Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Farrel 37mm Co-Rotating Twin Screw Extruder, Model FTX80H

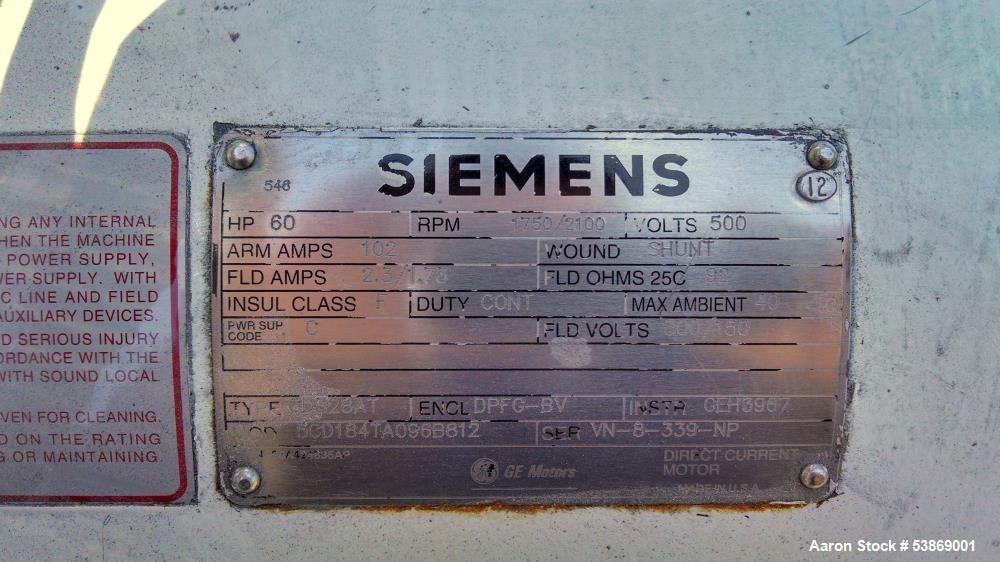

Used Farrel 37mm Co-Rotating Twin Screw Extruder, Model FTX80H. Co-rotating screw design. Approximately 40 to 1 L/D ratio. 9 barrel segments, 1 feed section, no hopper. Electrically heated, 370 degrees C, water cooled. Driven by a 60 hp, 500 volt, 1750/2100 rpm DC motor. Flender reducer. Approximately 41" centerline height. Includes a 4 1/2" wide slot die, a Mokon model DB4J00N9 temperature contoller, an operator pedestal control panel with a touchview panel, and a Siemens Simoreg drive. Built 2005.

Manufacturer Information:

- Brand: Farrel

- Model: FTX80H

- Year Built: 2005

Description:

The Farrel 37mm Co-Rotating Twin Screw Extruder, Model FTX80H, is designed for high-performance processing applications. With a co-rotating screw design and an approximately 40:1 L/D ratio, this extruder offers precise compounding and material blending capabilities. It features nine barrel segments and one feed section without a hopper, allowing for flexible material handling. The system is electrically heated and water-cooled for efficient temperature control.

Powered by a 60 HP, 500-volt DC motor with speeds of 1750/2100 rpm, the extruder is equipped with a Flender reducer for optimal torque transmission. The 41” centerline height allows for integration into various production lines. Additional components include a 4 ½” wide slot die, a Mokon model DB4J00N9 temperature controller, an operator pedestal control panel with a touchview interface, and a Siemens Simoreg drive for precise process control.

Specifications:

- Screw Diameter: 37mm

- Screw Type: Co-rotating twin screw

- L/D Ratio: ~40:1

- Barrel Segments: 9

- Feed Section: 1 (no hopper)

- Heating Method: Electrical

- Cooling Method: Water-cooled

- Motor: 60 HP, 500V DC, 1750/2100 rpm

- Reducer: Flender

- Centerline Height: 41”

- Die Included: 4 ½” wide slot die

- Temperature Controller: Mokon model DB4J00N9

- Control Panel: Operator pedestal with touchview panel

- Drive System: Siemens Simoreg

Applications:

The Farrel FTX80H Twin Screw Extruder is ideal for various industrial applications, including:

- Plastic compounding (masterbatch production, filler reinforcement)

- Polymer blending and alloying

- Reactive extrusion processes

- Biopolymer and biodegradable material processing

- Adhesives and sealant production

- Extrusion of engineered thermoplastics

- Food and pharmaceutical extrusion

- Chemical and industrial material processing

Compatible Products:

This extruder can be used for manufacturing or processing:

- Thermoplastic elastomers (TPE, TPU, TPO)

- Polypropylene (PP) and polyethylene (PE) compounds

- Engineering plastics (ABS, PC, PEEK, Nylon, etc.)

- Biodegradable plastics (PLA, PBAT, etc.)

- Filled and reinforced composites

- Pigment and additive masterbatches

- Specialty polymers and chemical formulations

- High-viscosity adhesive and sealant materials

- Farrel twin screw extruder

- Co-rotating extruder

- 37mm twin screw extruder

- Industrial extrusion machine

- Polymer processing extruder

- High-performance compounding

- Plastic extrusion equipment

- Siemens Simoreg drive extruder

- Twin screw extruder for plastic compounding

- Farrel FTX80H extrusion system

- 37mm co-rotating twin screw extruder

- Industrial extruder with Flender reducer

- High-torque polymer extrusion machine

- Temperature-controlled extrusion system

- Masterbatch production extruder

- Custom polymer processing extruder

- Used Farrel twin screw extruder with Siemens Simoreg drive

- High-performance 37mm co-rotating extruder for polymer blending

- Industrial compounding extruder with Flender reducer and Mokon controller

- Electrically heated and water-cooled twin screw extrusion system

- 60 HP DC motor-driven co-rotating extruder for engineered plastics

- Customizable extrusion machine for adhesive and sealant production

- Specialty polymer compounding extruder with touchview panel control

- High-L/D ratio extruder for thermoplastic processing

Used Farrel 37mm Co-Rotating Twin Screw Extruder, Model FTX80H. Co-rotating screw design. Approximately 40 to 1 L/D ratio. 9 barrel segments, 1 feed section, no hopper. Electrically heated, 370 degrees C, water cooled. Driven by a 60 hp, 500 volt, 1750/2100 rpm DC motor. Flender reducer. Approximately 41" centerline height. Includes a 4 1/2" wide slot die, a Mokon model DB4J00N9 temperature contoller, an operator pedestal control panel with a touchview panel, and a Siemens Simoreg drive. Built 2005.

Manufacturer Information:

- Brand: Farrel

- Model: FTX80H

- Year Built: 2005

Description:

The Farrel 37mm Co-Rotating Twin Screw Extruder, Model FTX80H, is designed for high-performance processing applications. With a co-rotating screw design and an approximately 40:1 L/D ratio, this extruder offers precise compounding and material blending capabilities. It features nine barrel segments and one feed section without a hopper, allowing for flexible material handling. The system is electrically heated and water-cooled for efficient temperature control.

Powered by a 60 HP, 500-volt DC motor with speeds of 1750/2100 rpm, the extruder is equipped with a Flender reducer for optimal torque transmission. The 41” centerline height allows for integration into various production lines. Additional components include a 4 ½” wide slot die, a Mokon model DB4J00N9 temperature controller, an operator pedestal control panel with a touchview interface, and a Siemens Simoreg drive for precise process control.

Specifications:

- Screw Diameter: 37mm

- Screw Type: Co-rotating twin screw

- L/D Ratio: ~40:1

- Barrel Segments: 9

- Feed Section: 1 (no hopper)

- Heating Method: Electrical

- Cooling Method: Water-cooled

- Motor: 60 HP, 500V DC, 1750/2100 rpm

- Reducer: Flender

- Centerline Height: 41”

- Die Included: 4 ½” wide slot die

- Temperature Controller: Mokon model DB4J00N9

- Control Panel: Operator pedestal with touchview panel

- Drive System: Siemens Simoreg

Applications:

The Farrel FTX80H Twin Screw Extruder is ideal for various industrial applications, including:

- Plastic compounding (masterbatch production, filler reinforcement)

- Polymer blending and alloying

- Reactive extrusion processes

- Biopolymer and biodegradable material processing

- Adhesives and sealant production

- Extrusion of engineered thermoplastics

- Food and pharmaceutical extrusion

- Chemical and industrial material processing

Compatible Products:

This extruder can be used for manufacturing or processing:

- Thermoplastic elastomers (TPE, TPU, TPO)

- Polypropylene (PP) and polyethylene (PE) compounds

- Engineering plastics (ABS, PC, PEEK, Nylon, etc.)

- Biodegradable plastics (PLA, PBAT, etc.)

- Filled and reinforced composites

- Pigment and additive masterbatches

- Specialty polymers and chemical formulations

- High-viscosity adhesive and sealant materials

- Farrel twin screw extruder

- Co-rotating extruder

- 37mm twin screw extruder

- Industrial extrusion machine

- Polymer processing extruder

- High-performance compounding

- Plastic extrusion equipment

- Siemens Simoreg drive extruder

- Twin screw extruder for plastic compounding

- Farrel FTX80H extrusion system

- 37mm co-rotating twin screw extruder

- Industrial extruder with Flender reducer

- High-torque polymer extrusion machine

- Temperature-controlled extrusion system

- Masterbatch production extruder

- Custom polymer processing extruder

- Used Farrel twin screw extruder with Siemens Simoreg drive

- High-performance 37mm co-rotating extruder for polymer blending

- Industrial compounding extruder with Flender reducer and Mokon controller

- Electrically heated and water-cooled twin screw extrusion system

- 60 HP DC motor-driven co-rotating extruder for engineered plastics

- Customizable extrusion machine for adhesive and sealant production

- Specialty polymer compounding extruder with touchview panel control

- High-L/D ratio extruder for thermoplastic processing

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory