Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Werner & Pfleiderer Twin Screw Pelletizing Line

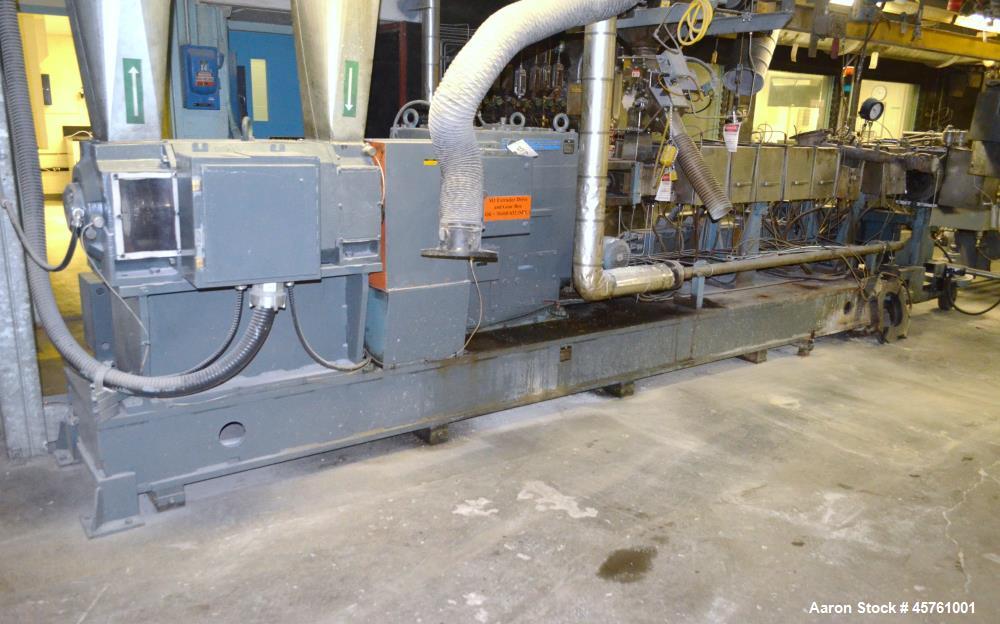

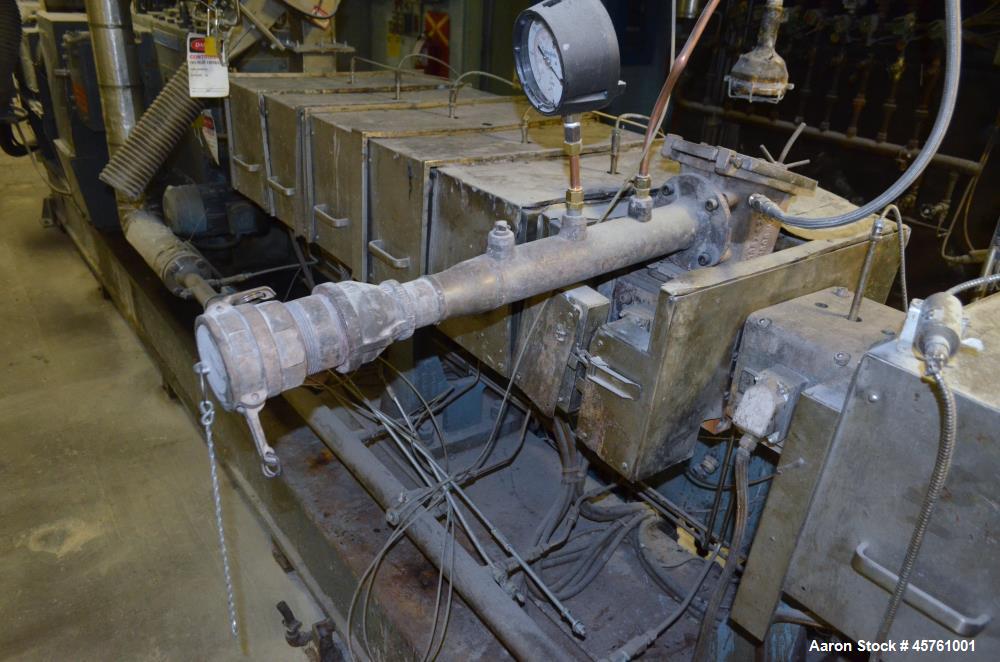

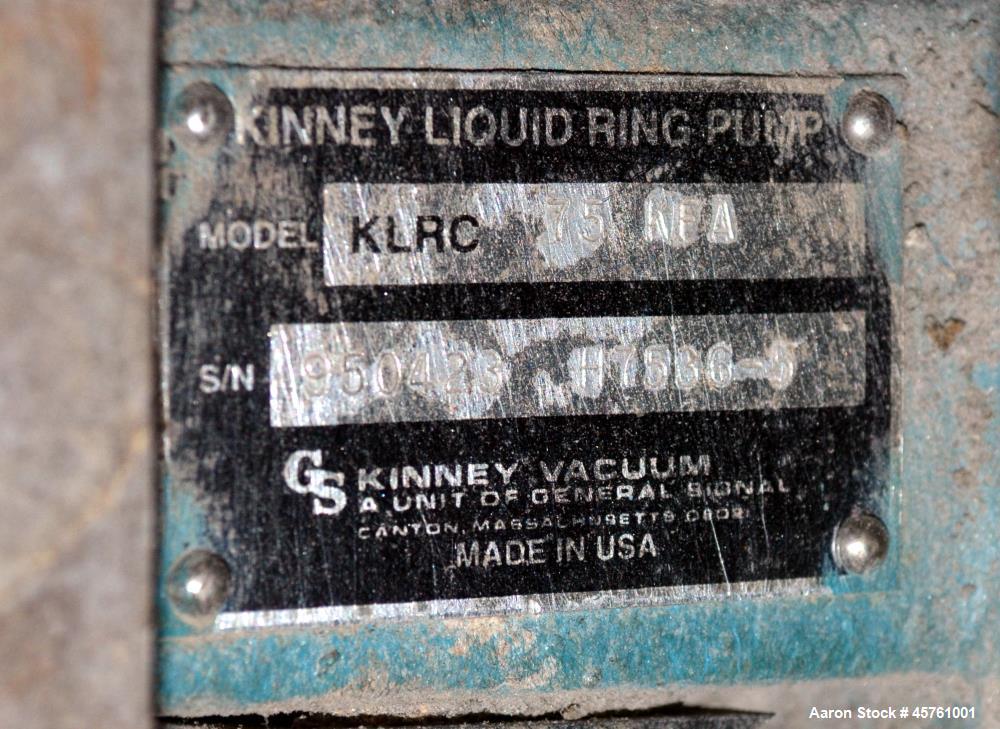

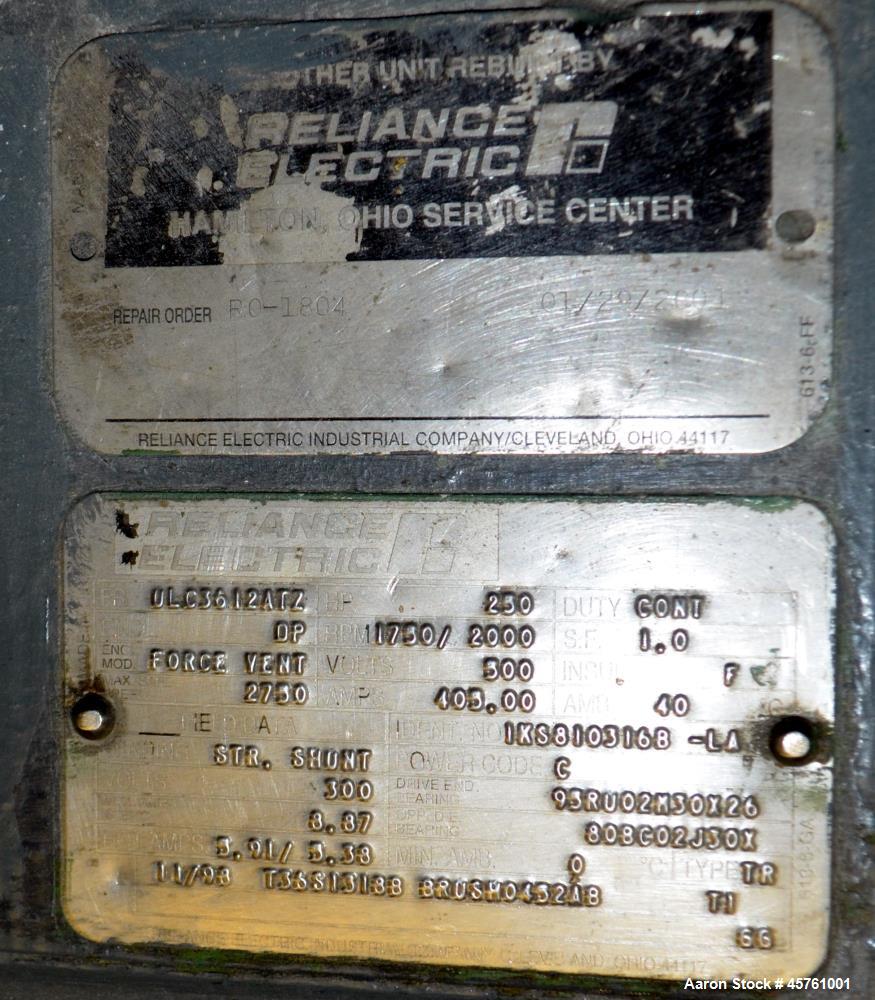

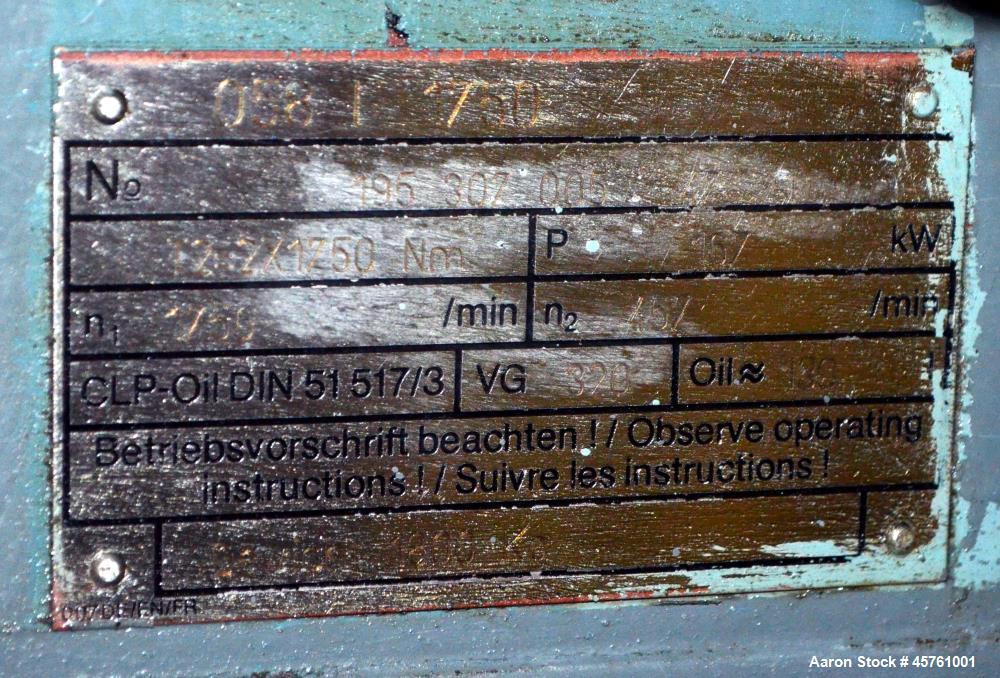

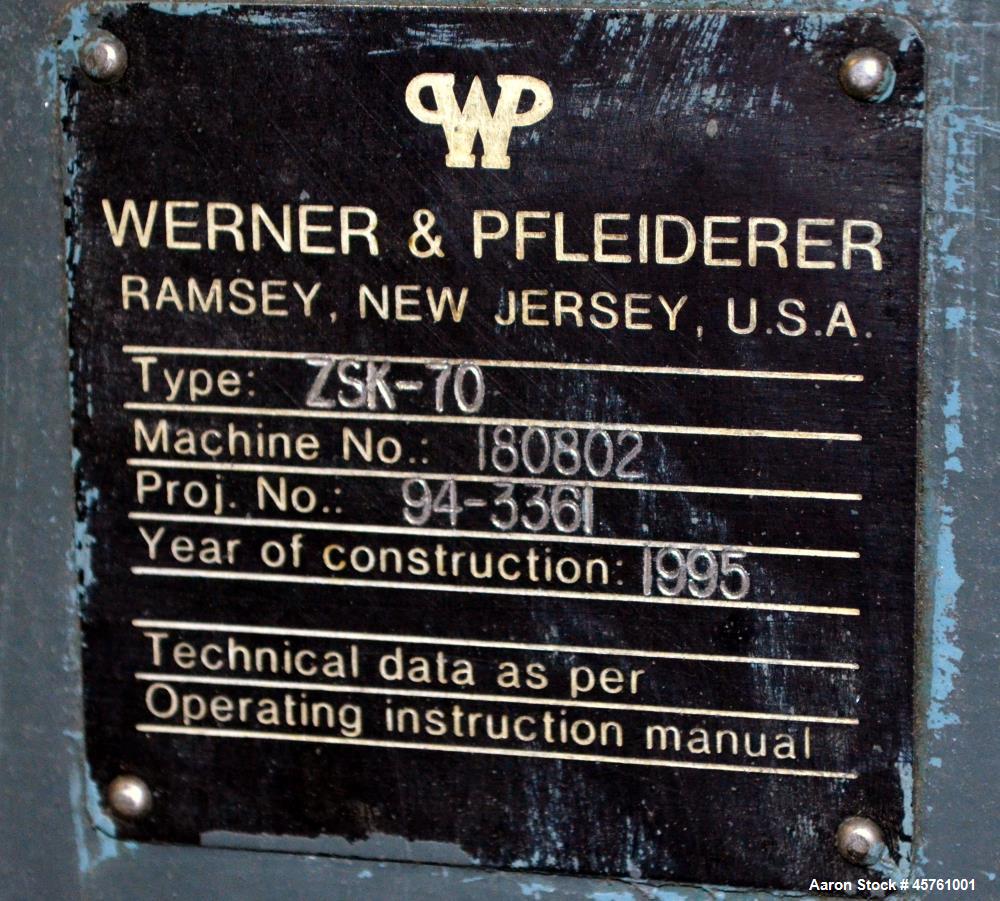

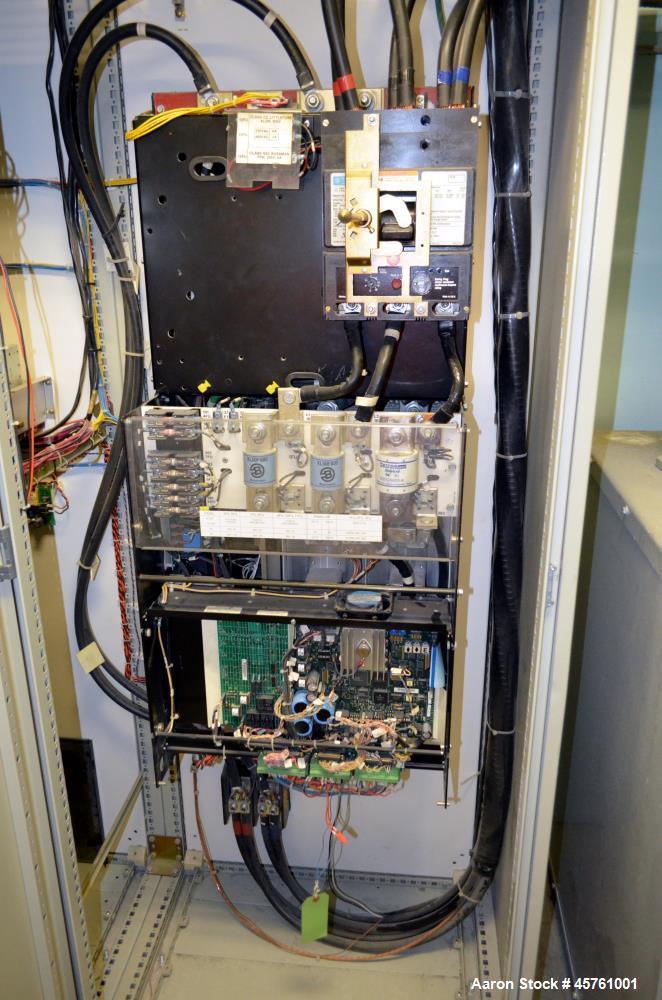

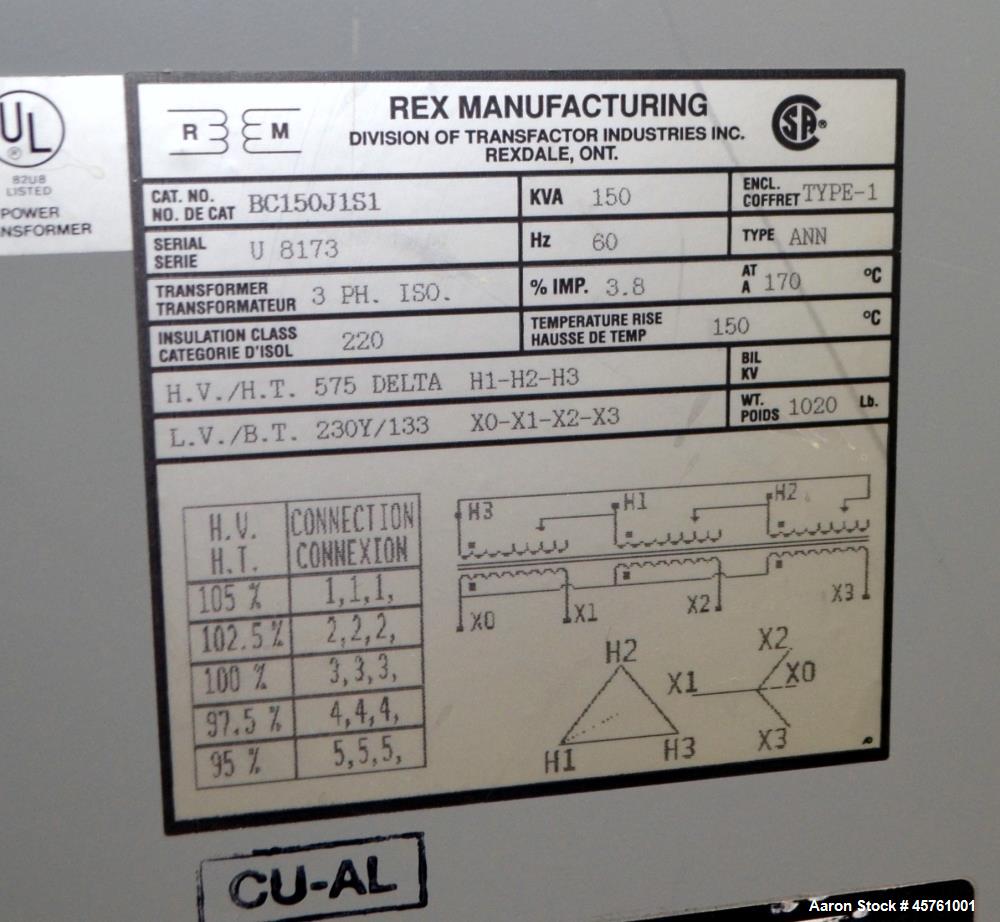

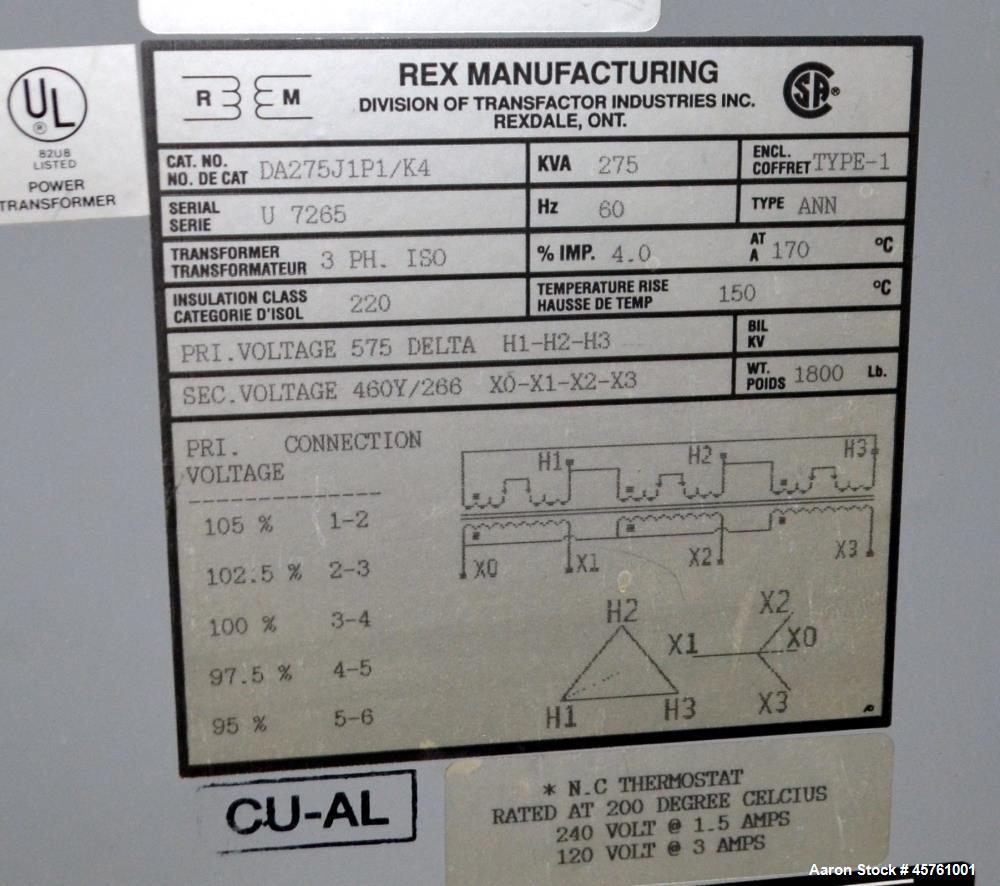

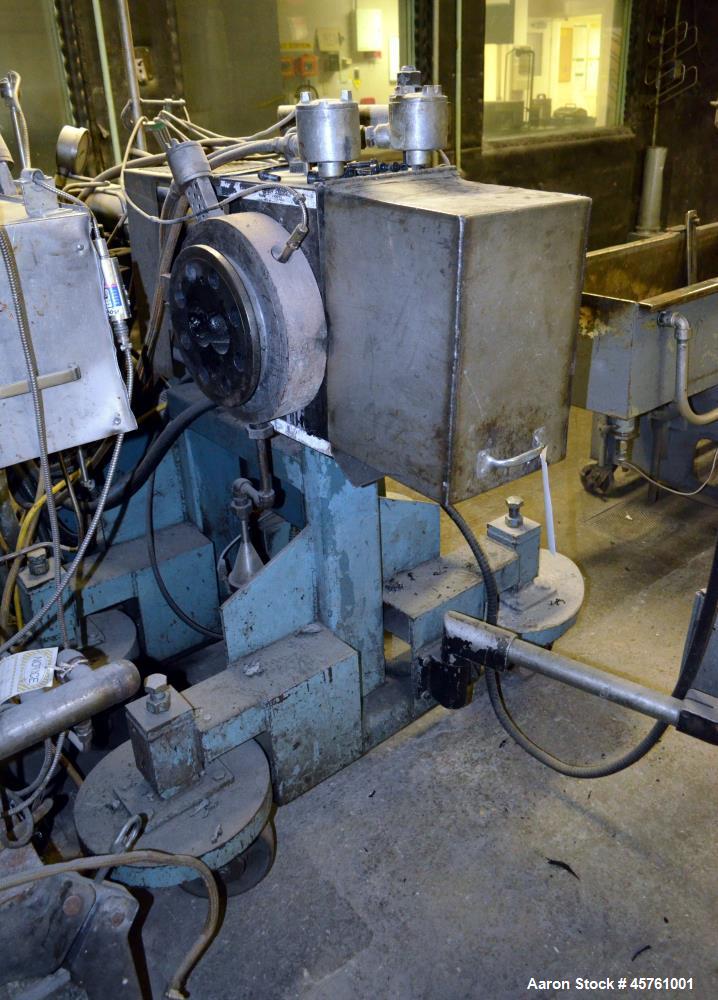

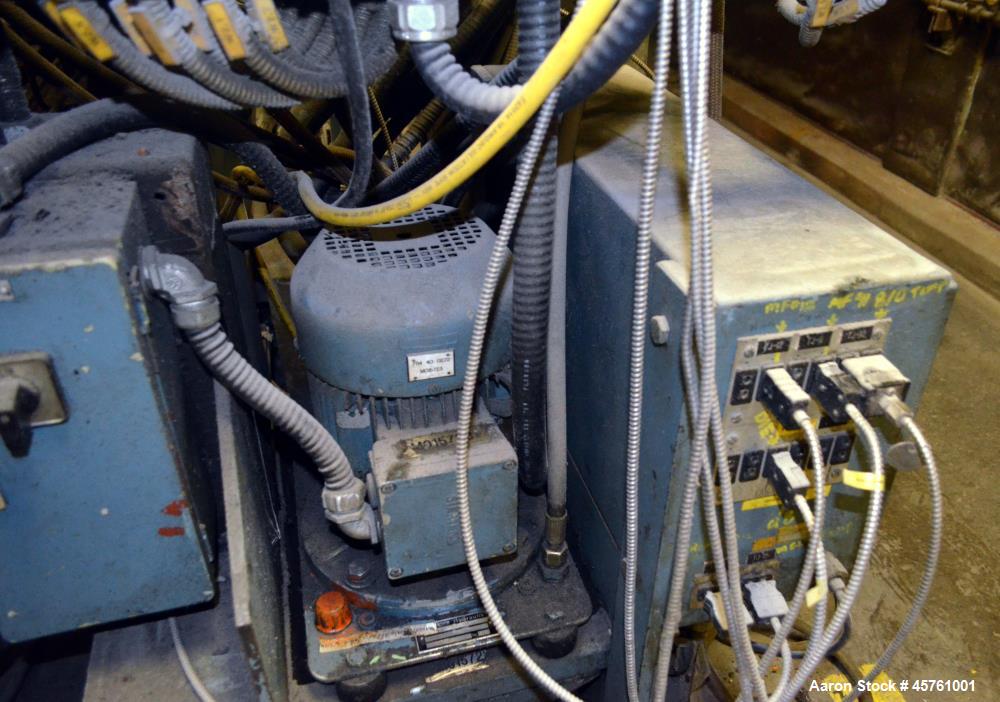

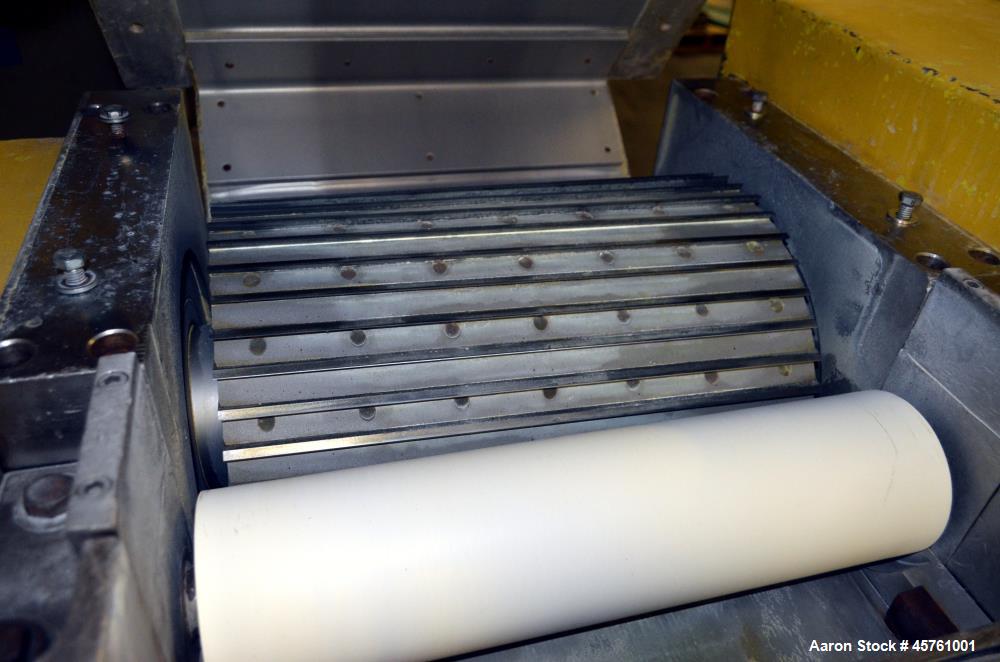

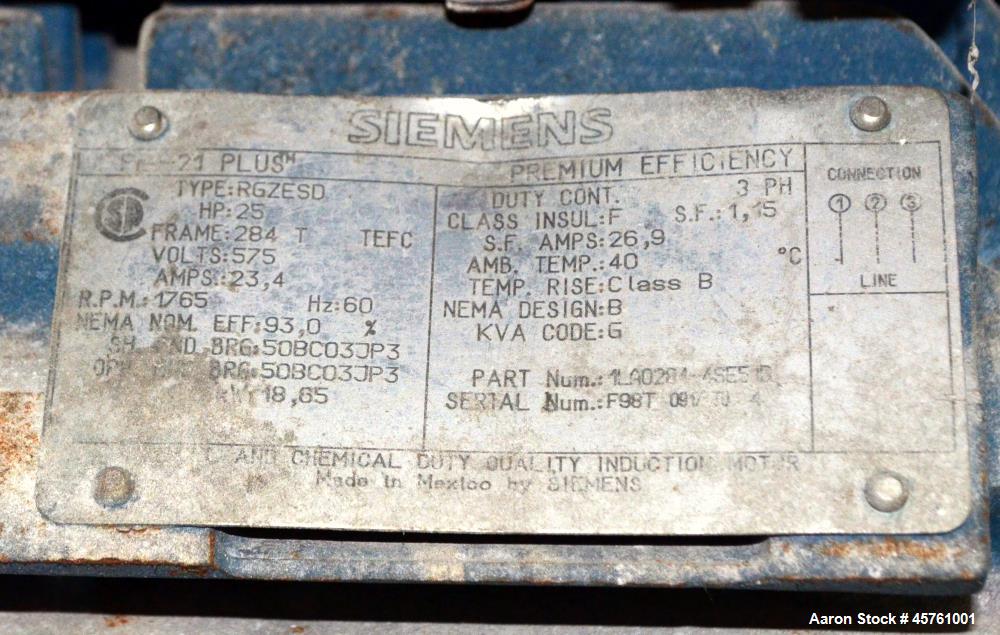

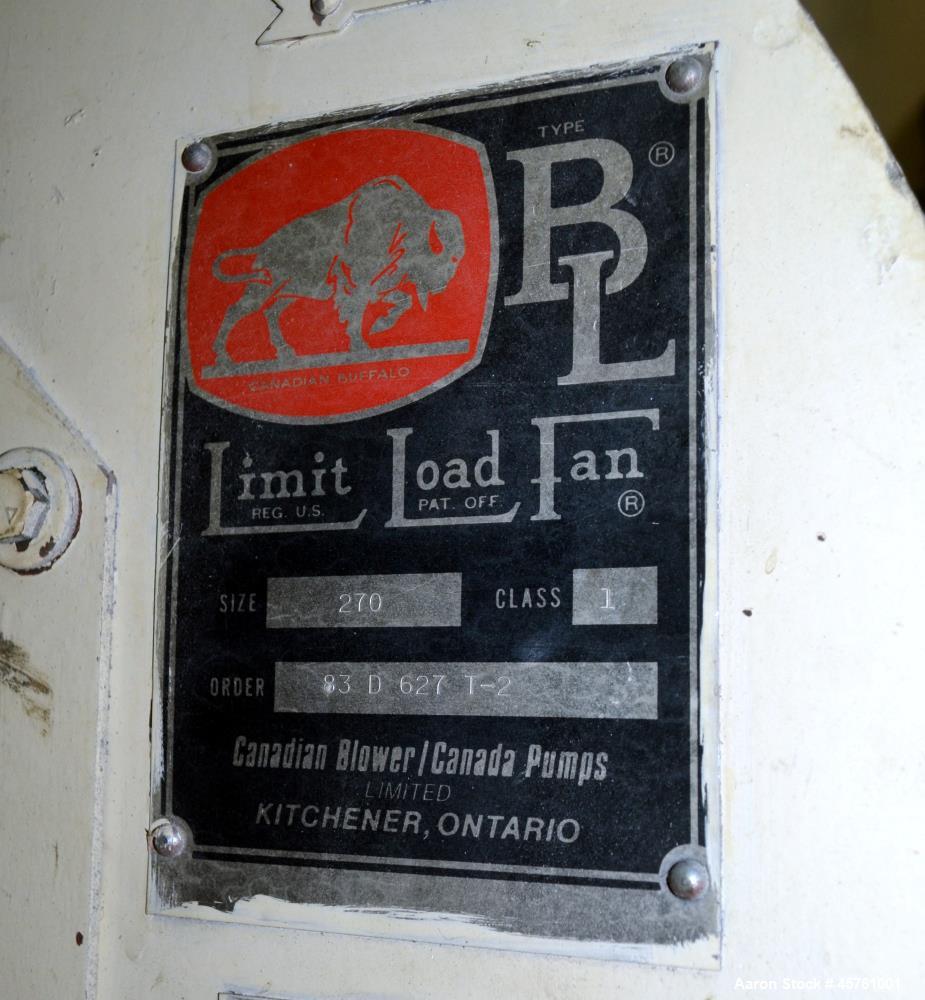

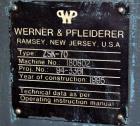

Used Werner & Pfleiderer Twin Screw Pelletizing Line Consisting of: (1) ZSK-70 70mm Co-Rotating twin screw extruder, approximate 36 to 1 L/D ratio, Serial# 180802, Project# 94-3361, built 1995. (9) Barrel sections with (1) feed with hopper, (1) top vented, electrically heated water cooled with a closed loop system with pump, tank, and heat exchanger. Approximate 42-1/2" centerline height. Driven by a 250 hp, 500 volt, 1750/2000 rpm DC motor thru a gearbox. (1) Kinney Model KLRC-75-KFA vacuum pump, Serial# 950423-H7536-5, driven by a 10 hp, 3/60/575 volt, 1745 rpm motor. Includes a Reliance drive panel, temperature control panel, (1) 150 KVA transformer, (1) 275 KVA transformer, (1) computer operator panel. (1) Kreyenborg hydraulic screen changer, Model K-SWE-125/P, Serial# 17172, built 1995, with a power pack, and control panel. (1) Die head, Serial# PA10695 with (2) 24 hole strand die lips. (1) Gatto stainless steel water bath, Model PWT-1218-14, Serial# 839748. Approximate 18" wide x 12" deep x 168" long with strand guides, brush and air knife (no blower). (1) Strand pelletizer with an approximate 16" wide 40 fixed knife helical rotor, (1) rubber, (1) metal pneumatically adjustable pull rolls, driven by a 25 hp, 3/60/575 volt, 1765 rpm motor. (1) Witte vibratory pellet cooler screener, stainless steel, Serial# 4258-2. Approximate 30" wide x 36" long slotted screen, top cover, 3 hp supply blower, (1) cyclone with exhaust blower and (1) stainless steel pellet discharge bin. (2) K-Tron Model SWB300 weigh belt feeders with hoppers, (1) K-Tron screw feeder, (1) Conair screw feeder.

Used Werner & Pfleiderer Twin Screw Pelletizing Line Consisting of: (1) ZSK-70 70mm Co-Rotating twin screw extruder, approximate 36 to 1 L/D ratio, Serial# 180802, Project# 94-3361, built 1995. (9) Barrel sections with (1) feed with hopper, (1) top vented, electrically heated water cooled with a closed loop system with pump, tank, and heat exchanger. Approximate 42-1/2" centerline height. Driven by a 250 hp, 500 volt, 1750/2000 rpm DC motor thru a gearbox. (1) Kinney Model KLRC-75-KFA vacuum pump, Serial# 950423-H7536-5, driven by a 10 hp, 3/60/575 volt, 1745 rpm motor. Includes a Reliance drive panel, temperature control panel, (1) 150 KVA transformer, (1) 275 KVA transformer, (1) computer operator panel. (1) Kreyenborg hydraulic screen changer, Model K-SWE-125/P, Serial# 17172, built 1995, with a power pack, and control panel. (1) Die head, Serial# PA10695 with (2) 24 hole strand die lips. (1) Gatto stainless steel water bath, Model PWT-1218-14, Serial# 839748. Approximate 18" wide x 12" deep x 168" long with strand guides, brush and air knife (no blower). (1) Strand pelletizer with an approximate 16" wide 40 fixed knife helical rotor, (1) rubber, (1) metal pneumatically adjustable pull rolls, driven by a 25 hp, 3/60/575 volt, 1765 rpm motor. (1) Witte vibratory pellet cooler screener, stainless steel, Serial# 4258-2. Approximate 30" wide x 36" long slotted screen, top cover, 3 hp supply blower, (1) cyclone with exhaust blower and (1) stainless steel pellet discharge bin. (2) K-Tron Model SWB300 weigh belt feeders with hoppers, (1) K-Tron screw feeder, (1) Conair screw feeder.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory