Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Pre-Owned Alar Auto-Vac 340 – 37.7 Sq Ft Filtering Area, 304SS Drum

$5,500.00

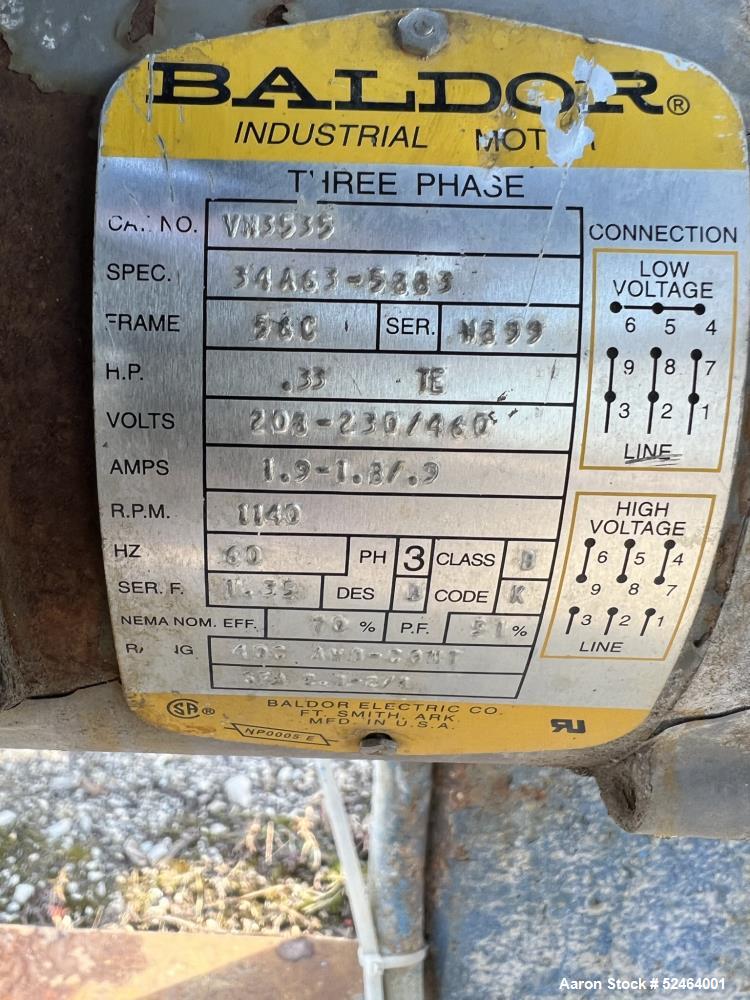

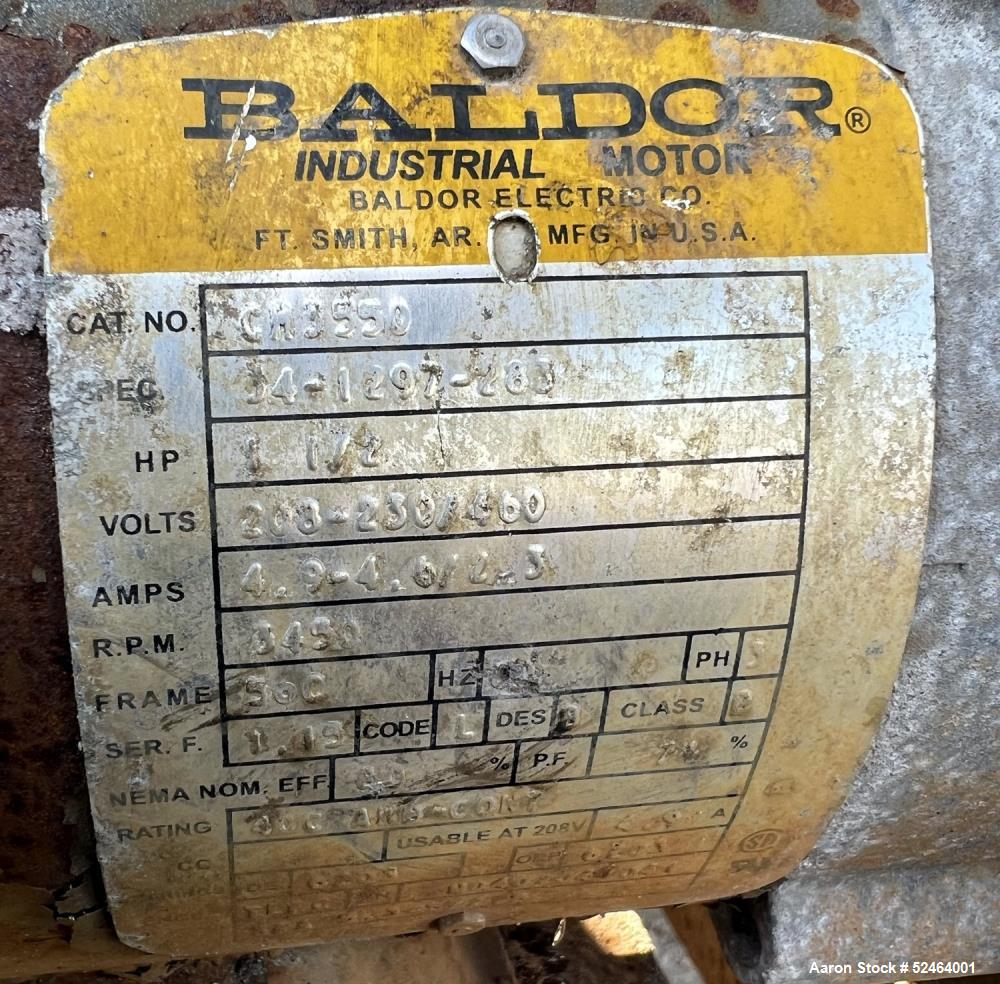

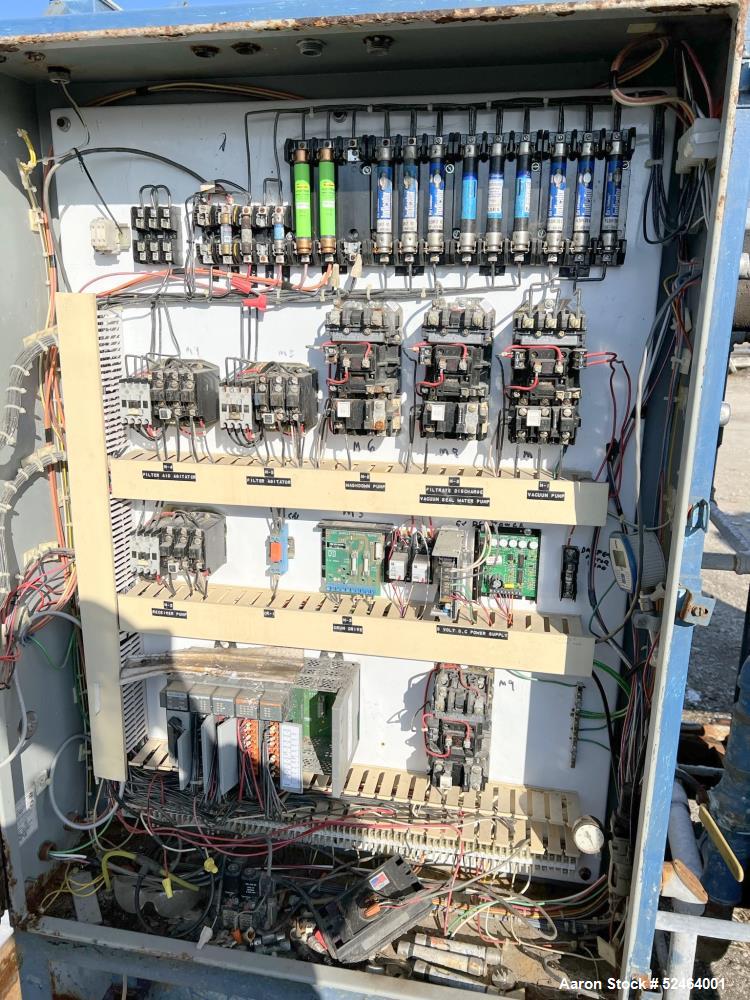

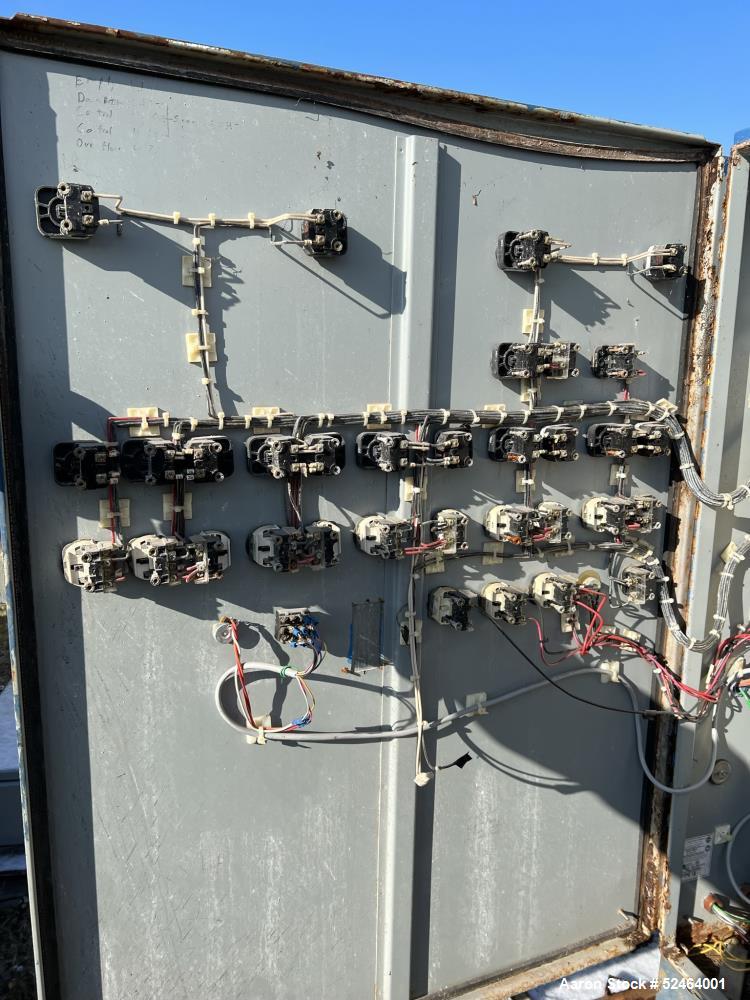

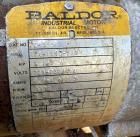

Used Alar Auto-Vac Rotary Vacuum Filter System, Model 340. 36" Diameter x 48" face 304SS drum, approximately 37.7 square feet nominal filtering area. Drum driven by an approximate .4hp, 1750 rpm gear motor, 288 to 1 ratio. Dry solids discharge with adjustable knife. Bottom holding tank with rake agitator, driven by a .33hp, 3/60/208-230/460 volt, 1140rpm motor. Receiver tank with pump, pump driven by a 1-1/2hp, 3/60/208-230/460 volt, 3450rpm motor. Control panel with Allen Bradley SLC PLC. Total connected horsepower 13. All unitized on a common carbon steel frame. Serial# 13121.

| Manufacturer | Alar EngineeringAlar Engineering |

| Model | 340 |

| Serial # | 13121 |

| Category | FiltersFilters |

| Subcategory | Rotary Vacuum FiltersRotary Vacuum Filters |

| Filter Area | 37.7 |

| Frame Material | Carbon Steel |

| Overall Dimensions | 186" x 74" x 112"T |

Manufacturer Information:

- Brand: Alar

- Model: Auto-Vac 340

- Material: 304 Stainless Steel Drum

- Serial Number: 13121

Description:

The Alar Auto-Vac Model 340 Rotary Vacuum Filter System is a high-efficiency liquid-solid separation system, designed for industrial filtration, wastewater treatment, and sludge dewatering applications.

This system features a 36” diameter x 48” face 304 stainless steel drum, providing 37.7 square feet of nominal filtering area. The drum is driven by a 0.4 HP, 1750 RPM gear motor (288:1 ratio), ensuring steady vacuum filtration performance.

The dry solids discharge system includes an adjustable knife for precise material removal. The bottom holding tank is equipped with a rake agitator, driven by a 0.33 HP motor (1140 RPM), ensuring consistent material flow.

Additionally, the system includes a receiver tank with a pump, powered by a 1.5 HP motor (3450 RPM) for efficient liquid handling. The system is controlled via an Allen Bradley SLC PLC, allowing for automated operation and monitoring.

All components are unitized on a common carbon steel frame, ensuring stability and easy integration into industrial processes.

Key Features:

- 36” Diameter x 48” Face 304 Stainless Steel Drum

- 37.7 Square Feet of Nominal Filtering Area for high-capacity filtration

- 0.4 HP, 1750 RPM Drum Drive Motor (288:1 Ratio)

- Dry Solids Discharge with Adjustable Knife for precise material removal

- Bottom Holding Tank with Rake Agitator (0.33 HP, 1140 RPM Motor)

- Receiver Tank with Pump (1.5 HP, 3450 RPM Motor)

- Allen Bradley SLC PLC Control Panel for automated operation

- Total Connected Horsepower: 13 HP

- Unitized on a Carbon Steel Frame for durability and stability

Specifications:

- Machine Type: Rotary Vacuum Filter System

- Brand: Alar

- Model: Auto-Vac 340

- Drum Size: 36” Diameter x 48” Face

- Filtering Area: 37.7 Square Feet

- Drum Drive Motor: 0.4 HP, 1750 RPM, 288:1 Ratio

- Solids Discharge: Adjustable Knife

- Agitator Motor: 0.33 HP, 1140 RPM

- Pump Motor: 1.5 HP, 3450 RPM

- Total Connected Horsepower: 13 HP

- Control Panel: Allen Bradley SLC PLC

- Frame: Carbon Steel

- Serial Number: 13121

Applications:

- Industrial Wastewater Treatment – Sludge dewatering and solid-liquid separation

- Chemical Processing – Filtration of chemical slurries and process byproducts

- Mining & Minerals – Dewatering of mineral and ore processing wastewater

- Food & Beverage Industry – Liquid-solid separation in food production

- Pharmaceutical Manufacturing – Recovery of valuable solids from liquid waste

What Products Would This Be Used For?

- Wastewater treatment and sludge dewatering

- Chemical and industrial filtration processes

- Removal of solids from food processing waste

- Recovery of valuable materials in pharmaceutical production

- Dewatering of mining and mineral processing slurries

Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Coatings (Water Based), Concrete, Dairy, Fat, Oil & Grease (FOG), Flexographic Printing, Grease, Hydraulic Fracturing, k-Cup, Metal Finishing, Oil Drilling, Paints (Water Based), Septic

- Alar Auto-Vac 340

- Used rotary vacuum filter

- Industrial sludge dewatering

- Wastewater vacuum filter

- 36” drum vacuum filter

- Used industrial filtration system

- Alar Model 340 for sale

- 304SS rotary drum filter

- Automated vacuum filter system

- Used wastewater treatment equipment

- Used Alar Auto-Vac 340 rotary vacuum filter for industrial wastewater treatment

- High-efficiency sludge dewatering system with 37.7 sq ft filtering area

- Pre-owned rotary drum vacuum filter with Allen Bradley PLC control

- Used Alar Model 340 vacuum filter with adjustable solids discharge knife

- Industrial vacuum filter system with 36” stainless steel drum

- Alar rotary vacuum filtration system for chemical processing applications

- Used wastewater treatment filter with bottom holding tank and rake agitator

- 304 stainless steel rotary drum vacuum filter for solid-liquid separation

- Pre-owned Alar Auto-Vac system with automated PLC operation

- Used industrial filtration equipment for chemical, mining, and food processing

- Used Alar Auto-Vac 340 rotary vacuum filter system with 36” drum and 37.7 sq ft filtering area

- Buy a pre-owned industrial vacuum filter with automated Allen Bradley PLC control

- High-capacity sludge dewatering system for wastewater treatment applications

- Used rotary vacuum filter with stainless steel drum and solids discharge knife

- Industrial filtration system with bottom holding tank and high-speed pump motor

- Pre-owned Alar Model 340 for solid-liquid separation in chemical and food processing industries

- Reliable used rotary drum vacuum filter for pharmaceutical manufacturing and mining applications

- Cost-effective used vacuum filtration system for sludge dewatering and wastewater management

- Used Alar Auto-Vac vacuum filter with high-efficiency rake agitator and receiver tank

- Industrial-grade rotary drum vacuum filter for liquid-solid separation processes

- Used Alar vacuum filter for sale

- Buy used rotary vacuum filter

- Industrial sludge dewatering system

- Affordable wastewater treatment equipment pricing

- Pre-owned rotary drum vacuum filter

- High-efficiency industrial filtration system

- Used vacuum filter for mining and chemical processing

- Alar Auto-Vac Model 340 availability

- Reliable used industrial filtration equipment

- Heavy-duty vacuum filter for wastewater treatment

- Buy used Alar Auto-Vac 340 rotary vacuum filter

- Sell industrial vacuum filter system

- Used sludge dewatering filter for sale

- Where to buy Alar Auto-Vac filtration systems

- Best rotary vacuum filter for wastewater treatment

- Affordable used industrial filtration system pricing

- Used Alar Auto-Vac availability for chemical processing

- Buy pre-owned rotary drum vacuum filter for sludge management

- Reliable used industrial wastewater filtration system for sale

- Used rotary vacuum filter with automated PLC control

Used Alar Auto-Vac Rotary Vacuum Filter System, Model 340. 36" Diameter x 48" face 304SS drum, approximately 37.7 square feet nominal filtering area. Drum driven by an approximate .4hp, 1750 rpm gear motor, 288 to 1 ratio. Dry solids discharge with adjustable knife. Bottom holding tank with rake agitator, driven by a .33hp, 3/60/208-230/460 volt, 1140rpm motor. Receiver tank with pump, pump driven by a 1-1/2hp, 3/60/208-230/460 volt, 3450rpm motor. Control panel with Allen Bradley SLC PLC. Total connected horsepower 13. All unitized on a common carbon steel frame. Serial# 13121.

Manufacturer Information:

- Brand: Alar

- Model: Auto-Vac 340

- Material: 304 Stainless Steel Drum

- Serial Number: 13121

Description:

The Alar Auto-Vac Model 340 Rotary Vacuum Filter System is a high-efficiency liquid-solid separation system, designed for industrial filtration, wastewater treatment, and sludge dewatering applications.

This system features a 36” diameter x 48” face 304 stainless steel drum, providing 37.7 square feet of nominal filtering area. The drum is driven by a 0.4 HP, 1750 RPM gear motor (288:1 ratio), ensuring steady vacuum filtration performance.

The dry solids discharge system includes an adjustable knife for precise material removal. The bottom holding tank is equipped with a rake agitator, driven by a 0.33 HP motor (1140 RPM), ensuring consistent material flow.

Additionally, the system includes a receiver tank with a pump, powered by a 1.5 HP motor (3450 RPM) for efficient liquid handling. The system is controlled via an Allen Bradley SLC PLC, allowing for automated operation and monitoring.

All components are unitized on a common carbon steel frame, ensuring stability and easy integration into industrial processes.

Key Features:

- 36” Diameter x 48” Face 304 Stainless Steel Drum

- 37.7 Square Feet of Nominal Filtering Area for high-capacity filtration

- 0.4 HP, 1750 RPM Drum Drive Motor (288:1 Ratio)

- Dry Solids Discharge with Adjustable Knife for precise material removal

- Bottom Holding Tank with Rake Agitator (0.33 HP, 1140 RPM Motor)

- Receiver Tank with Pump (1.5 HP, 3450 RPM Motor)

- Allen Bradley SLC PLC Control Panel for automated operation

- Total Connected Horsepower: 13 HP

- Unitized on a Carbon Steel Frame for durability and stability

Specifications:

- Machine Type: Rotary Vacuum Filter System

- Brand: Alar

- Model: Auto-Vac 340

- Drum Size: 36” Diameter x 48” Face

- Filtering Area: 37.7 Square Feet

- Drum Drive Motor: 0.4 HP, 1750 RPM, 288:1 Ratio

- Solids Discharge: Adjustable Knife

- Agitator Motor: 0.33 HP, 1140 RPM

- Pump Motor: 1.5 HP, 3450 RPM

- Total Connected Horsepower: 13 HP

- Control Panel: Allen Bradley SLC PLC

- Frame: Carbon Steel

- Serial Number: 13121

Applications:

- Industrial Wastewater Treatment – Sludge dewatering and solid-liquid separation

- Chemical Processing – Filtration of chemical slurries and process byproducts

- Mining & Minerals – Dewatering of mineral and ore processing wastewater

- Food & Beverage Industry – Liquid-solid separation in food production

- Pharmaceutical Manufacturing – Recovery of valuable solids from liquid waste

What Products Would This Be Used For?

- Wastewater treatment and sludge dewatering

- Chemical and industrial filtration processes

- Removal of solids from food processing waste

- Recovery of valuable materials in pharmaceutical production

- Dewatering of mining and mineral processing slurries

Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), Coatings (Water Based), Concrete, Dairy, Fat, Oil & Grease (FOG), Flexographic Printing, Grease, Hydraulic Fracturing, k-Cup, Metal Finishing, Oil Drilling, Paints (Water Based), Septic

| Manufacturer | Alar Engineering |

| Model | 340 |

| Serial # | 13121 |

| Category | Filters |

| Subcategory | Rotary Vacuum Filters |

| Filter Area | 37.7 |

| Frame Material | Carbon Steel |

| Overall Dimensions | 186" x 74" x 112"T |

- Alar Auto-Vac 340

- Used rotary vacuum filter

- Industrial sludge dewatering

- Wastewater vacuum filter

- 36” drum vacuum filter

- Used industrial filtration system

- Alar Model 340 for sale

- 304SS rotary drum filter

- Automated vacuum filter system

- Used wastewater treatment equipment

- Used Alar Auto-Vac 340 rotary vacuum filter for industrial wastewater treatment

- High-efficiency sludge dewatering system with 37.7 sq ft filtering area

- Pre-owned rotary drum vacuum filter with Allen Bradley PLC control

- Used Alar Model 340 vacuum filter with adjustable solids discharge knife

- Industrial vacuum filter system with 36” stainless steel drum

- Alar rotary vacuum filtration system for chemical processing applications

- Used wastewater treatment filter with bottom holding tank and rake agitator

- 304 stainless steel rotary drum vacuum filter for solid-liquid separation

- Pre-owned Alar Auto-Vac system with automated PLC operation

- Used industrial filtration equipment for chemical, mining, and food processing

- Used Alar Auto-Vac 340 rotary vacuum filter system with 36” drum and 37.7 sq ft filtering area

- Buy a pre-owned industrial vacuum filter with automated Allen Bradley PLC control

- High-capacity sludge dewatering system for wastewater treatment applications

- Used rotary vacuum filter with stainless steel drum and solids discharge knife

- Industrial filtration system with bottom holding tank and high-speed pump motor

- Pre-owned Alar Model 340 for solid-liquid separation in chemical and food processing industries

- Reliable used rotary drum vacuum filter for pharmaceutical manufacturing and mining applications

- Cost-effective used vacuum filtration system for sludge dewatering and wastewater management

- Used Alar Auto-Vac vacuum filter with high-efficiency rake agitator and receiver tank

- Industrial-grade rotary drum vacuum filter for liquid-solid separation processes

- Used Alar vacuum filter for sale

- Buy used rotary vacuum filter

- Industrial sludge dewatering system

- Affordable wastewater treatment equipment pricing

- Pre-owned rotary drum vacuum filter

- High-efficiency industrial filtration system

- Used vacuum filter for mining and chemical processing

- Alar Auto-Vac Model 340 availability

- Reliable used industrial filtration equipment

- Heavy-duty vacuum filter for wastewater treatment

- Buy used Alar Auto-Vac 340 rotary vacuum filter

- Sell industrial vacuum filter system

- Used sludge dewatering filter for sale

- Where to buy Alar Auto-Vac filtration systems

- Best rotary vacuum filter for wastewater treatment

- Affordable used industrial filtration system pricing

- Used Alar Auto-Vac availability for chemical processing

- Buy pre-owned rotary drum vacuum filter for sludge management

- Reliable used industrial wastewater filtration system for sale

- Used rotary vacuum filter with automated PLC control

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory