Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Rapid Granulator Model 600-90 150 HP, Rear Conveyor Infeed, 24"x36" Chamber, D2 Knives, Airveyor Discharge

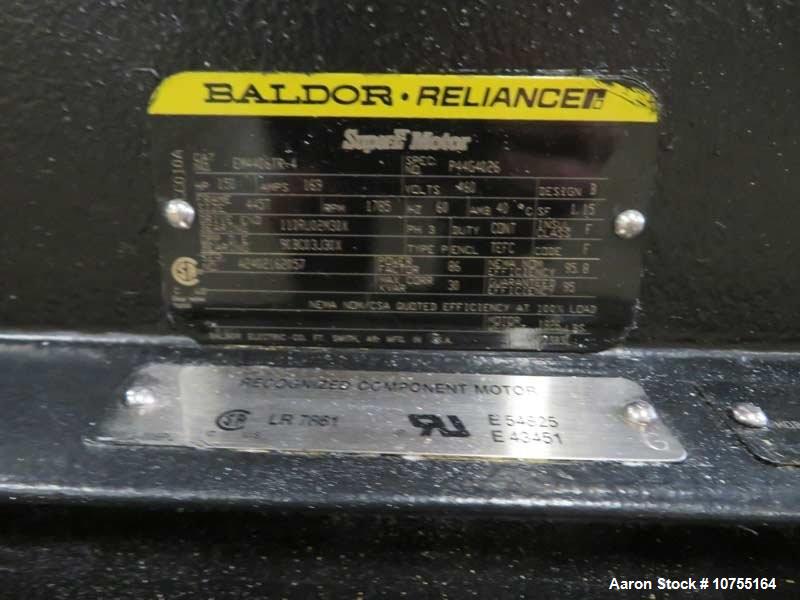

Used Rapid Granulator Model 600-90 150 HP, Rear Conveyor Infeed, 24"x36" Chamber, D2 Knives, Airveyor Discharge. Insulated w/ Power Jack Back; 24" x 36" Tangential cutting chamber with Dual Flywheels; 5 Knife Double Scissor Rotor; D2 Steel bed knives in 3 positions, 3rd one in position 5; 5/16" diameter of screen holes; Vibration pad base; 8" OD Airveyor Discharge (Right Hand OK200); 150 HP, 1785 RPM 460-volt Super E motor; Controls not included. Built 2025. Serial# 505035-20-1.

🏭 Manufacturer Info

-

Manufacturer: Rapid Granulator AB

-

Model: 600-90

-

Serial Number: 505035-20-1

-

Year Built: 2025

-

Country of Origin: Likely Sweden (Rapid Granulator HQ)

-

Condition: Used (Recently manufactured, controls not included)

📄 Product Description

This used Rapid Granulator Model 600-90 is a powerful, heavy-duty granulator designed for high-throughput plastic scrap reduction in post-industrial and recycling environments. With a 24" x 36" tangential cutting chamber and a 150 HP Super E motor, it is suited for processing thick walled parts, sheet, purge, or extrusion waste.

This unit features:

-

Rear-facing conveyor-style infeed with power jack back for ease of loading and maintenance

-

5 Knife Double Scissor Rotor design for superior cutting efficiency

-

D2 Steel Bed Knives installed in three positions (including one in position 5)

-

Dual flywheels for added torque and inertia during heavy loads

-

Insulated construction for reduced sound and operational vibration

-

Vibration pad base for stable floor mounting

-

8” OD Airveyor discharge (Right Hand, OK200) for efficient material evacuation

-

5/16” diameter screen holes ideal for medium-fine granulate

-

Controls not included

📐 Specifications

| Feature | Specification |

|---|---|

| Model | 600-90 |

| Cutting Chamber | 24" x 36", tangential style |

| Rotor Type | 5-Knife Double Scissor |

| Flywheels | Dual, for increased torque |

| Bed Knives | D2 steel, 3 installed, 1 in position 5 |

| Screen Size | 5/16” diameter holes |

| Discharge | 8” OD Airveyor (Right Hand, OK200) |

| Motor | 150 HP, 1785 RPM, 460V Super E Motor |

| Infeed | Rear-facing conveyor, insulated w/ jack back |

| Mounting | Vibration pad base |

| Controls | Not included |

| Year Built | 2025 |

| Serial Number | 505035-20-1 |

🧰 Applications

-

Plastic part size reduction (HDPE, ABS, PC, etc.)

-

Post-consumer or post-industrial scrap granulation

-

Blow molding and extrusion waste recycling

-

Injection molding runners and sprues

-

Film, sheet, or thermoformed plastic processing

-

Recycling of automotive interior or exterior parts

-

E-waste plastics size reduction

-

Purge and start-up waste processing

-

Pre-processing before pelletizing or densifying

-

Closed-loop plastic manufacturing systems

🛠️ What Might This Be Used For?

-

♻️ High-volume plastic scrap recycling

-

🧱 Granulating thick or rigid plastic parts

-

🏭 Feeding downstream washing or pelletizing lines

-

🔄 Closed-loop material re-use in plastic factories

-

📦 Shredding production rejects and packaging scrap

-

🔩 Prepping for compound blending or extrusion

-

🧪 Material sample processing in QA or R&D labs

-

🚗 Automotive plastics granulation

-

🧴 Bottle and container scrap reduction

-

🛠️ Handling purge waste from molding machines

-

Rapid granulator

-

Plastic granulator

-

Used granulator

-

Tangential cutter

-

150 HP granulator

-

Airveyor discharge

-

D2 knives

-

Double scissor rotor

-

Granulator 600-90

-

Scrap cutter

-

Rapid Model 600-90 granulator

-

Used 150 HP plastic cutter

-

Rear conveyor feed granulator

-

D2 knife plastic granulator

-

Tangential granulator for sale

-

Airveyor equipped granulator

-

Scrap recycler machine

-

Industrial granulator with flywheels

-

24x36 cutting chamber granulator

-

Post-industrial plastics cutter

-

Used Rapid Granulator 600-90 with rear conveyor infeed and 150 HP motor

-

Heavy-duty plastic granulator with tangential 24x36 cutting chamber

-

Granulator with D2 steel bed knives and double scissor rotor design

-

Industrial granulator for purge, sheet, or injection molding waste

-

Scrap recycling machine with 8” OD airveyor and insulated base

-

Plastic size reduction system with power jack back and vibration base

-

Post-consumer plastic granulator with medium-fine 5/16" screen

-

Rapid granulator without controls, perfect for integration in plant lines

-

Granulator with dual flywheels for added cutting torque

-

2025-built high-horsepower plastic scrap granulator

-

buy Rapid granulator

-

used 600-90 granulator

-

plastic cutter machine purchase

-

industrial scrap granulator

-

150 HP plastic granulator buy

-

granulator for thick plastics

-

granulator with conveyor infeed

-

post-industrial granulator for sale

-

D2 knife cutter machine buy

-

airveyor discharge granulator

-

sell Rapid 600-90 granulator

-

surplus plastic granulator

-

list used 150 HP cutter

-

used granulator resale

-

industrial plastics cutter sale

-

used Rapid granulator listing

-

high capacity granulator liquidation

-

post-molding granulator for sale

-

granulator without controls sale

-

2025 plastics cutter resale

Used Rapid Granulator Model 600-90 150 HP, Rear Conveyor Infeed, 24"x36" Chamber, D2 Knives, Airveyor Discharge. Insulated w/ Power Jack Back; 24" x 36" Tangential cutting chamber with Dual Flywheels; 5 Knife Double Scissor Rotor; D2 Steel bed knives in 3 positions, 3rd one in position 5; 5/16" diameter of screen holes; Vibration pad base; 8" OD Airveyor Discharge (Right Hand OK200); 150 HP, 1785 RPM 460-volt Super E motor; Controls not included. Built 2025. Serial# 505035-20-1.

🏭 Manufacturer Info

-

Manufacturer: Rapid Granulator AB

-

Model: 600-90

-

Serial Number: 505035-20-1

-

Year Built: 2025

-

Country of Origin: Likely Sweden (Rapid Granulator HQ)

-

Condition: Used (Recently manufactured, controls not included)

📄 Product Description

This used Rapid Granulator Model 600-90 is a powerful, heavy-duty granulator designed for high-throughput plastic scrap reduction in post-industrial and recycling environments. With a 24" x 36" tangential cutting chamber and a 150 HP Super E motor, it is suited for processing thick walled parts, sheet, purge, or extrusion waste.

This unit features:

-

Rear-facing conveyor-style infeed with power jack back for ease of loading and maintenance

-

5 Knife Double Scissor Rotor design for superior cutting efficiency

-

D2 Steel Bed Knives installed in three positions (including one in position 5)

-

Dual flywheels for added torque and inertia during heavy loads

-

Insulated construction for reduced sound and operational vibration

-

Vibration pad base for stable floor mounting

-

8” OD Airveyor discharge (Right Hand, OK200) for efficient material evacuation

-

5/16” diameter screen holes ideal for medium-fine granulate

-

Controls not included

📐 Specifications

| Feature | Specification |

|---|---|

| Model | 600-90 |

| Cutting Chamber | 24" x 36", tangential style |

| Rotor Type | 5-Knife Double Scissor |

| Flywheels | Dual, for increased torque |

| Bed Knives | D2 steel, 3 installed, 1 in position 5 |

| Screen Size | 5/16” diameter holes |

| Discharge | 8” OD Airveyor (Right Hand, OK200) |

| Motor | 150 HP, 1785 RPM, 460V Super E Motor |

| Infeed | Rear-facing conveyor, insulated w/ jack back |

| Mounting | Vibration pad base |

| Controls | Not included |

| Year Built | 2025 |

| Serial Number | 505035-20-1 |

🧰 Applications

-

Plastic part size reduction (HDPE, ABS, PC, etc.)

-

Post-consumer or post-industrial scrap granulation

-

Blow molding and extrusion waste recycling

-

Injection molding runners and sprues

-

Film, sheet, or thermoformed plastic processing

-

Recycling of automotive interior or exterior parts

-

E-waste plastics size reduction

-

Purge and start-up waste processing

-

Pre-processing before pelletizing or densifying

-

Closed-loop plastic manufacturing systems

🛠️ What Might This Be Used For?

-

♻️ High-volume plastic scrap recycling

-

🧱 Granulating thick or rigid plastic parts

-

🏭 Feeding downstream washing or pelletizing lines

-

🔄 Closed-loop material re-use in plastic factories

-

📦 Shredding production rejects and packaging scrap

-

🔩 Prepping for compound blending or extrusion

-

🧪 Material sample processing in QA or R&D labs

-

🚗 Automotive plastics granulation

-

🧴 Bottle and container scrap reduction

-

🛠️ Handling purge waste from molding machines

-

Rapid granulator

-

Plastic granulator

-

Used granulator

-

Tangential cutter

-

150 HP granulator

-

Airveyor discharge

-

D2 knives

-

Double scissor rotor

-

Granulator 600-90

-

Scrap cutter

-

Rapid Model 600-90 granulator

-

Used 150 HP plastic cutter

-

Rear conveyor feed granulator

-

D2 knife plastic granulator

-

Tangential granulator for sale

-

Airveyor equipped granulator

-

Scrap recycler machine

-

Industrial granulator with flywheels

-

24x36 cutting chamber granulator

-

Post-industrial plastics cutter

-

Used Rapid Granulator 600-90 with rear conveyor infeed and 150 HP motor

-

Heavy-duty plastic granulator with tangential 24x36 cutting chamber

-

Granulator with D2 steel bed knives and double scissor rotor design

-

Industrial granulator for purge, sheet, or injection molding waste

-

Scrap recycling machine with 8” OD airveyor and insulated base

-

Plastic size reduction system with power jack back and vibration base

-

Post-consumer plastic granulator with medium-fine 5/16" screen

-

Rapid granulator without controls, perfect for integration in plant lines

-

Granulator with dual flywheels for added cutting torque

-

2025-built high-horsepower plastic scrap granulator

-

buy Rapid granulator

-

used 600-90 granulator

-

plastic cutter machine purchase

-

industrial scrap granulator

-

150 HP plastic granulator buy

-

granulator for thick plastics

-

granulator with conveyor infeed

-

post-industrial granulator for sale

-

D2 knife cutter machine buy

-

airveyor discharge granulator

-

sell Rapid 600-90 granulator

-

surplus plastic granulator

-

list used 150 HP cutter

-

used granulator resale

-

industrial plastics cutter sale

-

used Rapid granulator listing

-

high capacity granulator liquidation

-

post-molding granulator for sale

-

granulator without controls sale

-

2025 plastics cutter resale

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory