Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

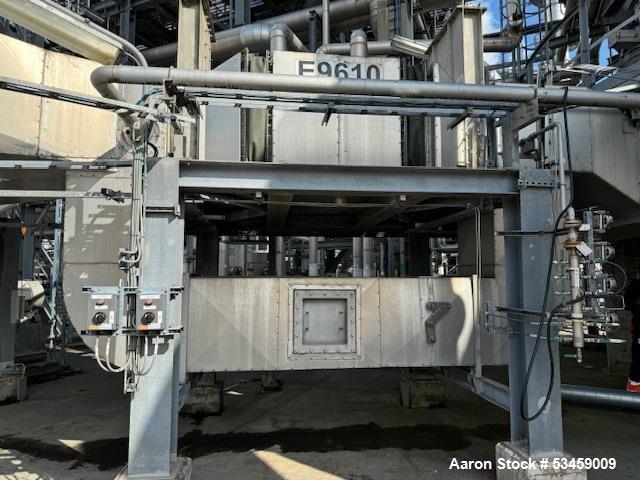

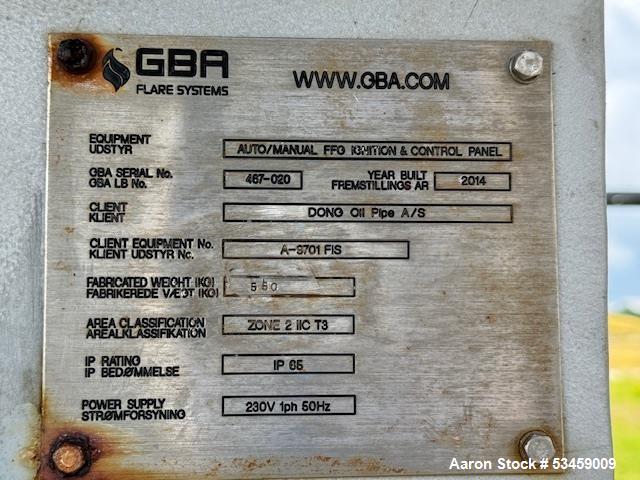

Used Degasser Unit (ID 9600) with Heat Transfer Unit – 153,000 BPD Crude Oil Stabilization Plant

Used Degasser Unit (ID 9600) with Heat Transfer Unit for 153Kbpd Crude Oil Stabilization Plant Incl. Degasser Trains A & B consisting of: 4x live oil/stabilized oil heat exchangers, Live oil/heat transfer fluid heater, Flow control valve, Degasser Vessel (NOT INCLUDED for train , A), Stabilized crude pump, Degasser water pump, 1st stage knock-out drum, Siemens fixed speed two stage centrifugal compressor, 1st stage condenser, 1st stage separator, 1st stage HC pump, 2nd stage knock-out drum, 2nd stage condenser, 2nd stage separator, Stabilizer feed pump, 2nd stage condenser. Incl. Heat Transfer Fluid (HTF) System: HTF Furnace, (2) forced draught fans, induced draught fan, Air preheater, Flue gas cooler, HTF storage tank, HTF make up pump, HTF expansion vessel, (2) HTF HT circulation pumps, (2) HTF LT circulation pumps, HTF drain collection vessel, HTF drain pump, Furnace LP fuel gas knock-out drum. Including piping, valves and additional infrastructure. Further details and technical documentation available upon request. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

| Category | Complete PlantsComplete Plants |

| Subcategory | Plant LinesPlant Lines |

Overview:

This Degasser Unit (ID 9600) is a key component of a 153,000 barrels per day (BPD) Crude Oil Stabilization Plant, designed to efficiently remove dissolved gases from crude oil and ensure safe and stable crude processing. The unit includes two parallel degasser trains (A & B), a heat transfer fluid (HTF) system, Siemens centrifugal compressors, multiple heat exchangers, condensers, and knock-out drums for effective gas-liquid separation.

Included Systems & Equipment:

1. Degasser Trains A & B:

- (4) Live Oil/Stabilized Oil Heat Exchangers – Preheats live oil using stabilized oil for energy efficiency.

- Live Oil/Heat Transfer Fluid Heater – Maintains the optimal temperature for crude degassing.

- Flow Control Valve – Regulates flow rate for precise process control.

- Degasser Vessel – (Not included for Train A), essential for gas separation.

- Stabilized Crude Pump – Transfers degassed crude oil for further processing.

- Degasser Water Pump – Handles water removal during degassing.

- 1st Stage Knock-Out Drum – Separates gas and liquid phases in the first degassing stage.

- Siemens Fixed Speed Two-Stage Centrifugal Compressor – Compresses gas extracted from crude oil.

- 1st Stage Condenser – Cools gas stream to enhance separation.

- 1st Stage Separator – Separates hydrocarbons and water after initial condensation.

- 1st Stage HC Pump – Moves hydrocarbons extracted in the first stage.

- 2nd Stage Knock-Out Drum – Further separation of gas, water, and hydrocarbons.

- 2nd Stage Condenser – Additional cooling for improved gas recovery.

- 2nd Stage Separator – Final separation of hydrocarbon gases and liquids.

- Stabilizer Feed Pump – Transfers stabilized crude for further refining.

2. Heat Transfer Fluid (HTF) System:

- HTF Furnace – Provides heat for process fluid temperature control.

- (2) Forced Draft Fans & Induced Draft Fan – Controls airflow for furnace combustion efficiency.

- Air Preheater – Recaptures heat from exhaust gases to preheat incoming air.

- Flue Gas Cooler – Reduces temperature of exhaust gases before release.

- HTF Storage Tank – Stores heat transfer fluid for continuous operation.

- HTF Make-Up Pump – Supplies fresh HTF to maintain system integrity.

- HTF Expansion Vessel – Accommodates thermal expansion of heat transfer fluid.

- (2) HTF High-Temperature Circulation Pumps – Circulates HTF for high-temperature applications.

- (2) HTF Low-Temperature Circulation Pumps – Circulates HTF for low-temperature applications.

- HTF Drain Collection Vessel – Collects drained HTF for disposal or recycling.

- HTF Drain Pump – Facilitates removal of drained heat transfer fluid.

- Furnace LP Fuel Gas Knock-Out Drum – Separates liquid contaminants from fuel gas.

3. Infrastructure & Piping:

- Piping & Valves – High-performance industrial piping and valves for fluid control.

- Additional Infrastructure – Includes monitoring, safety, and operational control systems.

- Technical Documentation – Further details available upon request.

Specifications:

- Processing Capacity: Part of 153,000 BPD Crude Oil Stabilization Plant

- Main Systems: Degasser Trains, Heat Transfer Fluid System, Centrifugal Compressors

- Heat Exchange Equipment: Live Oil Heat Exchangers, Condensers, and Flue Gas Coolers

- Pumping Systems: Stabilized Crude Pump, HC Pump, Circulation Pumps

- Cooling & Separation: Knock-Out Drums, Separators, Condensers

- Storage & Fuel Handling: HTF Storage Tank, Fuel Gas Knock-Out Drum

- Condition: Used – Available for immediate inspection

- Documentation: Further technical details available upon request

Applications:

- Crude Oil Degassing & Stabilization

- Oilfield Production & Refining Operations

- Midstream Oil & Gas Processing Facilities

- LPG & Hydrocarbon Gas Recovery

- Pipeline-Ready Crude Oil Processing

- Heavy Oil Upgrading & Treatment

- Petrochemical & Refining Gas Handling

- Natural Gas Processing & Recovery

- Industrial Heat Transfer & Fluid Systems

- Environmental & Emissions Control in Oil Processing

- Used Degasser Unit ID 9600

- Crude Oil Stabilization Equipment

- Heat Transfer System for Oil Processing

- Industrial Degassing System

- Two-Stage Crude Oil Degasser

- Gas Separation & Compression Unit

- Siemens Centrifugal Compressor System

- Oilfield Hydrocarbon Recovery Equipment

- 153K BPD Oil Refinery Degasser

- HTF Furnace & Heat Transfer Unit

- Used Degasser Unit for Crude Oil Stabilization

- High-Capacity Oil Degassing & Heat Transfer System

- Industrial Gas Separation & Crude Oil Processing Equipment

- Siemens Two-Stage Centrifugal Compressor for Gas Processing

- Used Oil Refinery Degasser with Heat Transfer Fluid System

- Crude Oil Stabilization & Hydrocarbon Recovery Unit

- Midstream Oil & Gas Processing Degasser System

- LPG & Hydrocarbon Gas Recovery System for Sale

- Used Heat Transfer Fluid Furnace & Circulation Pumps

- Complete Oil Refinery Degassing Unit with Knock-Out Drums

- Used Degasser Unit with Siemens Compressor & Heat Transfer Fluid System

- High-Capacity 153,000 BPD Crude Oil Degassing & Stabilization Equipment

- Two-Stage Industrial Oil Degasser for Midstream Processing Facilities

- Heat Transfer Fluid System with Circulation Pumps & HTF Furnace

- Crude Oil Refinery Degassing System with Knock-Out Drums & Condensers

- Best Used Industrial Degassing & Gas Recovery Equipment for Sale

- Oil Refinery Hydrocarbon Recovery & Fractionation System

- Heat Transfer Fluid Circulation & Cooling System for Oil Processing

- Complete Oil Refinery Degassing & Gas Compression System

- Industrial Heat Transfer & Flue Gas Cooling System for Refining

- Used Oil Refinery Degasser for Sale

- Heat Transfer System for Crude Oil Stabilization

- Industrial Gas Processing & Degassing Equipment

- Siemens Centrifugal Compressor System

- Oil & Gas Processing Facility Equipment

- Midstream Oil & Gas Hydrocarbon Recovery Unit

- Used Heat Transfer Fluid Furnace for Sale

- Two-Stage Knock-Out Drum Degassing Unit

- Best Industrial Degassing & Gas Compression System

- Oil Refinery Fractionation & Heat Recovery System

- Where to buy used oil refinery degassing units

- Best crude oil stabilization degasser for sale

- Siemens centrifugal gas compressor unit purchase

- Used heat transfer fluid system for industrial oil processing

- 153K BPD crude oil degasser available for sale

- Industrial gas separation & hydrocarbon recovery unit purchase

- Oil & gas midstream processing equipment for sale

- Used heat transfer fluid system with furnace & circulation pumps

- Complete oil refinery degassing & gas handling system purchase

- Buy used crude oil processing plant equipment

- Sell used oil refinery degasser unit

- Used heat transfer system resale

- Market used crude oil stabilization equipment

- Best platform to sell midstream oil processing equipment

- Selling industrial gas processing & hydrocarbon recovery system

- Find buyers for used Siemens centrifugal compressor units

- Used crude oil degassing & stabilization system for sale

- Resale opportunities for oil & gas fractionation units

- Selling used refinery heat transfer & fluid circulation system

- Best platforms for industrial gas processing equipment resale

Used Degasser Unit (ID 9600) with Heat Transfer Unit for 153Kbpd Crude Oil Stabilization Plant Incl. Degasser Trains A & B consisting of: 4x live oil/stabilized oil heat exchangers, Live oil/heat transfer fluid heater, Flow control valve, Degasser Vessel (NOT INCLUDED for train , A), Stabilized crude pump, Degasser water pump, 1st stage knock-out drum, Siemens fixed speed two stage centrifugal compressor, 1st stage condenser, 1st stage separator, 1st stage HC pump, 2nd stage knock-out drum, 2nd stage condenser, 2nd stage separator, Stabilizer feed pump, 2nd stage condenser. Incl. Heat Transfer Fluid (HTF) System: HTF Furnace, (2) forced draught fans, induced draught fan, Air preheater, Flue gas cooler, HTF storage tank, HTF make up pump, HTF expansion vessel, (2) HTF HT circulation pumps, (2) HTF LT circulation pumps, HTF drain collection vessel, HTF drain pump, Furnace LP fuel gas knock-out drum. Including piping, valves and additional infrastructure. Further details and technical documentation available upon request. Our freight specialists can assist you with door to door transportation and all customs documents needed to make the process go as smoothly as possible.

Overview:

This Degasser Unit (ID 9600) is a key component of a 153,000 barrels per day (BPD) Crude Oil Stabilization Plant, designed to efficiently remove dissolved gases from crude oil and ensure safe and stable crude processing. The unit includes two parallel degasser trains (A & B), a heat transfer fluid (HTF) system, Siemens centrifugal compressors, multiple heat exchangers, condensers, and knock-out drums for effective gas-liquid separation.

Included Systems & Equipment:

1. Degasser Trains A & B:

- (4) Live Oil/Stabilized Oil Heat Exchangers – Preheats live oil using stabilized oil for energy efficiency.

- Live Oil/Heat Transfer Fluid Heater – Maintains the optimal temperature for crude degassing.

- Flow Control Valve – Regulates flow rate for precise process control.

- Degasser Vessel – (Not included for Train A), essential for gas separation.

- Stabilized Crude Pump – Transfers degassed crude oil for further processing.

- Degasser Water Pump – Handles water removal during degassing.

- 1st Stage Knock-Out Drum – Separates gas and liquid phases in the first degassing stage.

- Siemens Fixed Speed Two-Stage Centrifugal Compressor – Compresses gas extracted from crude oil.

- 1st Stage Condenser – Cools gas stream to enhance separation.

- 1st Stage Separator – Separates hydrocarbons and water after initial condensation.

- 1st Stage HC Pump – Moves hydrocarbons extracted in the first stage.

- 2nd Stage Knock-Out Drum – Further separation of gas, water, and hydrocarbons.

- 2nd Stage Condenser – Additional cooling for improved gas recovery.

- 2nd Stage Separator – Final separation of hydrocarbon gases and liquids.

- Stabilizer Feed Pump – Transfers stabilized crude for further refining.

2. Heat Transfer Fluid (HTF) System:

- HTF Furnace – Provides heat for process fluid temperature control.

- (2) Forced Draft Fans & Induced Draft Fan – Controls airflow for furnace combustion efficiency.

- Air Preheater – Recaptures heat from exhaust gases to preheat incoming air.

- Flue Gas Cooler – Reduces temperature of exhaust gases before release.

- HTF Storage Tank – Stores heat transfer fluid for continuous operation.

- HTF Make-Up Pump – Supplies fresh HTF to maintain system integrity.

- HTF Expansion Vessel – Accommodates thermal expansion of heat transfer fluid.

- (2) HTF High-Temperature Circulation Pumps – Circulates HTF for high-temperature applications.

- (2) HTF Low-Temperature Circulation Pumps – Circulates HTF for low-temperature applications.

- HTF Drain Collection Vessel – Collects drained HTF for disposal or recycling.

- HTF Drain Pump – Facilitates removal of drained heat transfer fluid.

- Furnace LP Fuel Gas Knock-Out Drum – Separates liquid contaminants from fuel gas.

3. Infrastructure & Piping:

- Piping & Valves – High-performance industrial piping and valves for fluid control.

- Additional Infrastructure – Includes monitoring, safety, and operational control systems.

- Technical Documentation – Further details available upon request.

Specifications:

- Processing Capacity: Part of 153,000 BPD Crude Oil Stabilization Plant

- Main Systems: Degasser Trains, Heat Transfer Fluid System, Centrifugal Compressors

- Heat Exchange Equipment: Live Oil Heat Exchangers, Condensers, and Flue Gas Coolers

- Pumping Systems: Stabilized Crude Pump, HC Pump, Circulation Pumps

- Cooling & Separation: Knock-Out Drums, Separators, Condensers

- Storage & Fuel Handling: HTF Storage Tank, Fuel Gas Knock-Out Drum

- Condition: Used – Available for immediate inspection

- Documentation: Further technical details available upon request

Applications:

- Crude Oil Degassing & Stabilization

- Oilfield Production & Refining Operations

- Midstream Oil & Gas Processing Facilities

- LPG & Hydrocarbon Gas Recovery

- Pipeline-Ready Crude Oil Processing

- Heavy Oil Upgrading & Treatment

- Petrochemical & Refining Gas Handling

- Natural Gas Processing & Recovery

- Industrial Heat Transfer & Fluid Systems

- Environmental & Emissions Control in Oil Processing

| Category | Complete Plants |

| Subcategory | Plant Lines |

- Used Degasser Unit ID 9600

- Crude Oil Stabilization Equipment

- Heat Transfer System for Oil Processing

- Industrial Degassing System

- Two-Stage Crude Oil Degasser

- Gas Separation & Compression Unit

- Siemens Centrifugal Compressor System

- Oilfield Hydrocarbon Recovery Equipment

- 153K BPD Oil Refinery Degasser

- HTF Furnace & Heat Transfer Unit

- Used Degasser Unit for Crude Oil Stabilization

- High-Capacity Oil Degassing & Heat Transfer System

- Industrial Gas Separation & Crude Oil Processing Equipment

- Siemens Two-Stage Centrifugal Compressor for Gas Processing

- Used Oil Refinery Degasser with Heat Transfer Fluid System

- Crude Oil Stabilization & Hydrocarbon Recovery Unit

- Midstream Oil & Gas Processing Degasser System

- LPG & Hydrocarbon Gas Recovery System for Sale

- Used Heat Transfer Fluid Furnace & Circulation Pumps

- Complete Oil Refinery Degassing Unit with Knock-Out Drums

- Used Degasser Unit with Siemens Compressor & Heat Transfer Fluid System

- High-Capacity 153,000 BPD Crude Oil Degassing & Stabilization Equipment

- Two-Stage Industrial Oil Degasser for Midstream Processing Facilities

- Heat Transfer Fluid System with Circulation Pumps & HTF Furnace

- Crude Oil Refinery Degassing System with Knock-Out Drums & Condensers

- Best Used Industrial Degassing & Gas Recovery Equipment for Sale

- Oil Refinery Hydrocarbon Recovery & Fractionation System

- Heat Transfer Fluid Circulation & Cooling System for Oil Processing

- Complete Oil Refinery Degassing & Gas Compression System

- Industrial Heat Transfer & Flue Gas Cooling System for Refining

- Used Oil Refinery Degasser for Sale

- Heat Transfer System for Crude Oil Stabilization

- Industrial Gas Processing & Degassing Equipment

- Siemens Centrifugal Compressor System

- Oil & Gas Processing Facility Equipment

- Midstream Oil & Gas Hydrocarbon Recovery Unit

- Used Heat Transfer Fluid Furnace for Sale

- Two-Stage Knock-Out Drum Degassing Unit

- Best Industrial Degassing & Gas Compression System

- Oil Refinery Fractionation & Heat Recovery System

- Where to buy used oil refinery degassing units

- Best crude oil stabilization degasser for sale

- Siemens centrifugal gas compressor unit purchase

- Used heat transfer fluid system for industrial oil processing

- 153K BPD crude oil degasser available for sale

- Industrial gas separation & hydrocarbon recovery unit purchase

- Oil & gas midstream processing equipment for sale

- Used heat transfer fluid system with furnace & circulation pumps

- Complete oil refinery degassing & gas handling system purchase

- Buy used crude oil processing plant equipment

- Sell used oil refinery degasser unit

- Used heat transfer system resale

- Market used crude oil stabilization equipment

- Best platform to sell midstream oil processing equipment

- Selling industrial gas processing & hydrocarbon recovery system

- Find buyers for used Siemens centrifugal compressor units

- Used crude oil degassing & stabilization system for sale

- Resale opportunities for oil & gas fractionation units

- Selling used refinery heat transfer & fluid circulation system

- Best platforms for industrial gas processing equipment resale

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory