style, Tangential Configuration

- Blade Speed: 17/21 RPM

- Screw Discharge Size: 6” (150mm) Diameter

- Main Motor: 22.5 HP (15 kW), 380V, 50 Hz, 3-Phase, 1475 RPM

- Screw Discharge Motor: 11.25 HP (7.5 kW), 380V, 50 Hz, 3-Phase

- Mounting: Frame-Mounted

- Overall Dimensions: 85” (2600mm) L x 52” (1600mm) W x 5.9’ (1800mm) H

- Total Weight: 3 Tonnes

- Serial #: 193951

Applications:

- Rubber & Polymer Processing – Kneading and extrusion of high-viscosity compounds

- Plastic Compounding & Extrusion – Mixing and pre-processing of plastic formulations

- Chemical & Industrial Processing – Blending and homogenizing chemical materials

- Food Processing – Mixing high-viscosity food products like doughs, pastes, and confections

- Adhesive & Sealant Production – Consistent blending of thick industrial adhesives

What Products Would This Be Used For?

- Rubber and elastomer mixing

- Plastic and polymer processing

- High-viscosity chemical compounds

- Food and confectionery processing

- Industrial adhesives and sealants

- Werner & Pfleiderer mixer

- Used industrial extruder

- Sigma blade mixer extruder

- Carbon steel mixing system

- Industrial batch mixer

- Used industrial mixer extruder

- Werner & Pfleiderer sigma mixer

- Heavy-duty kneader for rubber and plastics

- Carbon steel sigma blade kneader

- Industrial compounding and extrusion equipment

- Used Werner & Pfleiderer UK12-AU3 sigma blade mixer/extruder

- High-capacity industrial mixer with 21-gallon working capacity

- Carbon steel mixing and extrusion system with screw discharge

- Heavy-duty kneading and extrusion machine for rubber, plastics, and chemicals

- Jacketed sigma blade mixer with 75 PSI rated bowl and tangential blade design

- Used Werner & Pfleiderer UK12-AU3 sigma mixer extruder with 21-gallon working capacity

- Industrial mixing and extrusion system with jacketed bowl, sigma blades, and screw discharge

- Werner & Pfleiderer sigma blade mixer with 22.5 HP motor and carbon steel construction

- Used high-capacity batch mixer for polymers, adhesives, and chemical processing

- Sigma blade kneader with jacketed heating/cooling bowl and 6” screw discharge

Used Werner & Pfleiderer Mixer/Extruder, Type UK12-AU3. 21 Gallon (80 liter) working capacity, 29.1 gallon (110 liter) total capacity. Material of construction is carbon steel on product contact parts. 20-1/2" (530 mm) long x 20-1/2" (530 mm) width x 19-1/2" (500 mm) deep jacketed bowl. Jacket estimated rated for 75 psi (5 bar). Sigma style blades with a speed of 17/21 RPM. Tangential. 6" (150 mm) dia. screw shafts. Standard packing glands. Counter balanced top cover. Screw product discharge. Belt driven thru gearbox by a 22.5HP/15 kw-380V/50cycle/3Ph-1475 RPM motor. Safety belt cover. Screw product discharge by a 11.25HP/7.5Kw-380volt/50cycle/3Ph motor. Frame mounted. Overall dimensions: 85" (2600 mm) long x 52" (1600 mm) width x 5.9" (1800 mm) high. Weight 3 tonnes. Serial # 193951. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

Manufacturer Information:

- Brand: Werner & Pfleiderer

- Type: Mixer/Extruder

- Model: UK12-AU3

- Material: Carbon Steel (Product Contact Parts)

- Serial #: 193951

Description:

This used Werner & Pfleiderer Mixer/Extruder (Type UK12-AU3) is a high-performance mixing and extrusion system, designed for heavy-duty industrial applications, including rubber, plastic, chemical, and food processing.

With a 21-gallon (80-liter) working capacity and a 29.1-gallon (110-liter) total capacity, this unit features a jacketed mixing bowl (20.5" x 20.5" x 19.5"), estimated rated for 75 psi (5 bar), providing efficient heating or cooling during processing.

The sigma-style blades operate at 17/21 RPM, ensuring thorough mixing and kneading of high-viscosity materials. The tangential blade configuration enhances material shearing and blending, making it suitable for high-consistency applications.

This machine includes a 6” (150mm) diameter screw discharge system, belt-driven through a gearbox, powered by a 22.5 HP (15 kW), 380V, 50 Hz, 3-phase motor operating at 1475 RPM. The screw discharge mechanism is driven by an 11.25 HP (7.5 kW), 380V, 50 Hz, 3-phase motor, ensuring efficient material output.

Mounted on a sturdy frame, this 3-ton mixer/extruder is built for durability and high-throughput processing.

Key Features:

- 21-Gallon (80L) Working Capacity | 29.1-Gallon (110L) Total Capacity

- Carbon Steel Construction for Heavy-Duty Industrial Use

- Jacketed Mixing Bowl (75 PSI Rated) for Heating & Cooling Applications

- Sigma-Style Tangential Blades Operating at 17/21 RPM for High-Viscosity Mixing

- 6” (150mm) Diameter Screw Shafts for Product Discharge

- 22.5 HP (15 kW) Main Motor | 11.25 HP (7.5 kW) Screw Discharge Motor

- Belt-Driven Through Gearbox for Smooth Operation

- Counterbalanced Top Cover for Safe & Easy Access

- Frame-Mounted Design for Stability & Heavy-Duty Performance

- Overall Dimensions: 85" (2600mm) L x 52" (1600mm) W x 5.9' (1800mm) H

- Total Weight: 3 Tonnes

- Serial #: 193951

Specifications:

- Model: UK12-AU3

- Material: Carbon Steel (Product Contact Parts)

- Working Capacity: 21 Gallons (80 Liters)

- Total Capacity: 29.1 Gallons (110 Liters)

- Bowl Dimensions: 20.5” L x 20.5” W x 19.5” D

- Jacket Pressure Rating: 75 PSI (5 Bar) (Estimated)

- Blade Type: Sigma-Style, Tangential Configuration

- Blade Speed: 17/21 RPM

- Screw Discharge Size: 6” (150mm) Diameter

- Main Motor: 22.5 HP (15 kW), 380V, 50 Hz, 3-Phase, 1475 RPM

- Screw Discharge Motor: 11.25 HP (7.5 kW), 380V, 50 Hz, 3-Phase

- Mounting: Frame-Mounted

- Overall Dimensions: 85” (2600mm) L x 52” (1600mm) W x 5.9’ (1800mm) H

- Total Weight: 3 Tonnes

- Serial #: 193951

Applications:

- Rubber & Polymer Processing – Kneading and extrusion of high-viscosity compounds

- Plastic Compounding & Extrusion – Mixing and pre-processing of plastic formulations

- Chemical & Industrial Processing – Blending and homogenizing chemical materials

- Food Processing – Mixing high-viscosity food products like doughs, pastes, and confections

- Adhesive & Sealant Production – Consistent blending of thick industrial adhesives

What Products Would This Be Used For?

- Rubber and elastomer mixing

- Plastic and polymer processing

- High-viscosity chemical compounds

- Food and confectionery processing

- Industrial adhesives and sealants

| Manufacturer | Werner & Pfleiderer |

| Model | UK12-AU3 |

| Serial # | 153951 |

| Category | Mixers |

| Subcategory | Double Arm Mixer Extruders |

- Werner & Pfleiderer mixer

- Used industrial extruder

- Sigma blade mixer extruder

- Carbon steel mixing system

- Industrial batch mixer

- Used industrial mixer extruder

- Werner & Pfleiderer sigma mixer

- Heavy-duty kneader for rubber and plastics

- Carbon steel sigma blade kneader

- Industrial compounding and extrusion equipment

- Used Werner & Pfleiderer UK12-AU3 sigma blade mixer/extruder

- High-capacity industrial mixer with 21-gallon working capacity

- Carbon steel mixing and extrusion system with screw discharge

- Heavy-duty kneading and extrusion machine for rubber, plastics, and chemicals

- Jacketed sigma blade mixer with 75 PSI rated bowl and tangential blade design

- Used Werner & Pfleiderer UK12-AU3 sigma mixer extruder with 21-gallon working capacity

- Industrial mixing and extrusion system with jacketed bowl, sigma blades, and screw discharge

- Werner & Pfleiderer sigma blade mixer with 22.5 HP motor and carbon steel construction

- Used high-capacity batch mixer for polymers, adhesives, and chemical processing

- Sigma blade kneader with jacketed heating/cooling bowl and 6” screw discharge

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory