Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Leistritz Model Micro-27/GL-48D Twin Screw Extruder. Manufactured new in 2006. 27mm screw diameter segmented and arranged to 48:1 L/D ratio. 500 rpm max screw speed. Gearbox currently arranged f...

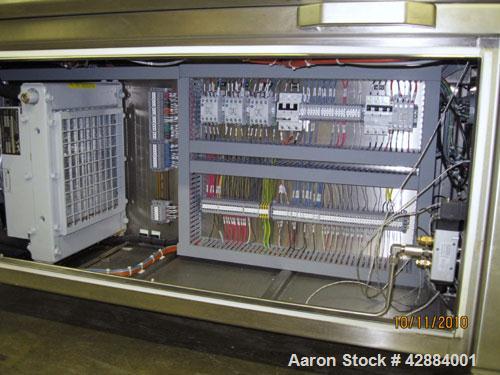

Used Leistritz Model Micro-27/GL-48D Twin Screw Extruder. Manufactured new in 2006. 27mm screw diameter segmented and arranged to 48:1 L/D ratio. 500 rpm max screw speed. Gearbox currently arranged for co-rotating design. Unit can be easily converted between co-rotation and counter- rotation, but to do so there will need to be a screw change (not included). The screw materials are upgraded and constructed of Hastelloy C276 with Stellite kneaders and lands. 14 barrel sections are also segmented and liners are upgrades to Alloy 60 and Inconel housings. They are electrically heated and water cooled. There is one feed opening and a liquid injection port included as well. Side feeder is a model LSB-24 driven by a 1/2 hp vari-speed motor thru gearbox. Liquid additive injection system to include pump and tank. Extruder is driven thru gearbox with an AC motor 15 hp, 460 volt, 1775-3565 rpm range. Temperature and drive controls are all unitized to the machine. Temperature controllers are Eurotherm digital auto-tune PID controllers. 270 hours of reported usage on meter. Entire machine is enshrouded in polished stainless steel covers having quick opening latches. Machine also includes (4) K-Tron Gravimetric feed system feeders and twin auger loss in weight feeders including hoppers and stands. System to include K-tron KSL multi-feeder display controller and control panel.

Used Leistritz Model Micro-27/GL-48D Twin Screw Extruder. Manufactured new in 2006. 27mm screw diameter segmented and arranged to 48:1 L/D ratio. 500 rpm max screw speed. Gearbox currently arranged for co-rotating design. Unit can be easily converted between co-rotation and counter- rotation, but to do so there will need to be a screw change (not included). The screw materials are upgraded and constructed of Hastelloy C276 with Stellite kneaders and lands. 14 barrel sections are also segmented and liners are upgrades to Alloy 60 and Inconel housings. They are electrically heated and water cooled. There is one feed opening and a liquid injection port included as well. Side feeder is a model LSB-24 driven by a 1/2 hp vari-speed motor thru gearbox. Liquid additive injection system to include pump and tank. Extruder is driven thru gearbox with an AC motor 15 hp, 460 volt, 1775-3565 rpm range. Temperature and drive controls are all unitized to the machine. Temperature controllers are Eurotherm digital auto-tune PID controllers. 270 hours of reported usage on meter. Entire machine is enshrouded in polished stainless steel covers having quick opening latches. Machine also includes (4) K-Tron Gravimetric feed system feeders and twin auger loss in weight feeders including hoppers and stands. System to include K-tron KSL multi-feeder display controller and control panel.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory