Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Twin Screw Pelletizing Line to include: Coperion STS 65 twin screw extruder, Busch Cobra NC 0250 A vacuum pump, built 1999, Brabender FW80/5 plus 200 volumetric feeder, built 2012, Kreyenborg sc...

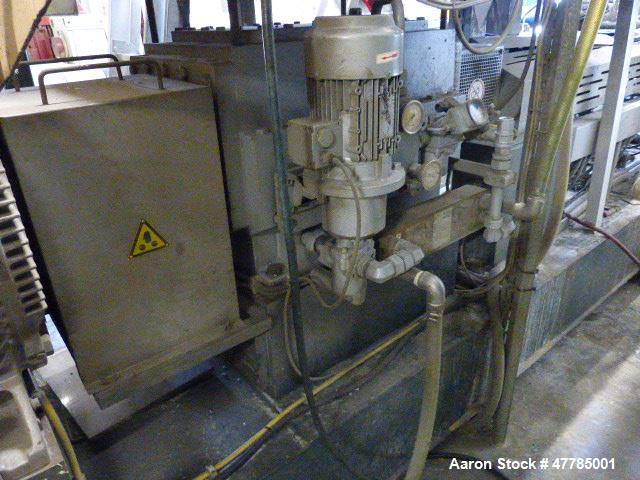

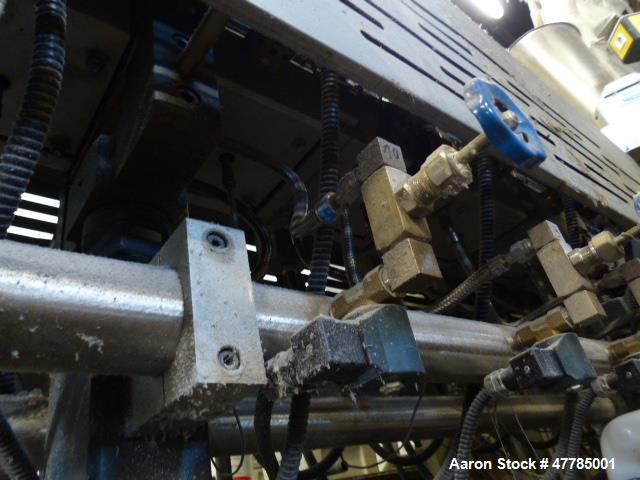

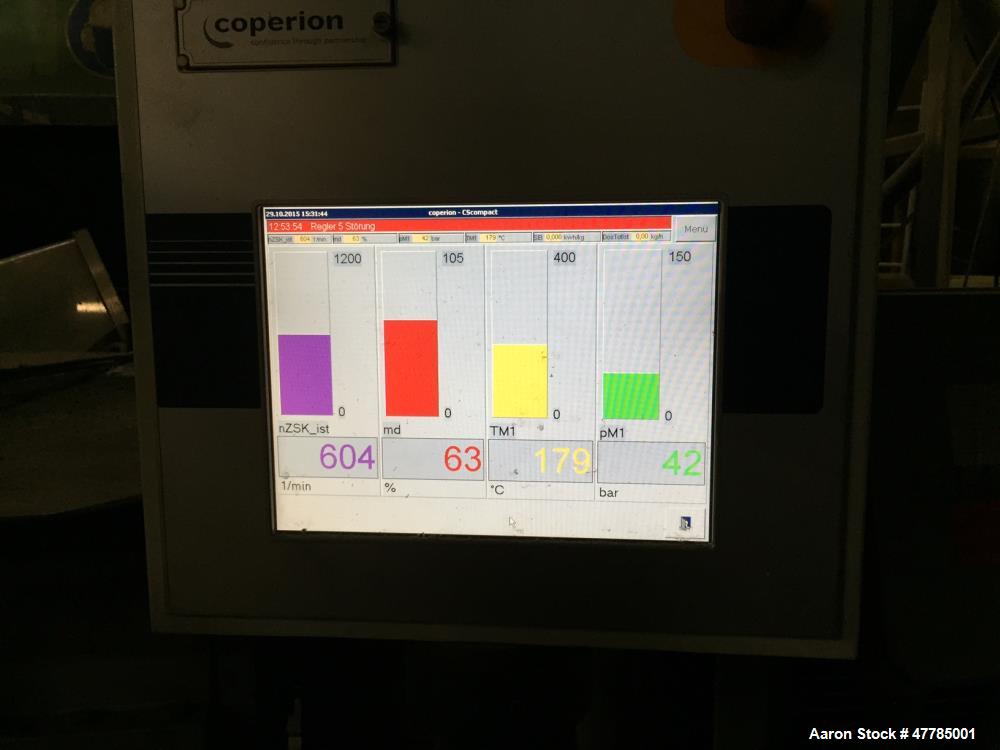

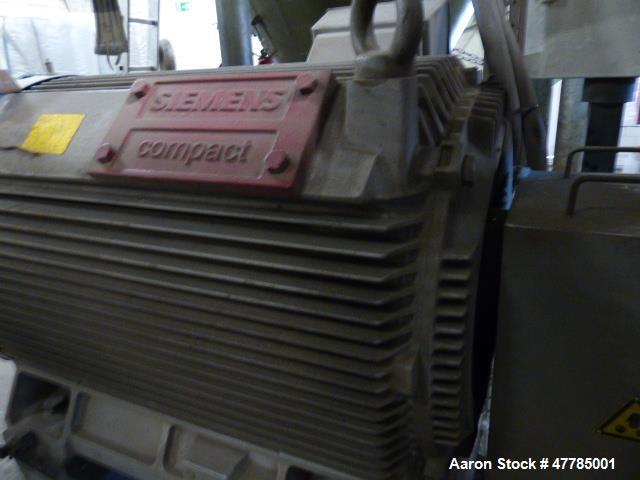

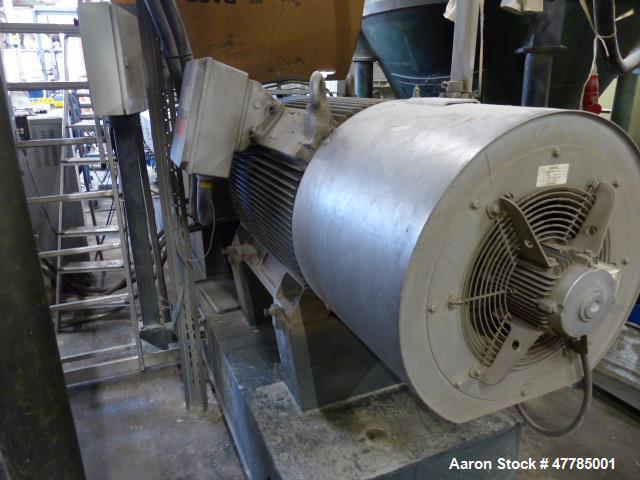

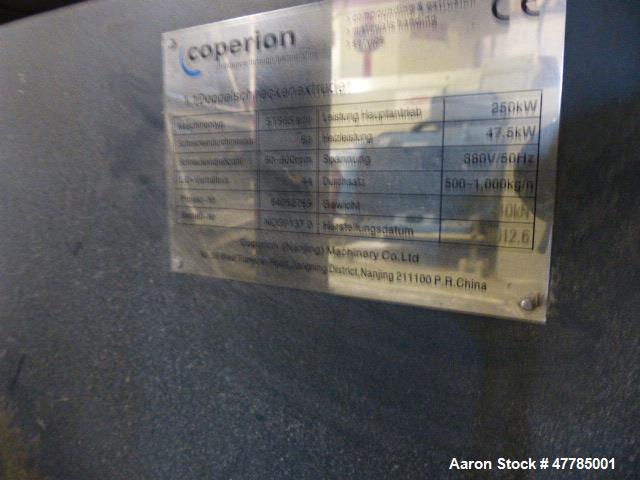

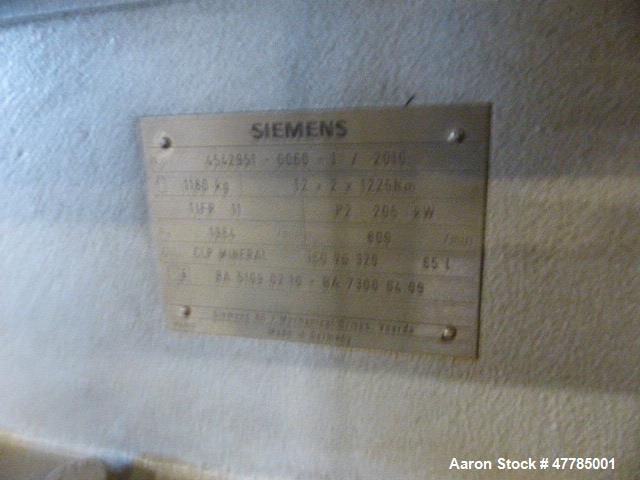

Used Twin Screw Pelletizing Line to include: Coperion STS 65 twin screw extruder, Busch Cobra NC 0250 A vacuum pump, built 1999, Brabender FW80/5 plus 200 volumetric feeder, built 2012, Kreyenborg screen changer and Artec water ring pelletizer. Extruder has 62mm diameter screws, 36:1 L/D ratio, co-rotating inter-meshing side by side screw design. 9 total barrel sections, (8) heated barrels, (1) feed, (2) open, (1) side feeder port. electrically heated water cooled, approximate 40.5" centerline height, driven by a 250 kw, 380 volt/ 1500 rpm motor with gear reducer. Screw speed maximum 800 rpm, throughput rate 500-1550 kg/h depending on process. Mfg. 2012. Kreyenborg screen changer is a model K-SWE-200-RS, built 1999. Artec water ring pelletizer is a model G50, built 2012.

Used Twin Screw Pelletizing Line to include: Coperion STS 65 twin screw extruder, Busch Cobra NC 0250 A vacuum pump, built 1999, Brabender FW80/5 plus 200 volumetric feeder, built 2012, Kreyenborg screen changer and Artec water ring pelletizer. Extruder has 62mm diameter screws, 36:1 L/D ratio, co-rotating inter-meshing side by side screw design. 9 total barrel sections, (8) heated barrels, (1) feed, (2) open, (1) side feeder port. electrically heated water cooled, approximate 40.5" centerline height, driven by a 250 kw, 380 volt/ 1500 rpm motor with gear reducer. Screw speed maximum 800 rpm, throughput rate 500-1550 kg/h depending on process. Mfg. 2012. Kreyenborg screen changer is a model K-SWE-200-RS, built 1999. Artec water ring pelletizer is a model G50, built 2012.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory