Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Title: Used Crown Iron Works Model 48 Milling Ring Flash Drying System? | Industrial Drying System

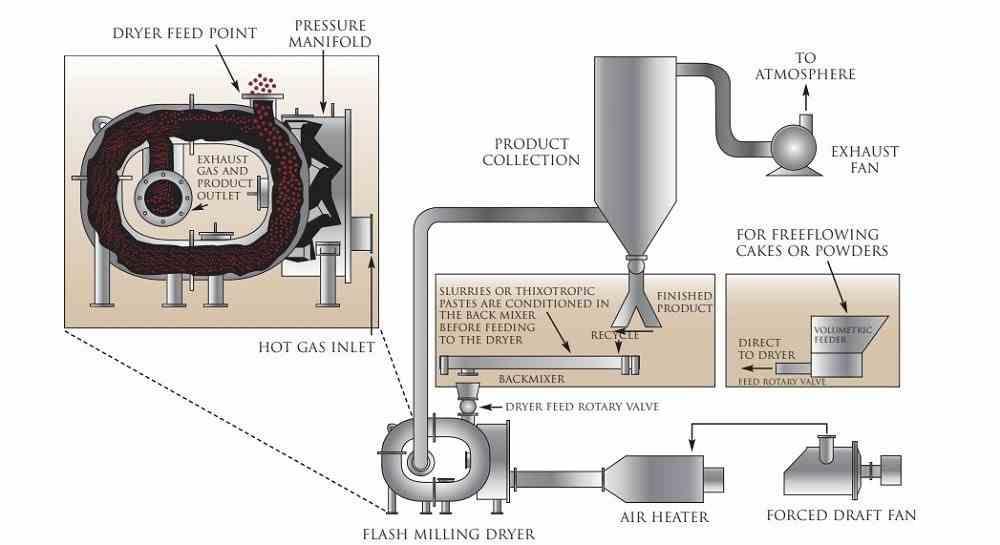

Used Crown Iron Works, Model 48, Milling Ring Flash Drying System. It was designed and used for food-grade orange pulp with 17,000 Lbs/Hr capacity but the plant can be used for a wide range of applications in various industries including: Drying food products such as grains, cereals, fruits, vegetables, herbs, and spices. Pharmaceutical ingredients, intermediates, and final products Drying various chemicals, including powders, granules, and crystalline materials Drying minerals and mining products such as ores, concentrates, and mineral powders Animal Feed Drying and processing environmental materials, such as sludges, biomass, and waste products. System designed for drying of powers, filter & centrifuge cakes, and slurries where a discrete and fine end product is desired. The Milling Flash Dryer is basically a low energy jet mill, that uses jets of low-pressure air to encourage inter particle collisions between pieces of feed material. These inter particle collisions break up the feed material in the dryer with no moving parts in the dryer or airstream. The dryer is in the shape of a torus, or donut that is broken up into 2 basic areas: (1) Manifold & Milling area; (2) Classifier. The ideal feed material for the Flash Dryer is a crumbly and free flowing cake that breaks up readily when it enters the drying air stream. The feed material enters the recirculating hot air upstream of the first nozzle, with the centrifugal forces generated by the air concentrating the material in the area above the nozzles. Particle-to-particle collisions begin immediately, deagglomerating the material before hard agglomerates can form. A tremendous amount of surface area is created allowing evaporation to occur quickly, thereby depressing air temperature in a very short period of time. Centrifugal forces are generated by the recirculating gases within the dryer, forcing the larger particles to the peripheral walls. Finer material is displaced towards the inside radius of the dryer where the classifier outlet is located. Fine product exits the dryer along with the exhaust gas vapor. Larger particles or agglomerates are recycled to the nozzle area dryer for further de-agglomeration and drying.

| Manufacturer | Crown Iron WorksCrown Iron Works |

| Category | Complete PlantsComplete Plants |

| Subcategory | Complete Plants 2Complete Plants 2 |

Manufacturer Information

- Brand: Crown Iron Works

- Model: 48

- System Type: Milling Ring Flash Dryer

- Condition: Used

- Original Application: Food-grade orange pulp

- Capacity: 17,000 lbs/hr

- Build Type: Industrial Grade

Description

This Crown Iron Works Model 48 Milling Ring Flash Drying System was originally designed and used for drying food-grade orange pulp at 17,000 lbs/hour but is highly versatile and suitable for a wide range of industries and applications. The system is capable of efficiently drying powders, filter cakes, centrifuge cakes, and slurries, particularly when a discrete and fine end product is desired.

The Milling Flash Dryer operates as a low-energy jet mill, utilizing jets of low-pressure air to create inter-particle collisions, which de-agglomerate and break up the feed material without any moving parts in the drying chamber. The torus (donut) shaped design includes two core sections:

- Manifold & Milling Area

- Classifier Area

The recirculating hot air promotes centrifugal forces that keep larger particles circulating for further drying and milling, while fine particles are extracted with the exhaust gas vapor for collection.

Applications

The Crown Iron Works Milling Ring Flash Dryer is suited for multiple industries and applications, including:

- Food Industry

- Drying grains, cereals, fruits, vegetables, herbs, and spices

- Orange pulp, purees, and food slurries

- Pharmaceutical Industry

- Drying pharmaceutical ingredients, intermediates, and finished products

- Chemical Industry

- Powders, granules, and crystalline materials

- Mining & Minerals

- Ores, concentrates, and mineral powders

- Animal Feed

- Meal drying and feed additives

- Environmental & Waste Management

- Drying sludges, biomass, and waste materials

- Process Optimization

- Ideal for crumbly and free-flowing cakes

System Features

- Drying Capacity: 17,000 lbs/hr (based on food-grade orange pulp)

- Drying Process: Flash drying with milling ring technology

- Feed Material: Crumbly, free-flowing cakes, slurries, filter cakes, and powders

- Operation:

- Jet mill design—no moving parts in the airstream

- Centrifugal force ensures efficient particle size separation

- Fine products collected via classifier outlet

- Recycles larger particles for continued drying and de-agglomeration

- Energy Efficiency: Low energy consumption due to optimized air circulation

- Product Outcome: Discrete and fine end-product with consistent moisture removal

Advantages

- High Efficiency – Rapid drying with minimal energy usage

- Versatile Applications – Suitable for food, pharmaceutical, chemical, and environmental industries

- Compact Design – Skid-mounted, minimal footprint

- Continuous Operation – Suitable for large-scale production

- Low Maintenance – No internal moving parts reduce wear and maintenance

- Precision Drying & Classification – High product quality with controlled particle size

- Flash dryer, milling ring dryer, Crown Iron Works dryer

- Used Crown Iron Works Model 48 Flash Dryer, high-capacity milling flash dryer, industrial food and chemical drying system

- Used Crown Iron Works Model 48 Milling Ring Flash Drying System for food-grade and industrial applications, high-capacity flash dryer for powders, slurries, and filter cakes, energy-efficient milling ring flash dryer for pharmaceuticals, chemicals, and biomass

- Milling ring flash dryer

- Industrial drying system

- Crown Iron Works dryer

- Model 48 flash dryer

- Powder drying equipment

- Food-grade drying system

- Pharmaceutical dryer

- Chemical processing dryer

- Mineral drying technology

- Sludge drying equipment

- Industrial flash dryer

- Milling ring dryer

- Crown Iron Works equipment

- Model 48 drying system

- High-capacity dryer

- Food industry dryer

- Pharmaceutical drying equipment

- Chemical industry dryer

- Mineral processing dryer

- Environmental drying solutions

- Used industrial flash dryer for sale

- Second-hand milling ring dryer

- Buy Crown Iron Works dryer

- Sell Model 48 flash dryer

- Industrial drying equipment marketplace

- Pre-owned food-grade dryer

- Pharmaceutical dryer resale

- Chemical processing dryer purchase

- Mineral dryer for sale

- Environmental equipment buy and sell

Used Crown Iron Works, Model 48, Milling Ring Flash Drying System. It was designed and used for food-grade orange pulp with 17,000 Lbs/Hr capacity but the plant can be used for a wide range of applications in various industries including: Drying food products such as grains, cereals, fruits, vegetables, herbs, and spices. Pharmaceutical ingredients, intermediates, and final products Drying various chemicals, including powders, granules, and crystalline materials Drying minerals and mining products such as ores, concentrates, and mineral powders Animal Feed Drying and processing environmental materials, such as sludges, biomass, and waste products. System designed for drying of powers, filter & centrifuge cakes, and slurries where a discrete and fine end product is desired. The Milling Flash Dryer is basically a low energy jet mill, that uses jets of low-pressure air to encourage inter particle collisions between pieces of feed material. These inter particle collisions break up the feed material in the dryer with no moving parts in the dryer or airstream. The dryer is in the shape of a torus, or donut that is broken up into 2 basic areas: (1) Manifold & Milling area; (2) Classifier. The ideal feed material for the Flash Dryer is a crumbly and free flowing cake that breaks up readily when it enters the drying air stream. The feed material enters the recirculating hot air upstream of the first nozzle, with the centrifugal forces generated by the air concentrating the material in the area above the nozzles. Particle-to-particle collisions begin immediately, deagglomerating the material before hard agglomerates can form. A tremendous amount of surface area is created allowing evaporation to occur quickly, thereby depressing air temperature in a very short period of time. Centrifugal forces are generated by the recirculating gases within the dryer, forcing the larger particles to the peripheral walls. Finer material is displaced towards the inside radius of the dryer where the classifier outlet is located. Fine product exits the dryer along with the exhaust gas vapor. Larger particles or agglomerates are recycled to the nozzle area dryer for further de-agglomeration and drying.

Manufacturer Information

- Brand: Crown Iron Works

- Model: 48

- System Type: Milling Ring Flash Dryer

- Condition: Used

- Original Application: Food-grade orange pulp

- Capacity: 17,000 lbs/hr

- Build Type: Industrial Grade

Description

This Crown Iron Works Model 48 Milling Ring Flash Drying System was originally designed and used for drying food-grade orange pulp at 17,000 lbs/hour but is highly versatile and suitable for a wide range of industries and applications. The system is capable of efficiently drying powders, filter cakes, centrifuge cakes, and slurries, particularly when a discrete and fine end product is desired.

The Milling Flash Dryer operates as a low-energy jet mill, utilizing jets of low-pressure air to create inter-particle collisions, which de-agglomerate and break up the feed material without any moving parts in the drying chamber. The torus (donut) shaped design includes two core sections:

- Manifold & Milling Area

- Classifier Area

The recirculating hot air promotes centrifugal forces that keep larger particles circulating for further drying and milling, while fine particles are extracted with the exhaust gas vapor for collection.

Applications

The Crown Iron Works Milling Ring Flash Dryer is suited for multiple industries and applications, including:

- Food Industry

- Drying grains, cereals, fruits, vegetables, herbs, and spices

- Orange pulp, purees, and food slurries

- Pharmaceutical Industry

- Drying pharmaceutical ingredients, intermediates, and finished products

- Chemical Industry

- Powders, granules, and crystalline materials

- Mining & Minerals

- Ores, concentrates, and mineral powders

- Animal Feed

- Meal drying and feed additives

- Environmental & Waste Management

- Drying sludges, biomass, and waste materials

- Process Optimization

- Ideal for crumbly and free-flowing cakes

System Features

- Drying Capacity: 17,000 lbs/hr (based on food-grade orange pulp)

- Drying Process: Flash drying with milling ring technology

- Feed Material: Crumbly, free-flowing cakes, slurries, filter cakes, and powders

- Operation:

- Jet mill design—no moving parts in the airstream

- Centrifugal force ensures efficient particle size separation

- Fine products collected via classifier outlet

- Recycles larger particles for continued drying and de-agglomeration

- Energy Efficiency: Low energy consumption due to optimized air circulation

- Product Outcome: Discrete and fine end-product with consistent moisture removal

Advantages

- High Efficiency – Rapid drying with minimal energy usage

- Versatile Applications – Suitable for food, pharmaceutical, chemical, and environmental industries

- Compact Design – Skid-mounted, minimal footprint

- Continuous Operation – Suitable for large-scale production

- Low Maintenance – No internal moving parts reduce wear and maintenance

- Precision Drying & Classification – High product quality with controlled particle size

| Manufacturer | Crown Iron Works |

| Category | Complete Plants |

| Subcategory | Complete Plants 2 |

- Flash dryer, milling ring dryer, Crown Iron Works dryer

- Used Crown Iron Works Model 48 Flash Dryer, high-capacity milling flash dryer, industrial food and chemical drying system

- Used Crown Iron Works Model 48 Milling Ring Flash Drying System for food-grade and industrial applications, high-capacity flash dryer for powders, slurries, and filter cakes, energy-efficient milling ring flash dryer for pharmaceuticals, chemicals, and biomass

- Milling ring flash dryer

- Industrial drying system

- Crown Iron Works dryer

- Model 48 flash dryer

- Powder drying equipment

- Food-grade drying system

- Pharmaceutical dryer

- Chemical processing dryer

- Mineral drying technology

- Sludge drying equipment

- Industrial flash dryer

- Milling ring dryer

- Crown Iron Works equipment

- Model 48 drying system

- High-capacity dryer

- Food industry dryer

- Pharmaceutical drying equipment

- Chemical industry dryer

- Mineral processing dryer

- Environmental drying solutions

- Used industrial flash dryer for sale

- Second-hand milling ring dryer

- Buy Crown Iron Works dryer

- Sell Model 48 flash dryer

- Industrial drying equipment marketplace

- Pre-owned food-grade dryer

- Pharmaceutical dryer resale

- Chemical processing dryer purchase

- Mineral dryer for sale

- Environmental equipment buy and sell

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory