Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used 4.2 MW AEG-Kanis G25 Steam Turbine Generator Set | ABB AMS 710 SL Generator | Back-Pressure Cogeneration System

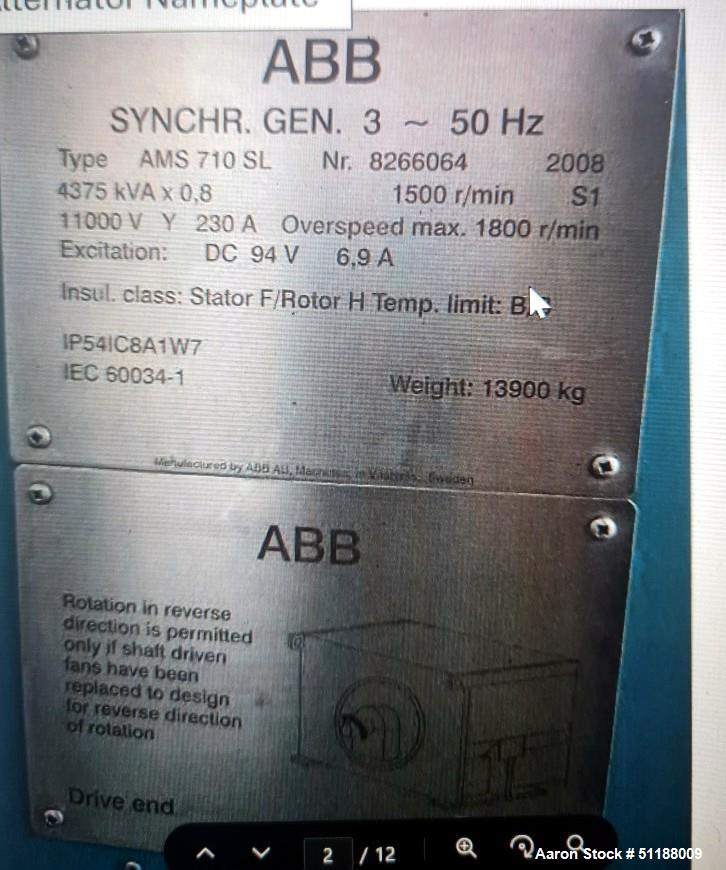

Used 4.2 MW AEG-Kanis G25 Steam Turbine Generator Set | ABB AMS 710 SL Generator | Back-Pressure Cogeneration System, industrial self-generation, or continuous base-load operation. The system consists of a 1979 AEG-Kanis G25 back-pressure steam turbine directly coupled to a 2008 ABB AMS 710 SL synchronous generator and includes all standard auxiliary components. The turbine is rated 4.2 MW mechanical and operates at 1500 rpm with superheated steam at approximately 31 bar (450 psig) and 400450C, exhausting to a process steam system. Included equipment consists of a turbine governor, throttle/control valve, lube-oil skid with pumps and coolers, overspeed trip mechanism, coupling, and base frame. The generator is rated 4375 kVA at 0.8 PF, 11 kV, 230 A, 50 Hz, and 1500 rpm, designed for S1 continuous duty with IC 81 W7 air-to-water cooling, IP54 enclosure protection, and Class F stator/Class H rotor insulation; total weight is approximately 13,900 kg. The package has been operated in an industrial environment with regular maintenance and remains in serviceable condition for relocation or refurbishment. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

| Manufacturer | AEGAEG |

| Model | G25 |

| Category | GeneratorsGenerators |

| Subcategory | Steam TurbineSteam Turbine |

🏭 Manufacturer Information

-

Turbine Manufacturer: AEG-Kanis

-

Turbine Model: G25 (Back-pressure steam turbine)

-

Turbine Year: 1979

-

Generator Manufacturer: ABB

-

Generator Model: AMS 710 SL

-

Generator Year: 2008

-

System Type: Industrial Steam Turbine-Generator Set (Cogeneration / Base-Load Duty)

⚙️ Product Description

This Used 4.2 MW Industrial Steam Turbine-Generator Set is a fully engineered back-pressure cogeneration system suitable for industrial self-generation, process steam utilization, and continuous base-load operation.

The system features a 1979 AEG-Kanis G25 back-pressure steam turbine directly coupled to a 2008 ABB AMS 710 SL synchronous generator. Designed for robust industrial duty, the package includes all major auxiliary systems, ensuring reliable and efficient operation.

The turbine operates at 1500 rpm with superheated steam at ~31 bar (450 psig) and 400–450°C, exhausting into a process steam header. Rated at 4.2 MW mechanical output, it is well suited for facilities requiring both electrical power and thermal energy (CHP).

The ABB generator is rated 4375 kVA, 0.8 PF, 11 kV, 230 A, 50 Hz, and is built for S1 continuous duty. Includes IC 81 W7 air-to-water cooling, IP54 enclosure, and Class F/H insulation, offering long-term durability.

Well maintained in an industrial environment, the package remains serviceable for relocation, recommissioning, or refurbishment.

📏 Specifications

Steam Turbine – AEG-Kanis G25

-

Type: Back-pressure industrial steam turbine

-

Mechanical Power: 4.2 MW

-

Speed: 1500 rpm

-

Steam Conditions:

-

Inlet: ~31 bar (450 psig)

-

Temperature: 400–450°C

-

-

Exhaust: To process steam system

-

Included Equipment:

-

Turbine governor

-

Throttle/control valve

-

Overspeed trip mechanism

-

Lube-oil skid with pumps, coolers & instrumentation

-

Coupling

-

Base frame

-

Generator – ABB AMS 710 SL

-

Electrical Rating: 4375 kVA

-

Power Factor: 0.8 PF

-

Voltage: 11 kV

-

Current: 230 A

-

Frequency: 50 Hz

-

Speed: 1500 rpm

-

Duty: S1 continuous

-

Cooling: IC 81 W7 (air-to-water heat exchanger)

-

Enclosure: IP54

-

Insulation: Class F stator / Class H rotor

-

Weight: ~13,900 kg

General System Information

-

Application: Cogeneration, base-load, industrial power & steam

-

Condition: Serviceable; maintained for industrial operation

-

Included: Turbine, generator, auxiliaries, controls, foundation frame

🧩 Applications

-

Industrial cogeneration (CHP)

-

Pulp & paper mills

-

Chemical plants

-

Food processing plants

-

Refineries & petrochemical facilities

-

Steam-intensive manufacturing

-

District heating systems

-

Biomass, waste-heat or boiler-driven power production

-

Base-load power generation

-

Process steam & electricity integration

⚗️ What This Might Be Used For

-

Producing both electrical power and process steam simultaneously

-

Replacing or upgrading existing steam turbine equipment

-

Lowering industrial energy costs through self-generation

-

Integrating into renewable or waste-heat-powered systems

-

Exporting excess power to the grid

-

steam turbine

-

4.2 MW turbine

-

cogeneration system

-

AEG-Kanis turbine

-

ABB generator

-

industrial turbine

-

back-pressure turbine

-

steam power unit

-

used turbine generator

-

CHP turbine

-

used 4.2 MW steam turbine generator set

-

AEG-Kanis G25 back-pressure turbine

-

industrial cogeneration steam turbine system

-

ABB AMS 710 SL synchronous generator

-

steam turbine for process steam and power

-

used CHP turbine generator equipment

-

turbine generator with lube oil skid

-

11 kV synchronous generator package

-

steam turbine for industrial energy recovery

-

base-load industrial power turbine

-

used AEG-Kanis G25 4.2 MW back-pressure steam turbine generator set with ABB AMS 710 SL 11 kV generator

-

industrial cogeneration turbine system with 31 bar 400–450°C steam inlet conditions

-

complete steam turbine package with lube-oil skid, controls, governor, valves, and auxiliaries

-

steam turbine-generator for continuous-duty industrial self-generation and process steam applications

-

used turbine system suitable for chemical, paper, refinery, and CHP power production facilities

-

4.2 MW industrial turbine with synchronous generator and IP54, IC81 W7 cooling configuration

-

complete back-pressure turbine generator package ready for refurbishment or relocation

-

heavy-duty steam turbine ideal for cogeneration and base-load industrial energy systems

-

used 11 kV synchronous generator coupled to steam turbine for industrial power applications

-

high-efficiency steam turbine set designed for cogeneration in steam-intensive manufacturing

-

used steam turbine generator

-

cogeneration equipment

-

industrial back-pressure turbine

-

power generation equipment

-

synchronous generator 11 kV

-

used turbine package

-

AEG Kanis turbine

-

ABB generator system

-

steam CHP unit

-

industrial energy systems

-

buy steam turbine generator

-

purchase CHP turbine package

-

industrial power equipment for sale

-

used turbine generator marketplace

-

buy cogeneration system

-

steam turbine supplier

-

used ABB generator dealer

-

industrial energy equipment

-

power plant equipment purchase

-

turbine replacement options

-

sell steam turbine

-

list turbine generator set

-

advertise 4.2 MW turbine

-

resell cogeneration equipment

-

auction used power systems

-

export steam turbine packages

-

trade industrial energy equipment

-

used generator resale platform

-

plant equipment liquidation

-

turbine system sales

Used 4.2 MW AEG-Kanis G25 Steam Turbine Generator Set | ABB AMS 710 SL Generator | Back-Pressure Cogeneration System, industrial self-generation, or continuous base-load operation. The system consists of a 1979 AEG-Kanis G25 back-pressure steam turbine directly coupled to a 2008 ABB AMS 710 SL synchronous generator and includes all standard auxiliary components. The turbine is rated 4.2 MW mechanical and operates at 1500 rpm with superheated steam at approximately 31 bar (450 psig) and 400450C, exhausting to a process steam system. Included equipment consists of a turbine governor, throttle/control valve, lube-oil skid with pumps and coolers, overspeed trip mechanism, coupling, and base frame. The generator is rated 4375 kVA at 0.8 PF, 11 kV, 230 A, 50 Hz, and 1500 rpm, designed for S1 continuous duty with IC 81 W7 air-to-water cooling, IP54 enclosure protection, and Class F stator/Class H rotor insulation; total weight is approximately 13,900 kg. The package has been operated in an industrial environment with regular maintenance and remains in serviceable condition for relocation or refurbishment. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

🏭 Manufacturer Information

-

Turbine Manufacturer: AEG-Kanis

-

Turbine Model: G25 (Back-pressure steam turbine)

-

Turbine Year: 1979

-

Generator Manufacturer: ABB

-

Generator Model: AMS 710 SL

-

Generator Year: 2008

-

System Type: Industrial Steam Turbine-Generator Set (Cogeneration / Base-Load Duty)

⚙️ Product Description

This Used 4.2 MW Industrial Steam Turbine-Generator Set is a fully engineered back-pressure cogeneration system suitable for industrial self-generation, process steam utilization, and continuous base-load operation.

The system features a 1979 AEG-Kanis G25 back-pressure steam turbine directly coupled to a 2008 ABB AMS 710 SL synchronous generator. Designed for robust industrial duty, the package includes all major auxiliary systems, ensuring reliable and efficient operation.

The turbine operates at 1500 rpm with superheated steam at ~31 bar (450 psig) and 400–450°C, exhausting into a process steam header. Rated at 4.2 MW mechanical output, it is well suited for facilities requiring both electrical power and thermal energy (CHP).

The ABB generator is rated 4375 kVA, 0.8 PF, 11 kV, 230 A, 50 Hz, and is built for S1 continuous duty. Includes IC 81 W7 air-to-water cooling, IP54 enclosure, and Class F/H insulation, offering long-term durability.

Well maintained in an industrial environment, the package remains serviceable for relocation, recommissioning, or refurbishment.

📏 Specifications

Steam Turbine – AEG-Kanis G25

-

Type: Back-pressure industrial steam turbine

-

Mechanical Power: 4.2 MW

-

Speed: 1500 rpm

-

Steam Conditions:

-

Inlet: ~31 bar (450 psig)

-

Temperature: 400–450°C

-

-

Exhaust: To process steam system

-

Included Equipment:

-

Turbine governor

-

Throttle/control valve

-

Overspeed trip mechanism

-

Lube-oil skid with pumps, coolers & instrumentation

-

Coupling

-

Base frame

-

Generator – ABB AMS 710 SL

-

Electrical Rating: 4375 kVA

-

Power Factor: 0.8 PF

-

Voltage: 11 kV

-

Current: 230 A

-

Frequency: 50 Hz

-

Speed: 1500 rpm

-

Duty: S1 continuous

-

Cooling: IC 81 W7 (air-to-water heat exchanger)

-

Enclosure: IP54

-

Insulation: Class F stator / Class H rotor

-

Weight: ~13,900 kg

General System Information

-

Application: Cogeneration, base-load, industrial power & steam

-

Condition: Serviceable; maintained for industrial operation

-

Included: Turbine, generator, auxiliaries, controls, foundation frame

🧩 Applications

-

Industrial cogeneration (CHP)

-

Pulp & paper mills

-

Chemical plants

-

Food processing plants

-

Refineries & petrochemical facilities

-

Steam-intensive manufacturing

-

District heating systems

-

Biomass, waste-heat or boiler-driven power production

-

Base-load power generation

-

Process steam & electricity integration

⚗️ What This Might Be Used For

-

Producing both electrical power and process steam simultaneously

-

Replacing or upgrading existing steam turbine equipment

-

Lowering industrial energy costs through self-generation

-

Integrating into renewable or waste-heat-powered systems

-

Exporting excess power to the grid

| Manufacturer | AEG |

| Model | G25 |

| Category | Generators |

| Subcategory | Steam Turbine |

-

steam turbine

-

4.2 MW turbine

-

cogeneration system

-

AEG-Kanis turbine

-

ABB generator

-

industrial turbine

-

back-pressure turbine

-

steam power unit

-

used turbine generator

-

CHP turbine

-

used 4.2 MW steam turbine generator set

-

AEG-Kanis G25 back-pressure turbine

-

industrial cogeneration steam turbine system

-

ABB AMS 710 SL synchronous generator

-

steam turbine for process steam and power

-

used CHP turbine generator equipment

-

turbine generator with lube oil skid

-

11 kV synchronous generator package

-

steam turbine for industrial energy recovery

-

base-load industrial power turbine

-

used AEG-Kanis G25 4.2 MW back-pressure steam turbine generator set with ABB AMS 710 SL 11 kV generator

-

industrial cogeneration turbine system with 31 bar 400–450°C steam inlet conditions

-

complete steam turbine package with lube-oil skid, controls, governor, valves, and auxiliaries

-

steam turbine-generator for continuous-duty industrial self-generation and process steam applications

-

used turbine system suitable for chemical, paper, refinery, and CHP power production facilities

-

4.2 MW industrial turbine with synchronous generator and IP54, IC81 W7 cooling configuration

-

complete back-pressure turbine generator package ready for refurbishment or relocation

-

heavy-duty steam turbine ideal for cogeneration and base-load industrial energy systems

-

used 11 kV synchronous generator coupled to steam turbine for industrial power applications

-

high-efficiency steam turbine set designed for cogeneration in steam-intensive manufacturing

-

used steam turbine generator

-

cogeneration equipment

-

industrial back-pressure turbine

-

power generation equipment

-

synchronous generator 11 kV

-

used turbine package

-

AEG Kanis turbine

-

ABB generator system

-

steam CHP unit

-

industrial energy systems

-

buy steam turbine generator

-

purchase CHP turbine package

-

industrial power equipment for sale

-

used turbine generator marketplace

-

buy cogeneration system

-

steam turbine supplier

-

used ABB generator dealer

-

industrial energy equipment

-

power plant equipment purchase

-

turbine replacement options

-

sell steam turbine

-

list turbine generator set

-

advertise 4.2 MW turbine

-

resell cogeneration equipment

-

auction used power systems

-

export steam turbine packages

-

trade industrial energy equipment

-

used generator resale platform

-

plant equipment liquidation

-

turbine system sales

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory