Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Chem Systems Starch Cooking System

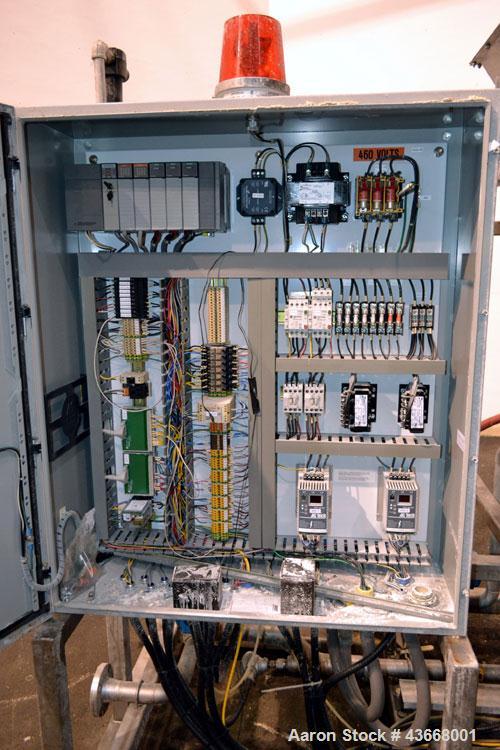

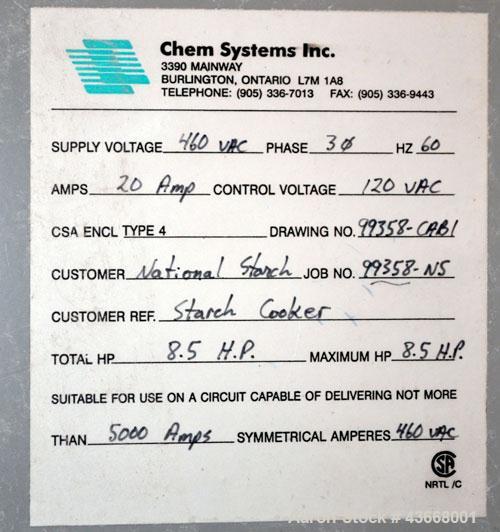

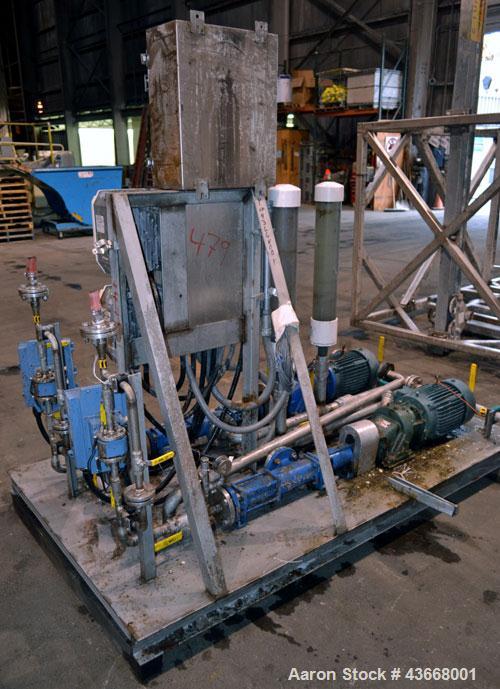

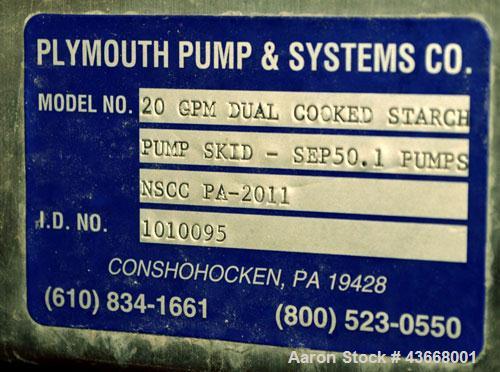

Used Chem Systems Starch Cooking System. Approximate flow rates: Starch (3% moisture)- 5000 pounds per day. Consisting of: (1) Stainless steel super sack unloader, 2 ton capacity. Frame approximate 156" tall with bag hanger, (1) Chem System Cooker, 316 stainless steel product contact areas. With a top feed hopper into an Acrison style feeder, approximate 2" diameter auger driven by a 1/2 hp gear motor, (1) Allweiler AG progressing cavity pump, type AED2N38, driven by a 2 hp gear motor, (6) cooking tubes, (2) basket filters, (1) Goulds vertical pump, model 2SVBK11, driven by a 5 hp motor, (1) control panel with an Allen-Bradley Panelview 1000, (2) AC Tech VFDs, and Allen-Bradley SLC 5/04 CPU, all mounted on a stainless steel frame. (1) Plymouth 20 gallons per minute dual cooked starch pump skid with (2) Shanley progressing cavity pump, type SEP50.1, each driven by a 3 hp gear motor, (1) control panel with Honeywell controllers, (2) Reliance VS drives, and miscellaneous piping and valves, all base mounted, (3) Plastic tanks

Used Chem Systems Starch Cooking System. Approximate flow rates: Starch (3% moisture)- 5000 pounds per day. Consisting of: (1) Stainless steel super sack unloader, 2 ton capacity. Frame approximate 156" tall with bag hanger, (1) Chem System Cooker, 316 stainless steel product contact areas. With a top feed hopper into an Acrison style feeder, approximate 2" diameter auger driven by a 1/2 hp gear motor, (1) Allweiler AG progressing cavity pump, type AED2N38, driven by a 2 hp gear motor, (6) cooking tubes, (2) basket filters, (1) Goulds vertical pump, model 2SVBK11, driven by a 5 hp motor, (1) control panel with an Allen-Bradley Panelview 1000, (2) AC Tech VFDs, and Allen-Bradley SLC 5/04 CPU, all mounted on a stainless steel frame. (1) Plymouth 20 gallons per minute dual cooked starch pump skid with (2) Shanley progressing cavity pump, type SEP50.1, each driven by a 3 hp gear motor, (1) control panel with Honeywell controllers, (2) Reliance VS drives, and miscellaneous piping and valves, all base mounted, (3) Plastic tanks

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory