Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Semi-Automated Mushroom Substrate Processing System for Sale

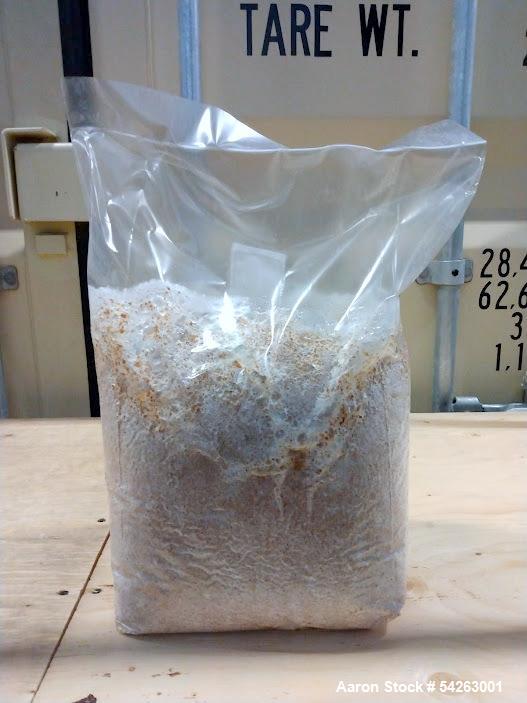

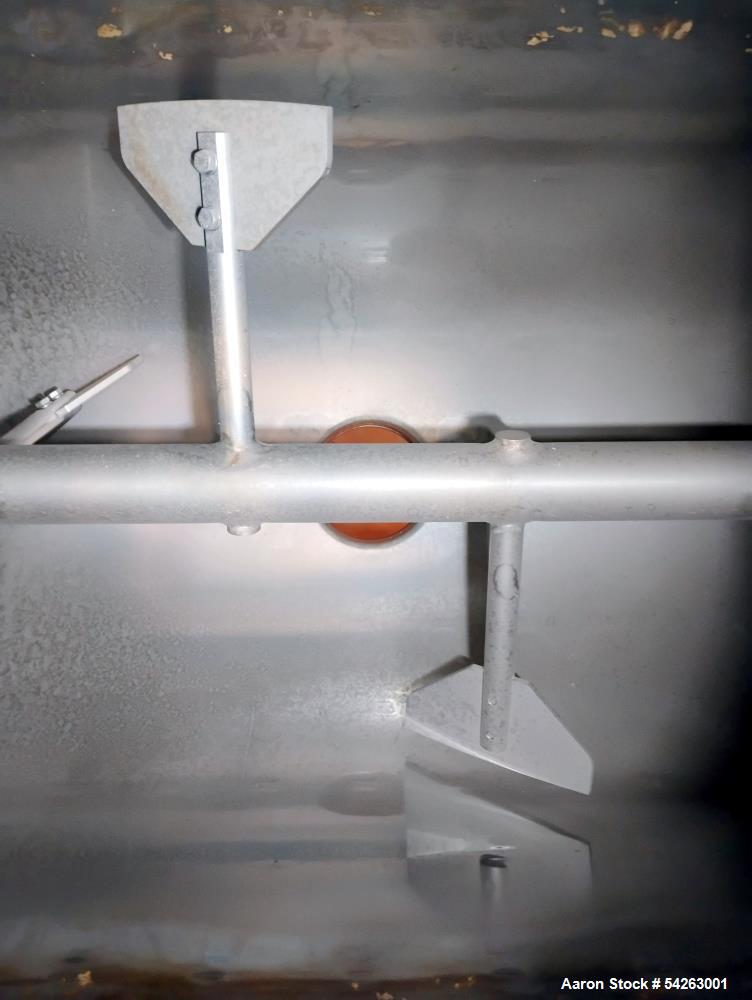

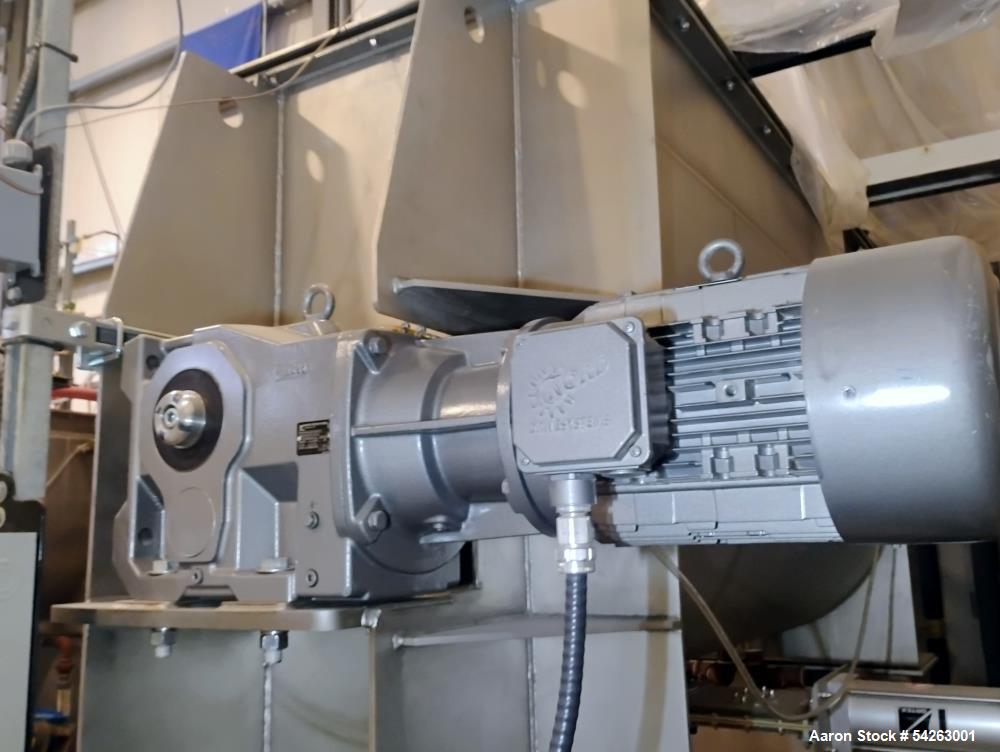

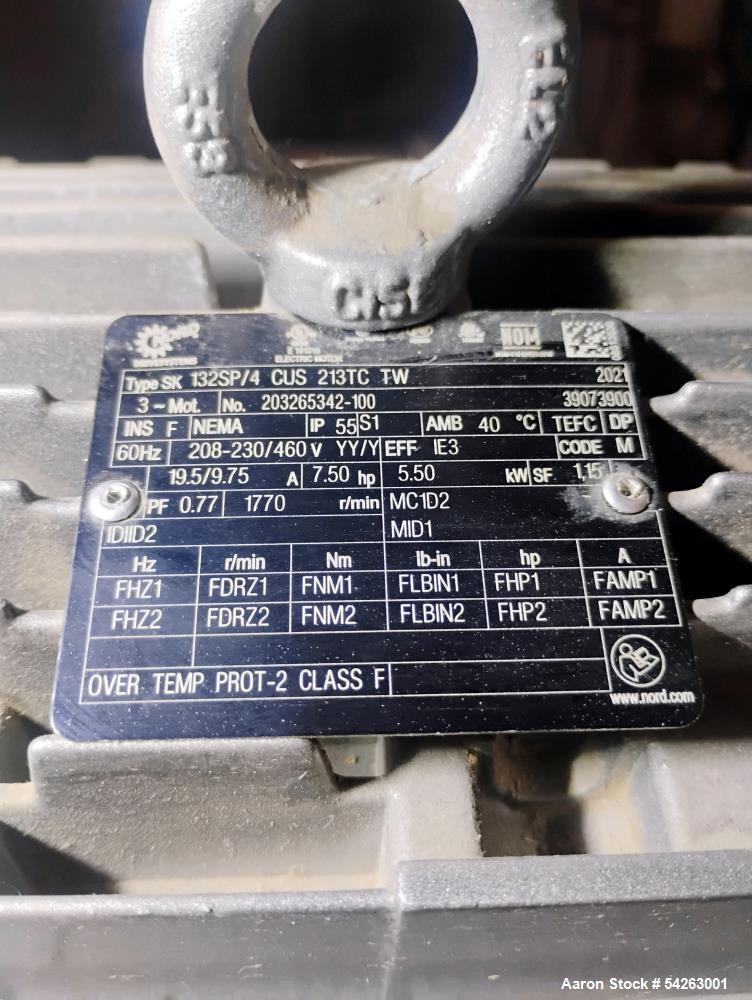

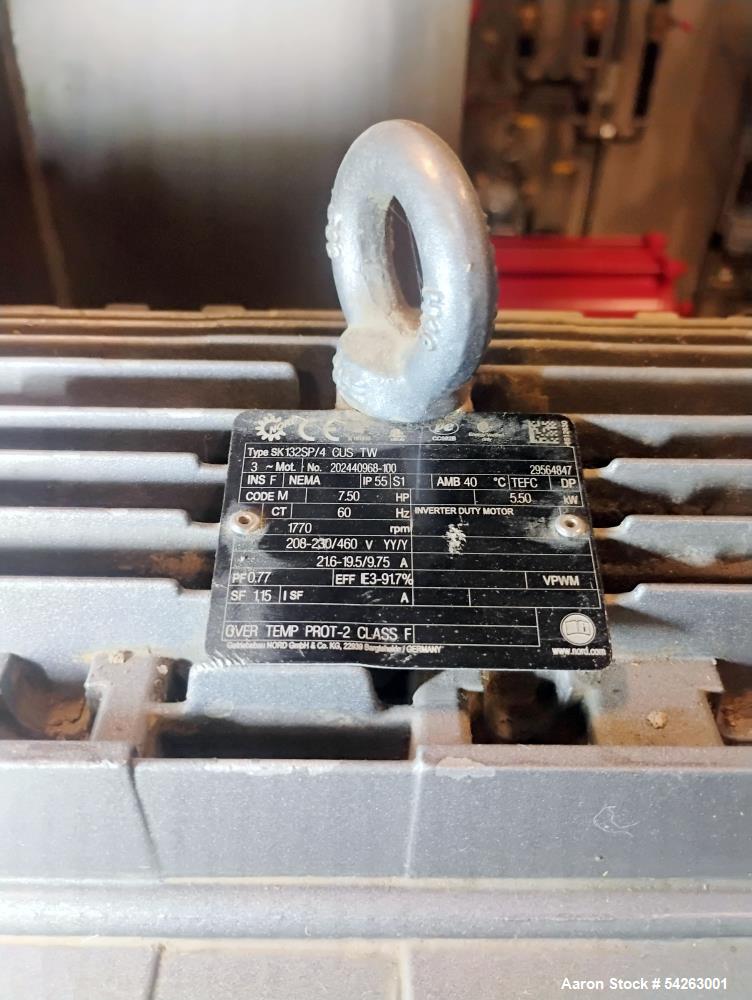

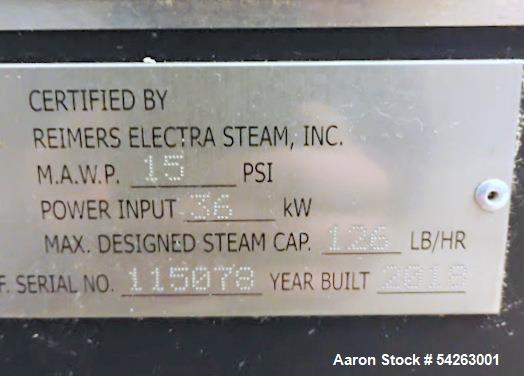

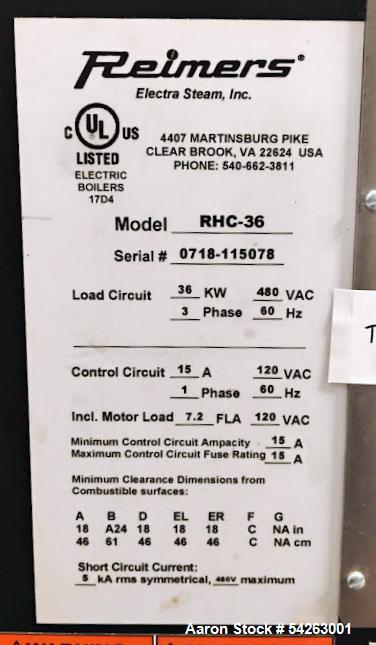

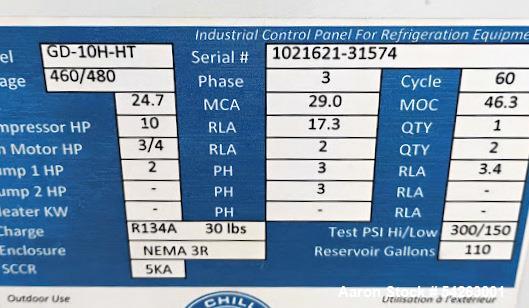

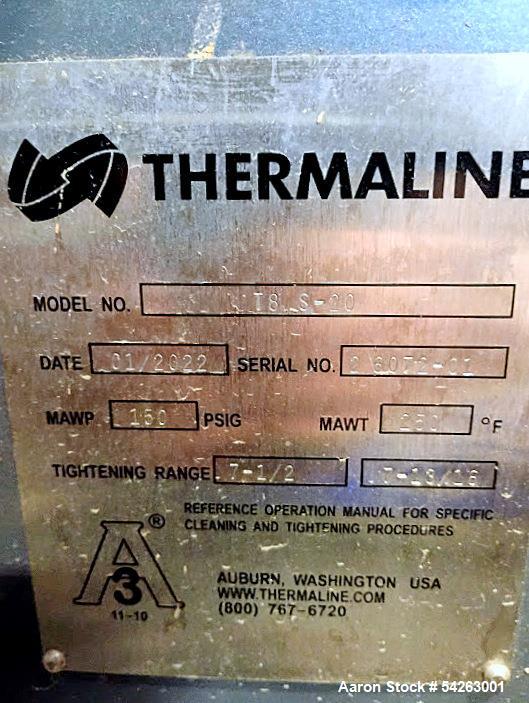

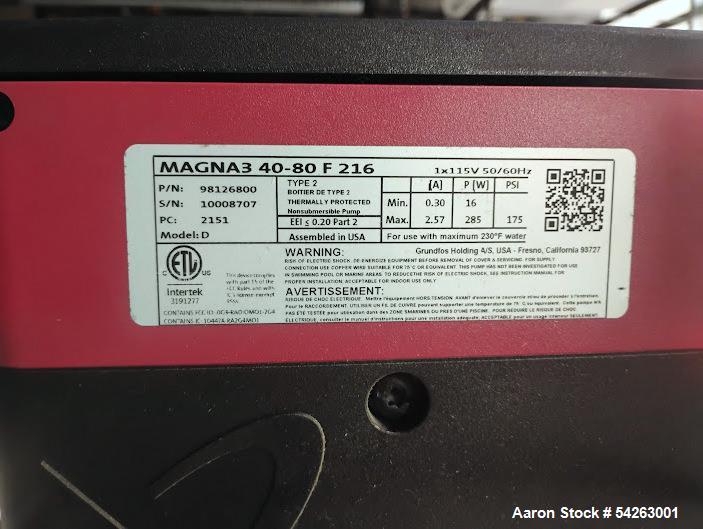

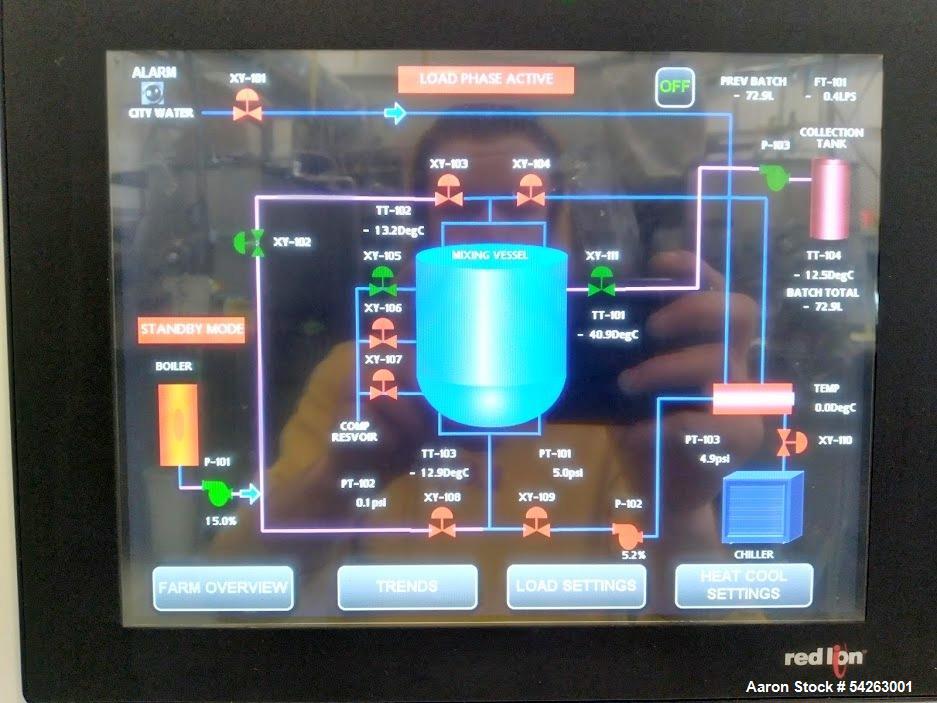

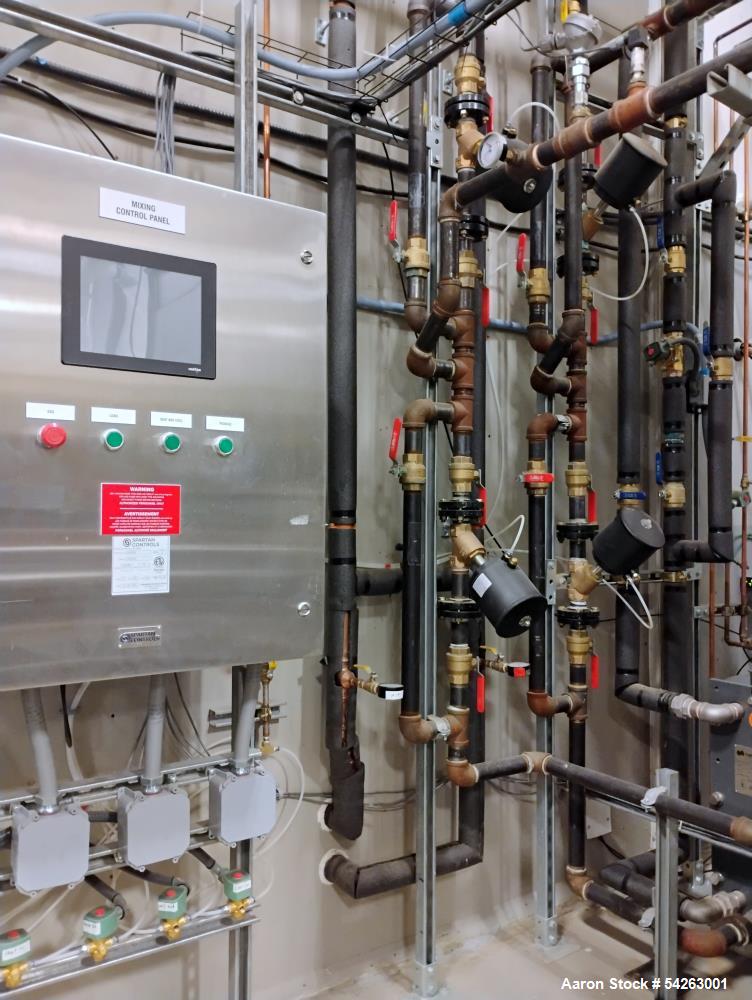

Used Semi-automated Mushroom Substrate Processing System. Integrates high-performance components to efficiently manage pasteurization, cooling, inoculation, and packaging all within a single vessel. Two jacketed Patterson All-Weld Paddle Mixers (37 cubic feet each) operate simultaneously to blend substrate ingredients uniformly while maintaining controlled processing conditions. Substrate moisture content is controlled using a Water Metering Sensor (FD-Q20C) and circulating pump, which measures amount of water added from a 120-gallon (A.O. Smith) hot water tank into the substrate. The mixers heat the substrate up to 98c through their closed loop hydronic heating jackets. The Reimers (RHC-360) Electric Steam Boiler feeds steam to the Cascade Flow Control Solutions Heat Exchanger (263450-004) which heats the hydronic jacket loop. A steam actuating valve (STERLCO D151-F) modulates steam flow from the boiler, maintaining optimal jacket temperatures and pressure needed to reliably pasteurize substrate. After pasteurization, the substrate is cooled via the jackets which are isolated and chilled through a two-stage Thermaline Heat Exchanger (T8 S-20). The first cooling stage transfers substrate heat to municipal water. The heated municipal water is collected in the 120 gallon water tank for later use in substrate hydration. The second cooling stage uses glycol chilled by a G&D 10 HP (GD-10H-HT) unit to rapidly reduce substrate temperature for inoculation. Inoculation is performed through a hatch under sterile Air Science flow hoods (36" and 24"), providing clean, positive-pressure air to prevent contamination. Substrate packaging takes place at the bottom of each vessel through an 8" pneumatic actuating valve in unicorn bags, long tubes, or by connection to another system. Mixer #2 uses a Spartan Controls automated control package to manage processing parameters like mixing, heating, cooling, and packaging via integrated sensors and pneumatic valves. Mixer #1 is manually operated. Sterile air filters from Davis Controls maintain sterile positive-pressure conditions in the mixers throughout the entire process. The steam and hydronic system include Axiom DMF-300 and CBF-2 chemical dosing units to maintain system pressure, fluid levels, and chemical treatment of jacket water. Supporting components including solenoid valves, expansion tanks, gauges, and pipework in steel, stainless, brass, copper, and PEX ensures durability and resistance to temperature fluctuations. Boiler chemicals in the heating loop and inhibited glycol in the chilling loop protect the system from oxidation. The integrated system enables efficient, scalable, and consistent production of high-quality mushroom substrate with reduced labor cost and precise control over all critical processing parameters.

| Category | Complete PlantsComplete Plants |

| Subcategory | Plant LinesPlant Lines |

🏭 Manufacturer Information

-

Mixers: Patterson All-Weld (2 units, 37 cu. ft. each)

-

Steam Boiler: Reimers (Model: RHC-360)

-

Heat Exchangers: Cascade Flow Control Solutions (Model: 263450-004), Thermaline (T8 S-20)

-

Water Sensor: FD-Q20C

-

Hot Water Tank: A.O. Smith (120-gallon)

-

Steam Valve: STERLCO (Model: D151-F)

-

Chiller: G&D Chillers (Model: GD-10H-HT, 10 HP)

-

Airflow Hoods: Air Science (36" & 24")

-

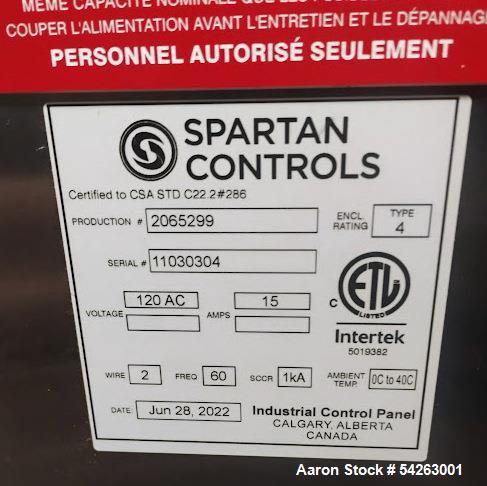

Automation: Spartan Controls (Mixer #2)

-

Sterile Filters: Davis Controls

-

Dosing Units: Axiom (Models: DMF-300, CBF-2)

📄 Product Description

This Used Semi-Automated Mushroom Substrate Processing System integrates top-tier industrial components to ensure complete control over substrate preparation—from pasteurization to packaging—all within dual 37 cu. ft. Patterson All-Weld Paddle Mixers. The system is designed for commercial mushroom cultivation operations seeking high throughput, consistency, and reduced manual labor.

Hydronic heating jackets and an electric steam boiler enable pasteurization up to 98°C, while a two-stage cooling loop ensures rapid temperature drops for sterile inoculation. Mixer #2 is automated via Spartan Controls while Mixer #1 is manually operated. Inoculation occurs under positive pressure sterile conditions, and substrate is packaged through bottom discharge valves into various formats. Ideal for scaling mushroom substrate production with reliable and consistent results.

📊 Specifications

-

Mixers: 2 x Patterson All-Weld Paddle Mixers (37 cu. ft. each)

-

Heating Method: Hydronic Jacket w/ Electric Steam Boiler (Reimers RHC-360)

-

Cooling Method: Two-stage Heat Exchanger (Thermaline T8 S-20, G&D Chiller)

-

Hot Water Tank: A.O. Smith 120-Gallon

-

Water Metering Sensor: FD-Q20C

-

Steam Control Valve: STERLCO D151-F

-

Inoculation: Under sterile Air Science flow hoods (36" & 24")

-

Packaging: 8" Pneumatic Valve, Bag or Tube

-

Automation: Spartan Controls (Mixer #2), Manual (Mixer #1)

-

Chemical Treatment: Axiom DMF-300 & CBF-2

-

Sterility: Davis Controls Air Filters

-

Chiller: G&D 10 HP (GD-10H-HT)

🧪 Applications

This system is designed for:

-

Commercial mushroom farms

-

Substrate preparation facilities

-

Mycology R&D labs

-

Mushroom spawn and block production

-

Gourmet and medicinal mushroom growers

-

Mushroom substrate sterilization/pasteurization operations

-

Scalable inoculation and substrate cooling

-

Sustainable agriculture operations

-

Composting operations needing sterilization

-

Biotech labs working with fungal cultures

📦 Compatible Product Outputs

-

Unicorn Mushroom Grow Bags

-

Polypropylene Tubes

-

Sterilized Bulk Substrate

-

Pasteurized Straw or Sawdust Blends

-

Inoculated Substrate Blocks

-

Pre-packaged Mushroom Spawn Units

-

Lab-scale Sterile Substrate Test Batches

-

Commercial-scale Substrate Batches

-

Gourmet Mushroom Ready-Grow Kits

-

Bioreactor Feedstock

-

mushroom substrate

-

pasteurization system

-

paddle mixer

-

substrate processor

-

mushroom equipment

-

steam boiler

-

inoculation hood

-

glycol chiller

-

heat exchanger

-

used mushroom system

-

used mushroom substrate processing equipment

-

semi-automated mushroom growing system

-

substrate paddle mixer with heating

-

mushroom substrate pasteurization unit

-

commercial mushroom processing line

-

hydronic jacketed mixer system

-

sterile air inoculation station

-

industrial mushroom substrate machine

-

substrate cooling and heating system

-

mushroom bagging and inoculation machine

-

used semi-automated mushroom substrate processing system for sale

-

paddle mixer with integrated heating and cooling for mushroom substrate

-

dual-vessel system for mushroom substrate pasteurization and inoculation

-

complete mushroom substrate preparation system with sterile airflow

-

used commercial mushroom substrate processing equipment with automation

-

high-capacity mushroom substrate mixer and pasteurizer

-

two-stage cooling system for mushroom substrate

-

automated mushroom substrate inoculation under sterile conditions

-

integrated steam boiler and chiller system for mushroom farms

-

full-process mushroom substrate production line with packaging

-

mushroom substrate machine

-

mushroom farming equipment

-

used industrial mixer

-

commercial mushroom system

-

substrate pasteurization unit

-

mushroom processing unit

-

steam heating system

-

glycol cooling system

-

inoculation station

-

mixer with heating jacket

-

for sale

-

used

-

buy now

-

best price

-

available

-

refurbished

-

second-hand

-

in stock

-

industrial

-

seller offer

Used Semi-automated Mushroom Substrate Processing System. Integrates high-performance components to efficiently manage pasteurization, cooling, inoculation, and packaging all within a single vessel. Two jacketed Patterson All-Weld Paddle Mixers (37 cubic feet each) operate simultaneously to blend substrate ingredients uniformly while maintaining controlled processing conditions. Substrate moisture content is controlled using a Water Metering Sensor (FD-Q20C) and circulating pump, which measures amount of water added from a 120-gallon (A.O. Smith) hot water tank into the substrate. The mixers heat the substrate up to 98c through their closed loop hydronic heating jackets. The Reimers (RHC-360) Electric Steam Boiler feeds steam to the Cascade Flow Control Solutions Heat Exchanger (263450-004) which heats the hydronic jacket loop. A steam actuating valve (STERLCO D151-F) modulates steam flow from the boiler, maintaining optimal jacket temperatures and pressure needed to reliably pasteurize substrate. After pasteurization, the substrate is cooled via the jackets which are isolated and chilled through a two-stage Thermaline Heat Exchanger (T8 S-20). The first cooling stage transfers substrate heat to municipal water. The heated municipal water is collected in the 120 gallon water tank for later use in substrate hydration. The second cooling stage uses glycol chilled by a G&D 10 HP (GD-10H-HT) unit to rapidly reduce substrate temperature for inoculation. Inoculation is performed through a hatch under sterile Air Science flow hoods (36" and 24"), providing clean, positive-pressure air to prevent contamination. Substrate packaging takes place at the bottom of each vessel through an 8" pneumatic actuating valve in unicorn bags, long tubes, or by connection to another system. Mixer #2 uses a Spartan Controls automated control package to manage processing parameters like mixing, heating, cooling, and packaging via integrated sensors and pneumatic valves. Mixer #1 is manually operated. Sterile air filters from Davis Controls maintain sterile positive-pressure conditions in the mixers throughout the entire process. The steam and hydronic system include Axiom DMF-300 and CBF-2 chemical dosing units to maintain system pressure, fluid levels, and chemical treatment of jacket water. Supporting components including solenoid valves, expansion tanks, gauges, and pipework in steel, stainless, brass, copper, and PEX ensures durability and resistance to temperature fluctuations. Boiler chemicals in the heating loop and inhibited glycol in the chilling loop protect the system from oxidation. The integrated system enables efficient, scalable, and consistent production of high-quality mushroom substrate with reduced labor cost and precise control over all critical processing parameters.

🏭 Manufacturer Information

-

Mixers: Patterson All-Weld (2 units, 37 cu. ft. each)

-

Steam Boiler: Reimers (Model: RHC-360)

-

Heat Exchangers: Cascade Flow Control Solutions (Model: 263450-004), Thermaline (T8 S-20)

-

Water Sensor: FD-Q20C

-

Hot Water Tank: A.O. Smith (120-gallon)

-

Steam Valve: STERLCO (Model: D151-F)

-

Chiller: G&D Chillers (Model: GD-10H-HT, 10 HP)

-

Airflow Hoods: Air Science (36" & 24")

-

Automation: Spartan Controls (Mixer #2)

-

Sterile Filters: Davis Controls

-

Dosing Units: Axiom (Models: DMF-300, CBF-2)

📄 Product Description

This Used Semi-Automated Mushroom Substrate Processing System integrates top-tier industrial components to ensure complete control over substrate preparation—from pasteurization to packaging—all within dual 37 cu. ft. Patterson All-Weld Paddle Mixers. The system is designed for commercial mushroom cultivation operations seeking high throughput, consistency, and reduced manual labor.

Hydronic heating jackets and an electric steam boiler enable pasteurization up to 98°C, while a two-stage cooling loop ensures rapid temperature drops for sterile inoculation. Mixer #2 is automated via Spartan Controls while Mixer #1 is manually operated. Inoculation occurs under positive pressure sterile conditions, and substrate is packaged through bottom discharge valves into various formats. Ideal for scaling mushroom substrate production with reliable and consistent results.

📊 Specifications

-

Mixers: 2 x Patterson All-Weld Paddle Mixers (37 cu. ft. each)

-

Heating Method: Hydronic Jacket w/ Electric Steam Boiler (Reimers RHC-360)

-

Cooling Method: Two-stage Heat Exchanger (Thermaline T8 S-20, G&D Chiller)

-

Hot Water Tank: A.O. Smith 120-Gallon

-

Water Metering Sensor: FD-Q20C

-

Steam Control Valve: STERLCO D151-F

-

Inoculation: Under sterile Air Science flow hoods (36" & 24")

-

Packaging: 8" Pneumatic Valve, Bag or Tube

-

Automation: Spartan Controls (Mixer #2), Manual (Mixer #1)

-

Chemical Treatment: Axiom DMF-300 & CBF-2

-

Sterility: Davis Controls Air Filters

-

Chiller: G&D 10 HP (GD-10H-HT)

🧪 Applications

This system is designed for:

-

Commercial mushroom farms

-

Substrate preparation facilities

-

Mycology R&D labs

-

Mushroom spawn and block production

-

Gourmet and medicinal mushroom growers

-

Mushroom substrate sterilization/pasteurization operations

-

Scalable inoculation and substrate cooling

-

Sustainable agriculture operations

-

Composting operations needing sterilization

-

Biotech labs working with fungal cultures

📦 Compatible Product Outputs

-

Unicorn Mushroom Grow Bags

-

Polypropylene Tubes

-

Sterilized Bulk Substrate

-

Pasteurized Straw or Sawdust Blends

-

Inoculated Substrate Blocks

-

Pre-packaged Mushroom Spawn Units

-

Lab-scale Sterile Substrate Test Batches

-

Commercial-scale Substrate Batches

-

Gourmet Mushroom Ready-Grow Kits

-

Bioreactor Feedstock

| Category | Complete Plants |

| Subcategory | Plant Lines |

-

mushroom substrate

-

pasteurization system

-

paddle mixer

-

substrate processor

-

mushroom equipment

-

steam boiler

-

inoculation hood

-

glycol chiller

-

heat exchanger

-

used mushroom system

-

used mushroom substrate processing equipment

-

semi-automated mushroom growing system

-

substrate paddle mixer with heating

-

mushroom substrate pasteurization unit

-

commercial mushroom processing line

-

hydronic jacketed mixer system

-

sterile air inoculation station

-

industrial mushroom substrate machine

-

substrate cooling and heating system

-

mushroom bagging and inoculation machine

-

used semi-automated mushroom substrate processing system for sale

-

paddle mixer with integrated heating and cooling for mushroom substrate

-

dual-vessel system for mushroom substrate pasteurization and inoculation

-

complete mushroom substrate preparation system with sterile airflow

-

used commercial mushroom substrate processing equipment with automation

-

high-capacity mushroom substrate mixer and pasteurizer

-

two-stage cooling system for mushroom substrate

-

automated mushroom substrate inoculation under sterile conditions

-

integrated steam boiler and chiller system for mushroom farms

-

full-process mushroom substrate production line with packaging

-

mushroom substrate machine

-

mushroom farming equipment

-

used industrial mixer

-

commercial mushroom system

-

substrate pasteurization unit

-

mushroom processing unit

-

steam heating system

-

glycol cooling system

-

inoculation station

-

mixer with heating jacket

-

for sale

-

used

-

buy now

-

best price

-

available

-

refurbished

-

second-hand

-

in stock

-

industrial

-

seller offer

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory