Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Coperion 25.5mm Co-Rotating Twin Screw MFG 2010 Pelletizing Line

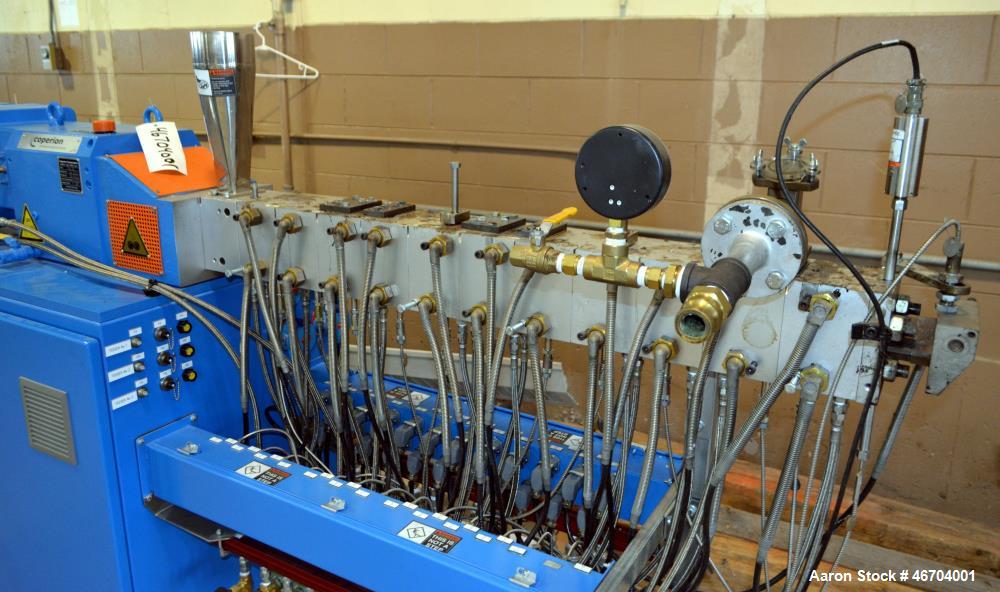

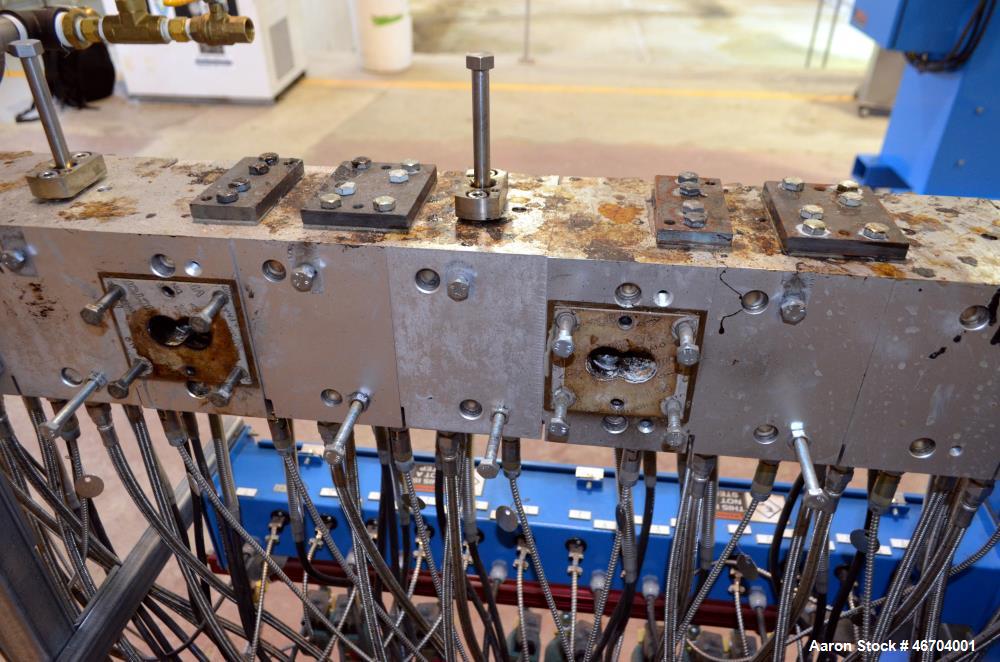

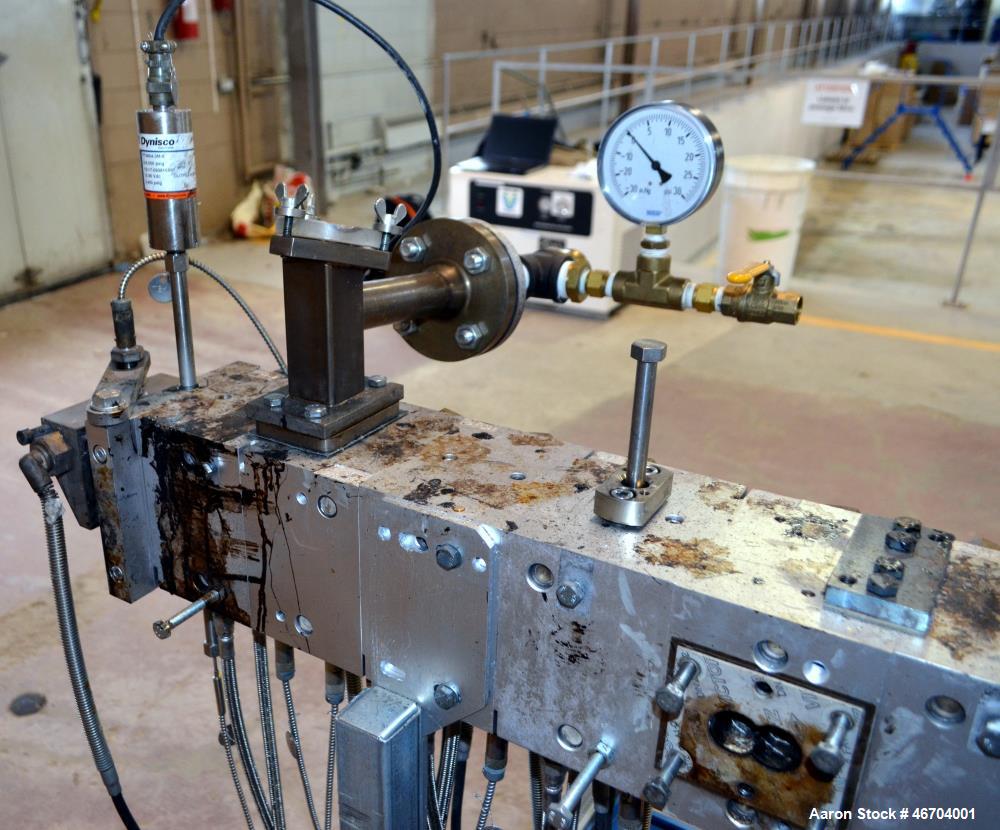

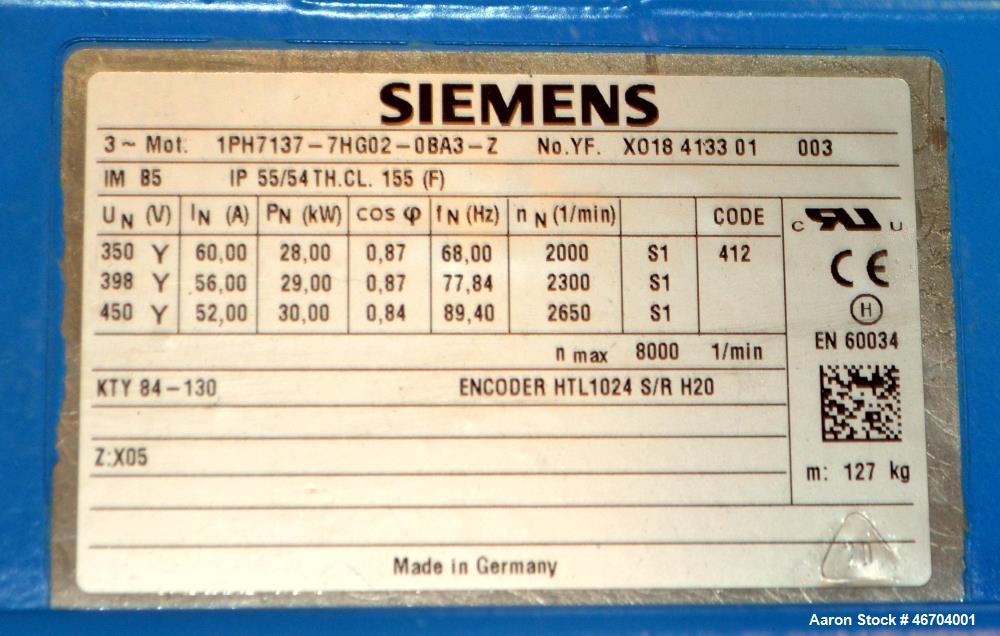

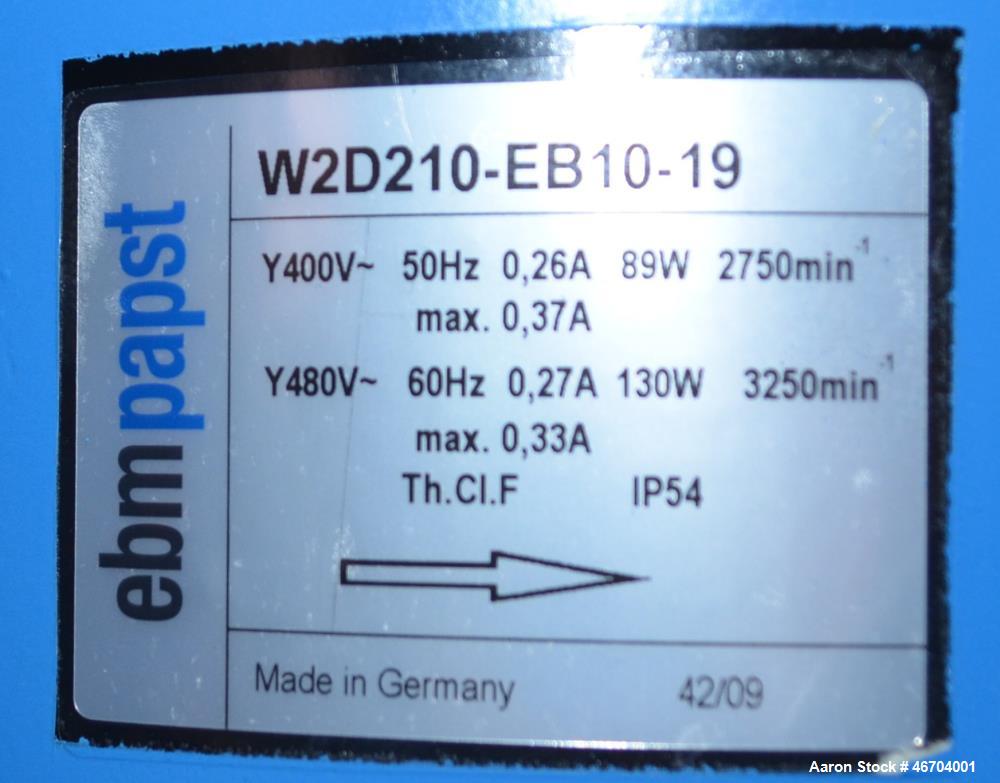

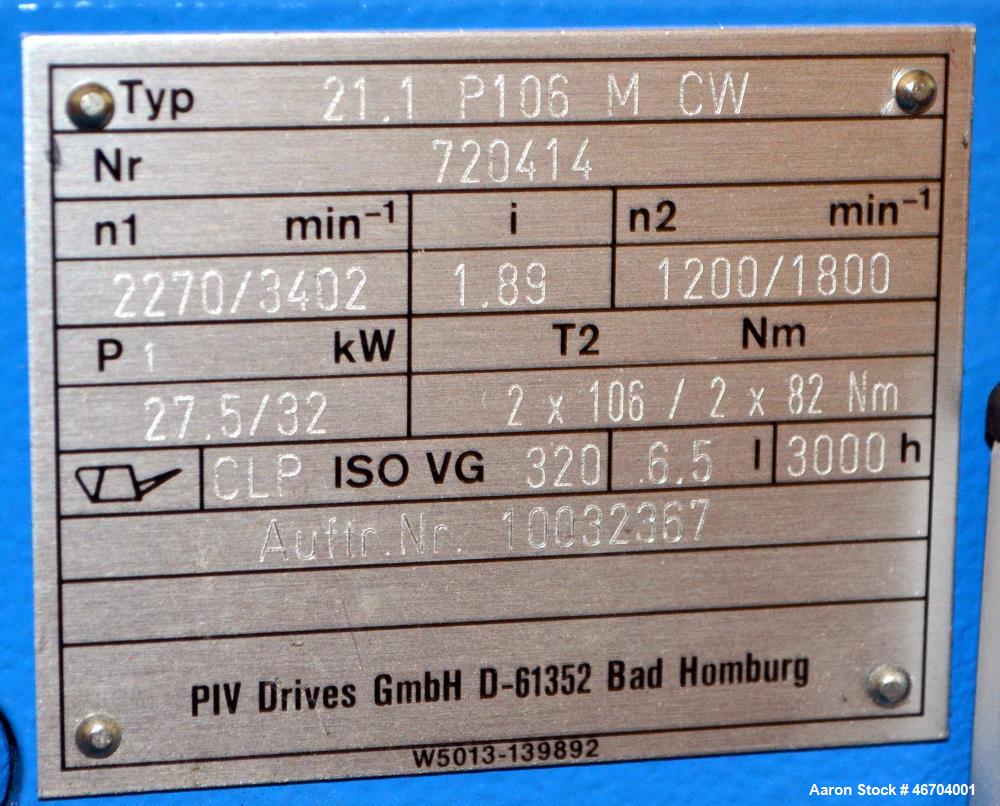

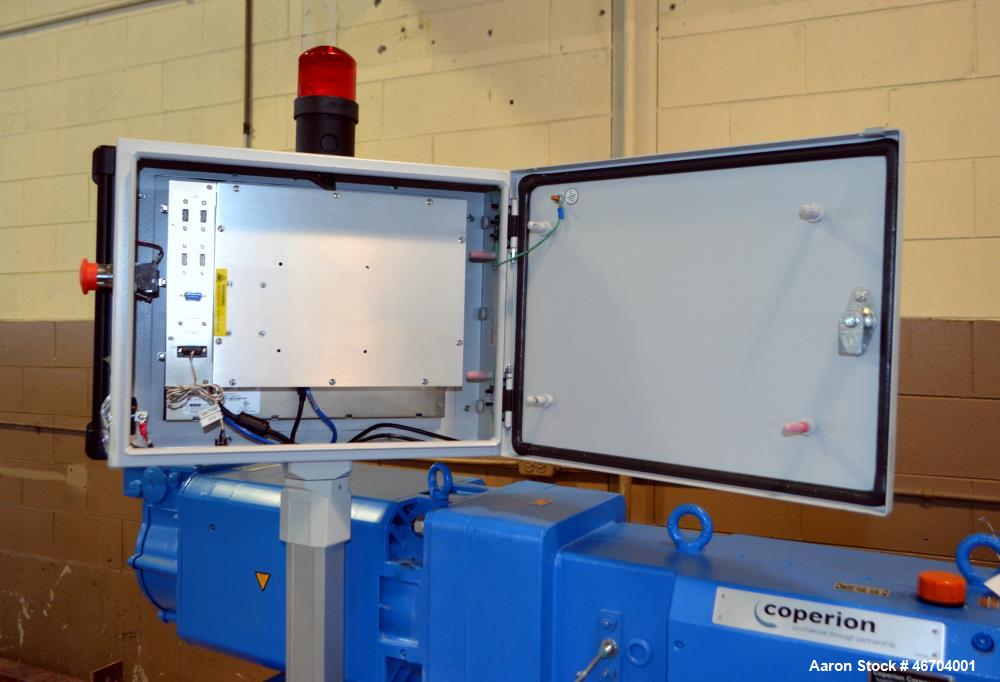

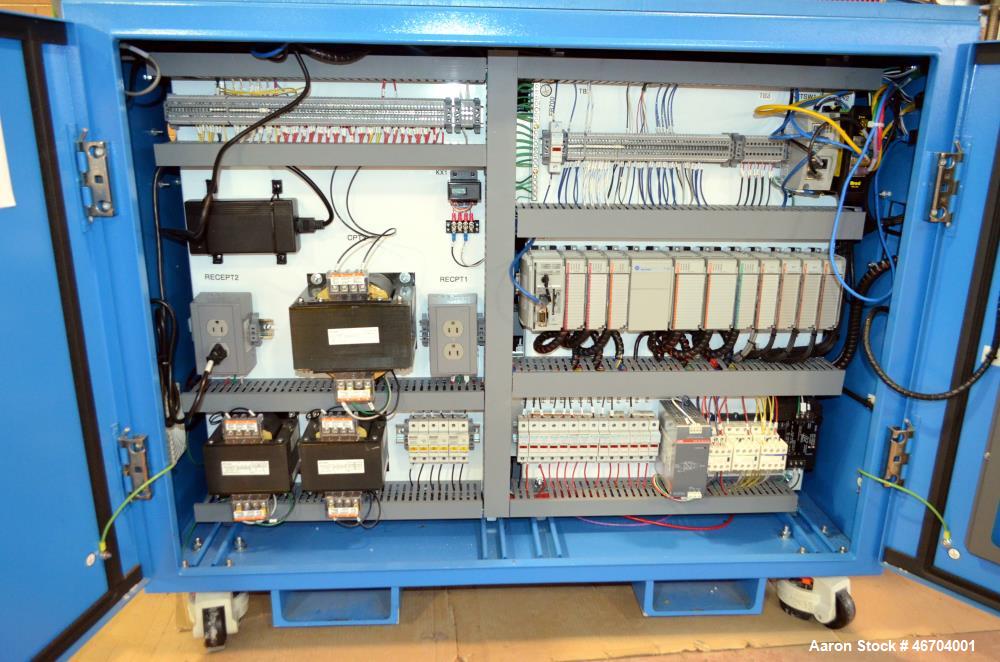

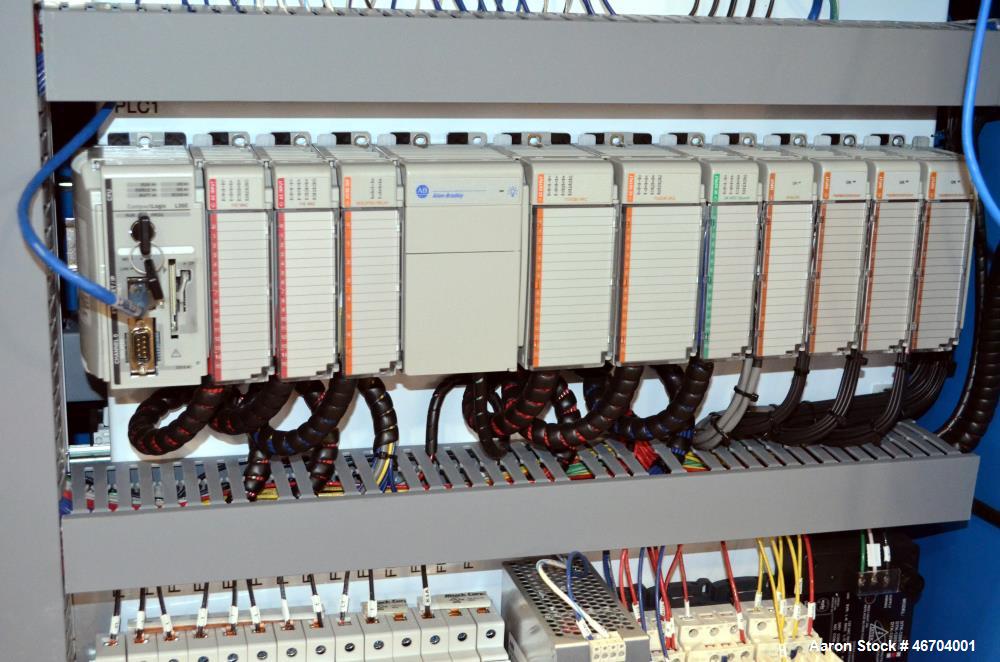

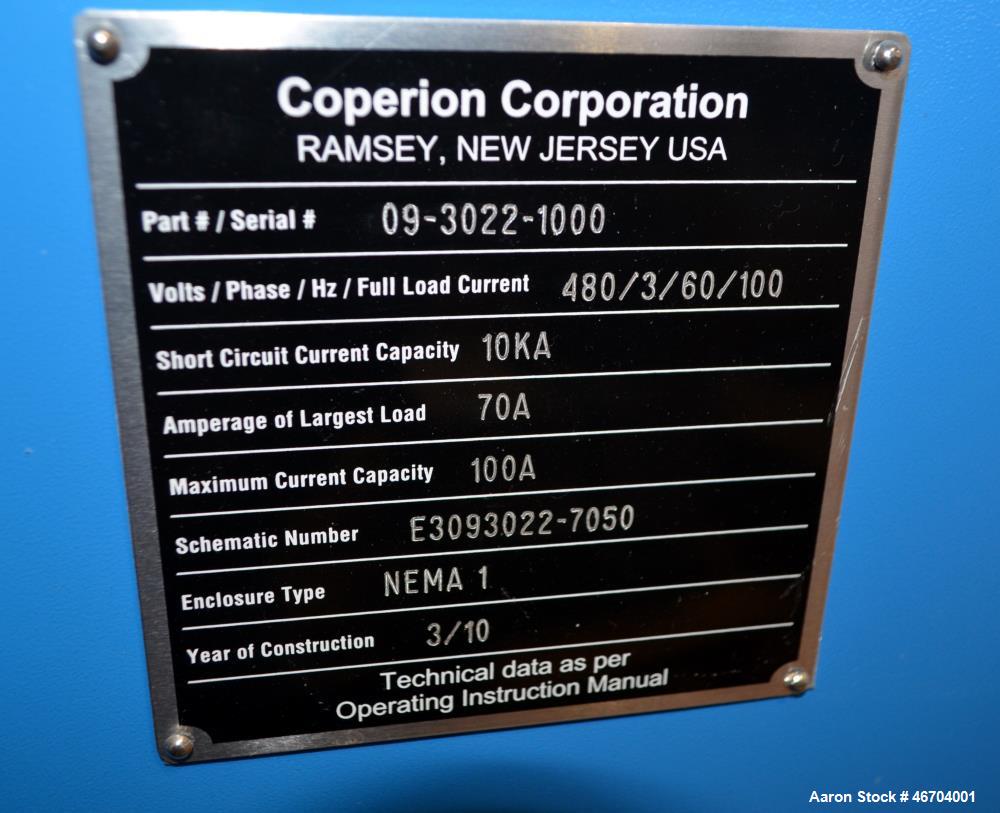

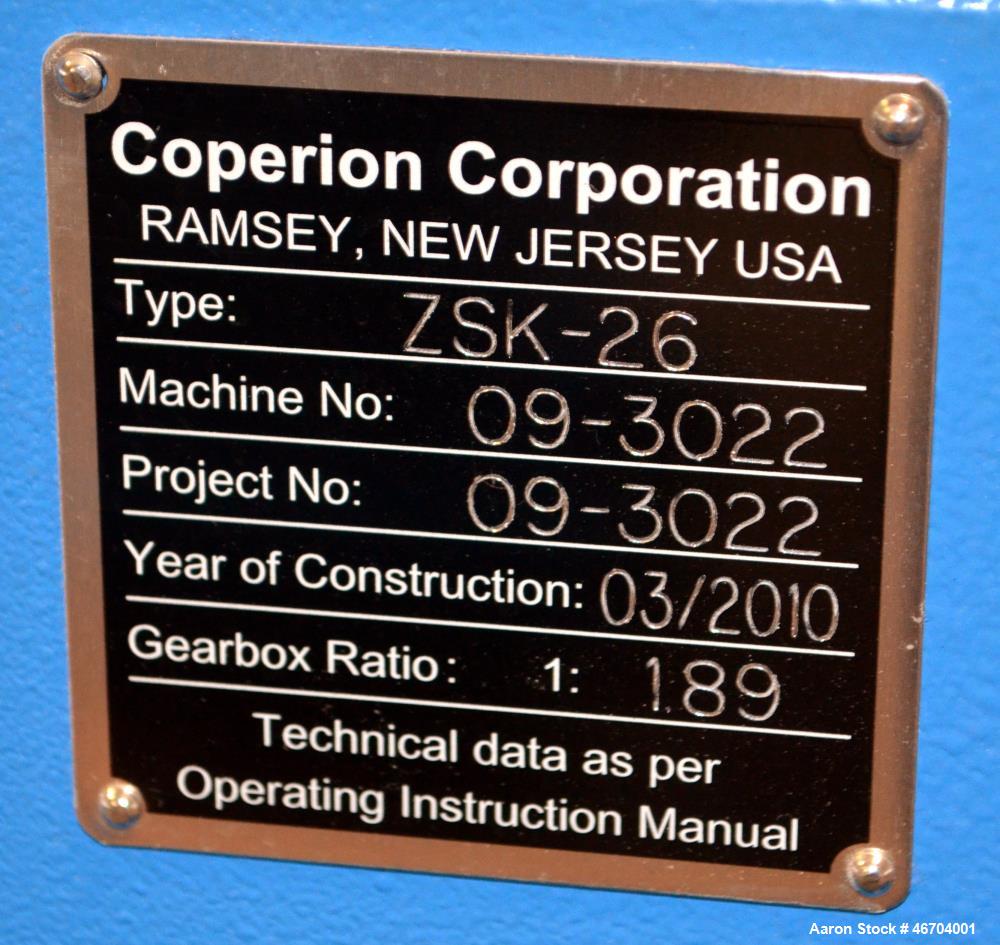

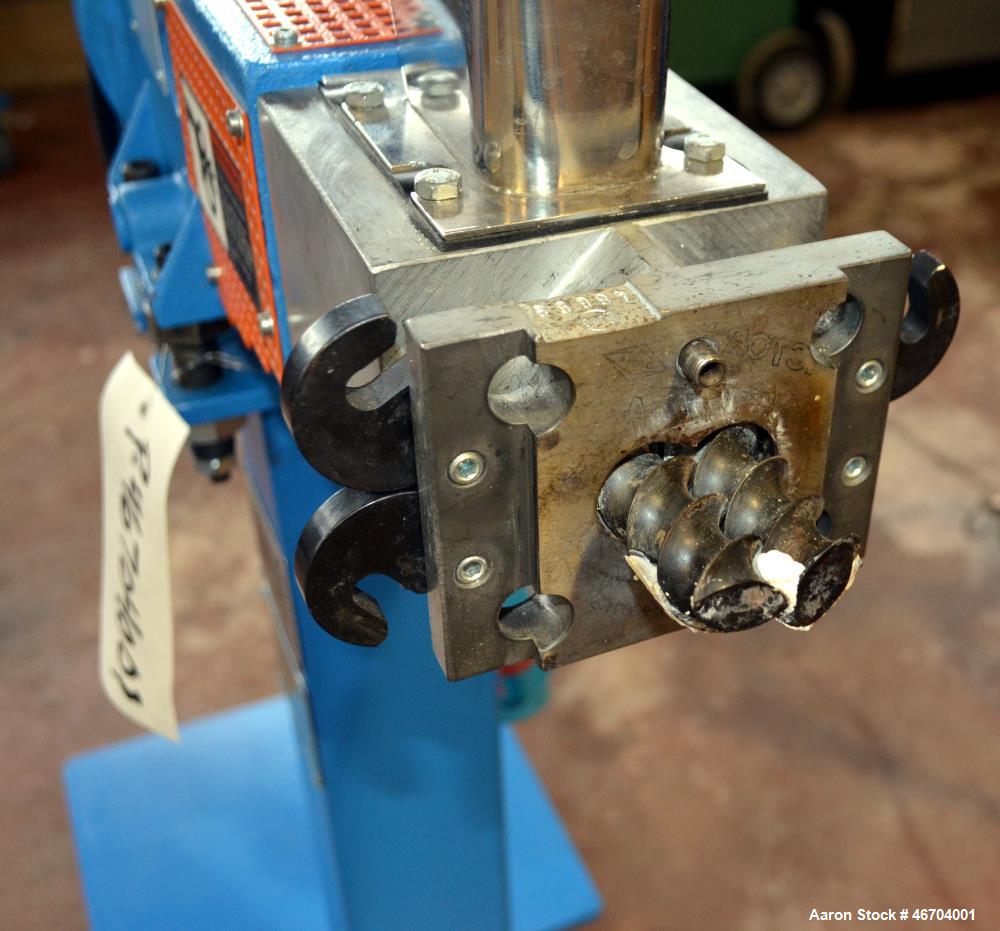

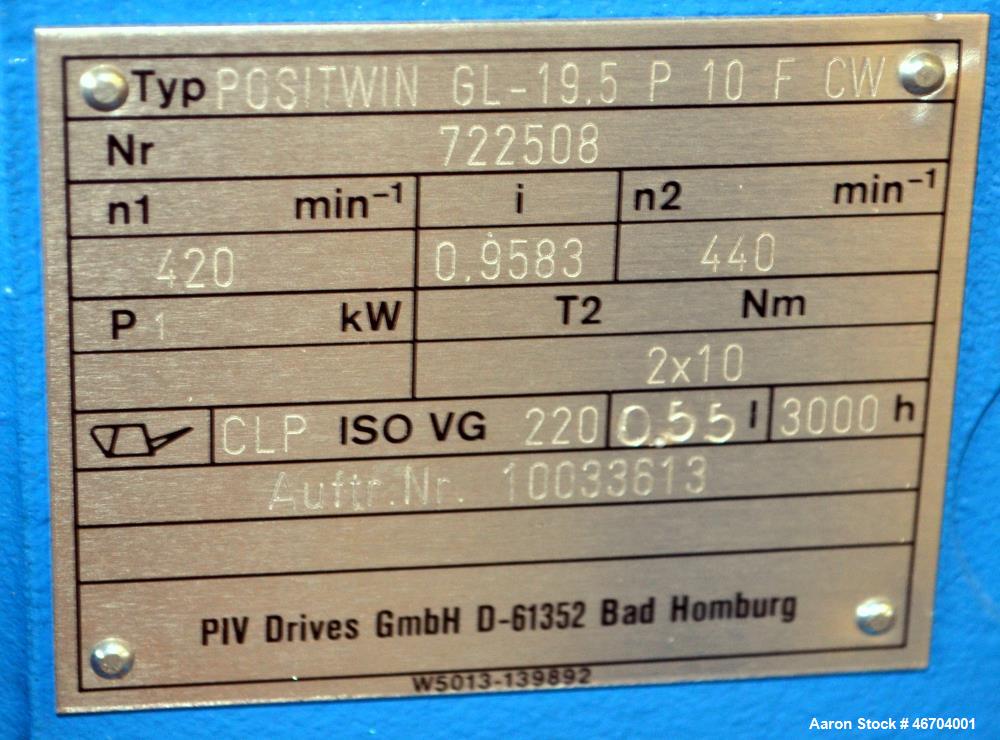

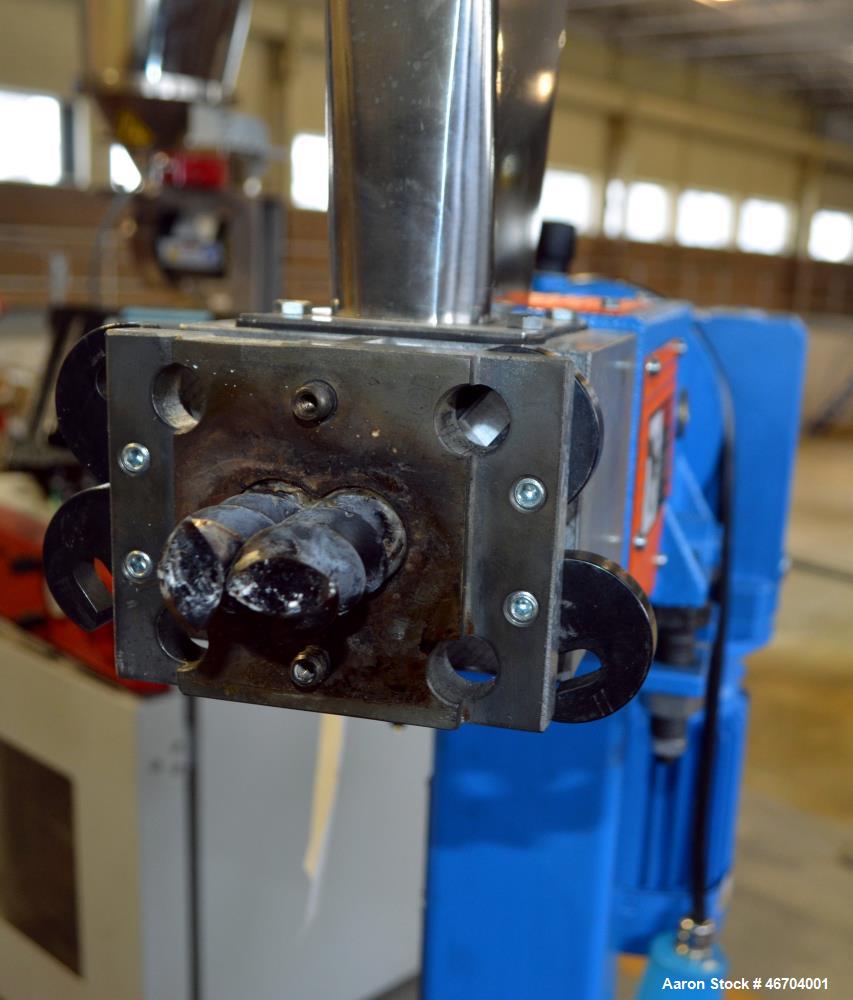

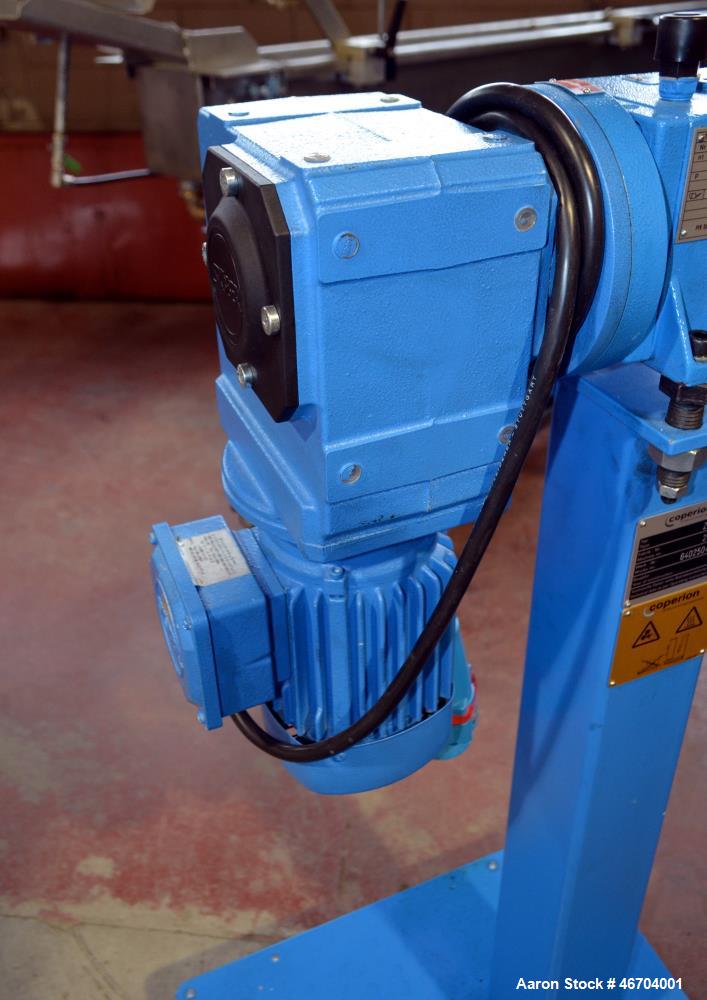

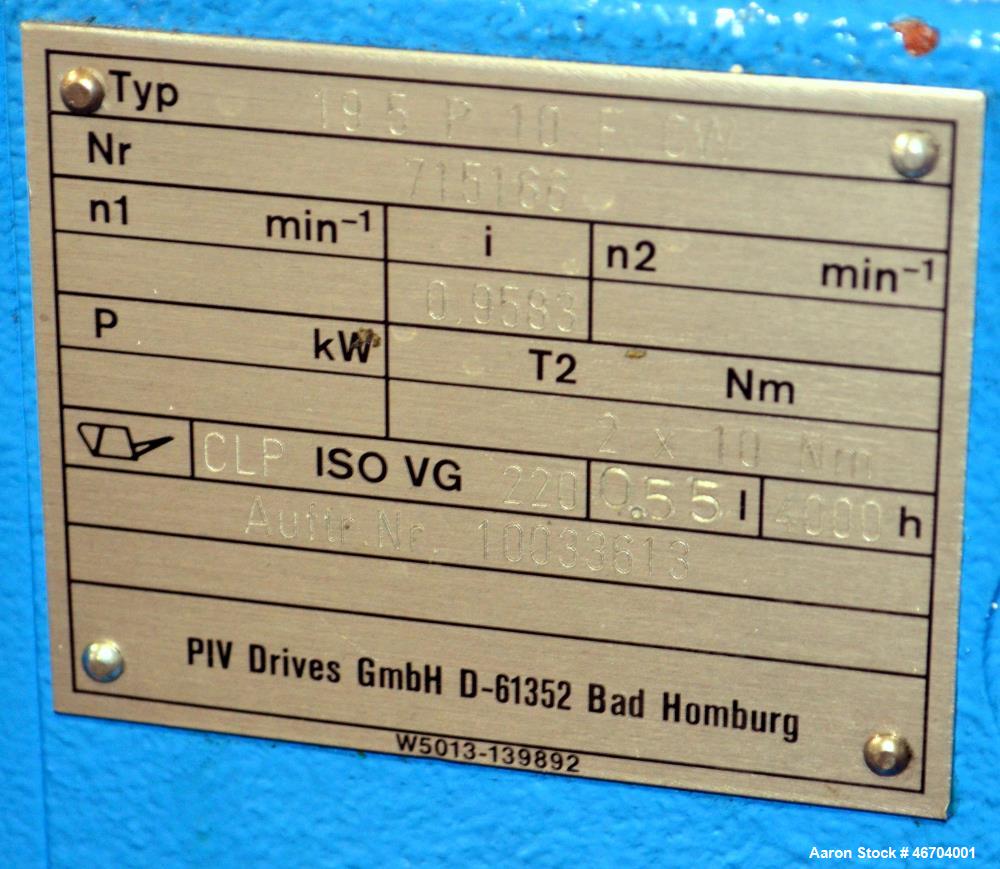

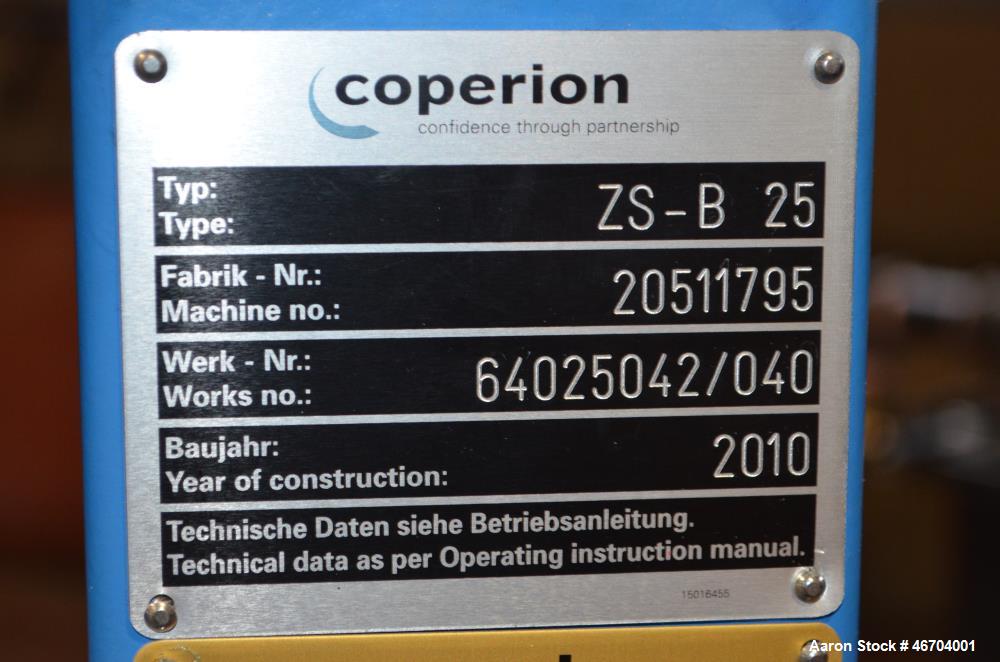

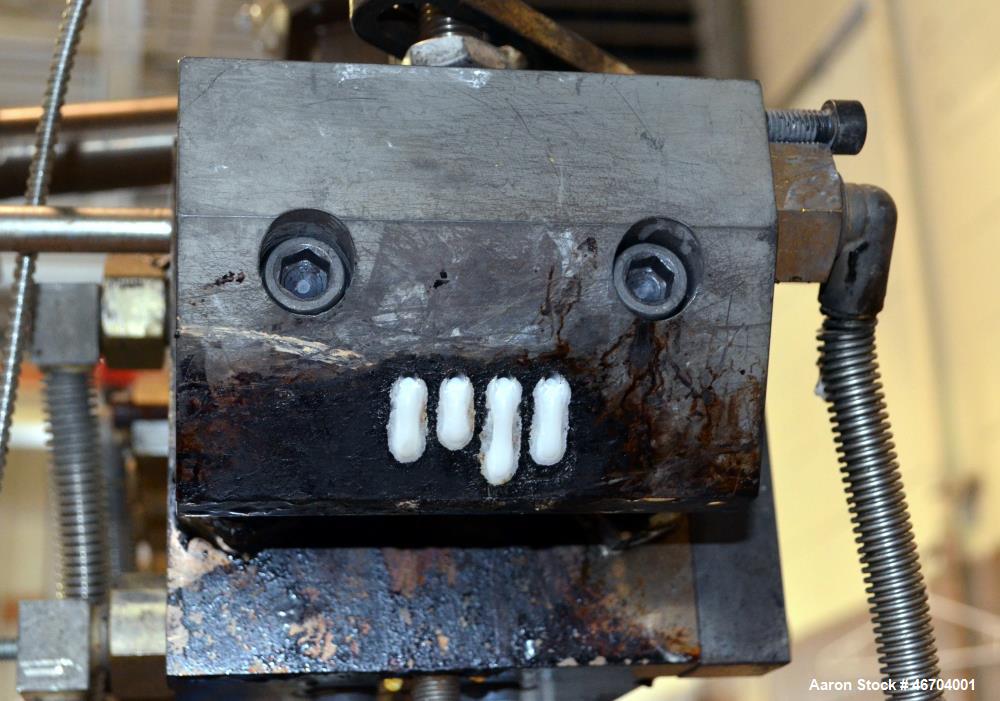

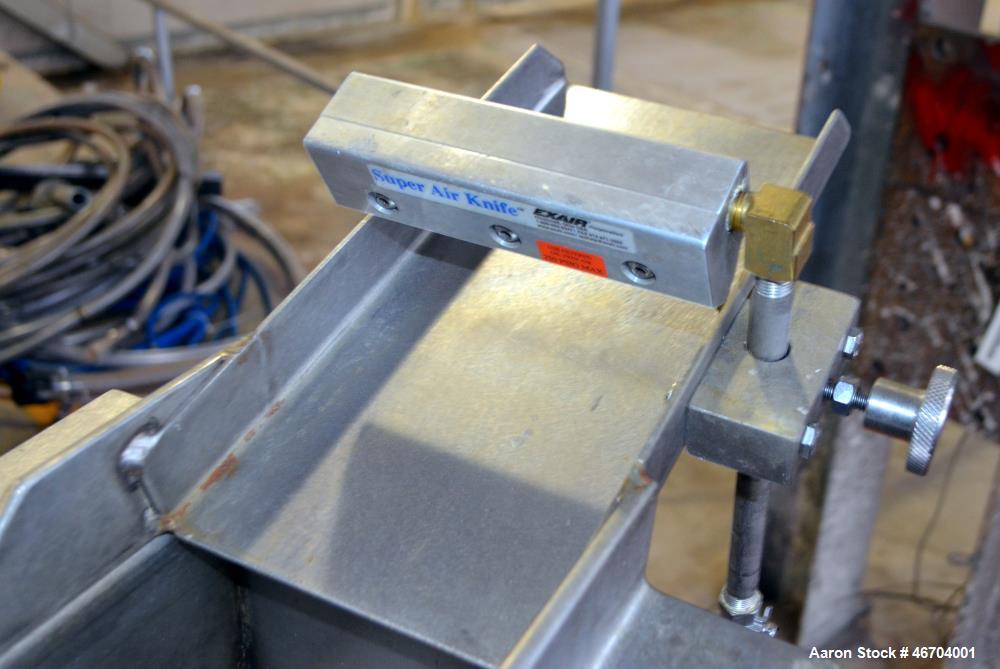

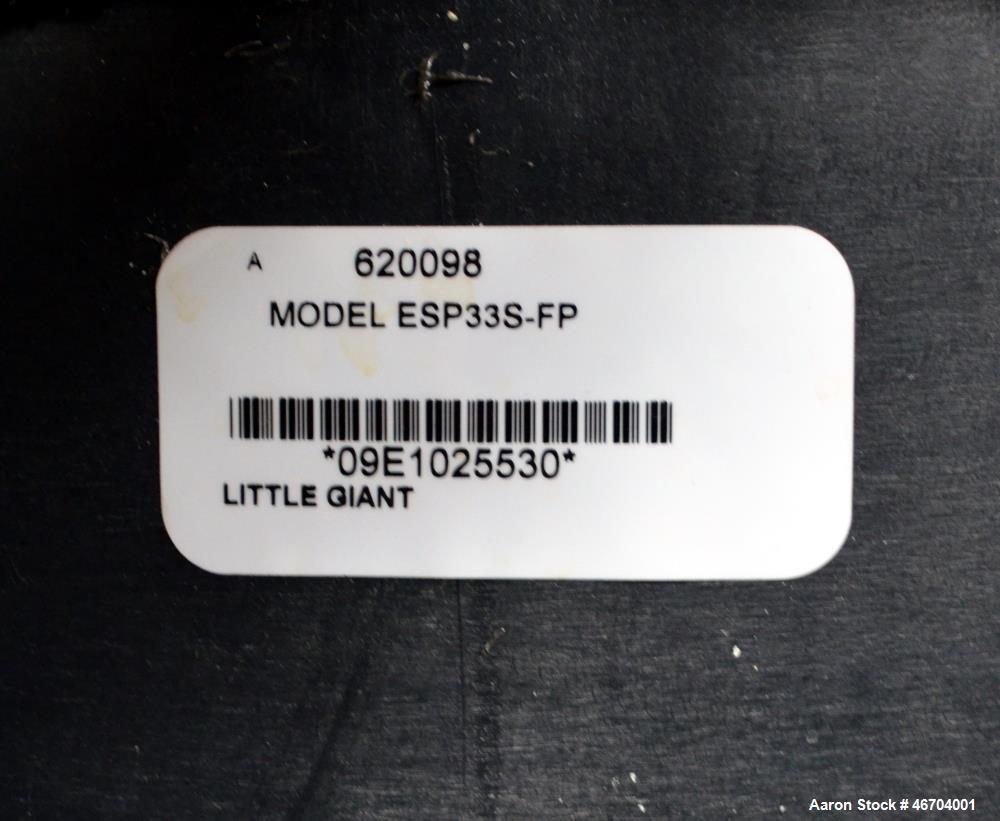

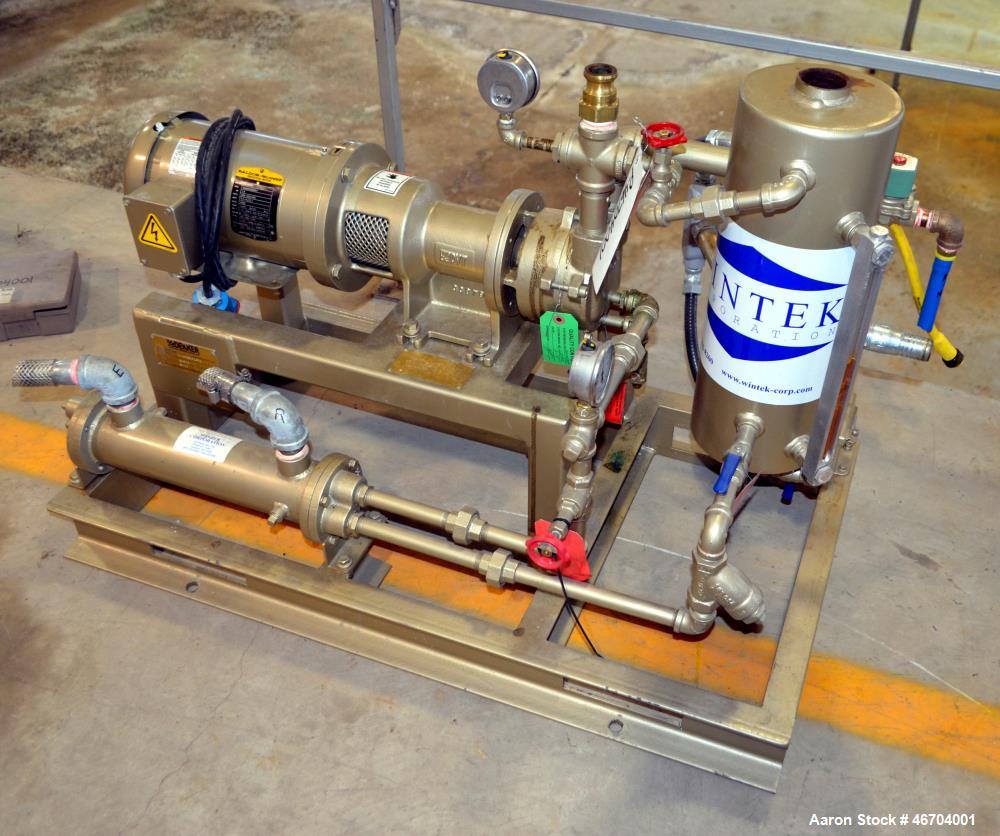

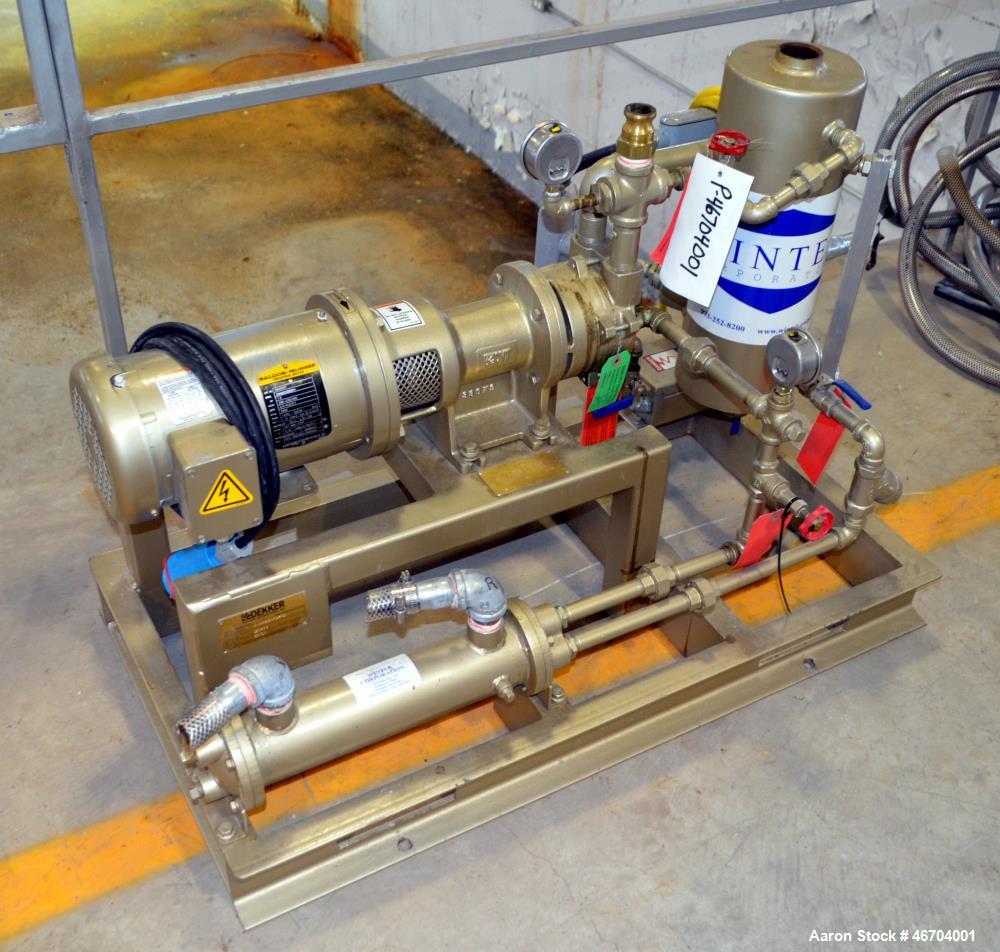

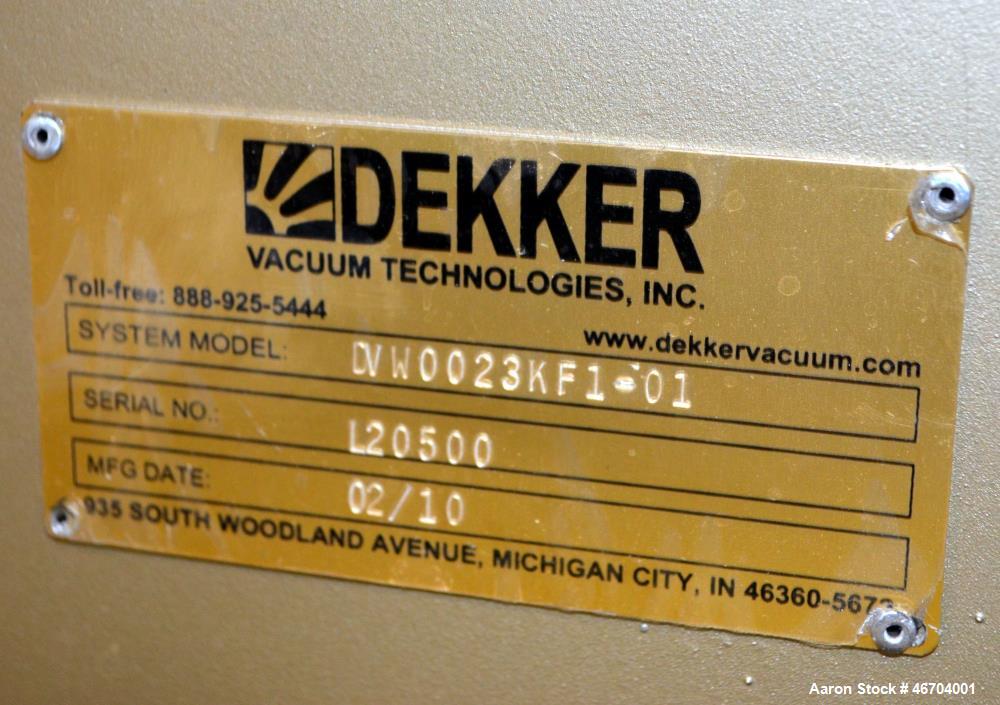

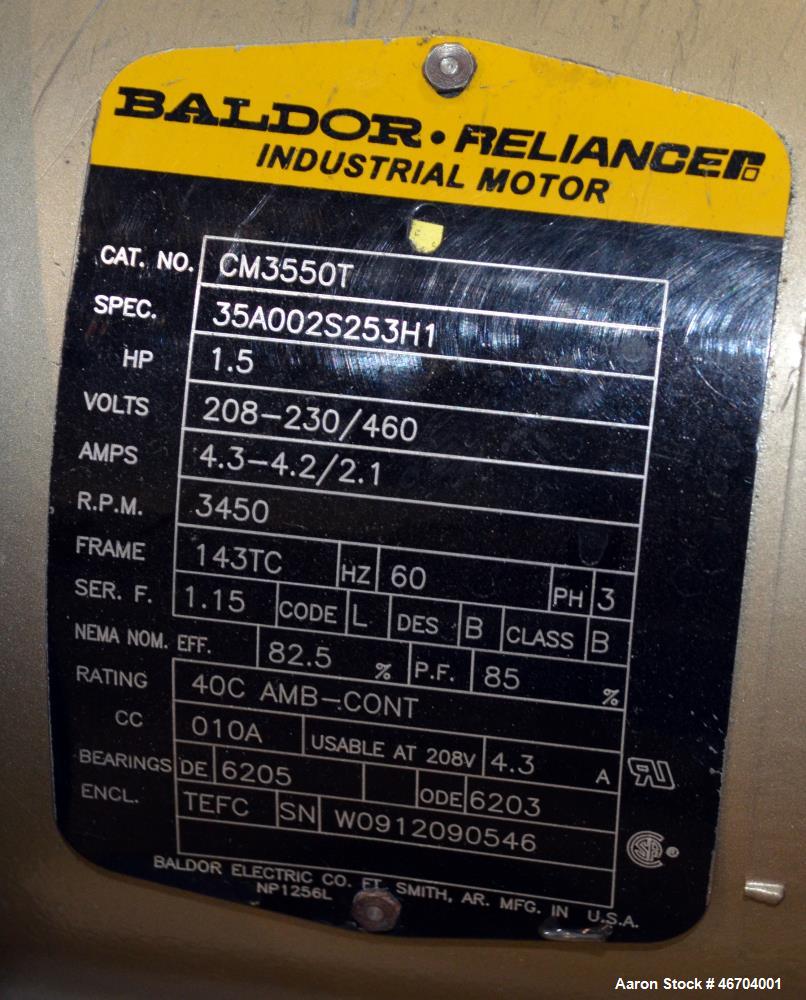

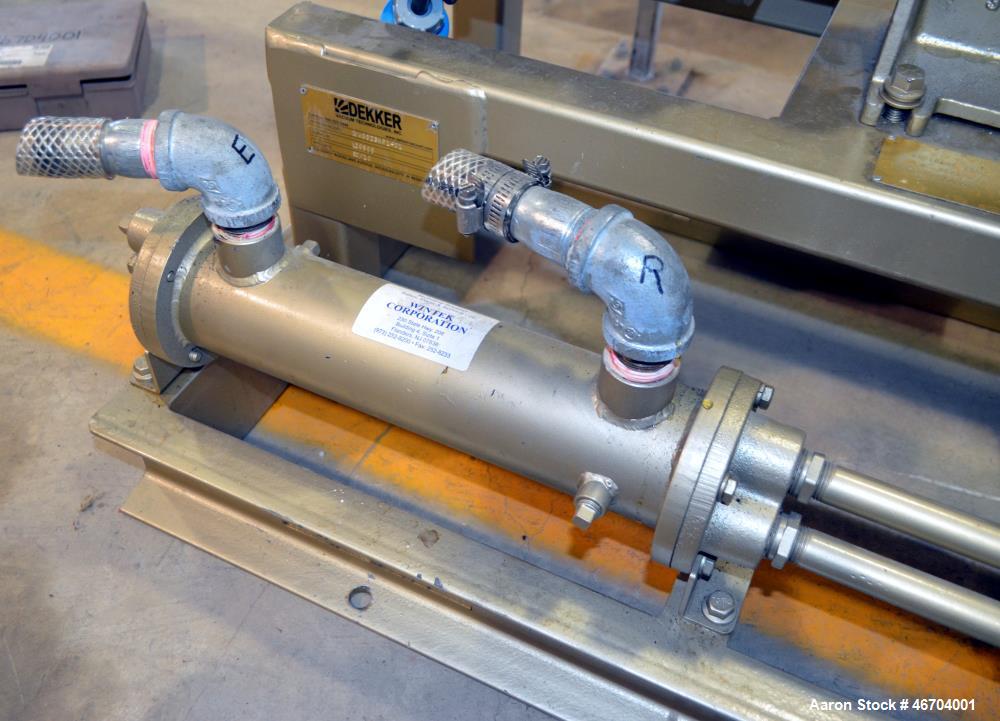

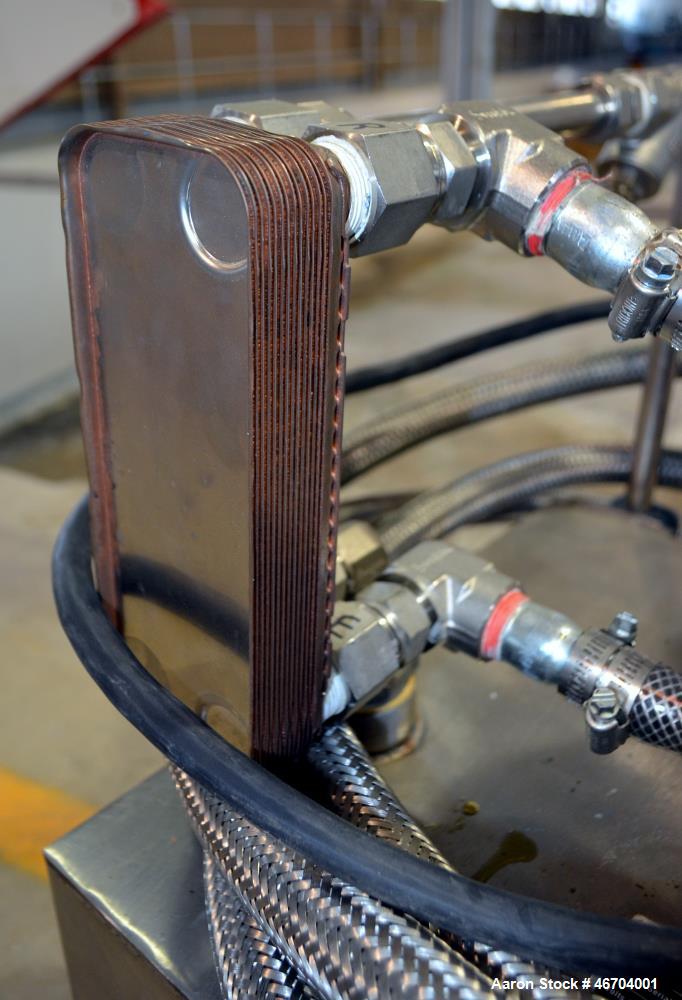

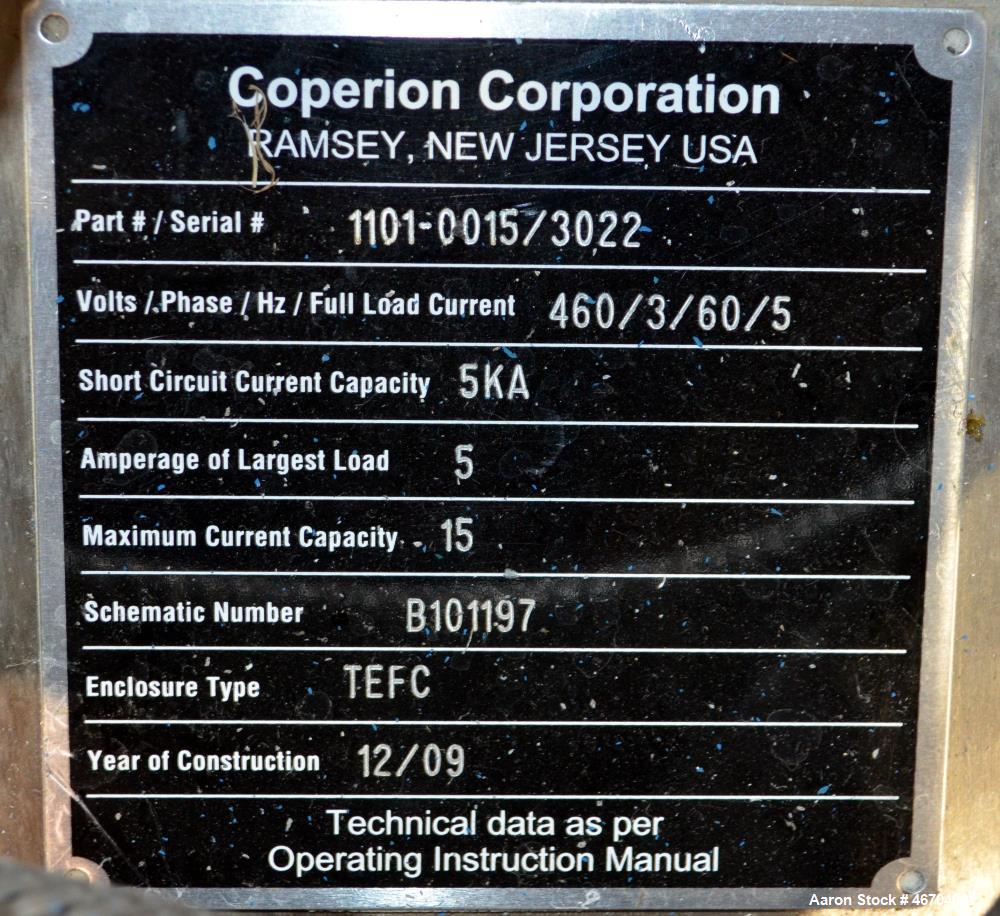

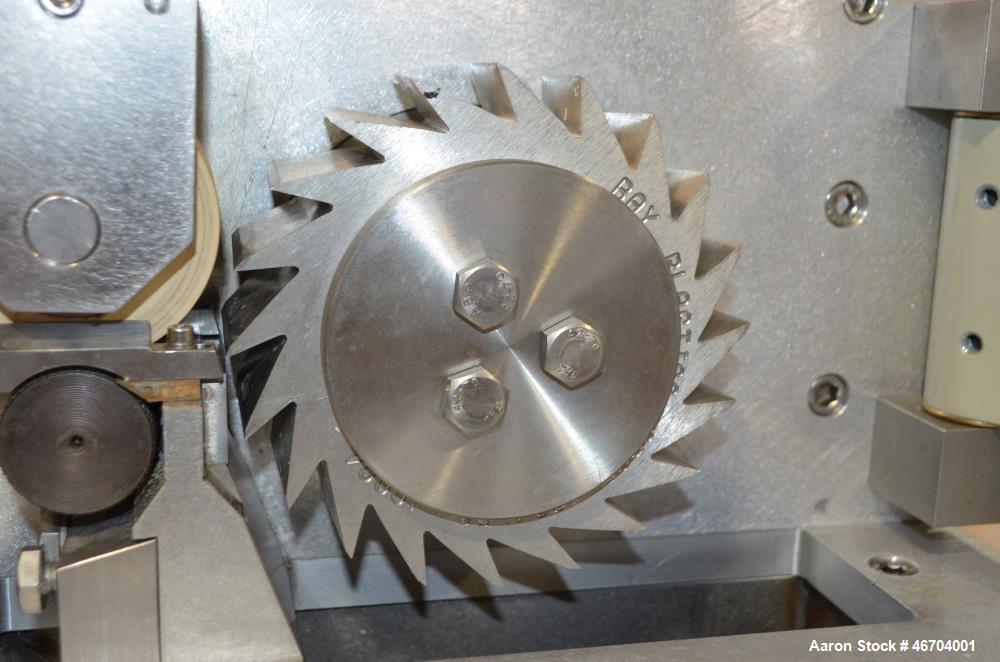

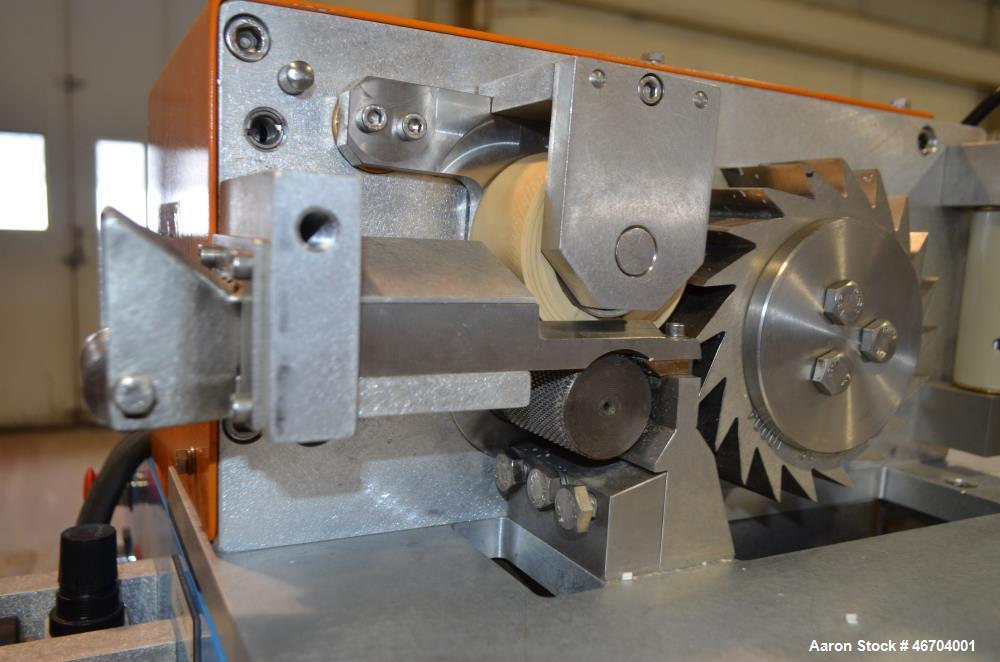

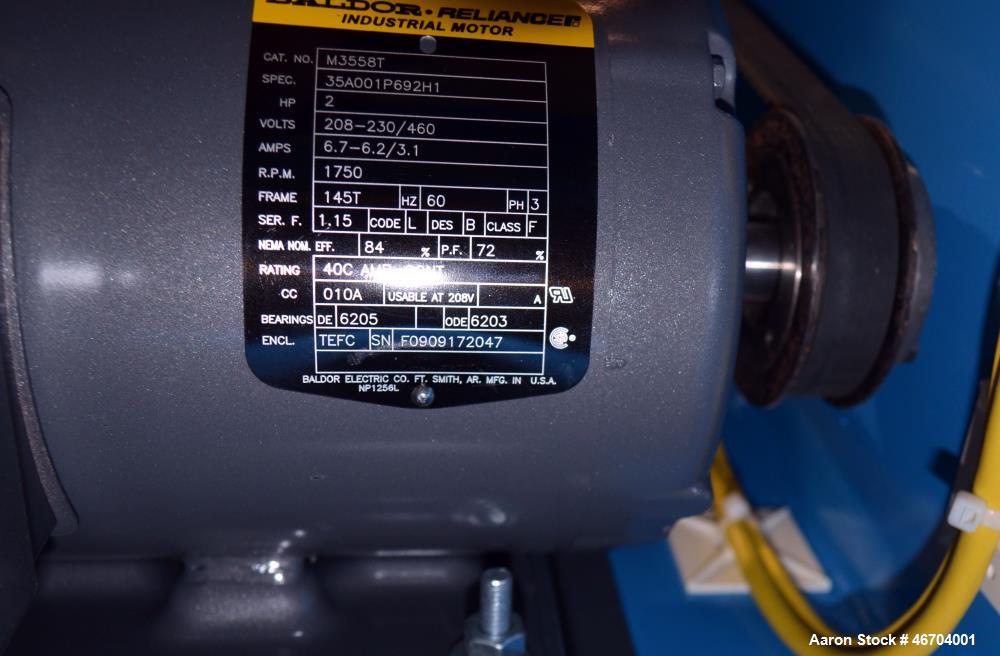

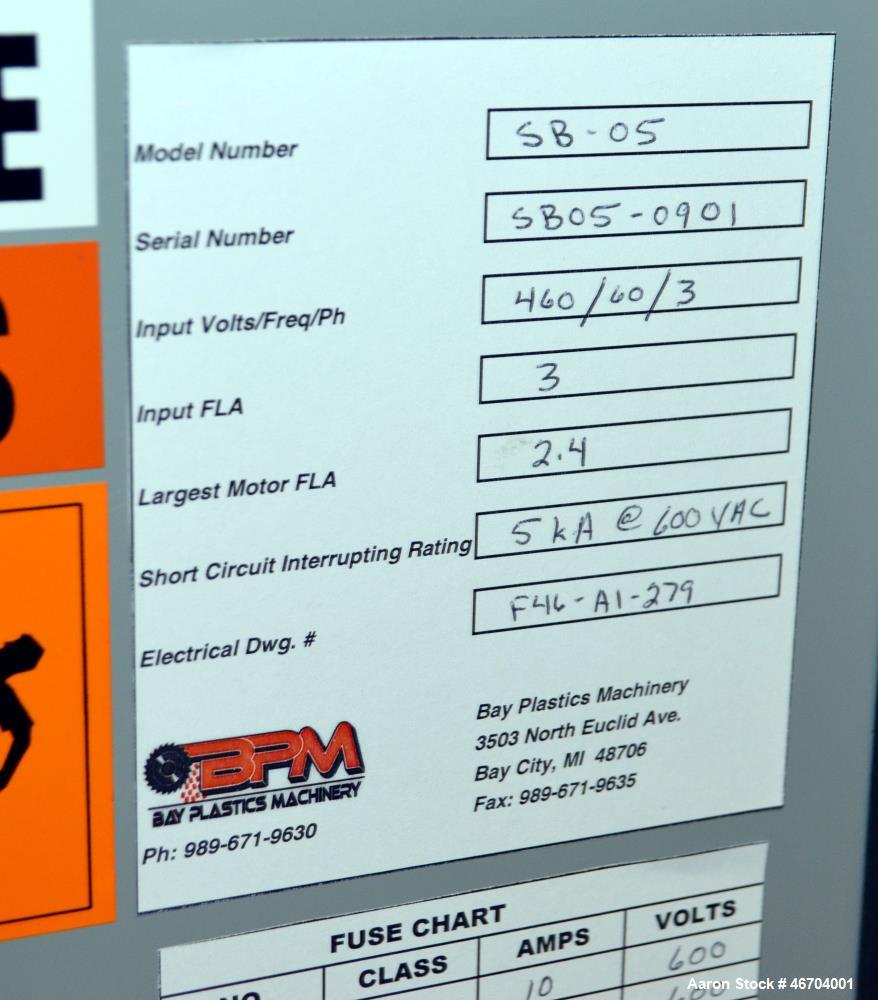

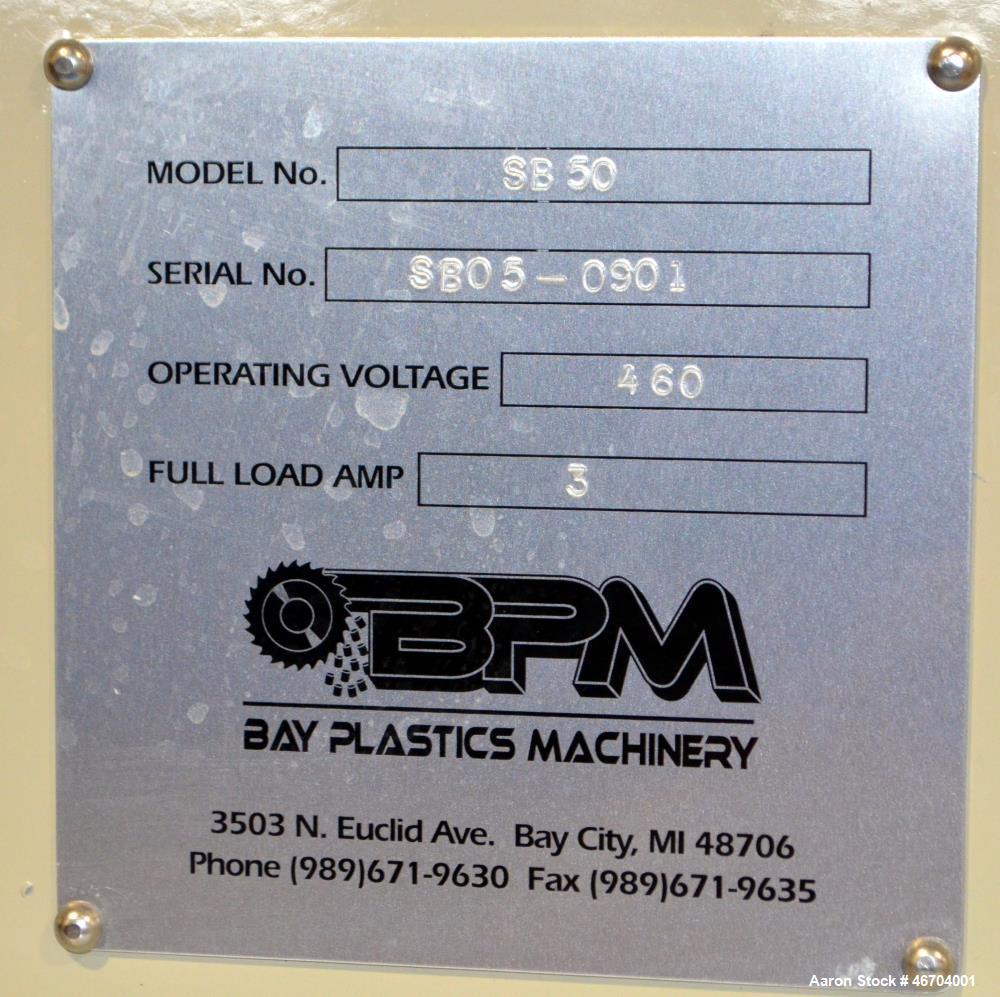

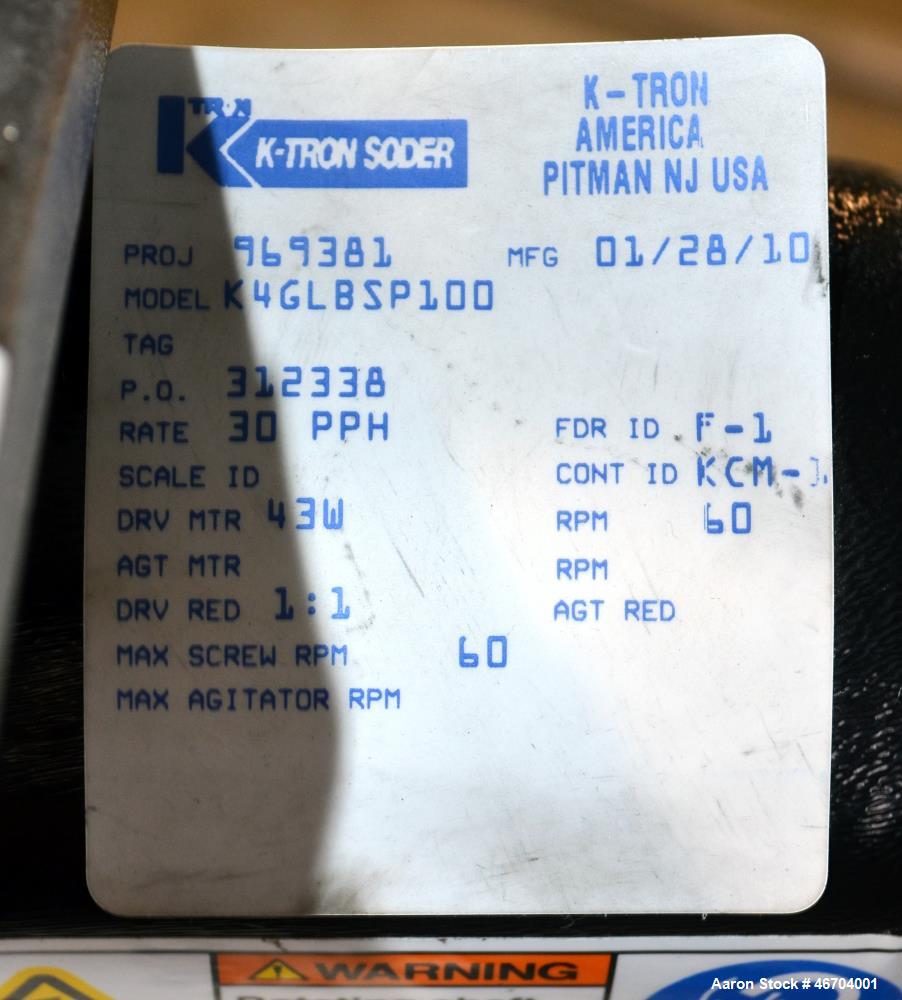

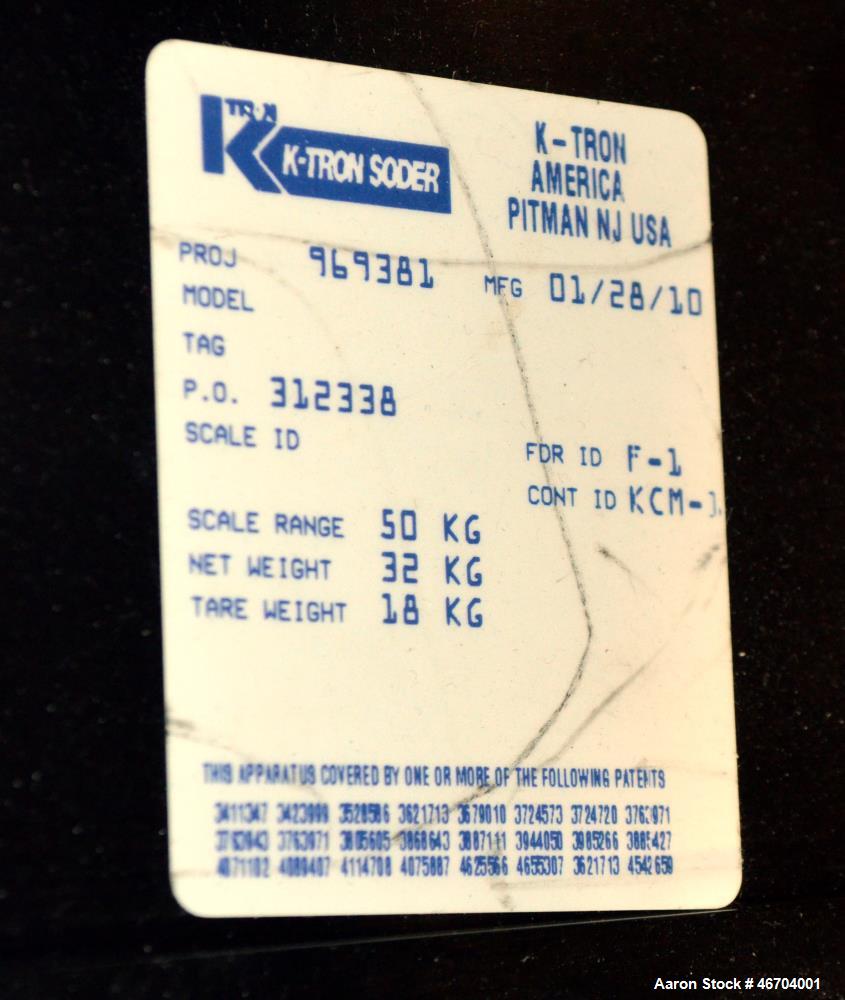

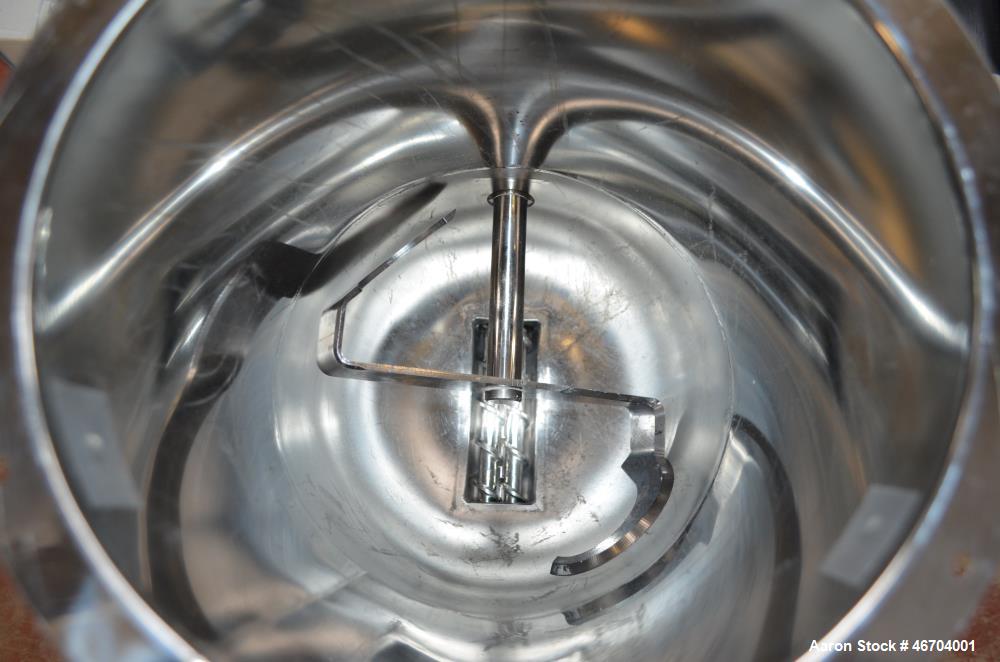

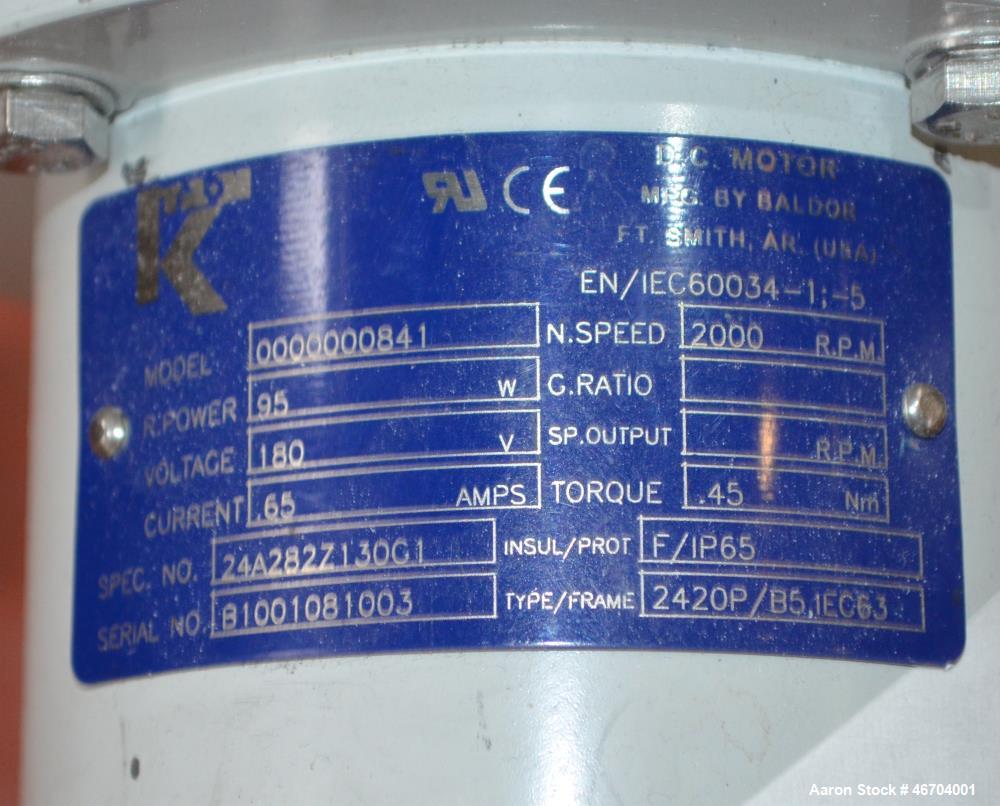

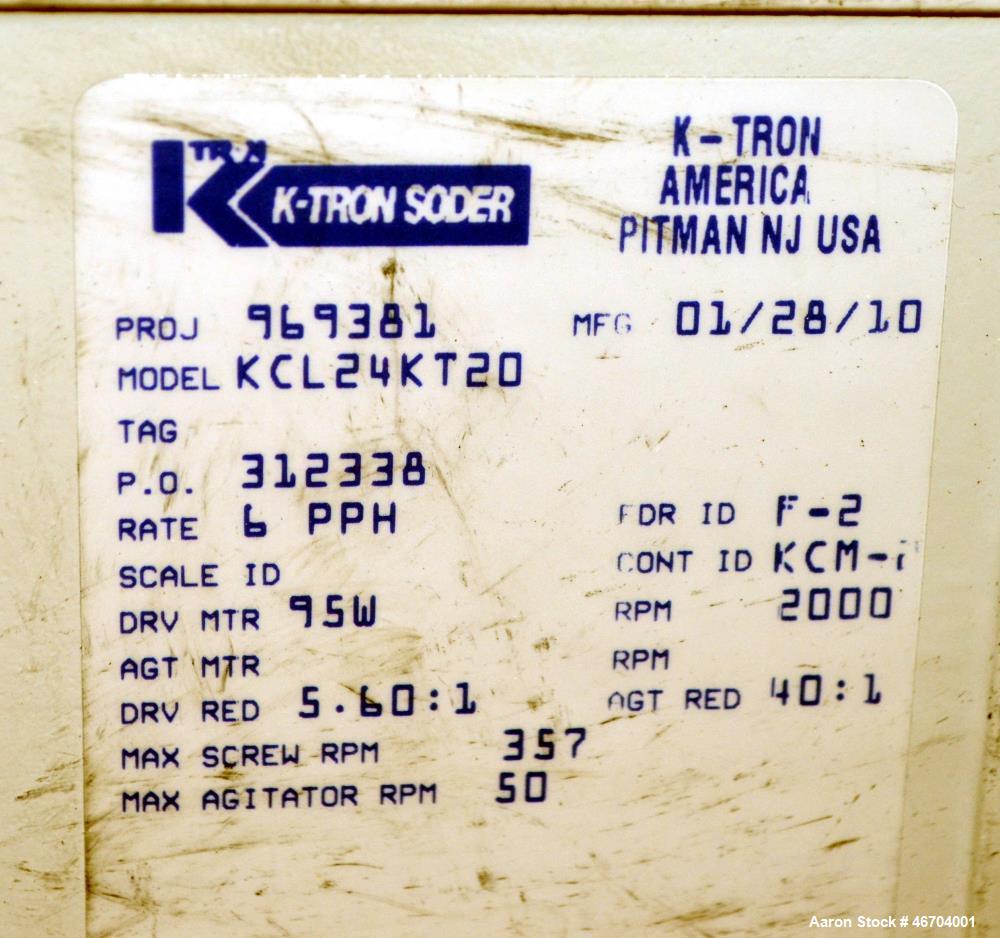

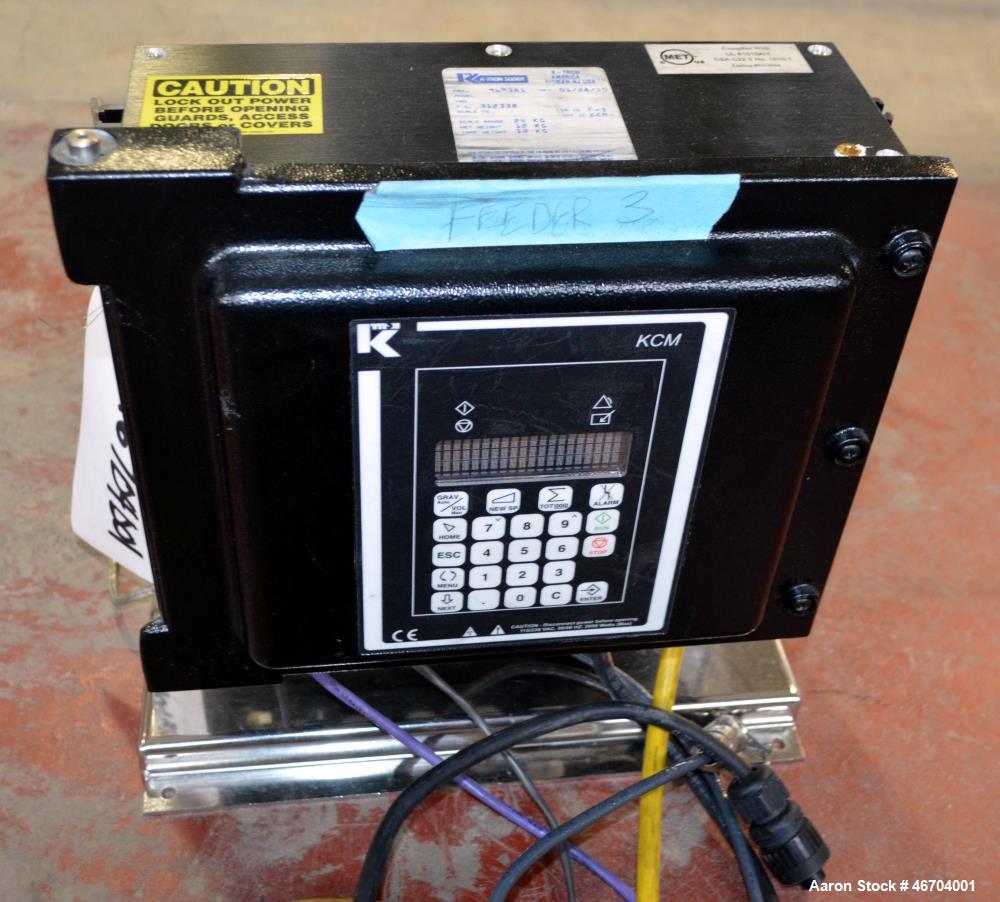

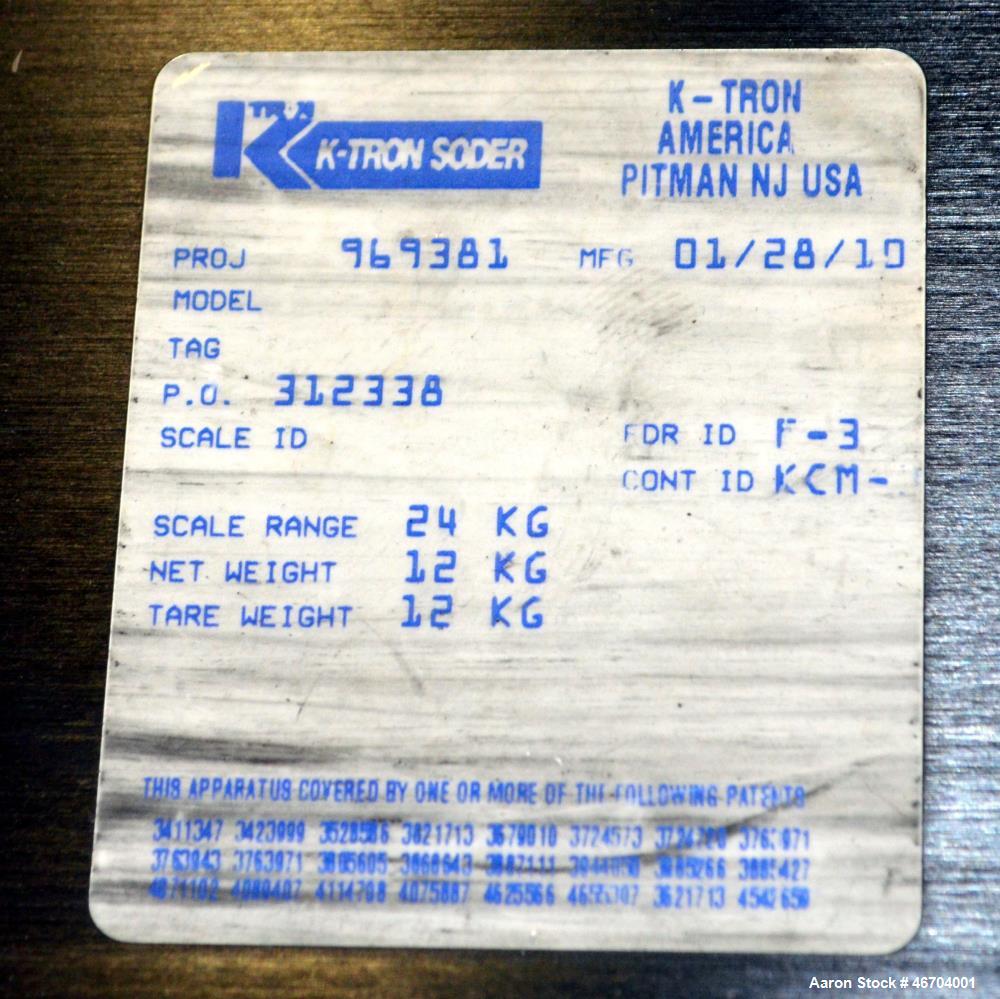

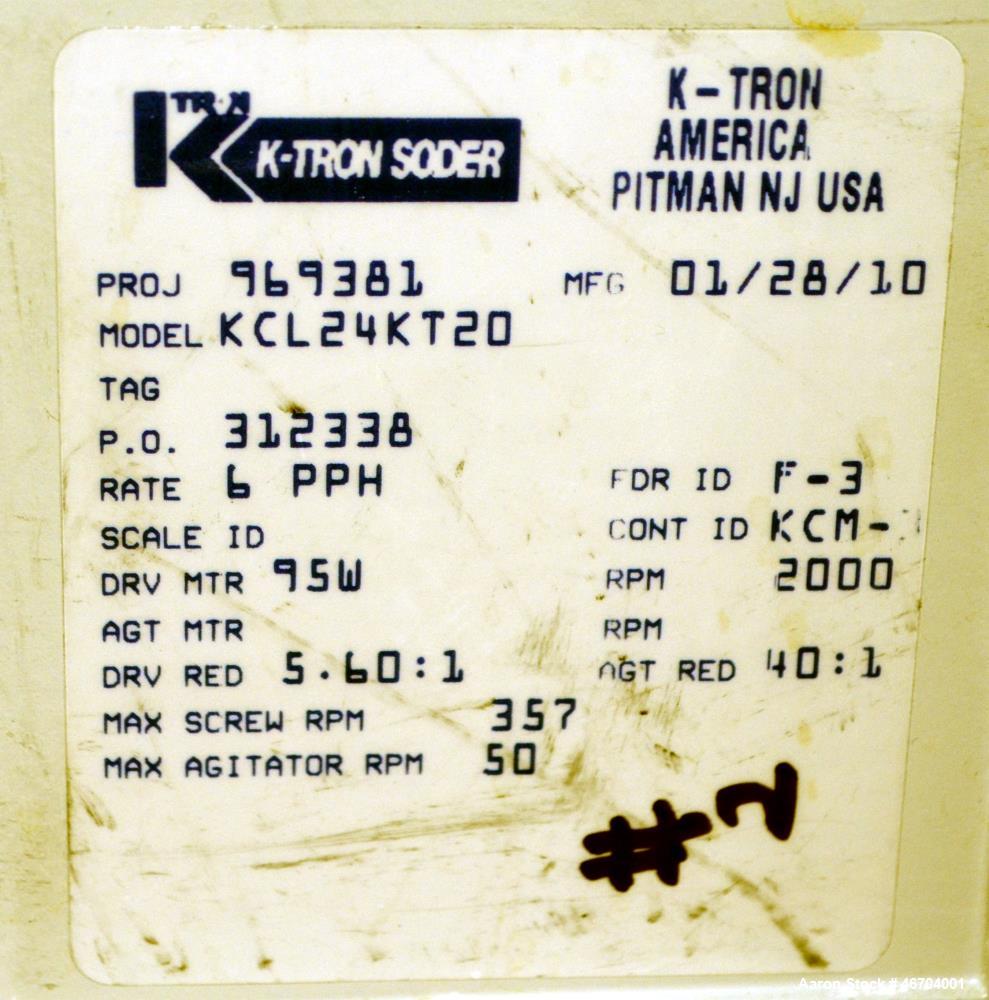

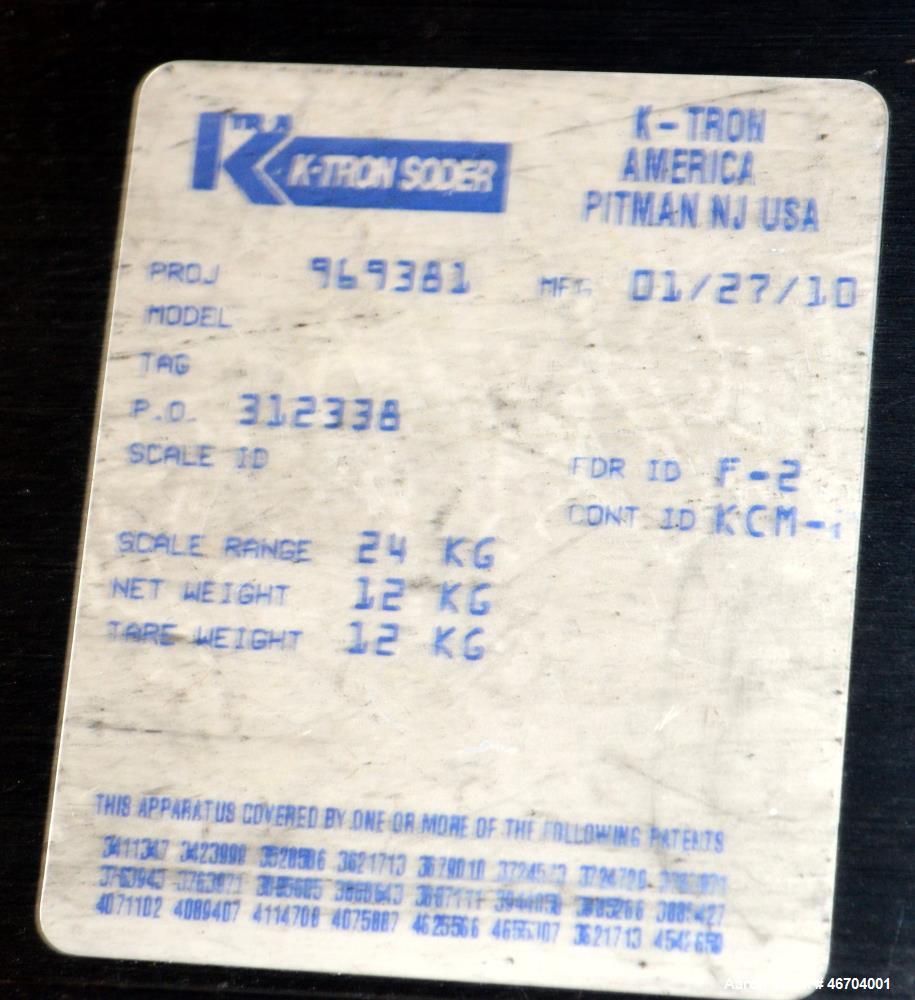

Used Coperion 25.5mm Co-Rotating Twin Screw MFG 2010 Pelletizing Line. Consisting of (1) Coperion Extruder, Type ZSK-26. Approximate 48:1 L/D ratio. Co-Rotating intermeshing side by side screw design. 12 Barrel sections consisting of (1) feed section with hopper, (6) closed, (3) vented, 2 plugged, 1 with vent port assembly, and (2) combi side feeder ports. Electrically heated, water cooled with a Coperion Model# 1101-0015 closed loop cooling system, Serial# 3022. Extruder driven by a 30 kw, 3/89.40/450 volt, 2650 rpm motor, thru a PIV gearbox, ratio 1.89 to 1. Approximate 42-1/2" centerline height. Includes a control panel with an Allen-Bradley CompactLogix L35E CPU, (2) Allen-Bradley PowerFlex 40 drives, an ABB drive, and an Arista operator panel. Mounted on casters. Built 2010, Serial# 09-3022. (2) Coperion 24mm ZS-B 25 twin screw side feeders, each driven by a 0.75 kw gear motor thru a PIV gearbox. Each includes feed hopper, and mounted on stands with casters, serial# 20511795 and 20511796. (1) Nitrided 4 hole strand die. (1) Bay Plastics Machinery stainless steel water trough. Approximate 6" wide x 96" long x 6" deep. With (1) Exair 6" wide super air knife, (1) Monarch pump, mounted on casters. (1) Bay Plastics Machinery SB50 pelletizer. Approximate 2" wide x 6" diameter 20 fixed knife rotor. (1) Rubber, (1) metal pull rolls, driven by a 2 hp motor. Includes a control panel with a Lenze drive, mounted on casters, Serial# SB05-0901. (1) Wintek water sealed liquid ring 15 ACFM vacuum system consisting of (1) Dekker vacuum pump, Model DVW0023KF1-01, driven by a 1.5 hp motor, Serial# L20500. With a heat exchanger, overflow tank, and knockout pot, frame mounted. (1) K-Tron BSP extruder feeder, Model K4GLBSP100. Approximate rating 30 pounds per hour, with (1) type SFT-III-500-N scale, and a KCM controller. (2) K-Tron side feeder feeders, Model KCL24KT20. Approximate rating 6 pounds per hour, each with agitated hoppers, Type K-SFS-24/6 scale, and a KCM controller. (1) Portable K-Tron.

Used Coperion 25.5mm Co-Rotating Twin Screw MFG 2010 Pelletizing Line. Consisting of (1) Coperion Extruder, Type ZSK-26. Approximate 48:1 L/D ratio. Co-Rotating intermeshing side by side screw design. 12 Barrel sections consisting of (1) feed section with hopper, (6) closed, (3) vented, 2 plugged, 1 with vent port assembly, and (2) combi side feeder ports. Electrically heated, water cooled with a Coperion Model# 1101-0015 closed loop cooling system, Serial# 3022. Extruder driven by a 30 kw, 3/89.40/450 volt, 2650 rpm motor, thru a PIV gearbox, ratio 1.89 to 1. Approximate 42-1/2" centerline height. Includes a control panel with an Allen-Bradley CompactLogix L35E CPU, (2) Allen-Bradley PowerFlex 40 drives, an ABB drive, and an Arista operator panel. Mounted on casters. Built 2010, Serial# 09-3022. (2) Coperion 24mm ZS-B 25 twin screw side feeders, each driven by a 0.75 kw gear motor thru a PIV gearbox. Each includes feed hopper, and mounted on stands with casters, serial# 20511795 and 20511796. (1) Nitrided 4 hole strand die. (1) Bay Plastics Machinery stainless steel water trough. Approximate 6" wide x 96" long x 6" deep. With (1) Exair 6" wide super air knife, (1) Monarch pump, mounted on casters. (1) Bay Plastics Machinery SB50 pelletizer. Approximate 2" wide x 6" diameter 20 fixed knife rotor. (1) Rubber, (1) metal pull rolls, driven by a 2 hp motor. Includes a control panel with a Lenze drive, mounted on casters, Serial# SB05-0901. (1) Wintek water sealed liquid ring 15 ACFM vacuum system consisting of (1) Dekker vacuum pump, Model DVW0023KF1-01, driven by a 1.5 hp motor, Serial# L20500. With a heat exchanger, overflow tank, and knockout pot, frame mounted. (1) K-Tron BSP extruder feeder, Model K4GLBSP100. Approximate rating 30 pounds per hour, with (1) type SFT-III-500-N scale, and a KCM controller. (2) K-Tron side feeder feeders, Model KCL24KT20. Approximate rating 6 pounds per hour, each with agitated hoppers, Type K-SFS-24/6 scale, and a KCM controller. (1) Portable K-Tron.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory