Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Industrial Used Patterson Kelley (PK) 3 Cubic Foot Twin Shell Solids Processor

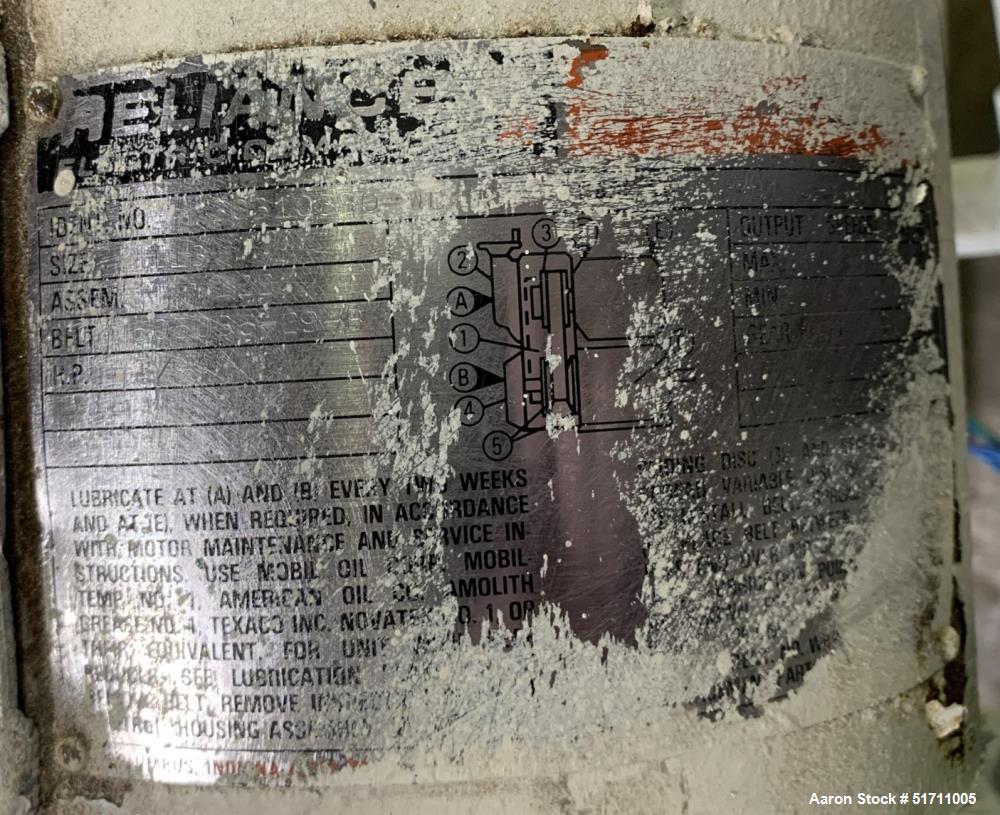

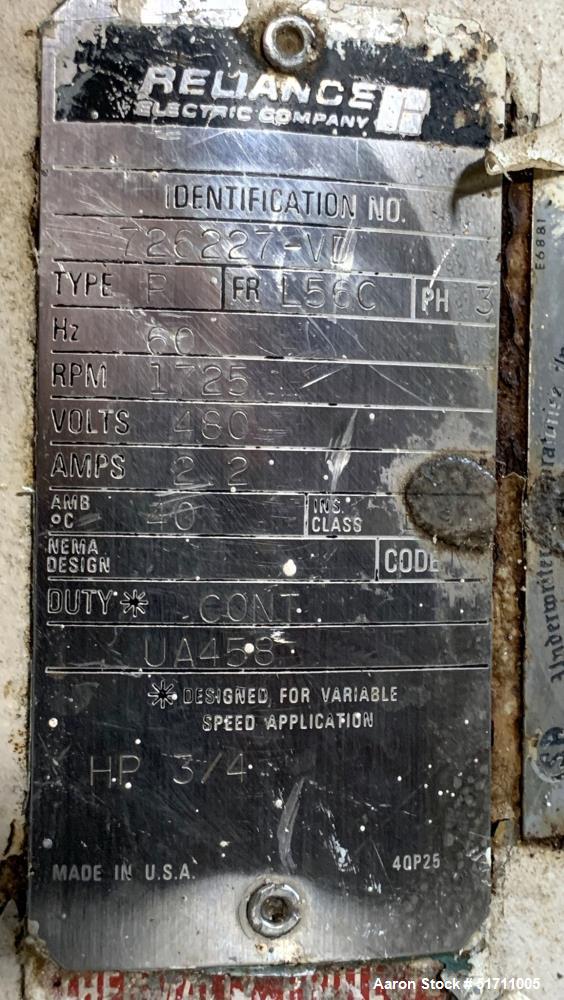

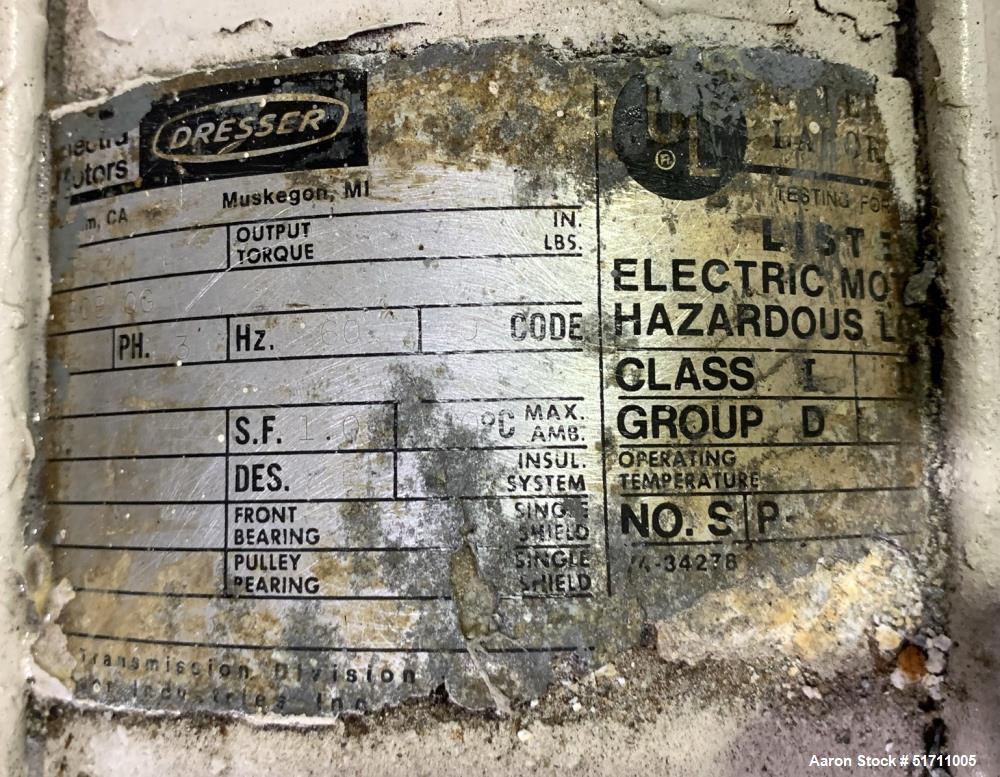

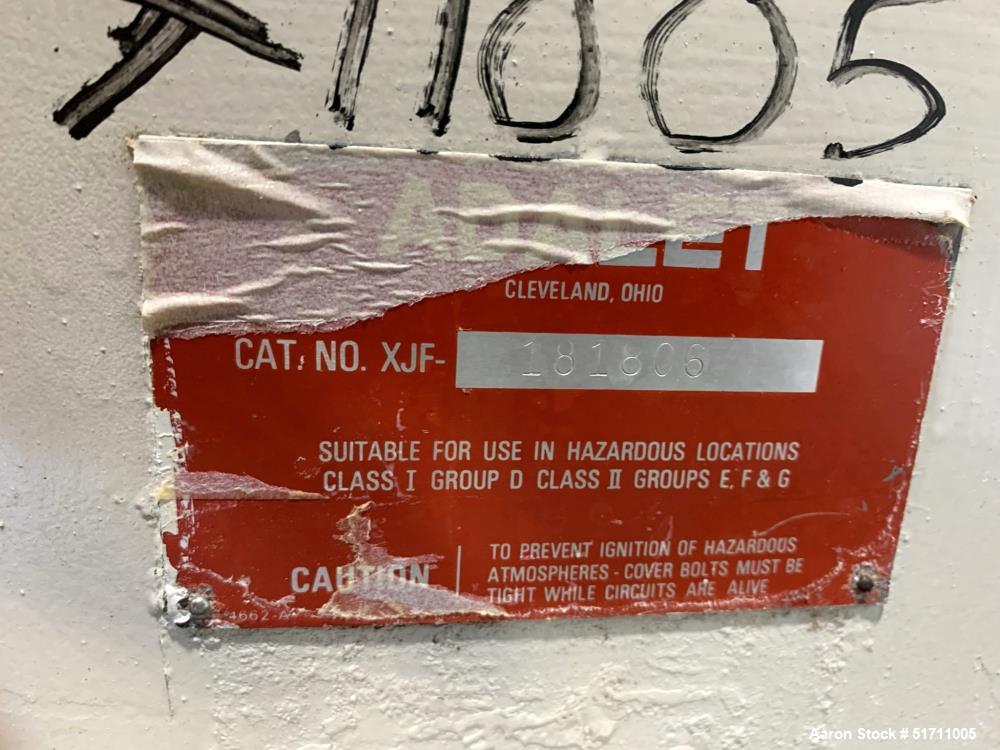

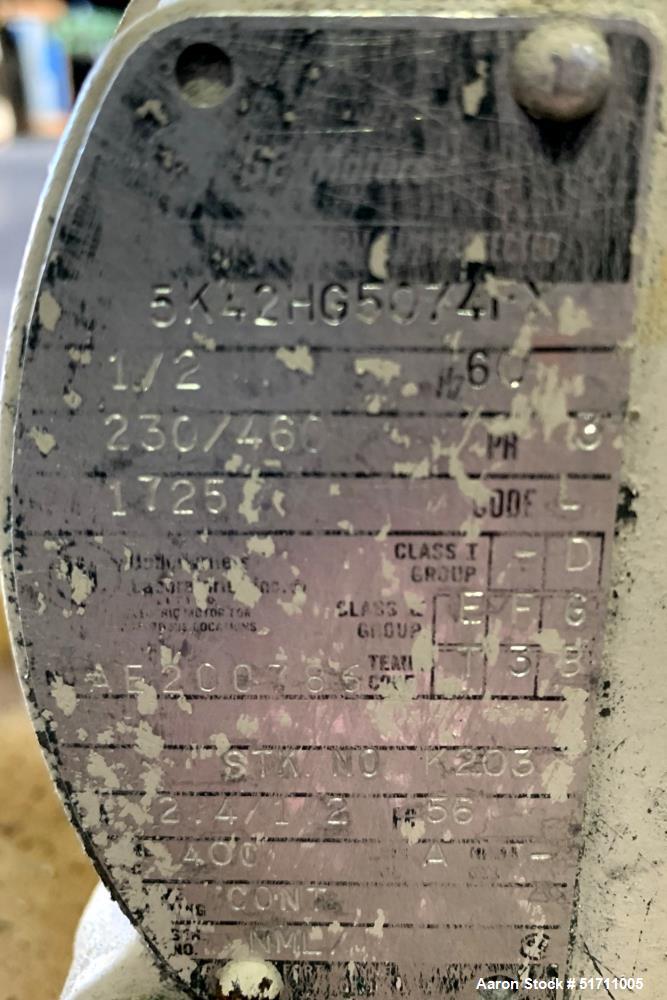

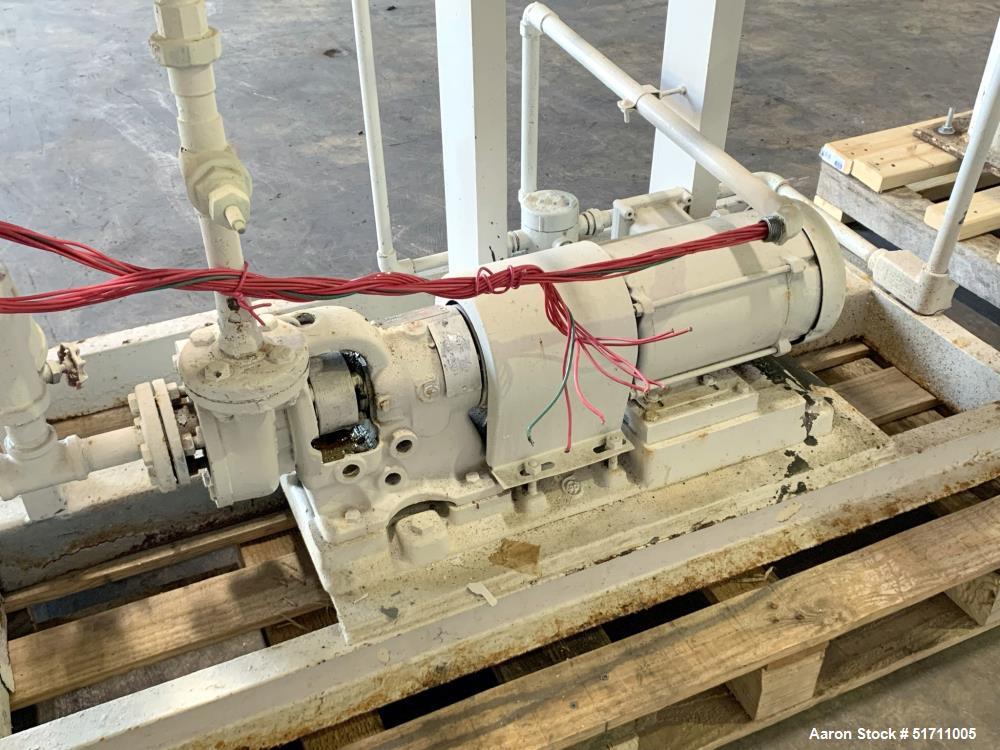

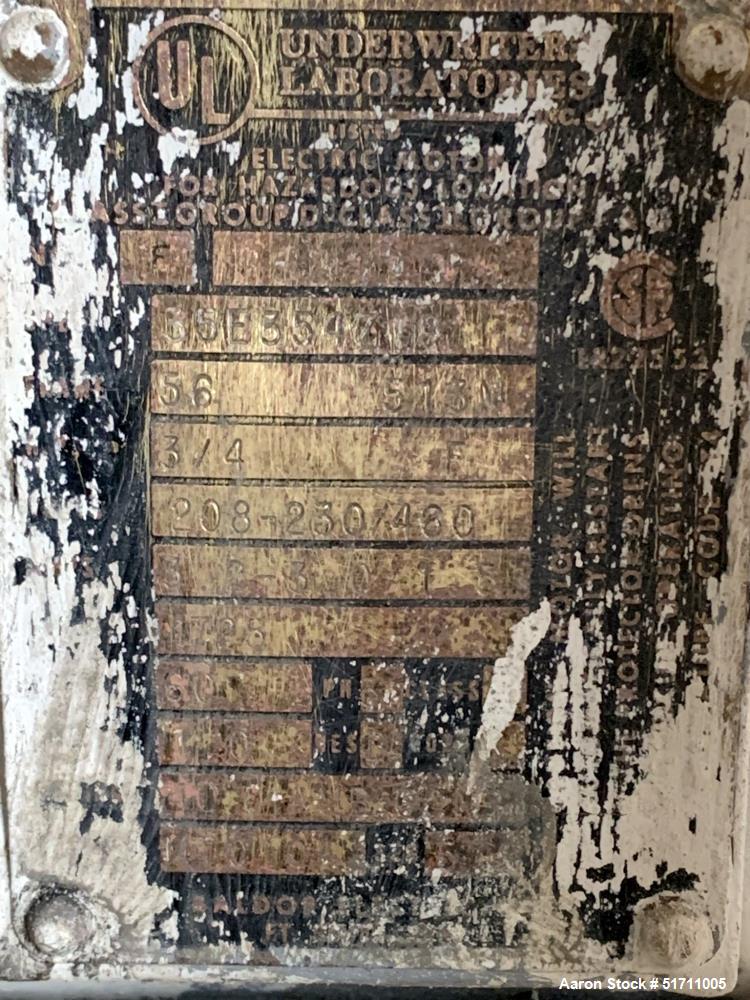

Used Patterson Kelley (PK) 3 Cubic feet working capacity Twin Shell Solids Processor. Maximum material density 100 pounds per cubic foot. 304 Stainless Steel Vessel, 316 Stainless Steel Shaft. Shell rated full vacuum at 250 degrees F maximum temperature. Jacket rated 30 psi at 250 degrees F. (2) 16" Diameter charge ports with quick change covers. Shell driven by Reeves manual adjustable speed drive with 3/4hp, 3/60/230/460 volt, 1725 rpm XP gear motor, 44:1 ratio, 10.6 to 84 rpm output speed. Intensifier bar driven by 2hp, 3/60/230/460 volt, 1725 rpm XP motor. 6" Center bottom outlet with manual butterfly valve, approximate discharge height 30". Includes explosion proof control panel, vacuum pump skid with 1/2hp vacuum pump and circulation skid with 3/4hp pump. Frame mounted. PK Serial# 24922, National board# 42372.

Patterson-Kelley (PK) Twin Shell Solids Processor - Used

Manufacturer Information:

- Patterson-Kelley (PK) - A division of Harsco Industrial. While PK is now part of other entities, their equipment is known for robust design and longevity. Finding detailed manufacturer specs on older models may require contacting Harsco or specialized used equipment dealers.

Specifications:

- Model: Twin Shell Solids Processor (Specific model number may be available on the unit's nameplate)

- Working Capacity: 3 cubic feet

- Maximum Material Density: 100 lbs/cubic foot

- Vessel Material: 304 Stainless Steel

- Shaft Material: 316 Stainless Steel

- Shell Rating: Full vacuum at 250°F maximum temperature

- Jacket Rating: 30 psi at 250°F

- Charge Ports: (2) 16" diameter with quick-change covers

- Shell Drive: Reeves manual adjustable speed drive, 3/4 HP, 3/60/230/460V, 1725 RPM XP gear motor, 44:1 ratio, 10.6 to 84 RPM output speed

- Intensifier Bar Drive: 2 HP, 3/60/230/460V, 1725 RPM XP motor

- Outlet: 6" center bottom outlet with manual butterfly valve, ~30" discharge height

- Controls: Explosion-proof control panel

- Ancillary Equipment: Vacuum pump skid with 1/2 HP vacuum pump, circulation skid with 3/4 HP pump

- Mounting: Frame mounted

- Serial Number: PK #24922

- National Board Number: 42372

Applications:

- Blending: Efficiently blends solids, powders, and granules. The twin shell design and intensifier bar promote thorough mixing.

- Drying: Jacketed design allows for heating or cooling, making it suitable for drying applications. Vacuum capability enhances drying efficiency.

- Coating: Can be used for coating applications with the addition of appropriate spray nozzles or other coating mechanisms.

- Granulation: The mixing action and potential for adding liquids make it adaptable for certain granulation processes.

- Chemical Processing: Suitable for various chemical reactions and processing steps where precise mixing and temperature control are required.

- Pharmaceuticals: Can be used in pharmaceutical processing for blending, drying, and granulation (subject to validation and sanitary considerations).

- Food Processing: Applicable in food processing for blending and mixing of ingredients (subject to sanitary considerations).

- Patterson-Kelley

- PK

- Twin Shell

- Solids Processor

- Blender

- Mixer

- Dryer

- Stainless Steel

- Used Equipment

- Industrial Equipment

- 3 Cubic Feet

- Vacuum

- Jacketed

- Explosion Proof

- Reeves Drive

- Used Patterson-Kelley Twin Shell Solids Processor for sale

- PK 3 cubic foot stainless steel blender

- Industrial twin shell mixer with vacuum and jacket

- Buy used PK solids processor with explosion proof controls

- Patterson Kelley twin shell dryer for sale

- 304 stainless steel twin shell blender for chemical processing

- Used PK mixer for powder blending

- Refurbished Patterson Kelley solids processor

- PK twin shell mixer for pharmaceutical use

- Find used PK equipment

Used Patterson Kelley (PK) 3 Cubic feet working capacity Twin Shell Solids Processor. Maximum material density 100 pounds per cubic foot. 304 Stainless Steel Vessel, 316 Stainless Steel Shaft. Shell rated full vacuum at 250 degrees F maximum temperature. Jacket rated 30 psi at 250 degrees F. (2) 16" Diameter charge ports with quick change covers. Shell driven by Reeves manual adjustable speed drive with 3/4hp, 3/60/230/460 volt, 1725 rpm XP gear motor, 44:1 ratio, 10.6 to 84 rpm output speed. Intensifier bar driven by 2hp, 3/60/230/460 volt, 1725 rpm XP motor. 6" Center bottom outlet with manual butterfly valve, approximate discharge height 30". Includes explosion proof control panel, vacuum pump skid with 1/2hp vacuum pump and circulation skid with 3/4hp pump. Frame mounted. PK Serial# 24922, National board# 42372.

Patterson-Kelley (PK) Twin Shell Solids Processor - Used

Manufacturer Information:

- Patterson-Kelley (PK) - A division of Harsco Industrial. While PK is now part of other entities, their equipment is known for robust design and longevity. Finding detailed manufacturer specs on older models may require contacting Harsco or specialized used equipment dealers.

Specifications:

- Model: Twin Shell Solids Processor (Specific model number may be available on the unit's nameplate)

- Working Capacity: 3 cubic feet

- Maximum Material Density: 100 lbs/cubic foot

- Vessel Material: 304 Stainless Steel

- Shaft Material: 316 Stainless Steel

- Shell Rating: Full vacuum at 250°F maximum temperature

- Jacket Rating: 30 psi at 250°F

- Charge Ports: (2) 16" diameter with quick-change covers

- Shell Drive: Reeves manual adjustable speed drive, 3/4 HP, 3/60/230/460V, 1725 RPM XP gear motor, 44:1 ratio, 10.6 to 84 RPM output speed

- Intensifier Bar Drive: 2 HP, 3/60/230/460V, 1725 RPM XP motor

- Outlet: 6" center bottom outlet with manual butterfly valve, ~30" discharge height

- Controls: Explosion-proof control panel

- Ancillary Equipment: Vacuum pump skid with 1/2 HP vacuum pump, circulation skid with 3/4 HP pump

- Mounting: Frame mounted

- Serial Number: PK #24922

- National Board Number: 42372

Applications:

- Blending: Efficiently blends solids, powders, and granules. The twin shell design and intensifier bar promote thorough mixing.

- Drying: Jacketed design allows for heating or cooling, making it suitable for drying applications. Vacuum capability enhances drying efficiency.

- Coating: Can be used for coating applications with the addition of appropriate spray nozzles or other coating mechanisms.

- Granulation: The mixing action and potential for adding liquids make it adaptable for certain granulation processes.

- Chemical Processing: Suitable for various chemical reactions and processing steps where precise mixing and temperature control are required.

- Pharmaceuticals: Can be used in pharmaceutical processing for blending, drying, and granulation (subject to validation and sanitary considerations).

- Food Processing: Applicable in food processing for blending and mixing of ingredients (subject to sanitary considerations).

- Patterson-Kelley

- PK

- Twin Shell

- Solids Processor

- Blender

- Mixer

- Dryer

- Stainless Steel

- Used Equipment

- Industrial Equipment

- 3 Cubic Feet

- Vacuum

- Jacketed

- Explosion Proof

- Reeves Drive

- Used Patterson-Kelley Twin Shell Solids Processor for sale

- PK 3 cubic foot stainless steel blender

- Industrial twin shell mixer with vacuum and jacket

- Buy used PK solids processor with explosion proof controls

- Patterson Kelley twin shell dryer for sale

- 304 stainless steel twin shell blender for chemical processing

- Used PK mixer for powder blending

- Refurbished Patterson Kelley solids processor

- PK twin shell mixer for pharmaceutical use

- Find used PK equipment

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory