Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Pre-Owned Berstorff ZE62 x 44D Extruder – 62mm Twin Screw

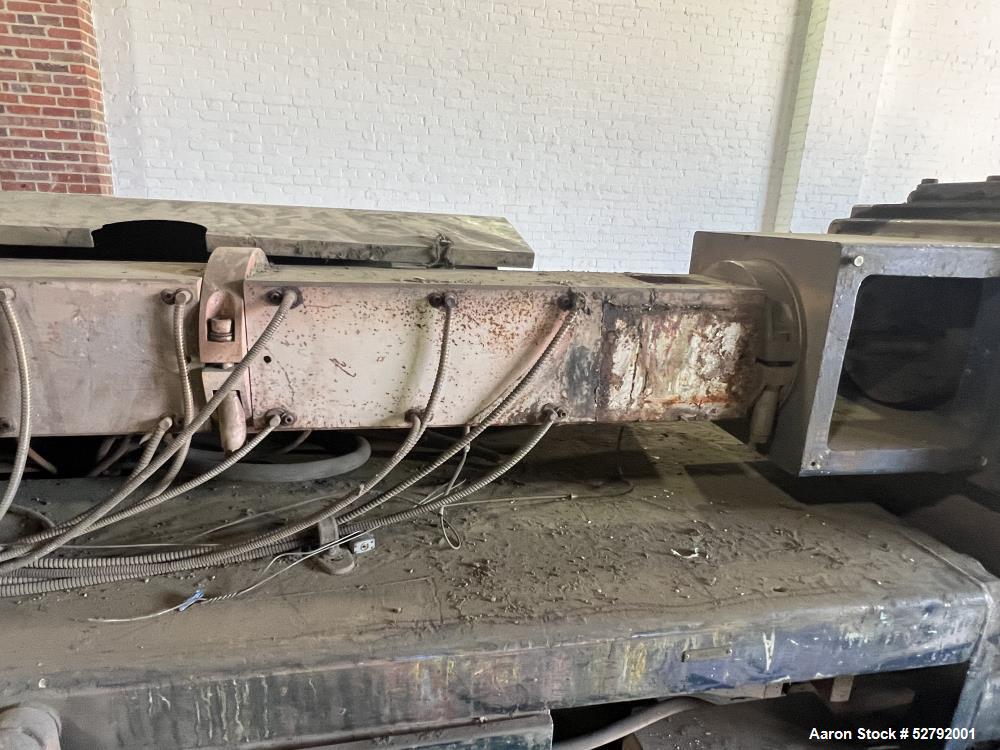

Used Berstorff ZE62 x 44D 62mm Twin Screw Extruder. Requires approximate 62mm x 104" long screws. 44/1 L/D. Electrically heated, water cooled. (9) barrel heating zones. Driven by Reliance AC 250 HP, 480/3/60 VAC, 3,000 RPM (limited to 242 HP). Flender gearbox, Year 2005, Serial# 4140712-0020-1, Ratio: 5:1. Control panel with Allen Bradley Drive PowerFlex 700S drive. Allen Bradley VersaView 1200P HMI. 4" X 4" Feed throat. Approximate 48" centerline height. Missing Screws.

Manufacturer Information:

- Brand: Berstorff

- Model: ZE62 x 44D

- Year: 2005

- Serial Number: 4140712-0020-1

Description:

The Berstorff ZE62 x 44D Twin Screw Extruder is a high-performance compounding extruder, ideal for plastics, polymers, and specialty materials processing. This unit features a 62mm barrel diameter with a 44:1 L/D ratio, providing efficient mixing, melting, and homogenization.

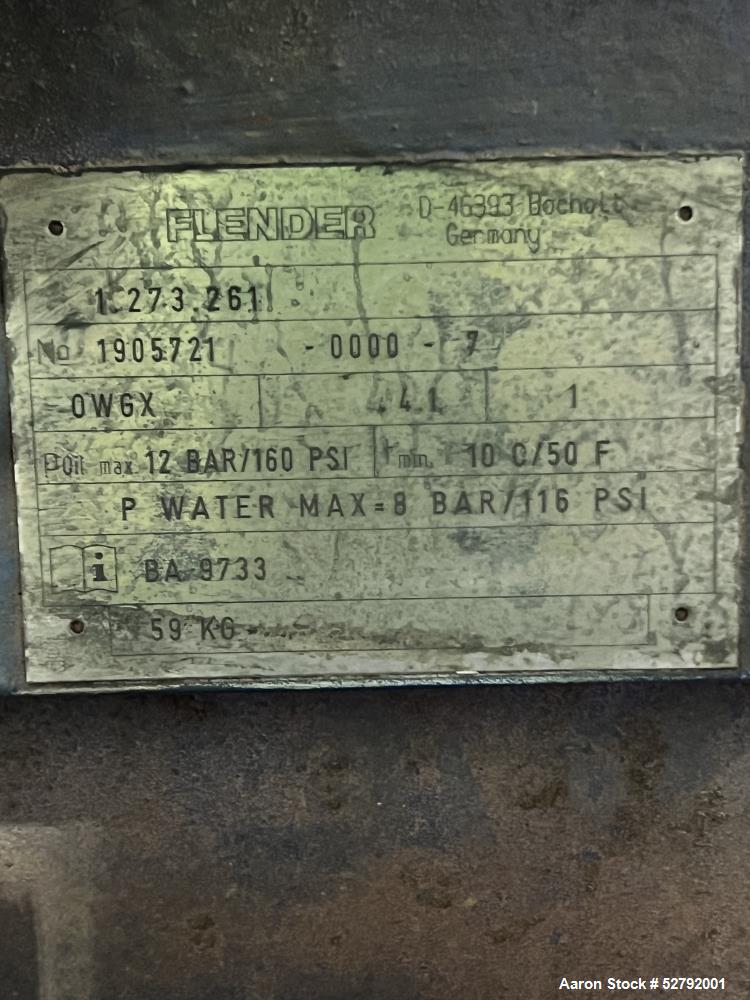

Equipped with electrical heating and water cooling, the extruder includes nine barrel heating zones, ensuring precise temperature control for optimized material processing. The system is driven by a Reliance AC 250 HP motor (480V, 3-phase, 60 Hz, 3,000 RPM, limited to 242 HP), paired with a Flender gearbox (5:1 ratio) for smooth operation.

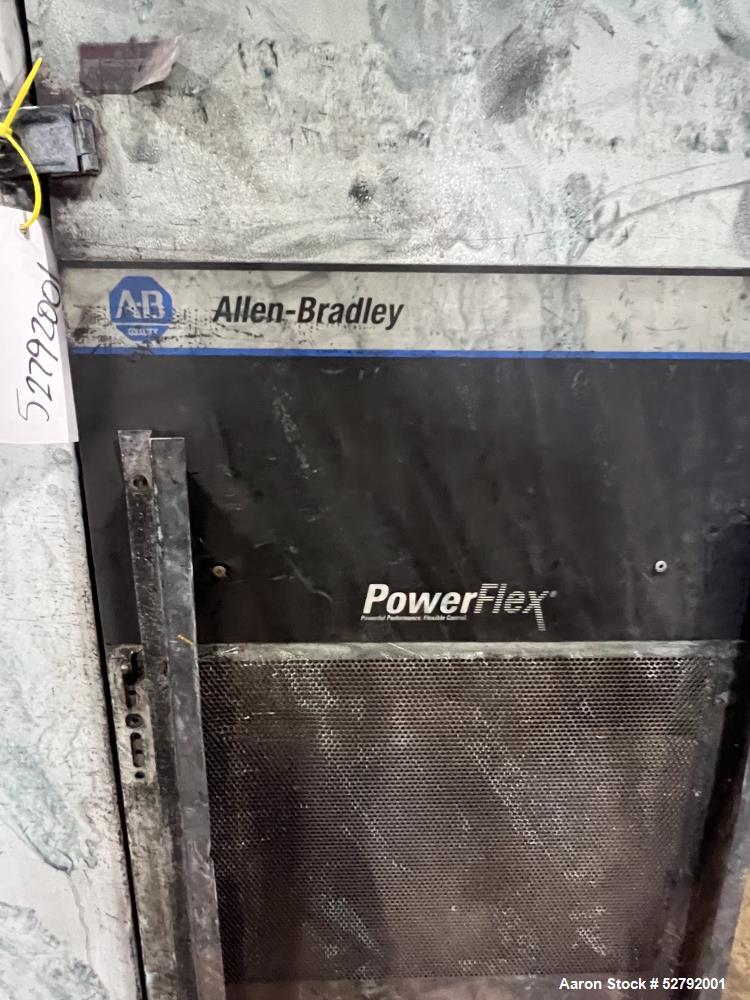

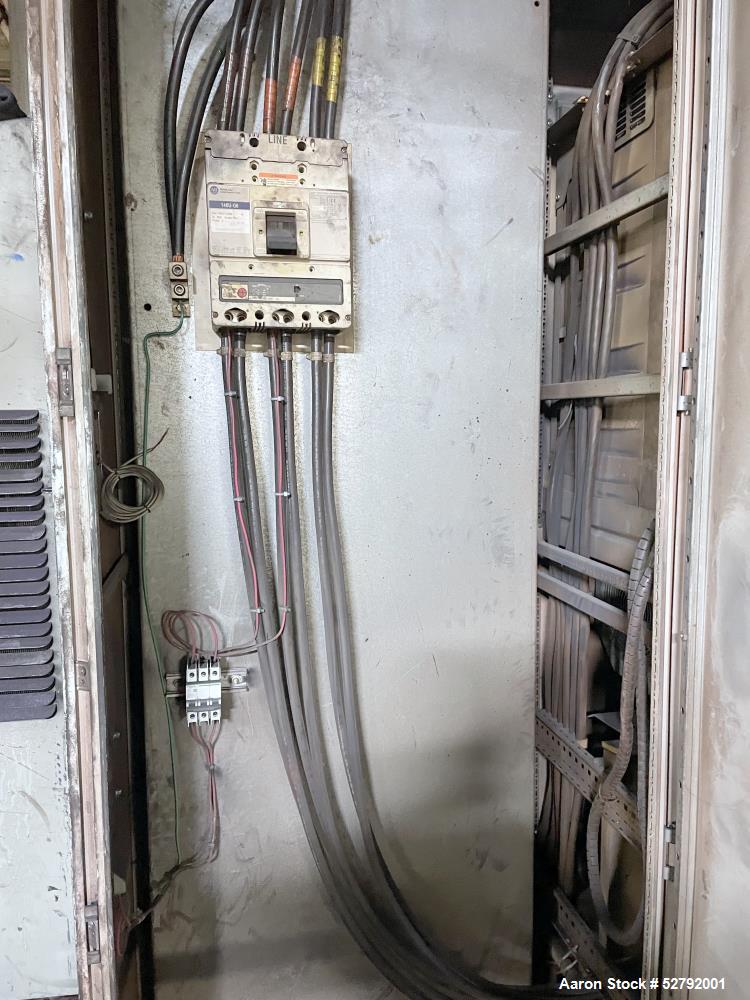

The extruder includes a control panel with an Allen Bradley PowerFlex 700S drive and an Allen Bradley VersaView 1200P HMI for precise process monitoring and control. It features a 4" x 4" feed throat and an approximate 48” centerline height for easy integration into production lines. Screws are missing.

Key Features:

- 62mm Barrel Diameter, 44:1 L/D Ratio

- Electrically Heated, Water-Cooled System

- Nine (9) Barrel Heating Zones for precise temperature control

- Reliance AC 250 HP Motor (480V, 3-Phase, 60Hz, 3,000 RPM, Limited to 242 HP)

- Flender Gearbox (Ratio 5:1) for smooth torque transmission

- Allen Bradley PowerFlex 700S Drive for motor control

- Allen Bradley VersaView 1200P HMI for process monitoring

- 4” x 4” Feed Throat for material input

- Approximate 48” Centerline Height

- Missing Screws – Requires replacement

Specifications:

- Machine Type: Twin Screw Extruder

- Brand: Berstorff

- Model: ZE62 x 44D

- Year: 2005

- Screw Diameter: 62mm (Requires New Screws)

- L/D Ratio: 44:1

- Heating Zones: 9 Electrically Heated Barrel Zones

- Cooling System: Water-Cooled

- Motor: Reliance AC 250 HP, 480V, 3-Phase, 60Hz, 3,000 RPM (Limited to 242 HP)

- Gearbox: Flender Gearbox, 5:1 Ratio

- Feed Throat: 4” x 4”

- Control System:

- Allen Bradley PowerFlex 700S Drive

- Allen Bradley VersaView 1200P HMI

- Centerline Height: Approx. 48”

- Serial Number: 4140712-0020-1

- Condition: Missing Screws

Applications:

- Plastics Processing: Compounding, masterbatch, polymer blending

- Chemical Industry: Specialty material processing and mixing

- Pharmaceutical Extrusion: Drug formulation and controlled release processing

- Food Processing: Extrusion of food-grade polymers and additives

- Recycling & Sustainability: Reprocessing of plastic waste and bio-based materials

What Products Would This Be Used For?

- Polymer and plastic compounding

- Thermoplastic elastomers (TPE) and thermoset processing

- Color masterbatch and additive compounding

- Biopolymer and biodegradable plastic production

- Chemical extrusion and industrial material processing

- Berstorff ZE62 x 44D extruder

- Used twin screw extruder

- Industrial plastic extruder

- 62mm compounding extruder

- High-performance extrusion system

- Used Berstorff extruder for sale

- Polymer processing machine

- 250 HP twin screw extruder

- Allen Bradley controlled extruder

- Missing screws twin screw extruder

- Used Berstorff ZE62 x 44D twin screw extruder for sale

- High-performance industrial extrusion machine with 62mm barrel

- Pre-owned Berstorff extruder with Allen Bradley control system

- Used polymer compounding extruder with water cooling system

- Twin screw plastic extruder with 44:1 L/D ratio and 250 HP motor

- Berstorff ZE62 twin screw extruder for chemical and material processing

- Used extrusion equipment with Flender gearbox and nine heating zones

- Large-scale plastic extrusion machine for polymer blending applications

- Missing screw extruder for repurposing in compounding industries

- Reliable used Berstorff extruder for masterbatch and polymer processing

- Used Berstorff ZE62 x 44D twin screw extruder with 62mm barrel and 250 HP motor

- Industrial twin screw extruder with Allen Bradley PowerFlex drive and VersaView HMI

- Buy a pre-owned Berstorff ZE62 extruder for high-performance polymer processing

- High-efficiency compounding extruder with water-cooled system and 44:1 L/D ratio

- Used Berstorff twin screw extruder with nine barrel heating zones and missing screws

- Large-capacity industrial extruder for plastic recycling and polymer formulation

- Cost-effective used extrusion machine for chemical and specialty material processing

- Pre-owned high-output twin screw extruder for thermoplastics and elastomers

- Used plastic compounding extruder with 62mm barrel and 4" x 4" feed throat

- Reliable industrial extrusion system for sustainable plastic and bio-based materials

- Used Berstorff twin screw extruder for sale

- Industrial 62mm plastic extrusion machine

- High-performance polymer compounding extruder

- Buy used Berstorff extruder

- Twin screw extruder with 250 HP motor

- Pre-owned industrial plastic extruder

- Large-scale compounding extruder for sale

- Water-cooled twin screw extrusion system

- Used masterbatch extrusion equipment

- Affordable used industrial extruder

- Buy used Berstorff ZE62 x 44D twin screw extruder

- Sell industrial polymer processing extruders

- Used twin screw extruder for sale

- Where to buy industrial extrusion equipment

- Best extrusion machine for polymer compounding

- Affordable used Berstorff extruder pricing

- Used plastic compounding equipment availability

- Buy pre-owned polymer processing extruder

- Reliable used twin screw extrusion system for sale

- High-output extrusion equipment for industrial material processing

- Used Plastics Equipment

- Used Plastics Extrusion Equipment

- Plastics Equipment

- Extrusion

- Twin Screw Extruder

- Used Extruder

- Used Plastics Extruder

Used Berstorff ZE62 x 44D 62mm Twin Screw Extruder. Requires approximate 62mm x 104" long screws. 44/1 L/D. Electrically heated, water cooled. (9) barrel heating zones. Driven by Reliance AC 250 HP, 480/3/60 VAC, 3,000 RPM (limited to 242 HP). Flender gearbox, Year 2005, Serial# 4140712-0020-1, Ratio: 5:1. Control panel with Allen Bradley Drive PowerFlex 700S drive. Allen Bradley VersaView 1200P HMI. 4" X 4" Feed throat. Approximate 48" centerline height. Missing Screws.

Manufacturer Information:

- Brand: Berstorff

- Model: ZE62 x 44D

- Year: 2005

- Serial Number: 4140712-0020-1

Description:

The Berstorff ZE62 x 44D Twin Screw Extruder is a high-performance compounding extruder, ideal for plastics, polymers, and specialty materials processing. This unit features a 62mm barrel diameter with a 44:1 L/D ratio, providing efficient mixing, melting, and homogenization.

Equipped with electrical heating and water cooling, the extruder includes nine barrel heating zones, ensuring precise temperature control for optimized material processing. The system is driven by a Reliance AC 250 HP motor (480V, 3-phase, 60 Hz, 3,000 RPM, limited to 242 HP), paired with a Flender gearbox (5:1 ratio) for smooth operation.

The extruder includes a control panel with an Allen Bradley PowerFlex 700S drive and an Allen Bradley VersaView 1200P HMI for precise process monitoring and control. It features a 4" x 4" feed throat and an approximate 48” centerline height for easy integration into production lines. Screws are missing.

Key Features:

- 62mm Barrel Diameter, 44:1 L/D Ratio

- Electrically Heated, Water-Cooled System

- Nine (9) Barrel Heating Zones for precise temperature control

- Reliance AC 250 HP Motor (480V, 3-Phase, 60Hz, 3,000 RPM, Limited to 242 HP)

- Flender Gearbox (Ratio 5:1) for smooth torque transmission

- Allen Bradley PowerFlex 700S Drive for motor control

- Allen Bradley VersaView 1200P HMI for process monitoring

- 4” x 4” Feed Throat for material input

- Approximate 48” Centerline Height

- Missing Screws – Requires replacement

Specifications:

- Machine Type: Twin Screw Extruder

- Brand: Berstorff

- Model: ZE62 x 44D

- Year: 2005

- Screw Diameter: 62mm (Requires New Screws)

- L/D Ratio: 44:1

- Heating Zones: 9 Electrically Heated Barrel Zones

- Cooling System: Water-Cooled

- Motor: Reliance AC 250 HP, 480V, 3-Phase, 60Hz, 3,000 RPM (Limited to 242 HP)

- Gearbox: Flender Gearbox, 5:1 Ratio

- Feed Throat: 4” x 4”

- Control System:

- Allen Bradley PowerFlex 700S Drive

- Allen Bradley VersaView 1200P HMI

- Centerline Height: Approx. 48”

- Serial Number: 4140712-0020-1

- Condition: Missing Screws

Applications:

- Plastics Processing: Compounding, masterbatch, polymer blending

- Chemical Industry: Specialty material processing and mixing

- Pharmaceutical Extrusion: Drug formulation and controlled release processing

- Food Processing: Extrusion of food-grade polymers and additives

- Recycling & Sustainability: Reprocessing of plastic waste and bio-based materials

What Products Would This Be Used For?

- Polymer and plastic compounding

- Thermoplastic elastomers (TPE) and thermoset processing

- Color masterbatch and additive compounding

- Biopolymer and biodegradable plastic production

- Chemical extrusion and industrial material processing

- Berstorff ZE62 x 44D extruder

- Used twin screw extruder

- Industrial plastic extruder

- 62mm compounding extruder

- High-performance extrusion system

- Used Berstorff extruder for sale

- Polymer processing machine

- 250 HP twin screw extruder

- Allen Bradley controlled extruder

- Missing screws twin screw extruder

- Used Berstorff ZE62 x 44D twin screw extruder for sale

- High-performance industrial extrusion machine with 62mm barrel

- Pre-owned Berstorff extruder with Allen Bradley control system

- Used polymer compounding extruder with water cooling system

- Twin screw plastic extruder with 44:1 L/D ratio and 250 HP motor

- Berstorff ZE62 twin screw extruder for chemical and material processing

- Used extrusion equipment with Flender gearbox and nine heating zones

- Large-scale plastic extrusion machine for polymer blending applications

- Missing screw extruder for repurposing in compounding industries

- Reliable used Berstorff extruder for masterbatch and polymer processing

- Used Berstorff ZE62 x 44D twin screw extruder with 62mm barrel and 250 HP motor

- Industrial twin screw extruder with Allen Bradley PowerFlex drive and VersaView HMI

- Buy a pre-owned Berstorff ZE62 extruder for high-performance polymer processing

- High-efficiency compounding extruder with water-cooled system and 44:1 L/D ratio

- Used Berstorff twin screw extruder with nine barrel heating zones and missing screws

- Large-capacity industrial extruder for plastic recycling and polymer formulation

- Cost-effective used extrusion machine for chemical and specialty material processing

- Pre-owned high-output twin screw extruder for thermoplastics and elastomers

- Used plastic compounding extruder with 62mm barrel and 4" x 4" feed throat

- Reliable industrial extrusion system for sustainable plastic and bio-based materials

- Used Berstorff twin screw extruder for sale

- Industrial 62mm plastic extrusion machine

- High-performance polymer compounding extruder

- Buy used Berstorff extruder

- Twin screw extruder with 250 HP motor

- Pre-owned industrial plastic extruder

- Large-scale compounding extruder for sale

- Water-cooled twin screw extrusion system

- Used masterbatch extrusion equipment

- Affordable used industrial extruder

- Buy used Berstorff ZE62 x 44D twin screw extruder

- Sell industrial polymer processing extruders

- Used twin screw extruder for sale

- Where to buy industrial extrusion equipment

- Best extrusion machine for polymer compounding

- Affordable used Berstorff extruder pricing

- Used plastic compounding equipment availability

- Buy pre-owned polymer processing extruder

- Reliable used twin screw extrusion system for sale

- High-output extrusion equipment for industrial material processing

- Used Plastics Equipment

- Used Plastics Extrusion Equipment

- Plastics Equipment

- Extrusion

- Twin Screw Extruder

- Used Extruder

- Used Plastics Extruder

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory