Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Potato Chips Line with capacity 600 kg/hour

Used Potato Chips Line with capacity 600 kg/hour. Major equipment includes the following items: Thermal oil boiler with capacity 2.4 MW made by Kirka Belgrade in 2014. Emptying bin with capacity 3.5 tonnes of potatoes, made by Florgo in 2000. Conveyors of various ages and manufacturers. Pre washer / cyclone destoner made by Komen + Kun in 2000. Weigh hopper batch peeler with capacity 2500 kg/hour of raw potato, made by Florigo in 2000. Slicer, 6-heads. made by Urschel in 2000. Water cleaning unit made by Florigo in 2000. Blancher made by FLorigo in 2000. Fryer made by Florigo in 2000. Flavouring drum with capacity of 600 kg/hour chips, Aroma machine K-tron Coperion in 2000. (2) Vopak-VE 280 packaging machines, double head weigher, made by Yamato in 2000. (2) Packaging machines, single head weigher, made by Simionato in 2000. (3) Packaging machines made by Volpack in 2007, single head weighers made by Yamato in 2007.

Manufacturer Information

- Capacity: 600 kg/hour

- Condition: Used

- Year of Manufacture: Various (2000 - 2014)

- Previous Use: Potato Chips Manufacturing

Description

This complete potato chips processing line is designed for industrial-scale snack production, handling potatoes from raw intake to final packaged chips. The system includes major components from leading manufacturers, ensuring high efficiency and consistent quality output.

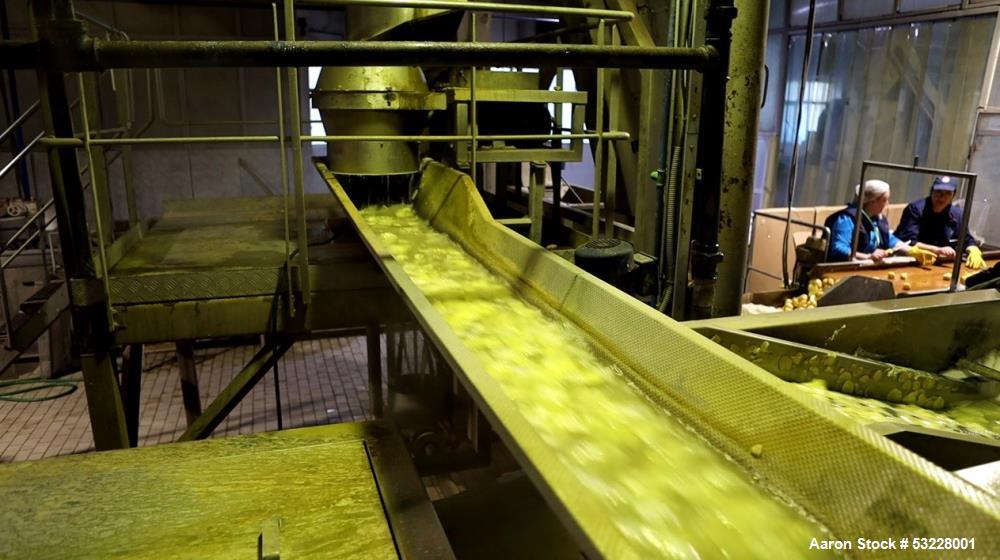

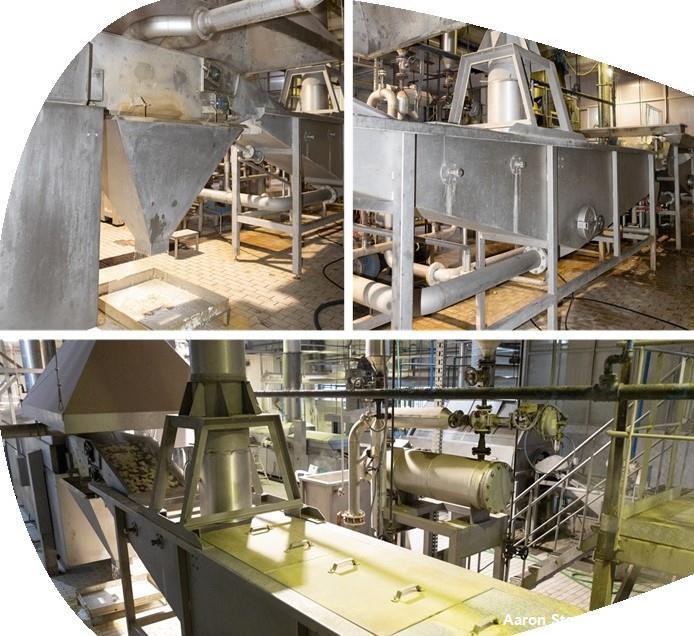

The line starts with an emptying bin (3.5-tonne capacity) and a pre-washer/cyclone destoner to clean raw potatoes. The Florigo weigh hopper batch peeler (2,500 kg/hr capacity) ensures uniform peeling, followed by an Urschel 6-head slicer for precise chip cutting.

The water cleaning unit, blancher, and Florigo fryer ensure optimal texture and flavor. The system is completed with a flavoring drum and an Aroma K-tron Coperion seasoning machine, offering consistent chip coating and seasoning.

The line includes multiple packaging machines from Yamato, Simionato, and Volpack, ensuring efficient weighing, bagging, and sealing of finished products.

A thermal oil boiler (2.4 MW, Kirka Belgrade, 2014) provides efficient heat for the frying process.

Major Equipment List & Features

- Thermal Oil Boiler – 2.4 MW (Kirka Belgrade, 2014) – Provides heating for the fryer

- Emptying Bin – 3.5 Tonne Capacity (Florigo, 2000) – Handles bulk potato intake

- Conveyors – Various manufacturers and ages for seamless product movement

- Pre-Washer / Cyclone Destoner (Komen + Kun, 2000) – Removes dirt, stones, and debris

- Weigh Hopper Batch Peeler – 2,500 kg/hr (Florigo, 2000) – Ensures consistent peeling

- Slicer – 6-Head (Urschel, 2000) – Cuts uniform chips for frying

- Water Cleaning Unit (Florigo, 2000) – Further cleans sliced potatoes

- Blancher (Florigo, 2000) – Improves texture and removes excess starch

- Fryer (Florigo, 2000) – Ensures even frying and crispness

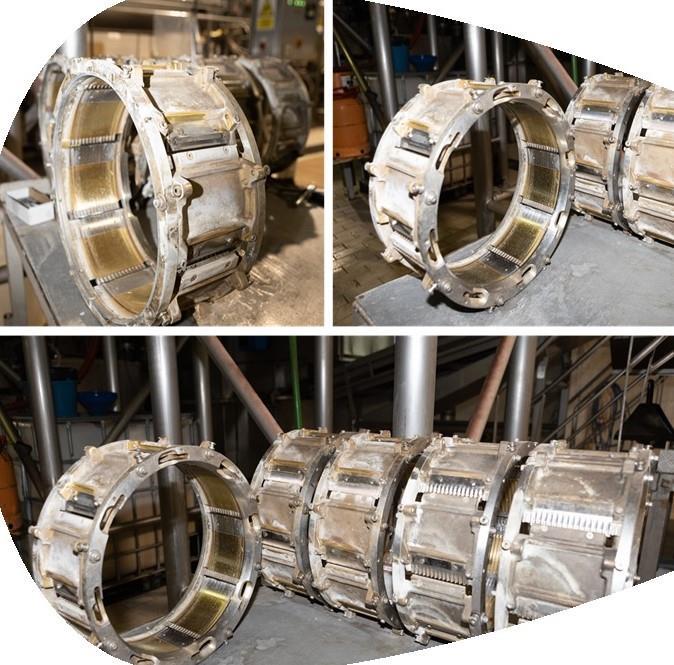

- Flavouring Drum – 600 kg/hr (Aroma K-tron Coperion, 2000) – Evenly seasons chips

- Packaging Machines:

- (2) Vopak-VE 280 with Double Head Weighers (Yamato, 2000)

- (2) Simionato with Single Head Weighers (2000)

- (3) Volpack with Single Head Weighers (Yamato, 2007)

Specifications

- Production Capacity: 600 kg/hour

- Peeling Capacity: 2,500 kg/hour raw potatoes

- Fryer Type: Thermal Oil Heated Fryer (Florigo, 2000)

- Heat Source: 2.4 MW Thermal Oil Boiler (Kirka Belgrade, 2014)

- Packaging System:

- Double & Single Head Weighers

- Automated Bagging & Sealing

Applications

- Potato Chips Manufacturing – From raw potato processing to packaged chips

- Snack Food Production – Processing and packaging of fried snack foods

- Food Processing Facilities – Large-scale frying and seasoning operations

- Industrial Packaging – Automated weighing and bagging systems for snack foods

Compatible Products

- Fully automated potato chip production lines

- Industrial batch peelers and slicers

- High-efficiency flavoring and seasoning systems

- Advanced snack food packaging machinery

Food Industry, Food Manufacturing, Food Plants, Food Processing, Food Production, Food Products, Foods, Snack, Snack Chips, Snack Foods

- Potato chips line, industrial fryer, food processing equipment

- Used potato chip production line, complete snack food frying system, high-capacity chip packaging equipment

- Used 600 kg/hr industrial potato chip production line with frying, seasoning, and packaging system, fully automated snack food processing system with thermal oil fryer, high-efficiency potato chip processing line with multiple packaging machines

Used Potato Chips Line with capacity 600 kg/hour. Major equipment includes the following items: Thermal oil boiler with capacity 2.4 MW made by Kirka Belgrade in 2014. Emptying bin with capacity 3.5 tonnes of potatoes, made by Florgo in 2000. Conveyors of various ages and manufacturers. Pre washer / cyclone destoner made by Komen + Kun in 2000. Weigh hopper batch peeler with capacity 2500 kg/hour of raw potato, made by Florigo in 2000. Slicer, 6-heads. made by Urschel in 2000. Water cleaning unit made by Florigo in 2000. Blancher made by FLorigo in 2000. Fryer made by Florigo in 2000. Flavouring drum with capacity of 600 kg/hour chips, Aroma machine K-tron Coperion in 2000. (2) Vopak-VE 280 packaging machines, double head weigher, made by Yamato in 2000. (2) Packaging machines, single head weigher, made by Simionato in 2000. (3) Packaging machines made by Volpack in 2007, single head weighers made by Yamato in 2007.

Manufacturer Information

- Capacity: 600 kg/hour

- Condition: Used

- Year of Manufacture: Various (2000 - 2014)

- Previous Use: Potato Chips Manufacturing

Description

This complete potato chips processing line is designed for industrial-scale snack production, handling potatoes from raw intake to final packaged chips. The system includes major components from leading manufacturers, ensuring high efficiency and consistent quality output.

The line starts with an emptying bin (3.5-tonne capacity) and a pre-washer/cyclone destoner to clean raw potatoes. The Florigo weigh hopper batch peeler (2,500 kg/hr capacity) ensures uniform peeling, followed by an Urschel 6-head slicer for precise chip cutting.

The water cleaning unit, blancher, and Florigo fryer ensure optimal texture and flavor. The system is completed with a flavoring drum and an Aroma K-tron Coperion seasoning machine, offering consistent chip coating and seasoning.

The line includes multiple packaging machines from Yamato, Simionato, and Volpack, ensuring efficient weighing, bagging, and sealing of finished products.

A thermal oil boiler (2.4 MW, Kirka Belgrade, 2014) provides efficient heat for the frying process.

Major Equipment List & Features

- Thermal Oil Boiler – 2.4 MW (Kirka Belgrade, 2014) – Provides heating for the fryer

- Emptying Bin – 3.5 Tonne Capacity (Florigo, 2000) – Handles bulk potato intake

- Conveyors – Various manufacturers and ages for seamless product movement

- Pre-Washer / Cyclone Destoner (Komen + Kun, 2000) – Removes dirt, stones, and debris

- Weigh Hopper Batch Peeler – 2,500 kg/hr (Florigo, 2000) – Ensures consistent peeling

- Slicer – 6-Head (Urschel, 2000) – Cuts uniform chips for frying

- Water Cleaning Unit (Florigo, 2000) – Further cleans sliced potatoes

- Blancher (Florigo, 2000) – Improves texture and removes excess starch

- Fryer (Florigo, 2000) – Ensures even frying and crispness

- Flavouring Drum – 600 kg/hr (Aroma K-tron Coperion, 2000) – Evenly seasons chips

- Packaging Machines:

- (2) Vopak-VE 280 with Double Head Weighers (Yamato, 2000)

- (2) Simionato with Single Head Weighers (2000)

- (3) Volpack with Single Head Weighers (Yamato, 2007)

Specifications

- Production Capacity: 600 kg/hour

- Peeling Capacity: 2,500 kg/hour raw potatoes

- Fryer Type: Thermal Oil Heated Fryer (Florigo, 2000)

- Heat Source: 2.4 MW Thermal Oil Boiler (Kirka Belgrade, 2014)

- Packaging System:

- Double & Single Head Weighers

- Automated Bagging & Sealing

Applications

- Potato Chips Manufacturing – From raw potato processing to packaged chips

- Snack Food Production – Processing and packaging of fried snack foods

- Food Processing Facilities – Large-scale frying and seasoning operations

- Industrial Packaging – Automated weighing and bagging systems for snack foods

Compatible Products

- Fully automated potato chip production lines

- Industrial batch peelers and slicers

- High-efficiency flavoring and seasoning systems

- Advanced snack food packaging machinery

Food Industry, Food Manufacturing, Food Plants, Food Processing, Food Production, Food Products, Foods, Snack, Snack Chips, Snack Foods

- Potato chips line, industrial fryer, food processing equipment

- Used potato chip production line, complete snack food frying system, high-capacity chip packaging equipment

- Used 600 kg/hr industrial potato chip production line with frying, seasoning, and packaging system, fully automated snack food processing system with thermal oil fryer, high-efficiency potato chip processing line with multiple packaging machines

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory