Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Entek 73 mm Co-Rotating Twin Screw Extruder, Model E-MAX 73MM 48L/D, 48 to 1 L/D ratio. (11) Barrel sections electrically heated, water cooled with system including pump, heat exchanger, and hol...

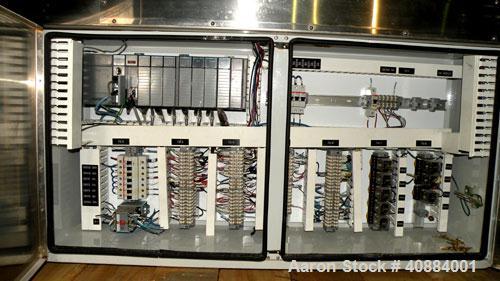

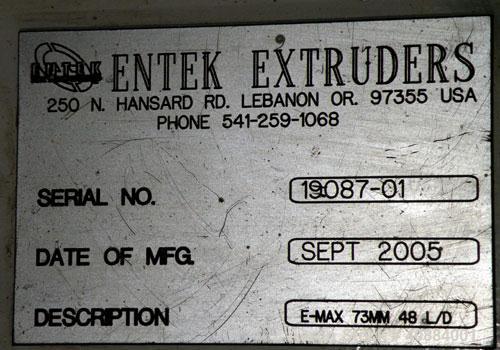

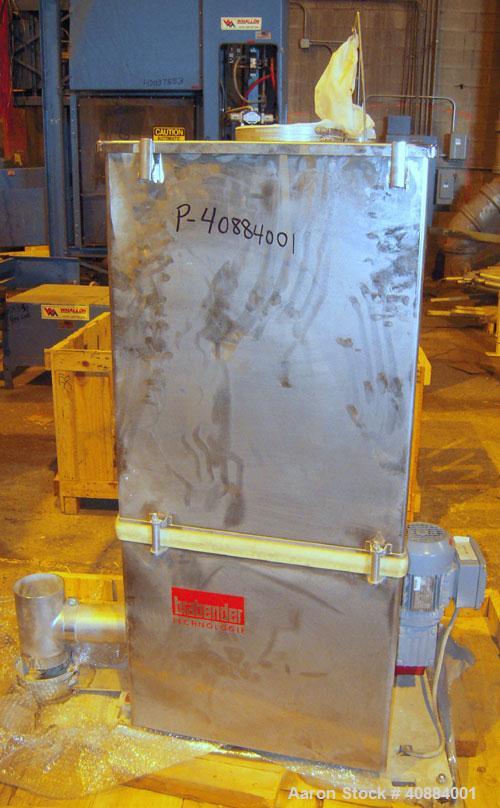

Used Entek 73 mm Co-Rotating Twin Screw Extruder, Model E-MAX 73MM 48L/D, 48 to 1 L/D ratio. (11) Barrel sections electrically heated, water cooled with system including pump, heat exchanger, and holding tank. (1) Water cooled feed section with hopper. (2) Spline shafts with 70mm elements, (40) conveying elements 120mm long, (14) conveying elements 45mm long, (4) large kneading elements 120mm long, (4) small kneading elements 60mm long, and (12) TME mixing elements 60mm long. Driven by a 300 hp, 60/460 volt, 1785 Inverter Duty Induction Motor thru a Henschel reducer. Includes (1) control panel with digital temperature controllers, (1) control panel with an ABB drive, serial# 19087-01, built 2005. (2) Entek 70mm vacuum stuffers, each driven by a 3hp gearmotor, (2) Entek 70mm side feeders, each driven by a 3hp gearmotor, mounted on cabinets with Reliance MD60 AC drives, and casters, (1) Brabender feeder, model DDW-H33-FW120//2-270, serial# W007040/4, built 2005, (1) Brabender feeder, model DDW-MD6-FW80/5 Plus-200, serial# W007040/1, built 2005, (3) Brabender feeder, model DDW-MD5-FW40/5 Plus-50, serial# W007040/2, /3, /5, built 2005, (1) Nash vacuum pump, model GL 60/7, serial# 05D0254, built 2005, includes tank, and heat exchanger, driven by a 20 hp motor, (1) Maag melt pump, model EX-110-4STE, driven by a 40hp, 3/60/230/460 volt, 1470 rpm motor thru a reducer, ratio 37.28 to 1, Includes an Allen Bradley Panel Mate, serial# 50072159-10, built 2005.

Used Entek 73 mm Co-Rotating Twin Screw Extruder, Model E-MAX 73MM 48L/D, 48 to 1 L/D ratio. (11) Barrel sections electrically heated, water cooled with system including pump, heat exchanger, and holding tank. (1) Water cooled feed section with hopper. (2) Spline shafts with 70mm elements, (40) conveying elements 120mm long, (14) conveying elements 45mm long, (4) large kneading elements 120mm long, (4) small kneading elements 60mm long, and (12) TME mixing elements 60mm long. Driven by a 300 hp, 60/460 volt, 1785 Inverter Duty Induction Motor thru a Henschel reducer. Includes (1) control panel with digital temperature controllers, (1) control panel with an ABB drive, serial# 19087-01, built 2005. (2) Entek 70mm vacuum stuffers, each driven by a 3hp gearmotor, (2) Entek 70mm side feeders, each driven by a 3hp gearmotor, mounted on cabinets with Reliance MD60 AC drives, and casters, (1) Brabender feeder, model DDW-H33-FW120//2-270, serial# W007040/4, built 2005, (1) Brabender feeder, model DDW-MD6-FW80/5 Plus-200, serial# W007040/1, built 2005, (3) Brabender feeder, model DDW-MD5-FW40/5 Plus-50, serial# W007040/2, /3, /5, built 2005, (1) Nash vacuum pump, model GL 60/7, serial# 05D0254, built 2005, includes tank, and heat exchanger, driven by a 20 hp motor, (1) Maag melt pump, model EX-110-4STE, driven by a 40hp, 3/60/230/460 volt, 1470 rpm motor thru a reducer, ratio 37.28 to 1, Includes an Allen Bradley Panel Mate, serial# 50072159-10, built 2005.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory