Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

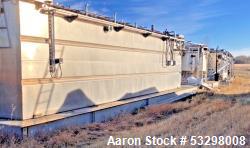

Hydrogen Plant, designed by Hydro-Chem (a Linde company)

Used Hydrogen Plant, designed by Hydro-Chem (a Linde company), operates at a capacity of 2,266 Nm/hr (80,000 SCFH) and produces hydrogen with a purity of 99.99%. Built in 2004, the plant was engineered to use natural gas feedstock composed of 97.97% methane, 1.37% CO2, 2.49% N2, and 3.53% ethane. The hydrogen product maintains a 99.99% purity at a maximum temperature of 100F and a minimum discharge pressure of 200 psig. The syngas reformer utilizes a nickel catalyst. The plant equipment has been dismantled and is ready for quick shipment. Major equipment includes the Feed Heater (HX-101), Desulfurizer Vessel (V-101), Steam/Gas Lateral (SP-779), Reformer (R-101), Reformer Effluent Steam Generator (WH-104), Shift Converter (V-102), Shift Effluent Steam Generator (WH-105), Process Cooler (HX-104), Deaerator Exchanger (HX-103), Boiler Feed Water Exchangers (HX-102A & B), Deaerator (V-106), Steam Drum (V-107), Cold Condensate Separator (V-104), Flue Gas Steam Superheater (WH-101), Flue Gas Steam Generator (WH-102), Blowdown Drum (V-108), Economizer (WH-103), ID Fan (F-101), Cold Condensate Drum (V-104), Vent Gas Drum (V-105), and Adsorbers (A-101A through A-101D).

| Category | Complete PlantsComplete Plants |

| Subcategory | Complete Plants 2Complete Plants 2 |

Manufacturer Information

- Designer: Hydro-Chem (a Linde company)

- Built: 2004

- Condition: Dismantled & Ready for Shipment

Description

This Hydro-Chem (Linde) designed Hydrogen Plant has a production capacity of 2,266 Nm³/hr (80,000 SCFH), delivering hydrogen with 99.99% purity. Built in 2004, the plant was engineered to process natural gas feedstock containing 97.97% methane, 1.37% CO₂, 2.49% nitrogen, and 3.53% ethane.

The hydrogen product is maintained at a maximum temperature of 100°F and a minimum discharge pressure of 200 psig. The plant’s syngas reformer utilizes a nickel catalyst, providing high efficiency and reliability in hydrogen production.

This complete hydrogen plant has been dismantled and is ready for quick shipment, making it a cost-effective and fast solution for hydrogen generation needs.

Specifications

- Production Capacity: 2,266 Nm³/hr (80,000 SCFH)

- Hydrogen Purity: 99.99%

- Feedstock:

- 97.97% Methane

- 1.37% CO₂

- 2.49% Nitrogen

- 3.53% Ethane

- Product Conditions:

- Max Temperature: 100°F

- Min Discharge Pressure: 200 psig

- Catalyst: Nickel Catalyst in the Syngas Reformer

Major Equipment Included

- Feed Heater (HX-101)

- Desulfurizer Vessel (V-101)

- Steam/Gas Lateral (SP-779)

- Reformer (R-101)

- Reformer Effluent Steam Generator (WH-104)

- Shift Converter (V-102)

- Shift Effluent Steam Generator (WH-105)

- Process Cooler (HX-104)

- Deaerator Exchanger (HX-103)

- Boiler Feed Water Exchangers (HX-102A & B)

- Deaerator (V-106)

- Steam Drum (V-107)

- Cold Condensate Separator (V-104)

- Flue Gas Steam Superheater (WH-101)

- Flue Gas Steam Generator (WH-102)

- Blowdown Drum (V-108)

- Economizer (WH-103)

- ID Fan (F-101)

- Vent Gas Drum (V-105)

- Adsorbers (A-101A through A-101D)

Applications

- Refineries – Hydrogen production for hydrocracking, desulfurization, and other refining processes

- Ammonia and Methanol Production

- Steel Industry – Hydrogen for annealing and reduction

- Electronics – Ultra-high purity hydrogen for semiconductor manufacturing

- Fuel Cell Applications – Hydrogen supply for energy production

- Chemical Processing – Feedstock for various chemical synthesis processes

Compatible Industries

- Oil & Gas

- Petrochemical

- Renewable Energy (Hydrogen Economy/Fuel Cells)

- Industrial Gas Supply

- Steel & Metallurgy

- Semiconductor Manufacturing

- Hydrogen plant, hydrogen production, hydrogen generator

- Used hydrogen plant 80,000 SCFH, high purity hydrogen generator, Hydro-Chem hydrogen production unit

- Used Hydro-Chem 2,266 Nm³/hr hydrogen plant producing 99.99% pure hydrogen, dismantled hydrogen plant with reformer and nickel catalyst, high-efficiency hydrogen production plant for refineries and industrial applications

Used Hydrogen Plant, designed by Hydro-Chem (a Linde company), operates at a capacity of 2,266 Nm/hr (80,000 SCFH) and produces hydrogen with a purity of 99.99%. Built in 2004, the plant was engineered to use natural gas feedstock composed of 97.97% methane, 1.37% CO2, 2.49% N2, and 3.53% ethane. The hydrogen product maintains a 99.99% purity at a maximum temperature of 100F and a minimum discharge pressure of 200 psig. The syngas reformer utilizes a nickel catalyst. The plant equipment has been dismantled and is ready for quick shipment. Major equipment includes the Feed Heater (HX-101), Desulfurizer Vessel (V-101), Steam/Gas Lateral (SP-779), Reformer (R-101), Reformer Effluent Steam Generator (WH-104), Shift Converter (V-102), Shift Effluent Steam Generator (WH-105), Process Cooler (HX-104), Deaerator Exchanger (HX-103), Boiler Feed Water Exchangers (HX-102A & B), Deaerator (V-106), Steam Drum (V-107), Cold Condensate Separator (V-104), Flue Gas Steam Superheater (WH-101), Flue Gas Steam Generator (WH-102), Blowdown Drum (V-108), Economizer (WH-103), ID Fan (F-101), Cold Condensate Drum (V-104), Vent Gas Drum (V-105), and Adsorbers (A-101A through A-101D).

Manufacturer Information

- Designer: Hydro-Chem (a Linde company)

- Built: 2004

- Condition: Dismantled & Ready for Shipment

Description

This Hydro-Chem (Linde) designed Hydrogen Plant has a production capacity of 2,266 Nm³/hr (80,000 SCFH), delivering hydrogen with 99.99% purity. Built in 2004, the plant was engineered to process natural gas feedstock containing 97.97% methane, 1.37% CO₂, 2.49% nitrogen, and 3.53% ethane.

The hydrogen product is maintained at a maximum temperature of 100°F and a minimum discharge pressure of 200 psig. The plant’s syngas reformer utilizes a nickel catalyst, providing high efficiency and reliability in hydrogen production.

This complete hydrogen plant has been dismantled and is ready for quick shipment, making it a cost-effective and fast solution for hydrogen generation needs.

Specifications

- Production Capacity: 2,266 Nm³/hr (80,000 SCFH)

- Hydrogen Purity: 99.99%

- Feedstock:

- 97.97% Methane

- 1.37% CO₂

- 2.49% Nitrogen

- 3.53% Ethane

- Product Conditions:

- Max Temperature: 100°F

- Min Discharge Pressure: 200 psig

- Catalyst: Nickel Catalyst in the Syngas Reformer

Major Equipment Included

- Feed Heater (HX-101)

- Desulfurizer Vessel (V-101)

- Steam/Gas Lateral (SP-779)

- Reformer (R-101)

- Reformer Effluent Steam Generator (WH-104)

- Shift Converter (V-102)

- Shift Effluent Steam Generator (WH-105)

- Process Cooler (HX-104)

- Deaerator Exchanger (HX-103)

- Boiler Feed Water Exchangers (HX-102A & B)

- Deaerator (V-106)

- Steam Drum (V-107)

- Cold Condensate Separator (V-104)

- Flue Gas Steam Superheater (WH-101)

- Flue Gas Steam Generator (WH-102)

- Blowdown Drum (V-108)

- Economizer (WH-103)

- ID Fan (F-101)

- Vent Gas Drum (V-105)

- Adsorbers (A-101A through A-101D)

Applications

- Refineries – Hydrogen production for hydrocracking, desulfurization, and other refining processes

- Ammonia and Methanol Production

- Steel Industry – Hydrogen for annealing and reduction

- Electronics – Ultra-high purity hydrogen for semiconductor manufacturing

- Fuel Cell Applications – Hydrogen supply for energy production

- Chemical Processing – Feedstock for various chemical synthesis processes

Compatible Industries

- Oil & Gas

- Petrochemical

- Renewable Energy (Hydrogen Economy/Fuel Cells)

- Industrial Gas Supply

- Steel & Metallurgy

- Semiconductor Manufacturing

| Category | Complete Plants |

| Subcategory | Complete Plants 2 |

- Hydrogen plant, hydrogen production, hydrogen generator

- Used hydrogen plant 80,000 SCFH, high purity hydrogen generator, Hydro-Chem hydrogen production unit

- Used Hydro-Chem 2,266 Nm³/hr hydrogen plant producing 99.99% pure hydrogen, dismantled hydrogen plant with reformer and nickel catalyst, high-efficiency hydrogen production plant for refineries and industrial applications

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory