Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

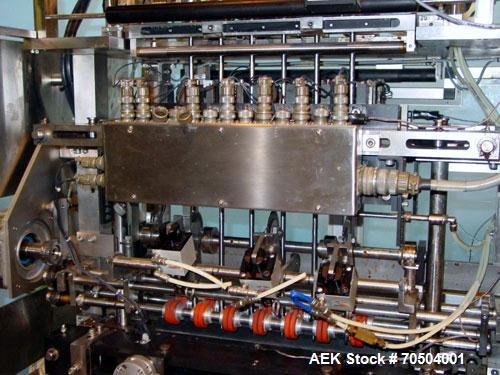

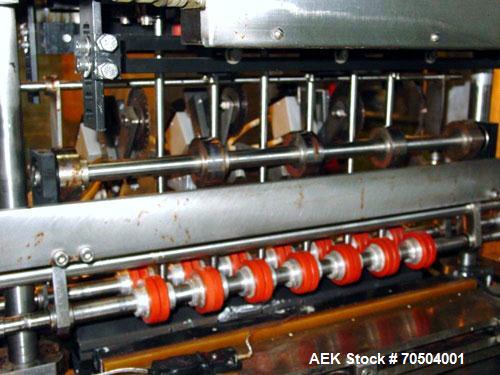

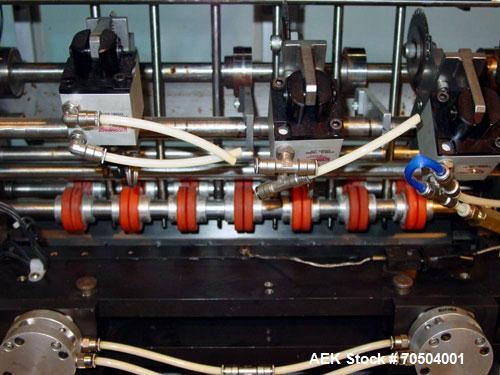

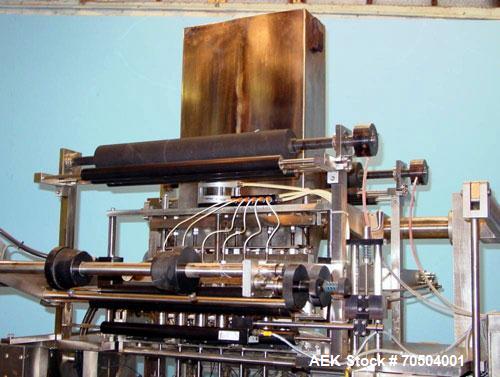

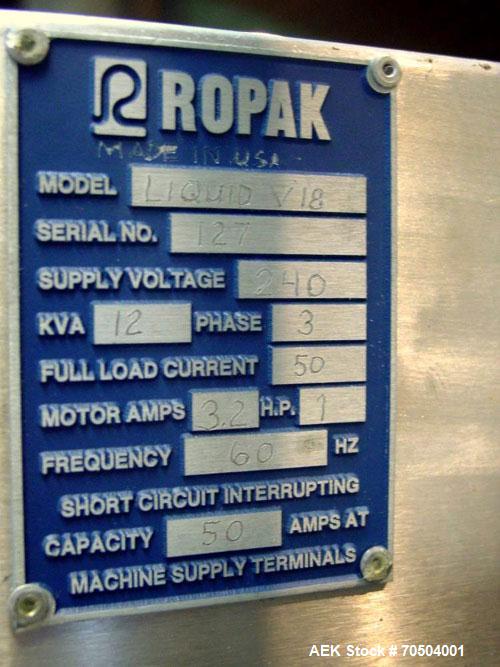

Used Ropak Model Liquid 18-V (6) Head VFFS Pouch Filler. For single or dual packs, for 1/4 oz to 1 oz pouches of gels, conditioners, shampoo, ointments and creams.3 - 6 up configuration in a 4 sided ...

Used Ropak Model Liquid 18-V (6) Head VFFS Pouch Filler. For single or dual packs, for 1/4 oz to 1 oz pouches of gels, conditioners, shampoo, ointments and creams.3 - 6 up configuration in a 4 sided seal dual pouchnow tooled for 3 x 118 mm wide x 130 mmlong w/ (6) 1/4" OD stainless steel nozzles, (3) vertical cutting wheels, 18" wide horizontal seal bar with knife, 20" with stainless steel discharge chute, (7) sets of film pull down wheels, 21" wide bulk film rollers, 15" x 6" x 30" deep stainless steel divided feed hopper, cam controlled piston pump assembly, servo controlled web advance with photo-electric controlled front& back web registration, pneumatically controlled seal assemblies, Ppneumatically operated cut-off and rotary valve, one rotary perforation blade assembly to perforate between the dual pouches, one corner spout with side seal nick for easy opening, one set of plunger style fill tubes with air blow off. Heavy duty stainless steel and bar stock frame, stainless steel wash down electrical enclosures, all product contact surfaces are stainless steel or food grade plastics. Programmable controller with push button touch pad, air requirement 100 psi at 15 scfm.Maximum film roll diameter of 20" with 3" core ID, heat sealable film composite-foil, PET/LDPE-white/A1/EAA/LLDPE-F.Production rate speed of 30+ cycles/min.230V, 3 phase, 60 hz.Rebuilt by Ropak in 2001, never installed.

Used Ropak Model Liquid 18-V (6) Head VFFS Pouch Filler. For single or dual packs, for 1/4 oz to 1 oz pouches of gels, conditioners, shampoo, ointments and creams.3 - 6 up configuration in a 4 sided seal dual pouchnow tooled for 3 x 118 mm wide x 130 mmlong w/ (6) 1/4" OD stainless steel nozzles, (3) vertical cutting wheels, 18" wide horizontal seal bar with knife, 20" with stainless steel discharge chute, (7) sets of film pull down wheels, 21" wide bulk film rollers, 15" x 6" x 30" deep stainless steel divided feed hopper, cam controlled piston pump assembly, servo controlled web advance with photo-electric controlled front& back web registration, pneumatically controlled seal assemblies, Ppneumatically operated cut-off and rotary valve, one rotary perforation blade assembly to perforate between the dual pouches, one corner spout with side seal nick for easy opening, one set of plunger style fill tubes with air blow off. Heavy duty stainless steel and bar stock frame, stainless steel wash down electrical enclosures, all product contact surfaces are stainless steel or food grade plastics. Programmable controller with push button touch pad, air requirement 100 psi at 15 scfm.Maximum film roll diameter of 20" with 3" core ID, heat sealable film composite-foil, PET/LDPE-white/A1/EAA/LLDPE-F.Production rate speed of 30+ cycles/min.230V, 3 phase, 60 hz.Rebuilt by Ropak in 2001, never installed.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory