Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

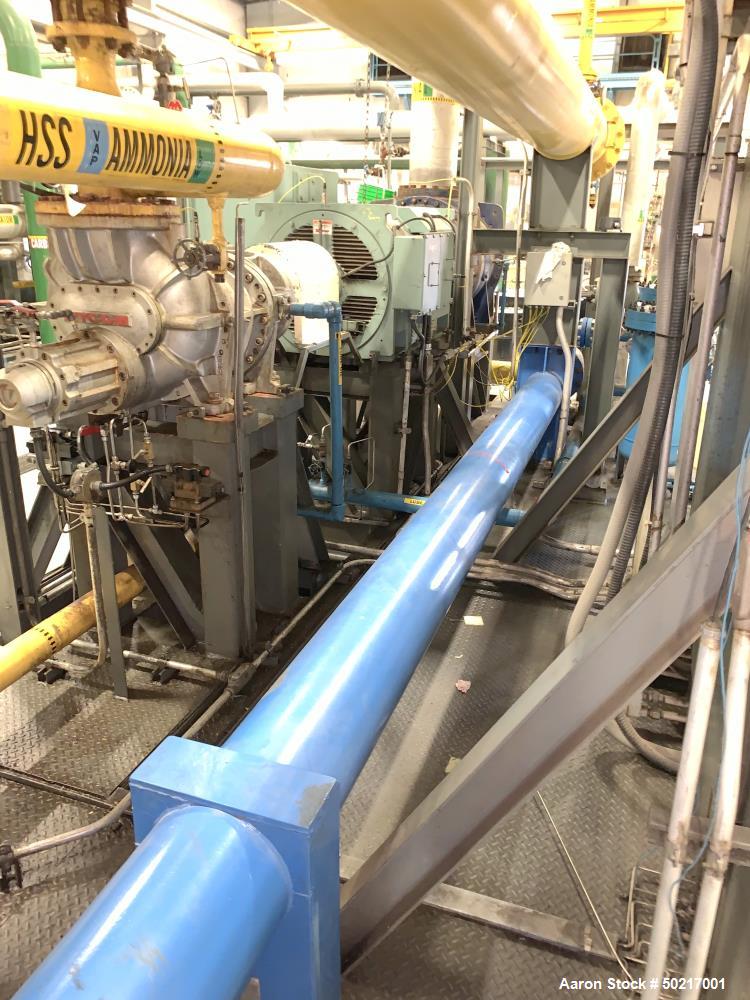

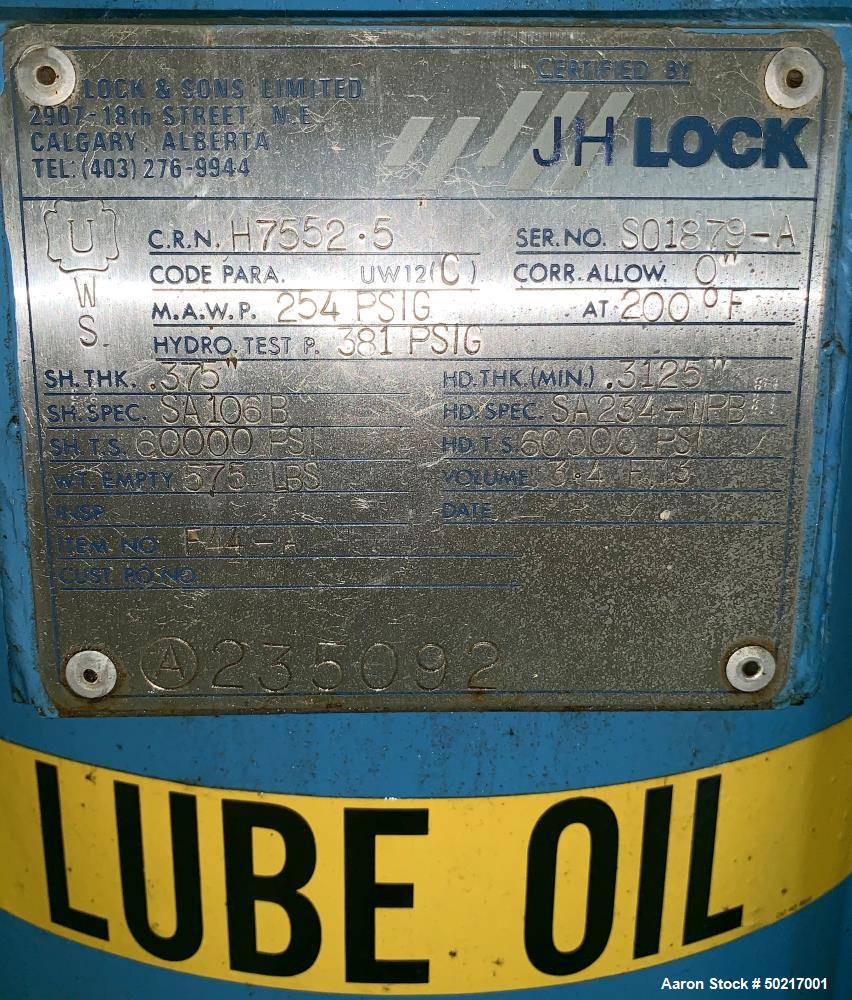

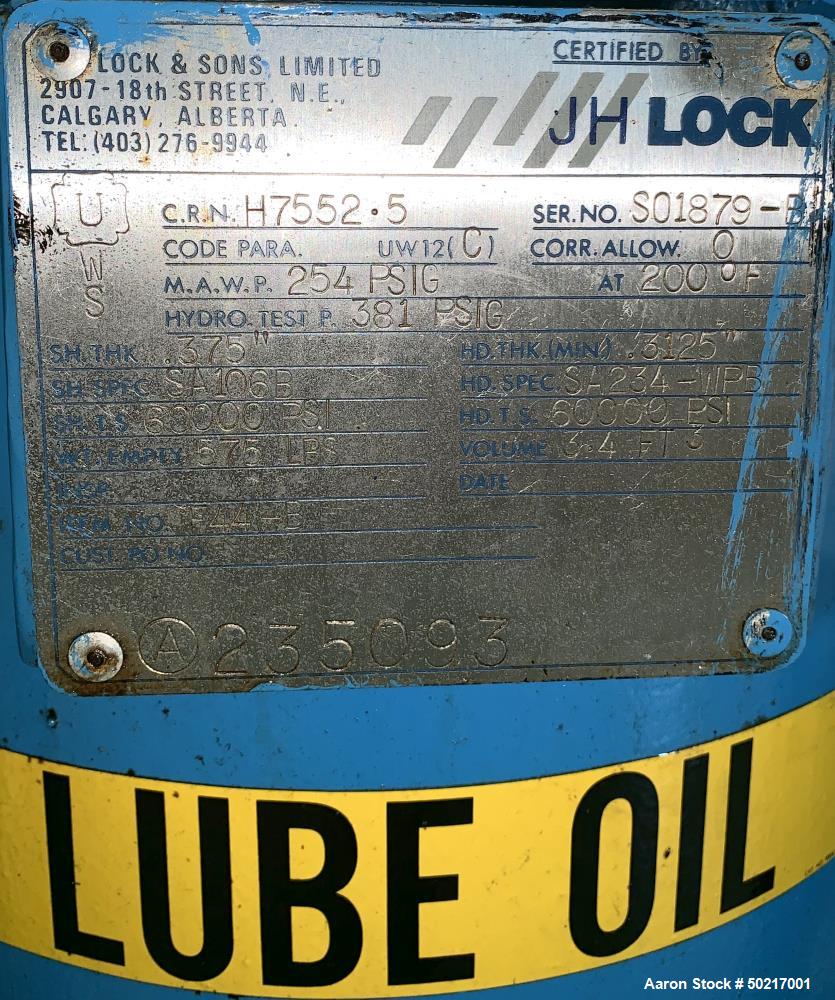

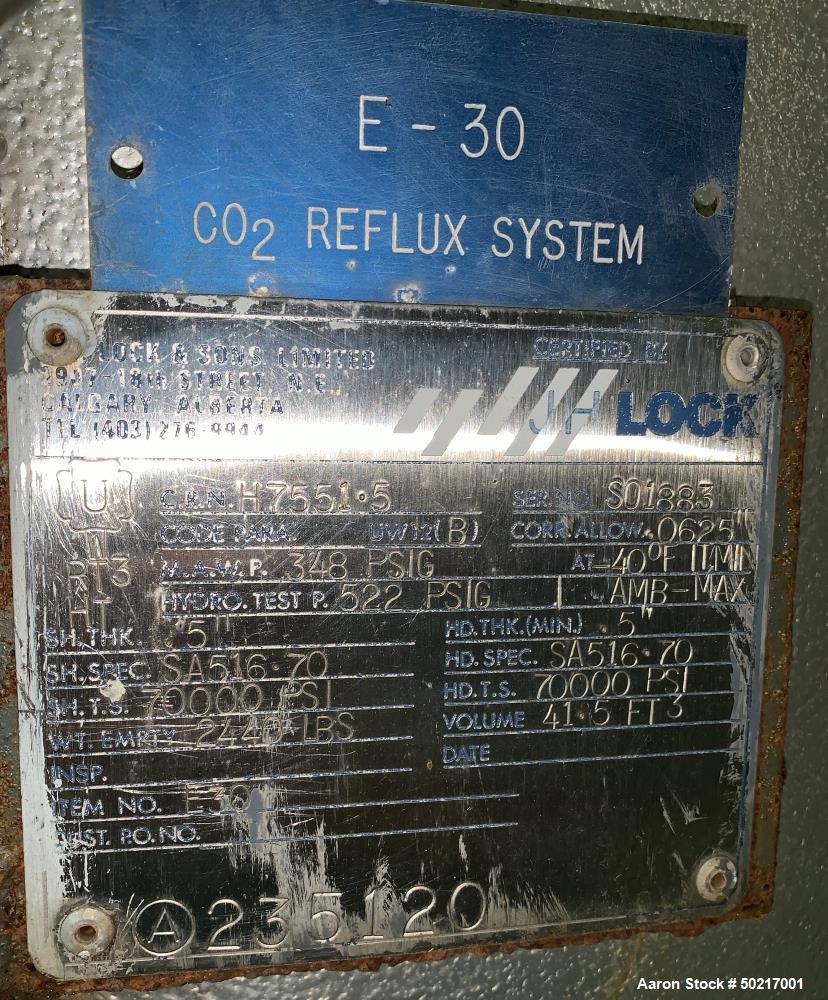

Used Complete CO2 Plant, Closed Loop Ammonia System.

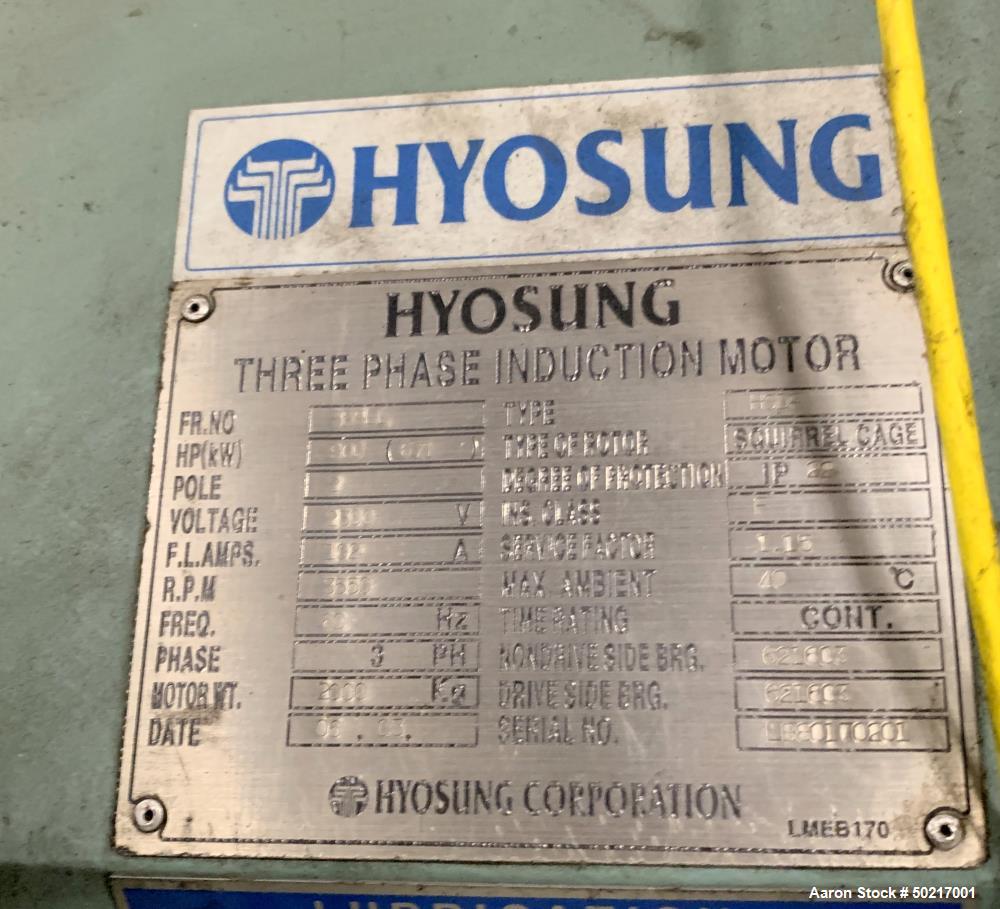

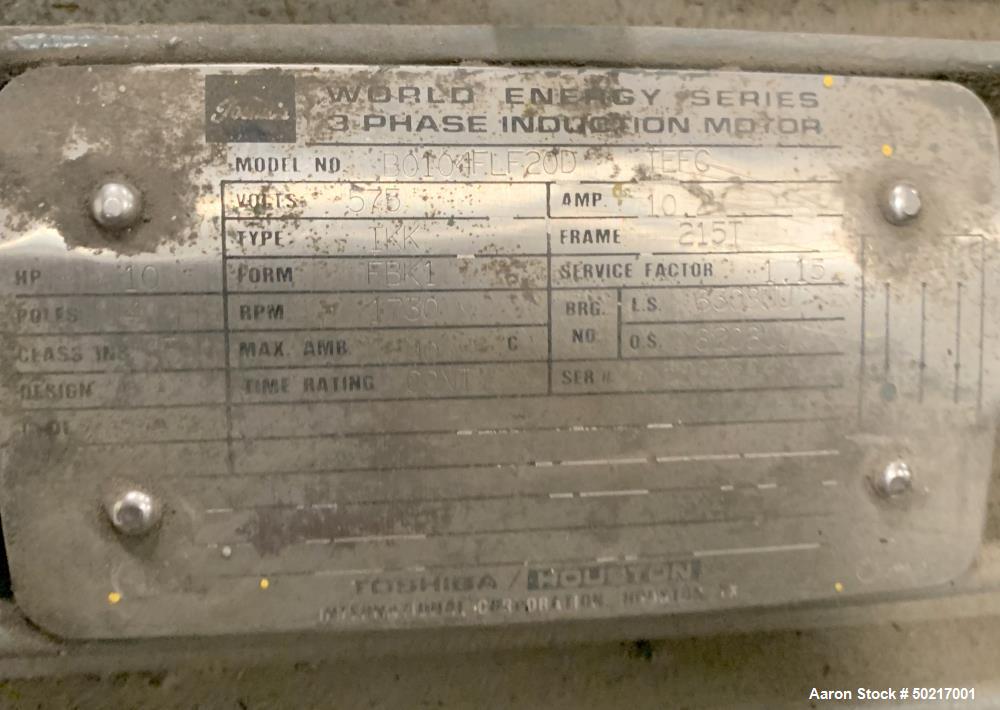

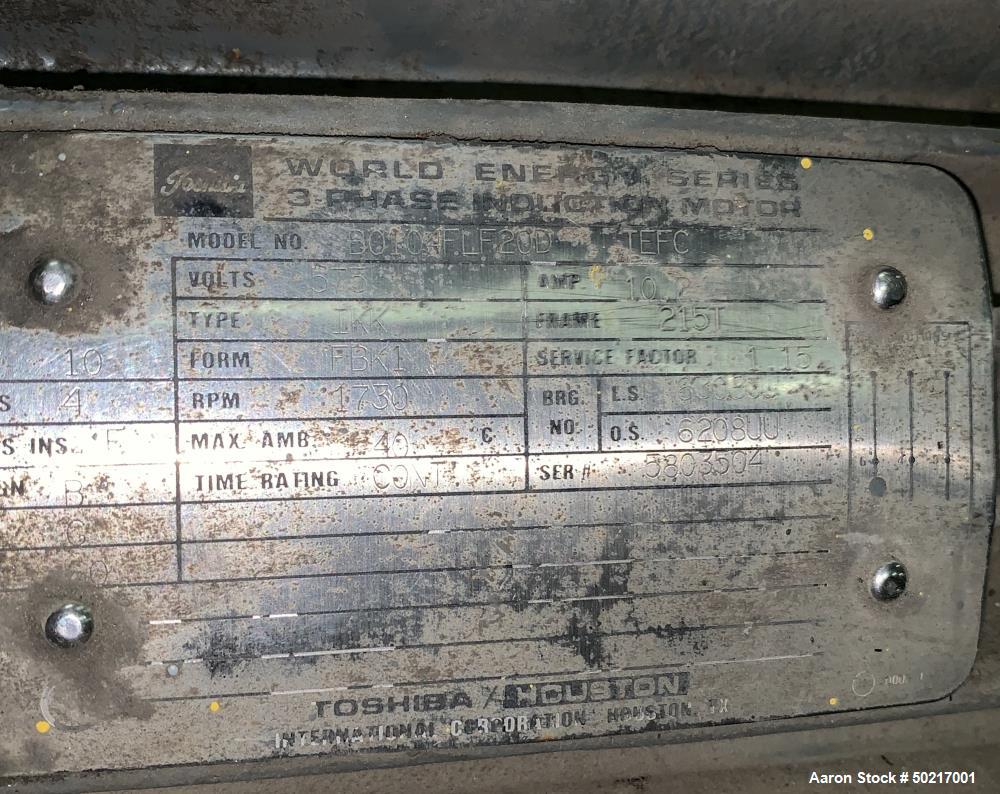

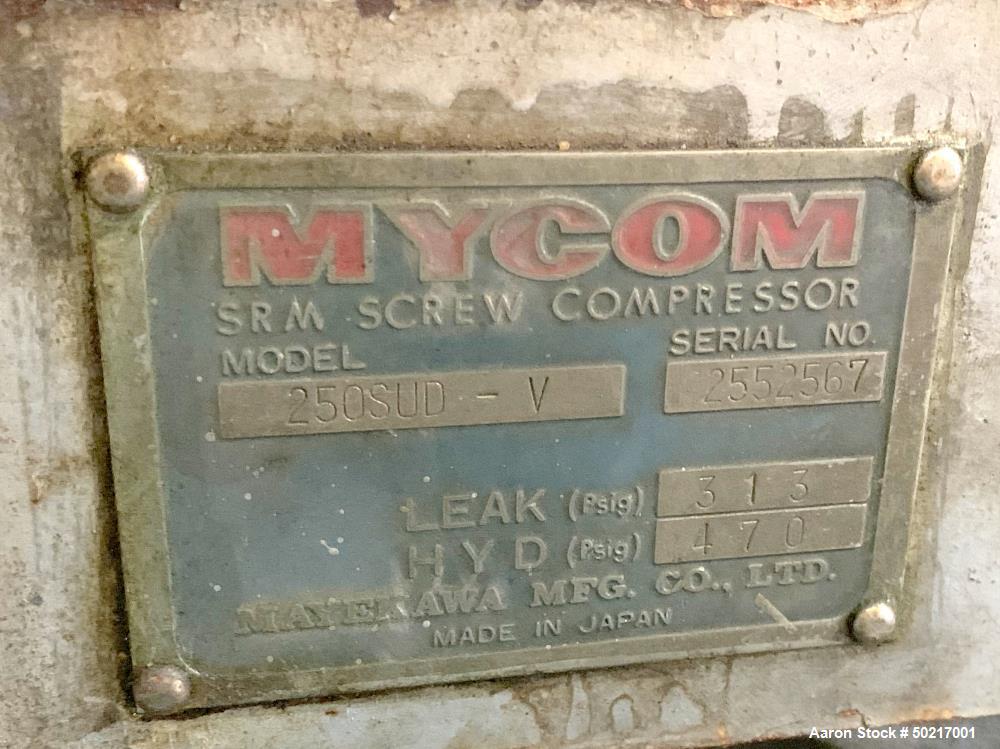

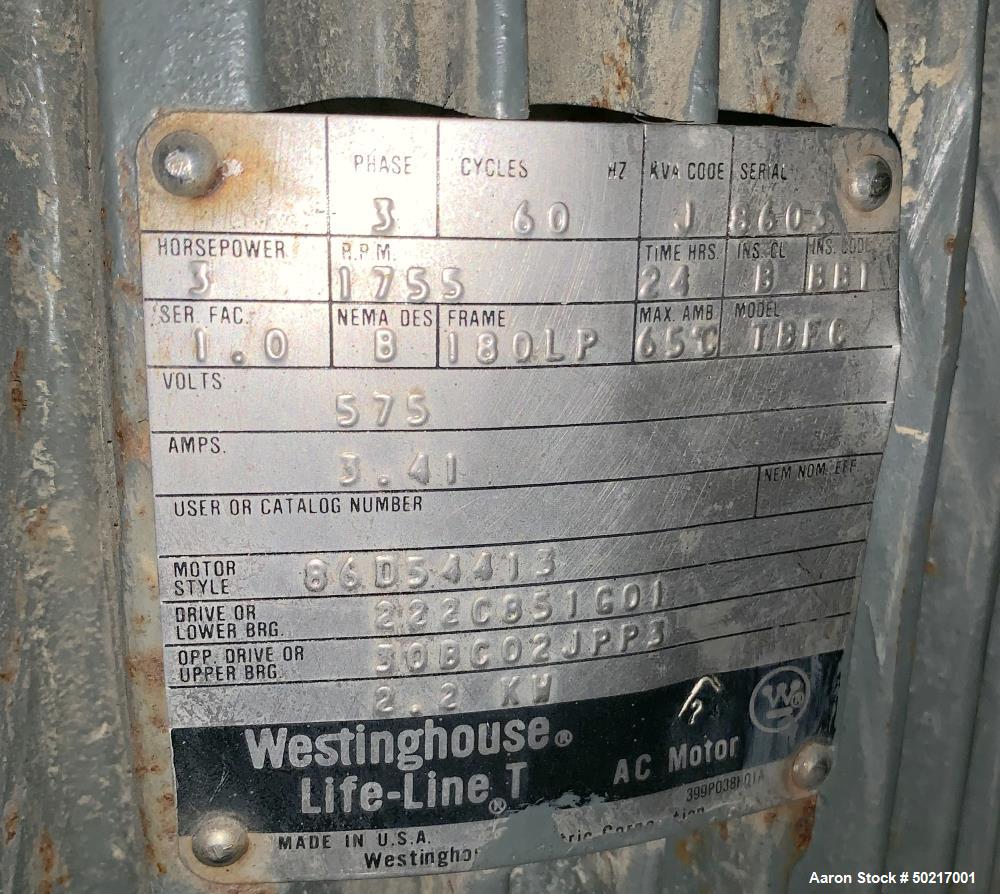

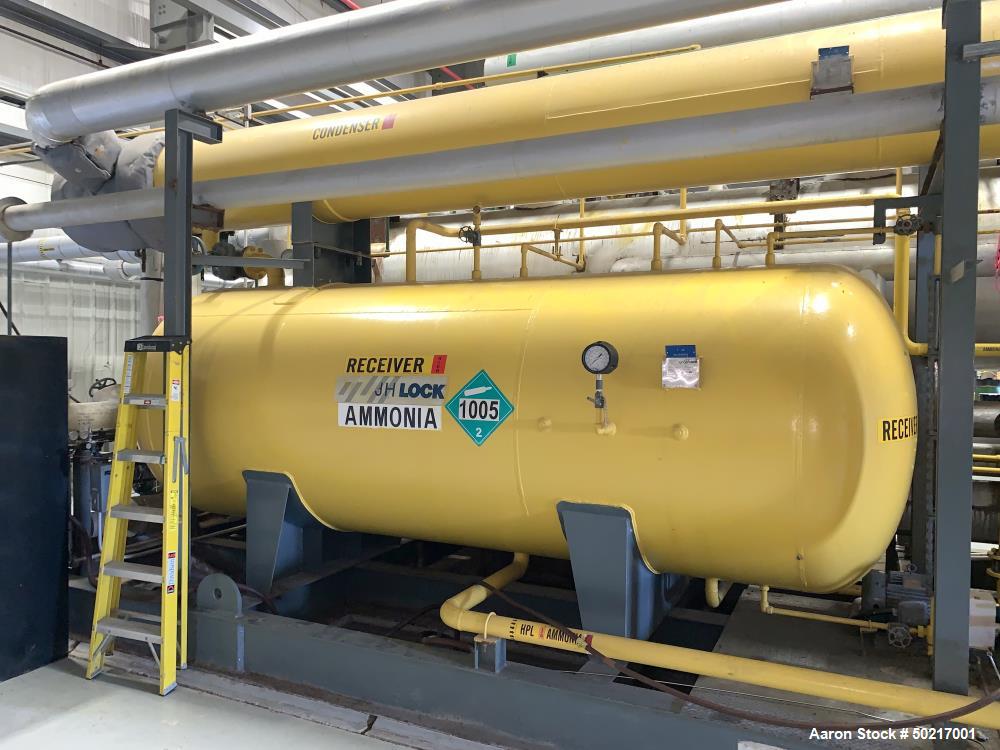

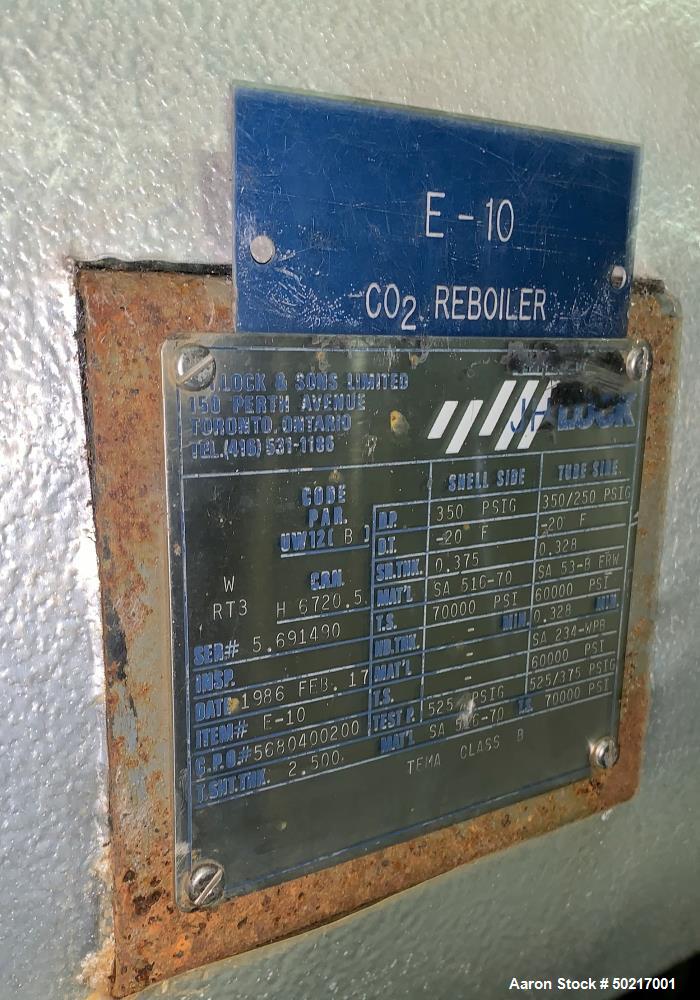

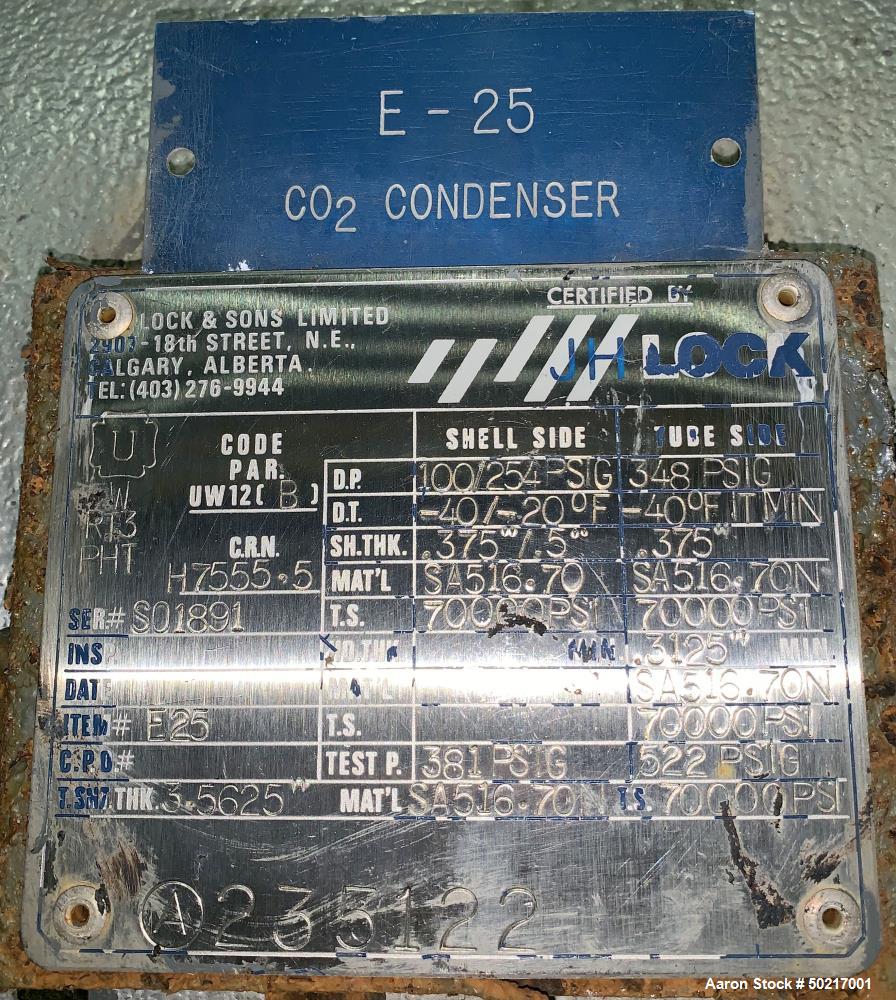

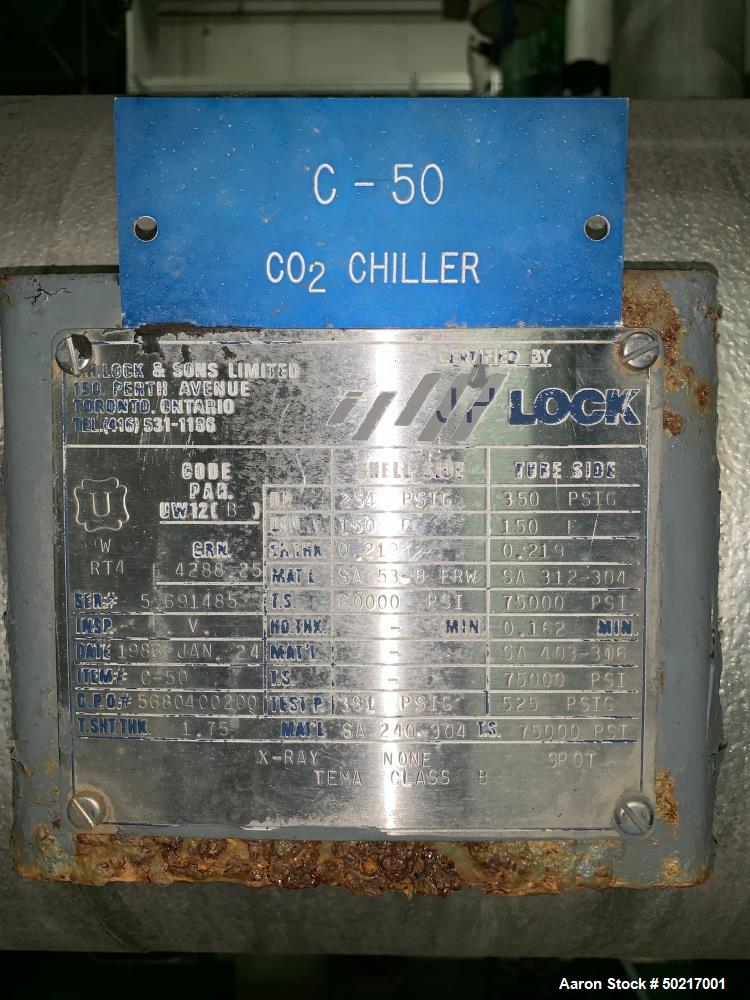

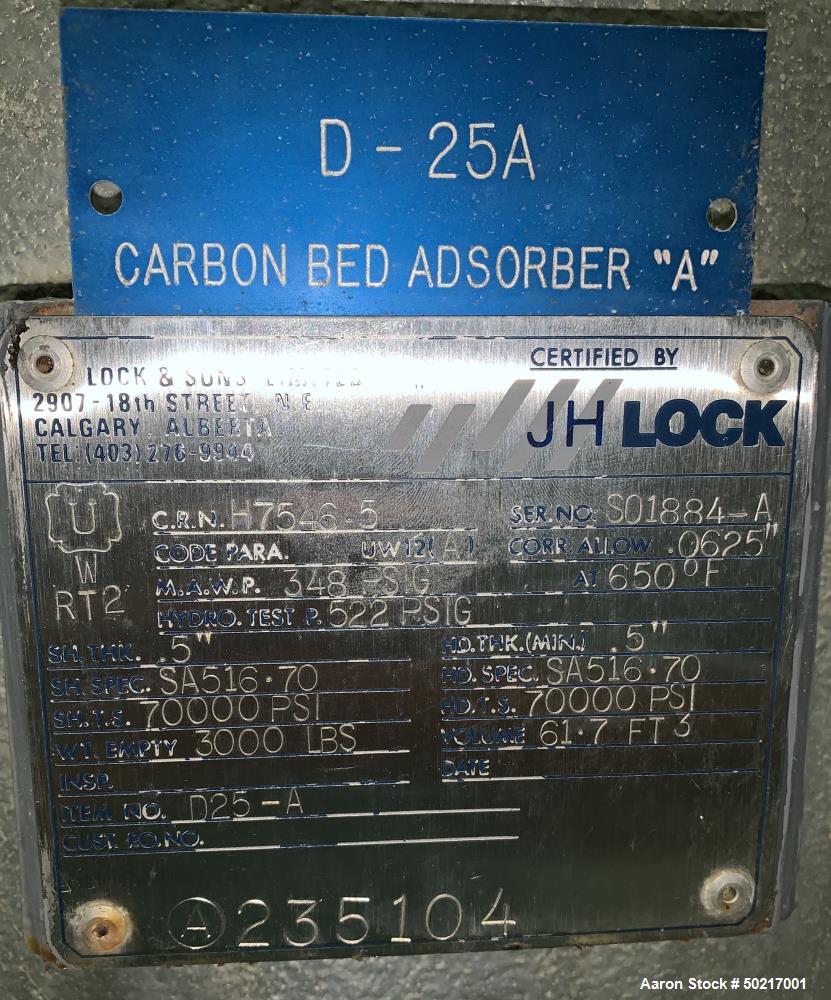

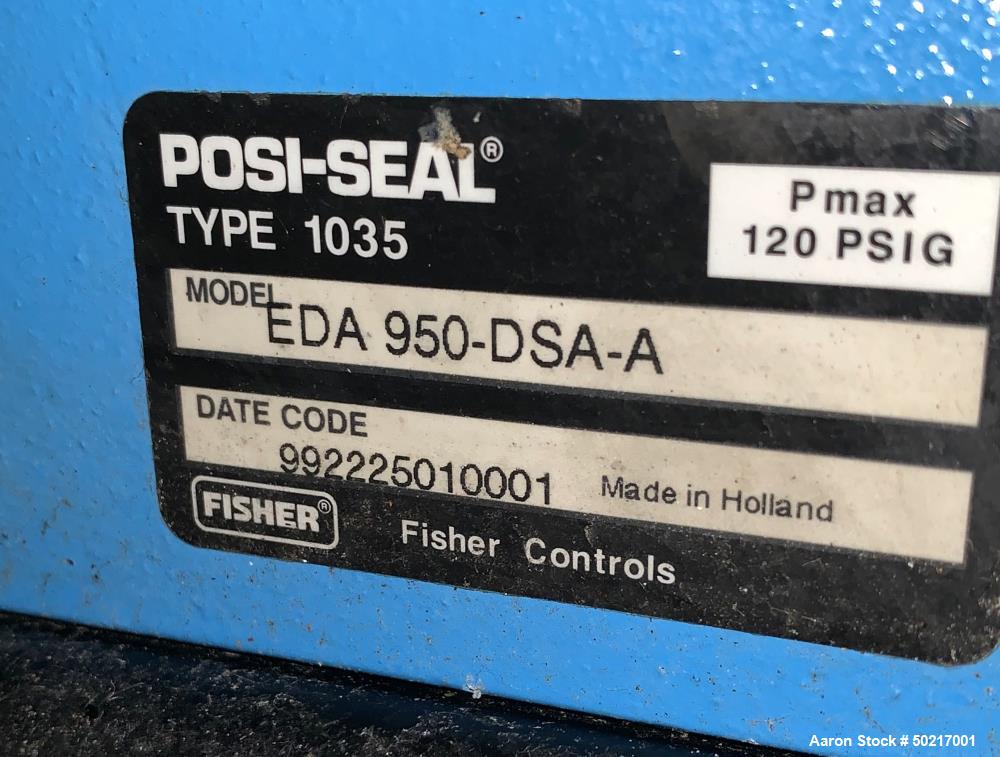

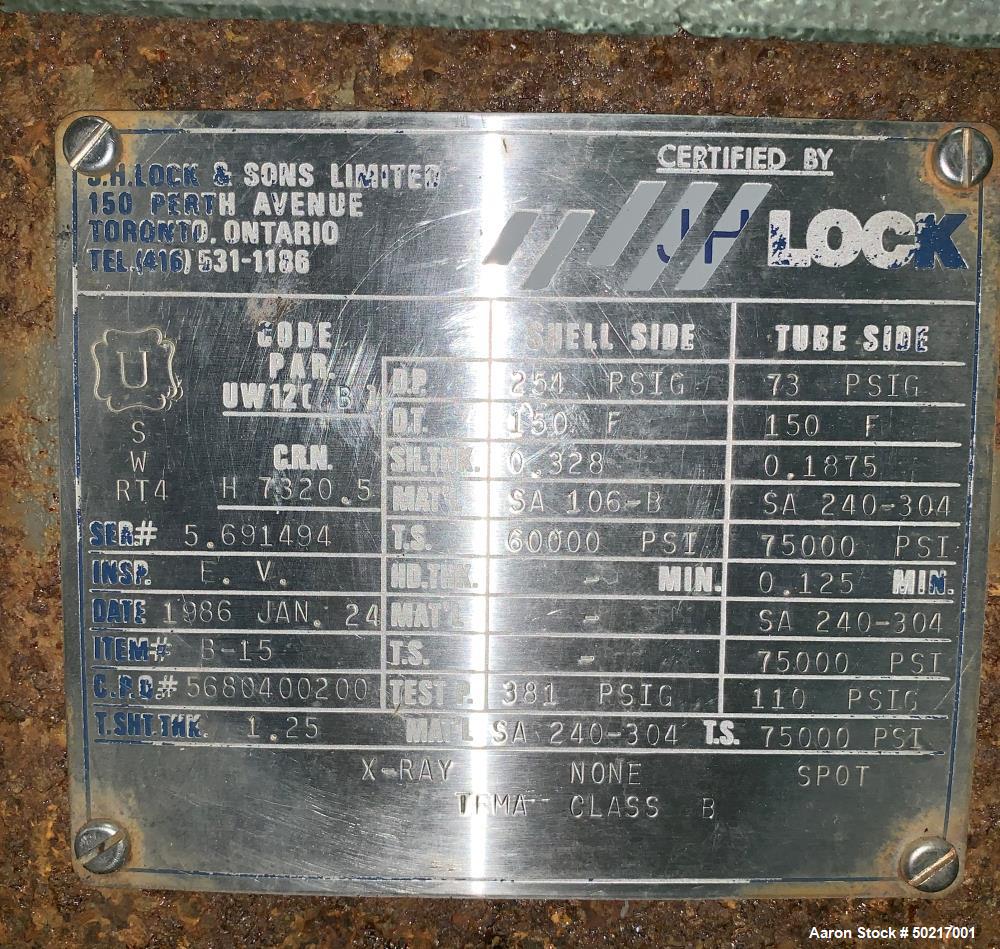

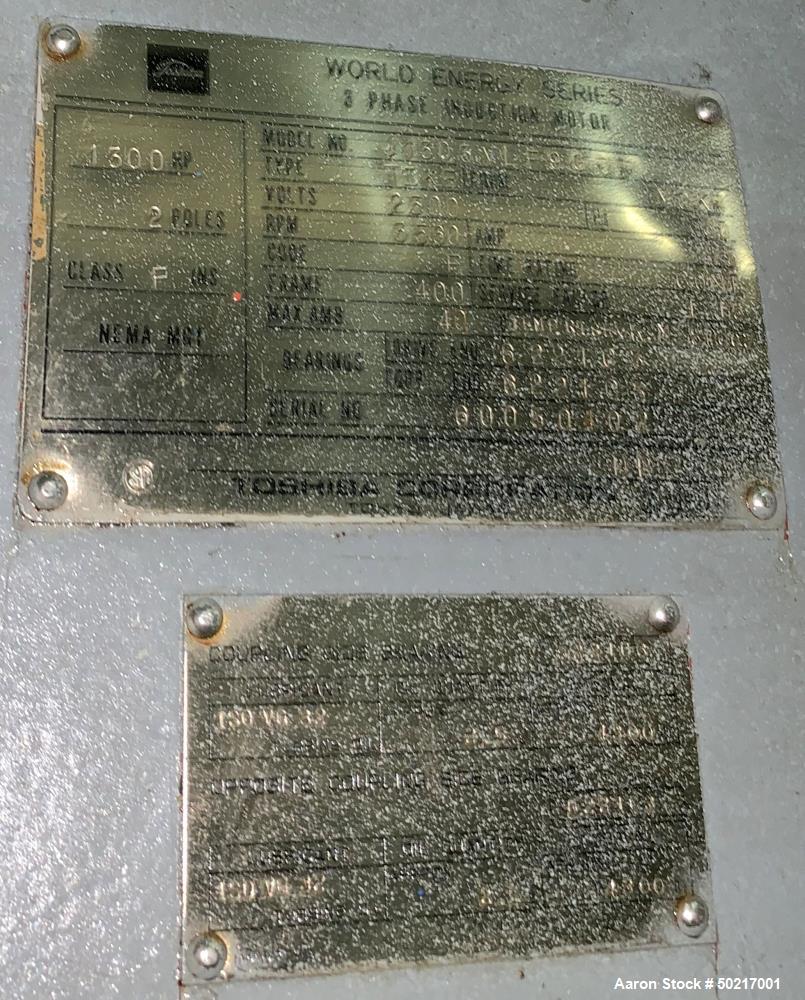

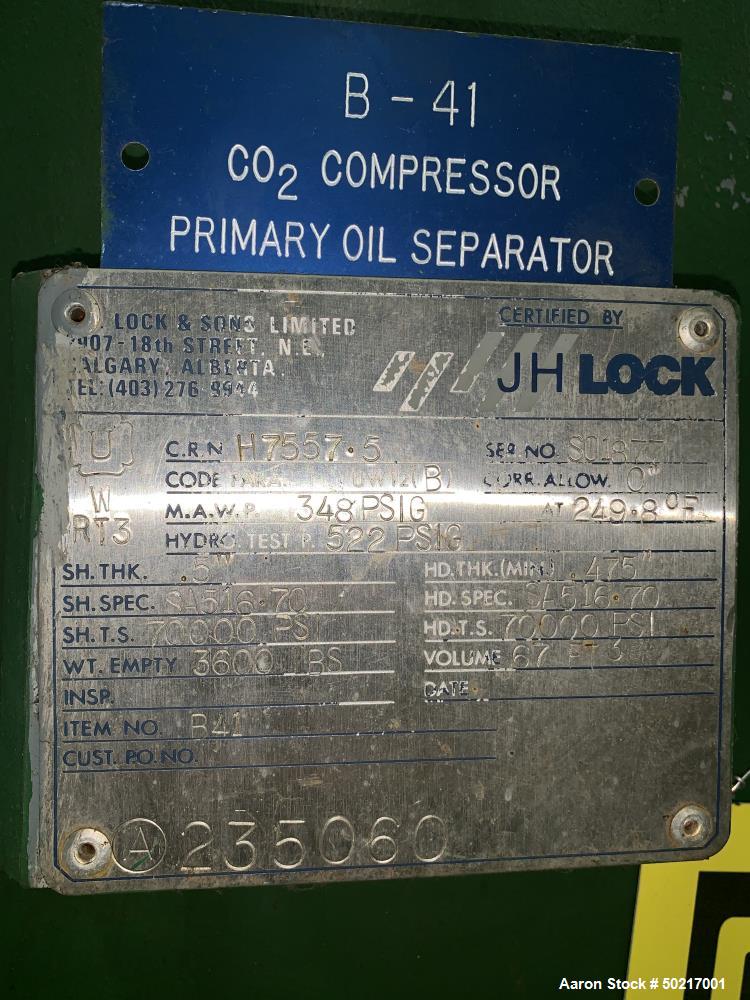

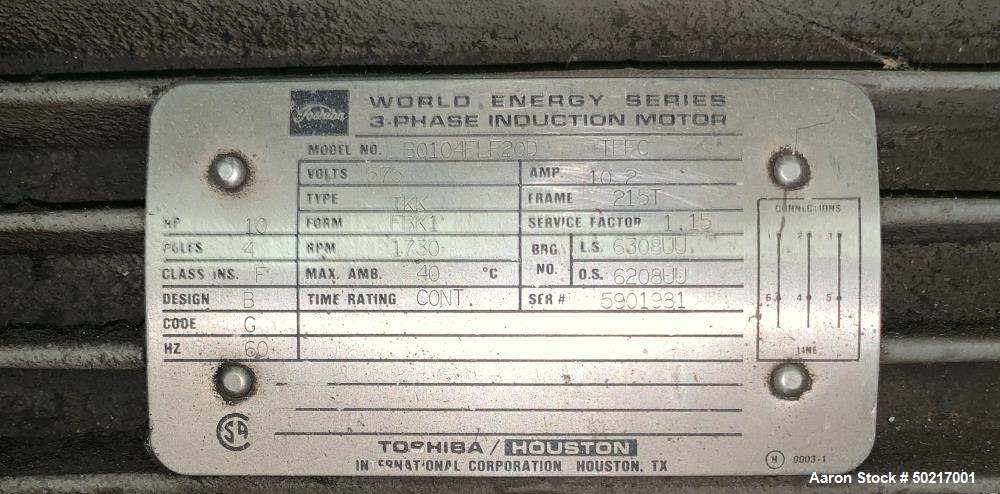

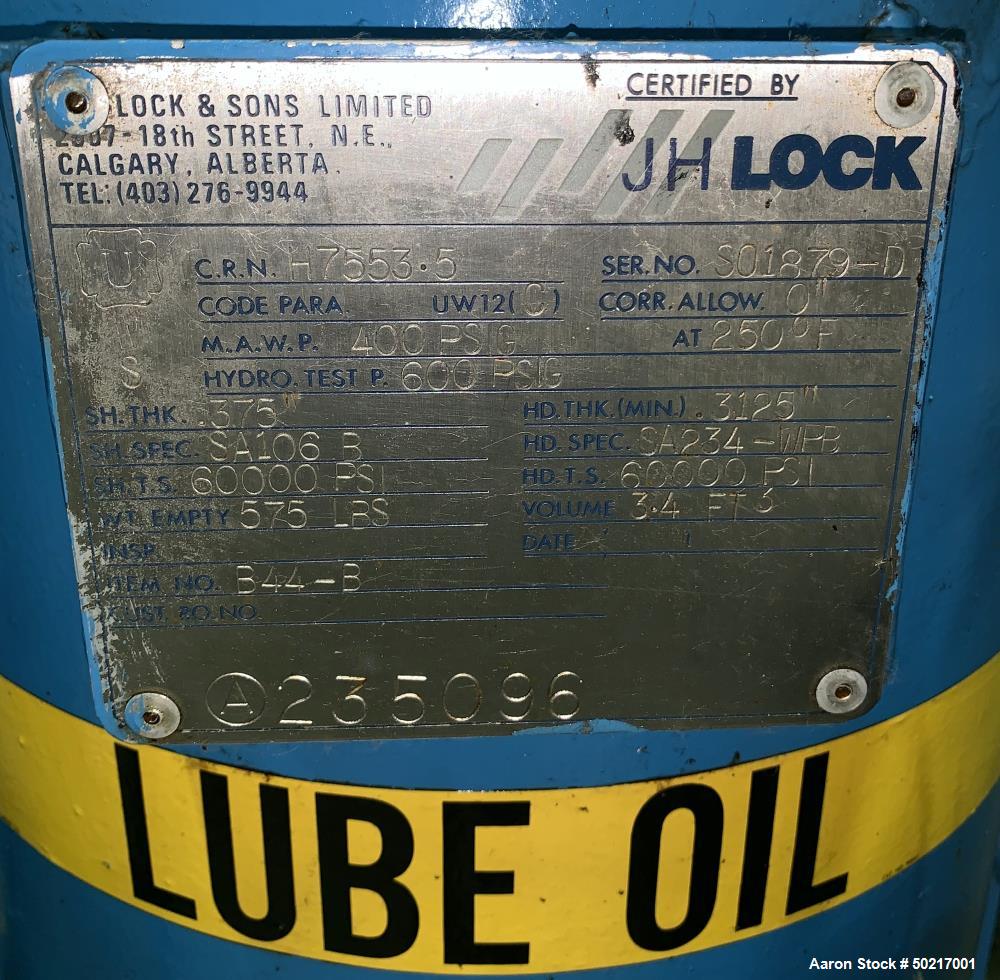

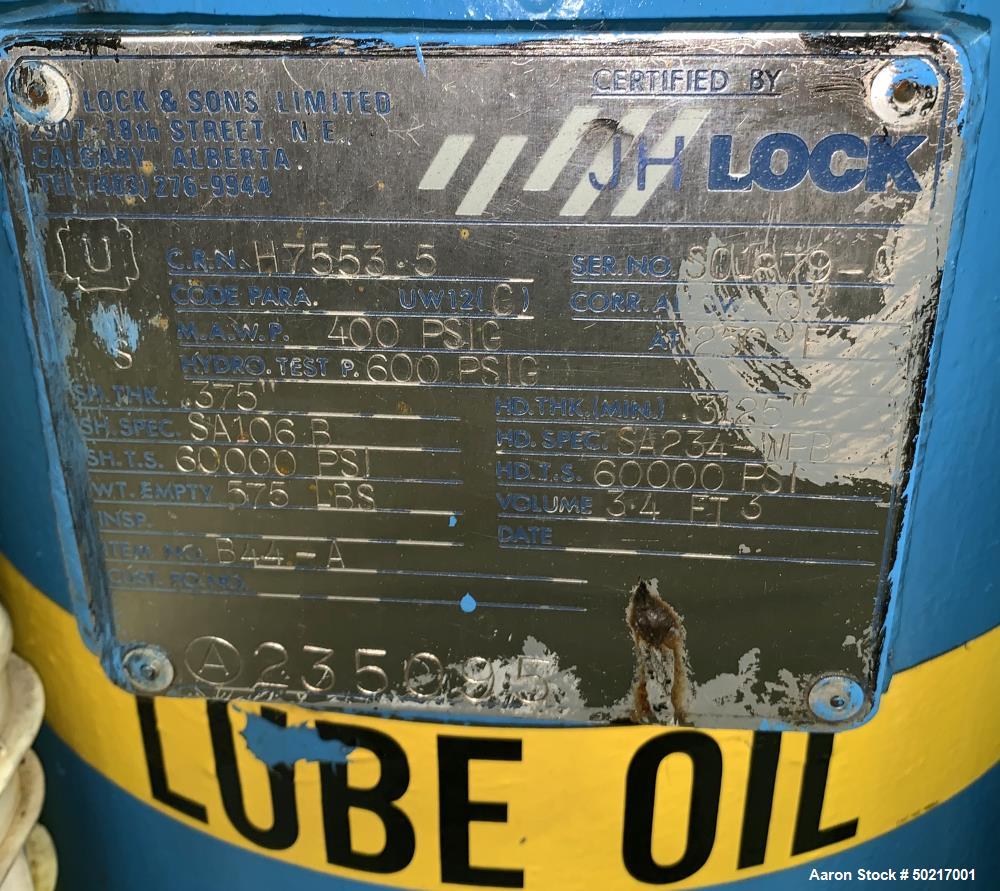

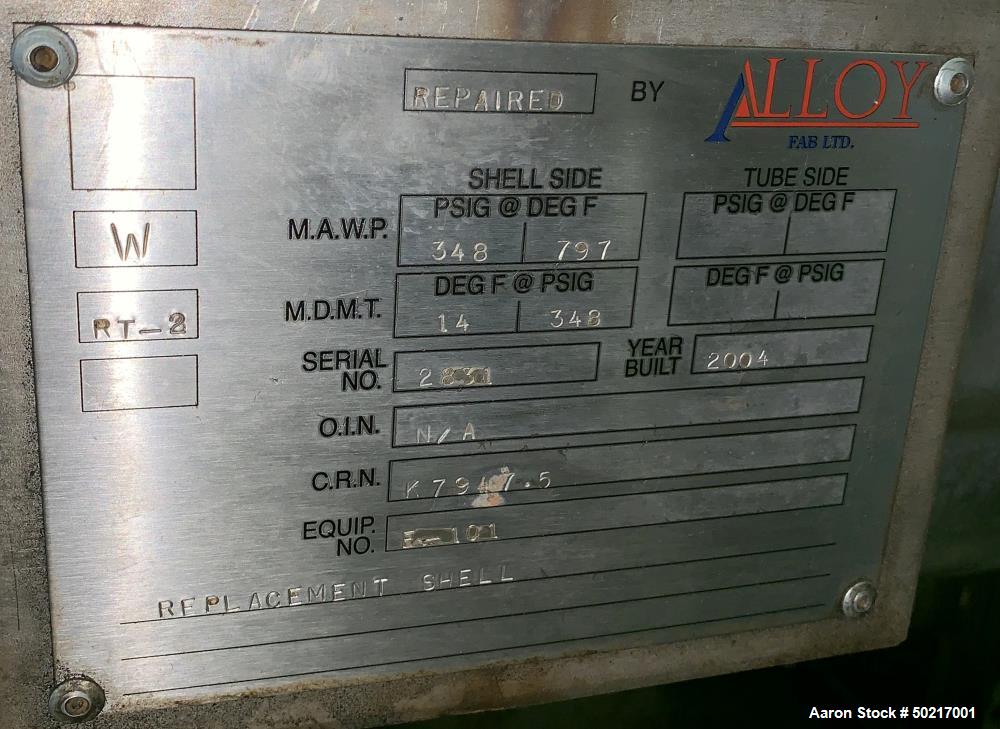

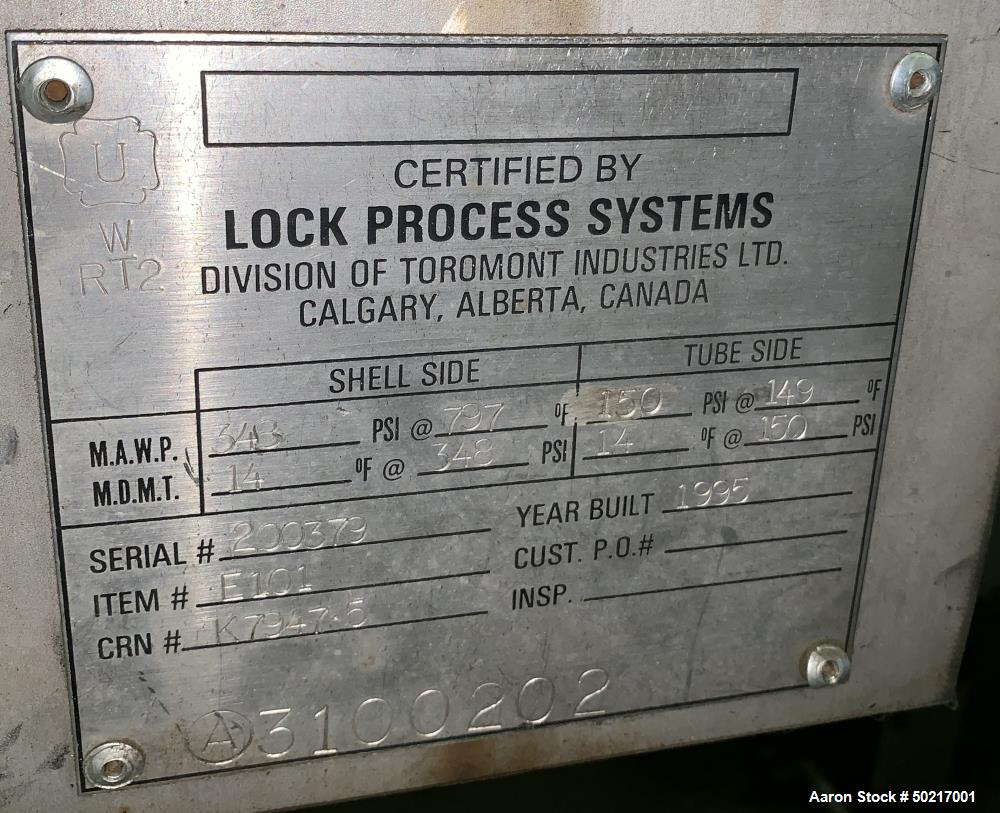

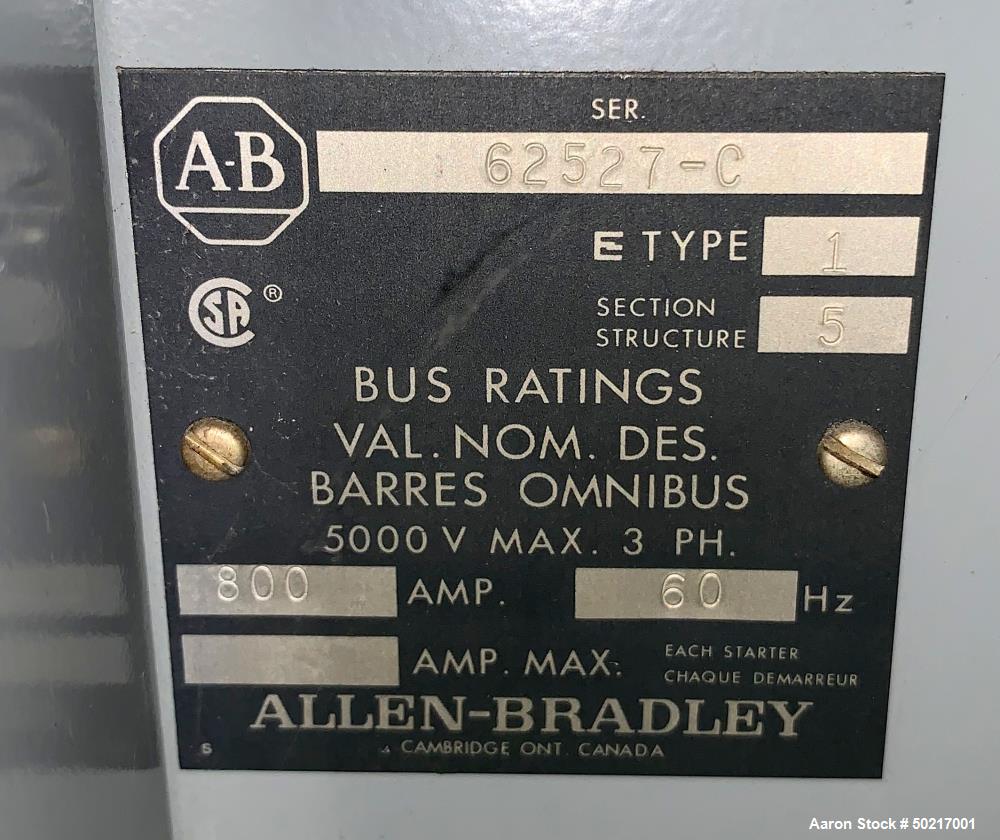

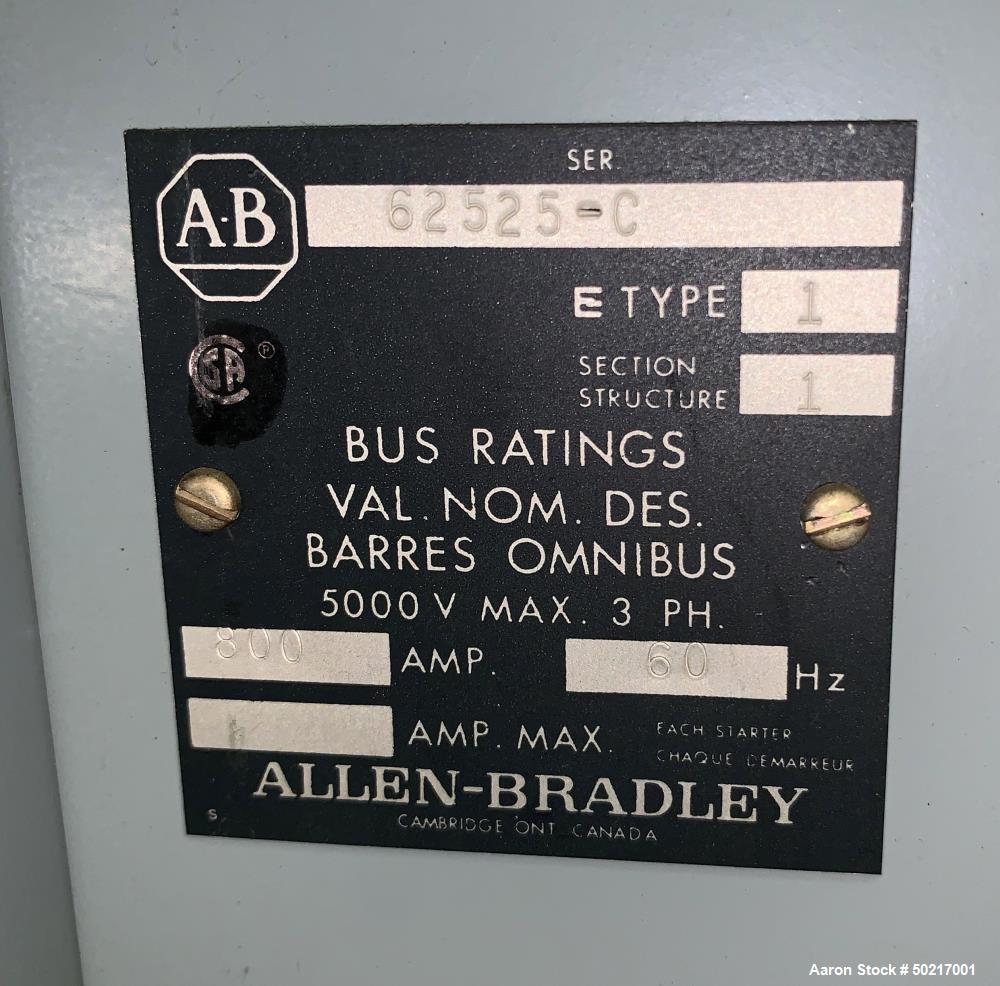

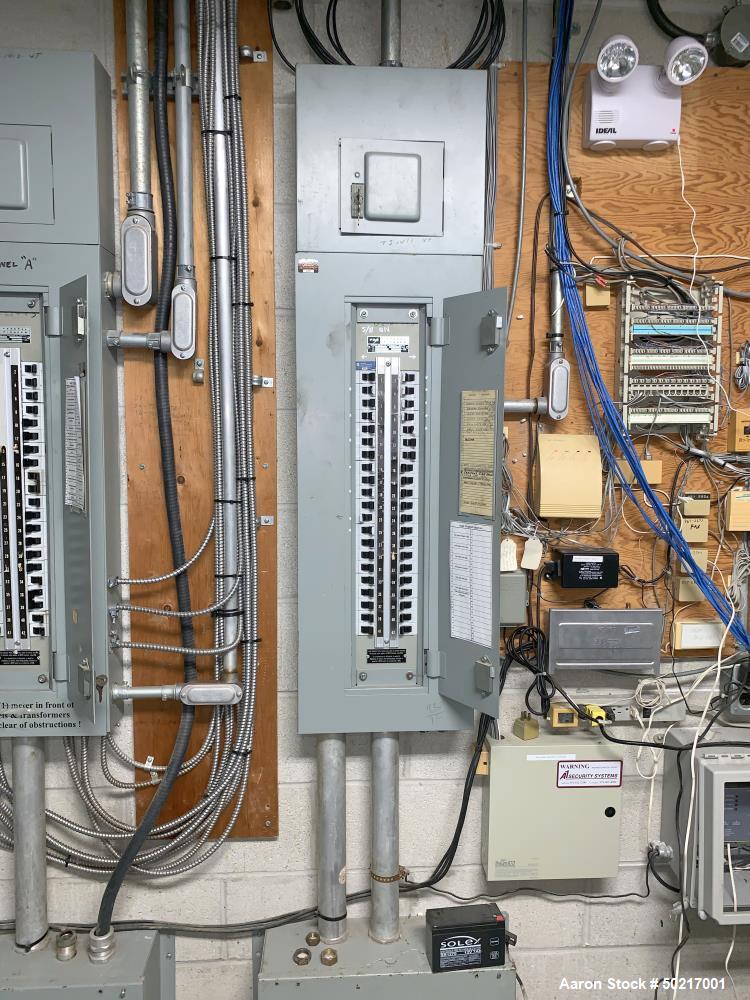

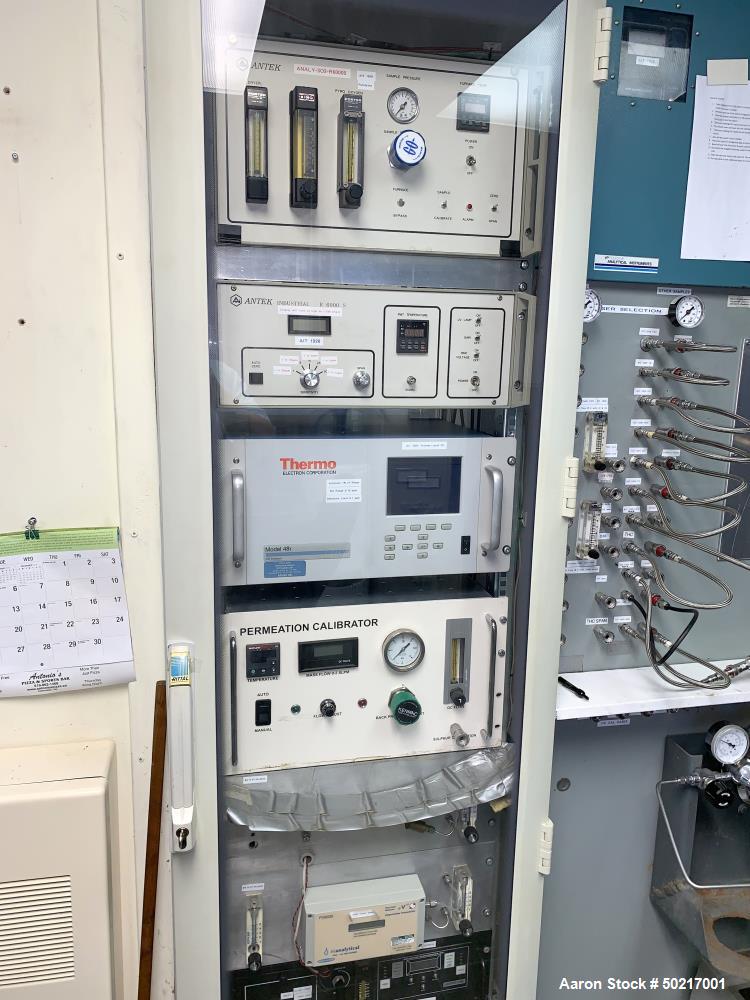

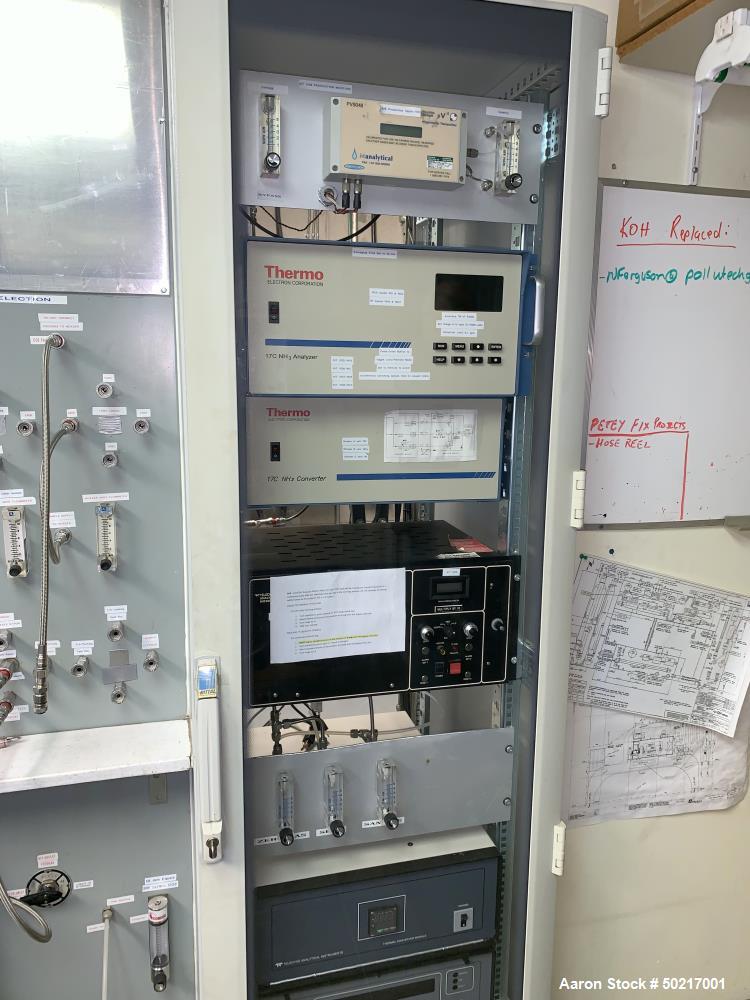

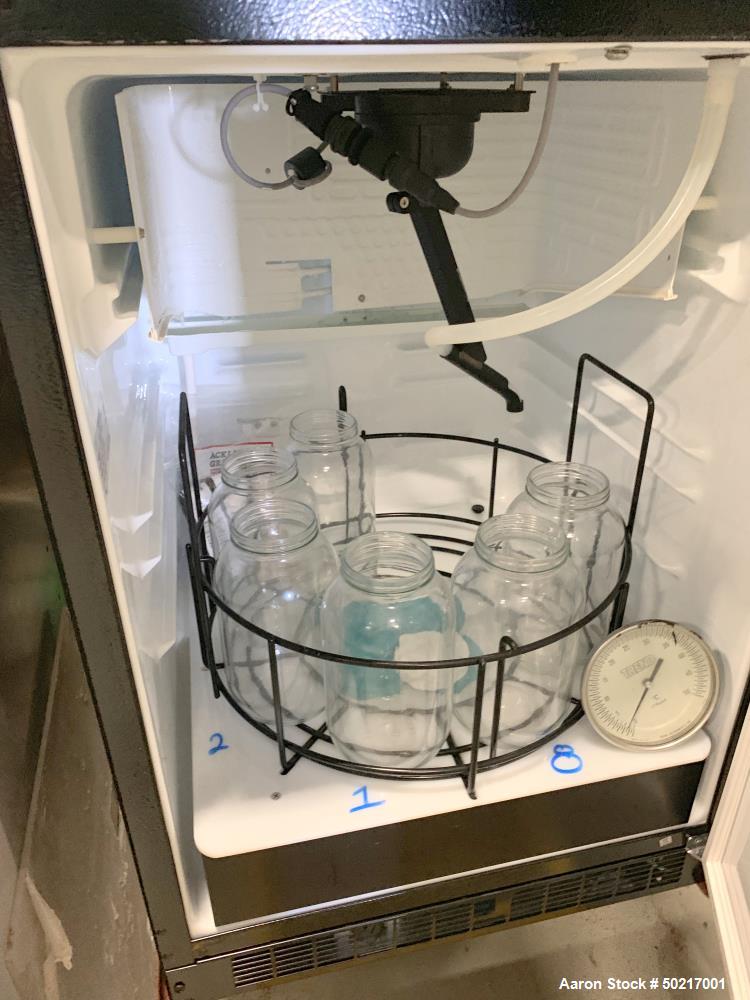

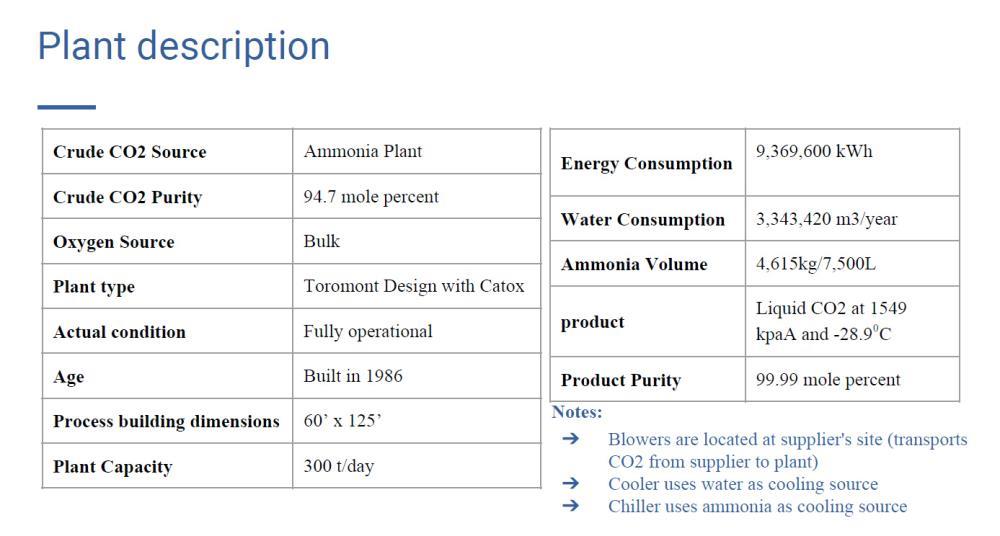

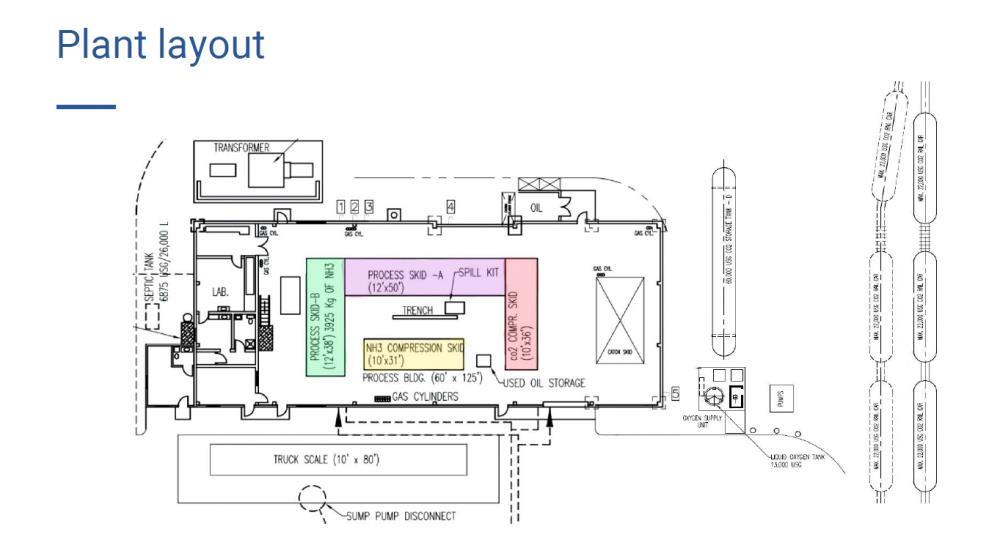

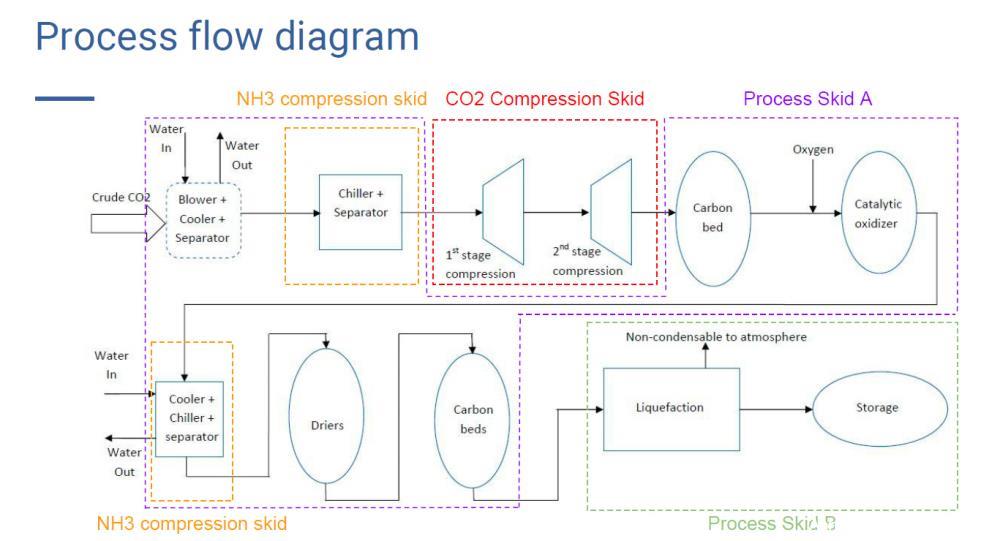

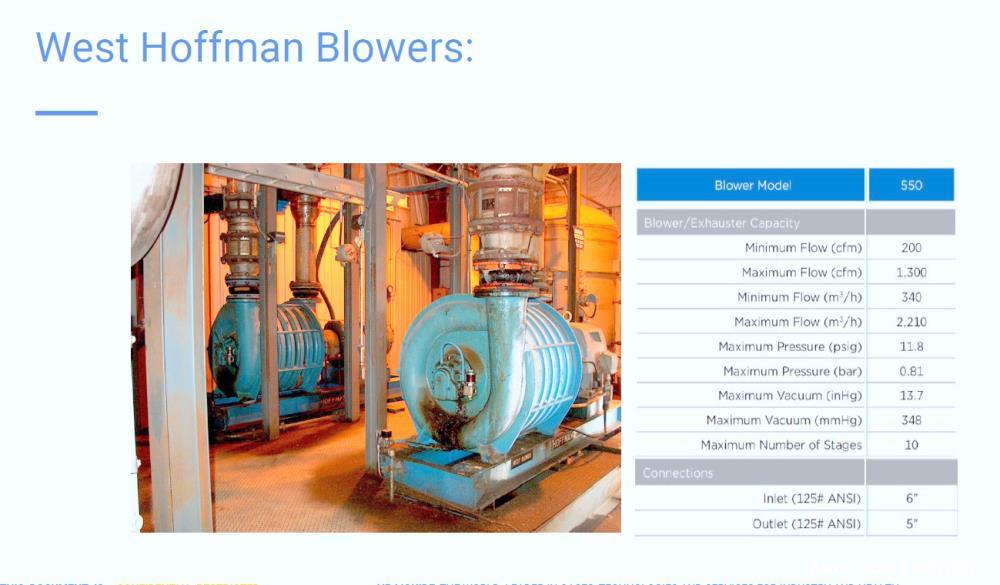

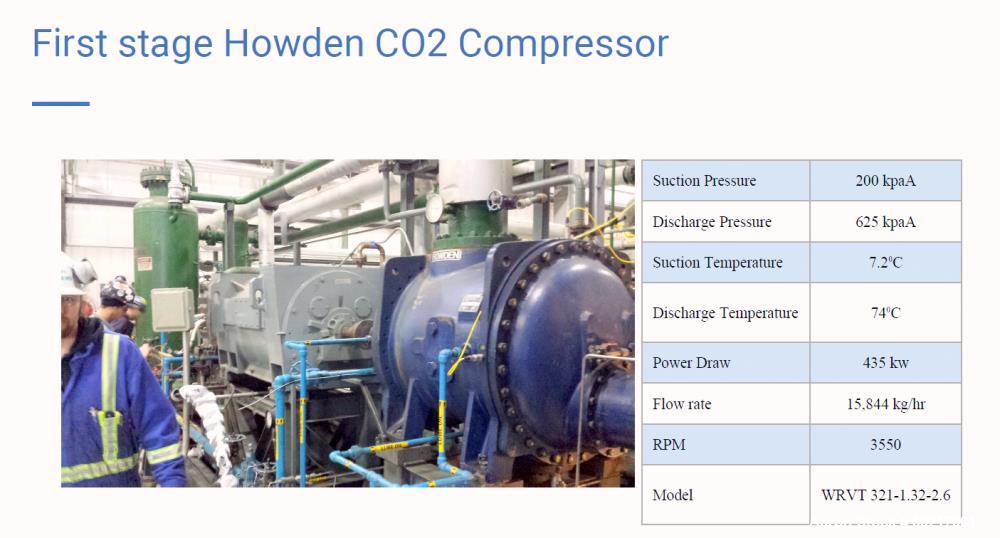

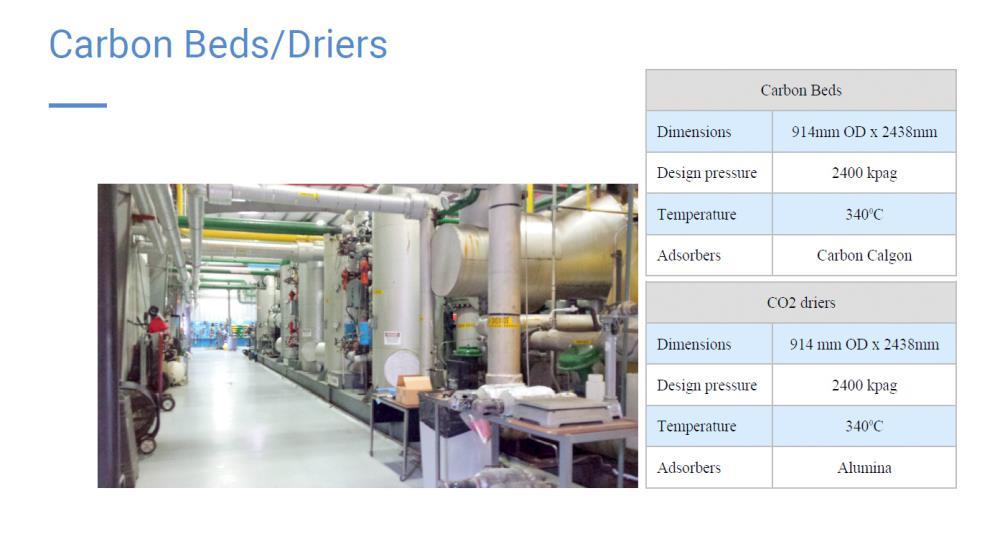

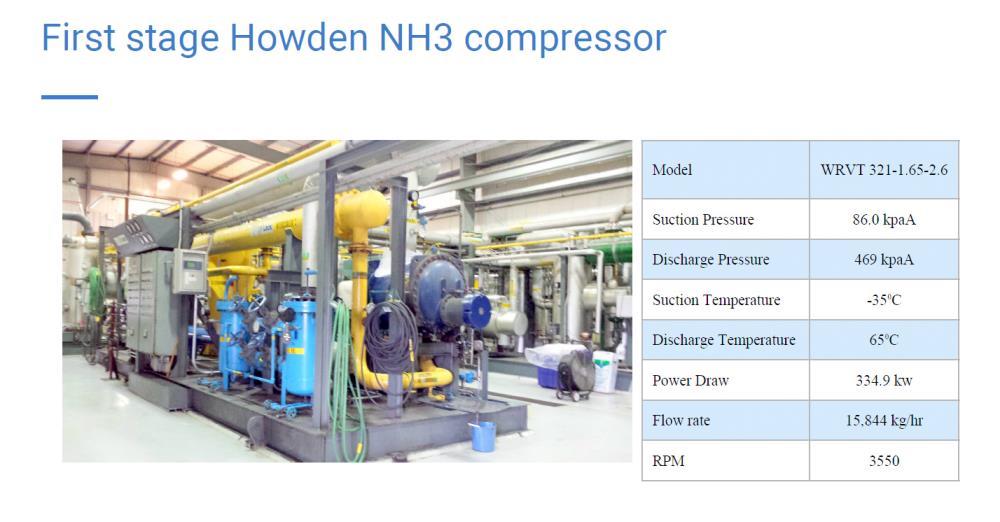

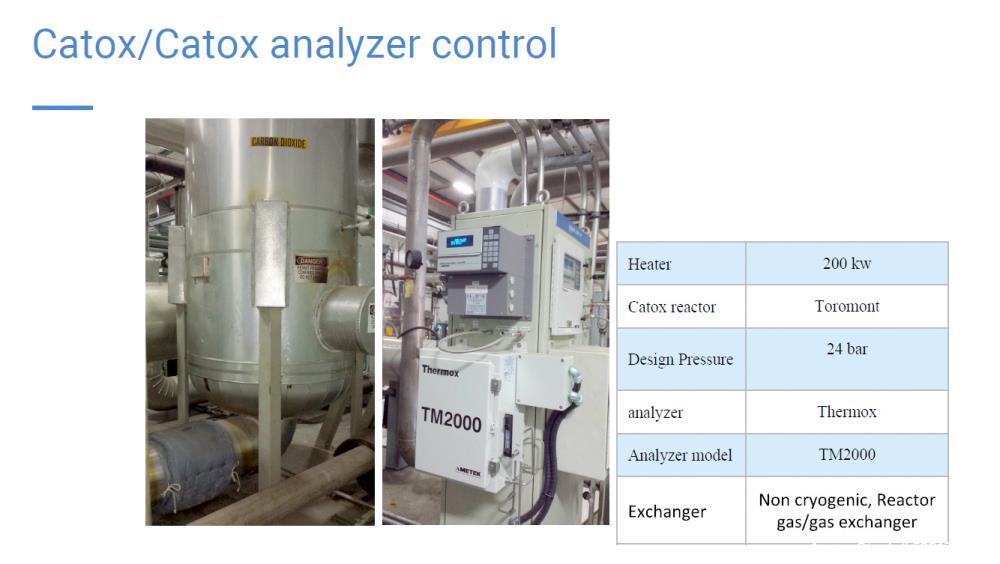

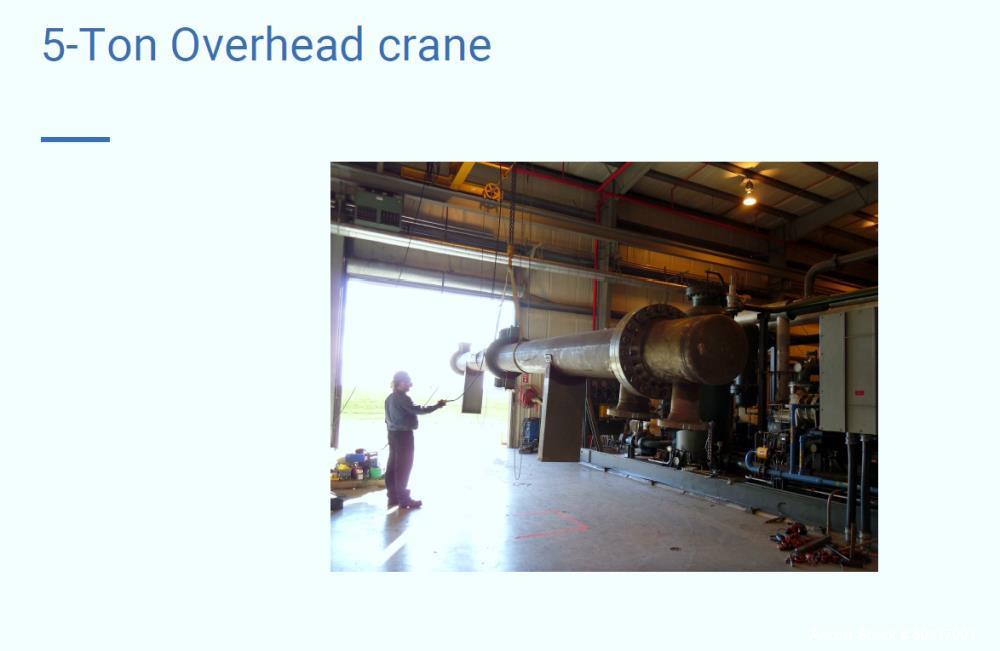

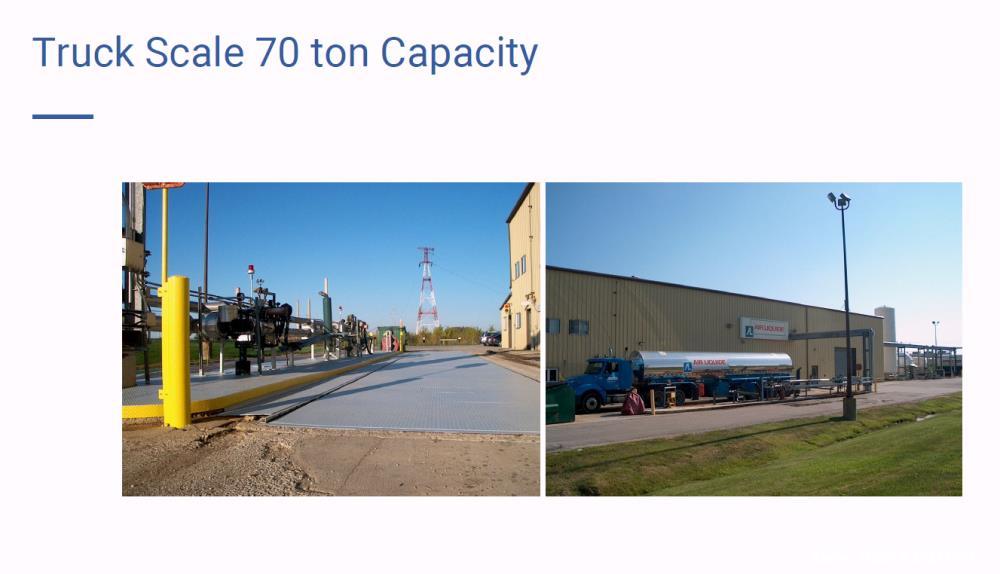

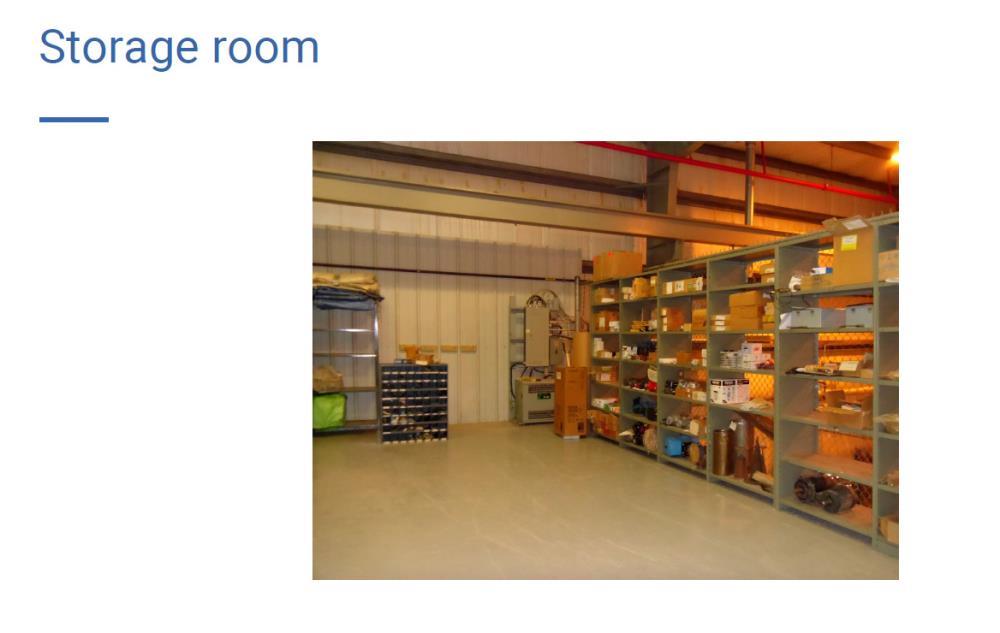

Used Complete CO2 Plant, Closed Loop Ammonia System. With 2 stages of compression that is used as refrigerant for the liquefaction skid and other chillers in the process. There is also a Catalytic oxidizer that is used to remove the hydrocarbons. There is also a blower and a cooler at the CO2 supplier plant before CO2 gets to the plant. Chillers use ammonia as the refrigerant and the other utilities use water as a cooling source. Crude CO2 Source (Ammonia Plant), Crude CO2 Purity (94.7 mole percent), Oxygen Source (Bulk), Plant type (Toromont Design with Catox), Age (Built in 1986), Process building dimensions (60 x 125), Plant Capacity (300 t/day), Energy Consumption (9,369,600 kWh), Water Consumption (3,343,420 m3/year), Ammonia Volume (4,615kg/7,500L), Product (Liquid CO2 at 1549 kpaA and -28.9C), Product Purity (99.99 mole percent). Components of plant; (2) West Hoffman Blowers, First Stage Howden CO2 Compressor, Second Stage Mycom CO2 Compressor, CO2 Compression Electromotor, Carbon Beds/CO2 Driers, CO2 Lube Oil System, First Stage Howden NH3 Compressor, Second Stage Mycom Screw NH3 Compressor, NH3 Compression Electromotor, Catox Analyzer Control, 60,000 US Gallon Storage Tank, 5 Ton Overhead Crane, 70 Ton Capacity Truck Scale, Storage Room with Parts and Spares. Plant was Running with Fertilizers Crude CO2. Final Purity was Meeting ISBT Beverage Grade. 300-310 TPD. Last Production Date, September 2018.

Used Complete CO2 Plant, Closed Loop Ammonia System. With 2 stages of compression that is used as refrigerant for the liquefaction skid and other chillers in the process. There is also a Catalytic oxidizer that is used to remove the hydrocarbons. There is also a blower and a cooler at the CO2 supplier plant before CO2 gets to the plant. Chillers use ammonia as the refrigerant and the other utilities use water as a cooling source. Crude CO2 Source (Ammonia Plant), Crude CO2 Purity (94.7 mole percent), Oxygen Source (Bulk), Plant type (Toromont Design with Catox), Age (Built in 1986), Process building dimensions (60 x 125), Plant Capacity (300 t/day), Energy Consumption (9,369,600 kWh), Water Consumption (3,343,420 m3/year), Ammonia Volume (4,615kg/7,500L), Product (Liquid CO2 at 1549 kpaA and -28.9C), Product Purity (99.99 mole percent). Components of plant; (2) West Hoffman Blowers, First Stage Howden CO2 Compressor, Second Stage Mycom CO2 Compressor, CO2 Compression Electromotor, Carbon Beds/CO2 Driers, CO2 Lube Oil System, First Stage Howden NH3 Compressor, Second Stage Mycom Screw NH3 Compressor, NH3 Compression Electromotor, Catox Analyzer Control, 60,000 US Gallon Storage Tank, 5 Ton Overhead Crane, 70 Ton Capacity Truck Scale, Storage Room with Parts and Spares. Plant was Running with Fertilizers Crude CO2. Final Purity was Meeting ISBT Beverage Grade. 300-310 TPD. Last Production Date, September 2018.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory