Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Complete Flexline Frozen Meal Kitchen and Assembly Production Line. Accuracy: Precision meal component placement within a tray. Variety: 11 depositing stations for meal components, sauce, glaze ...

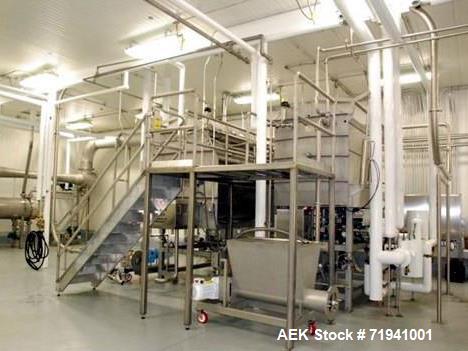

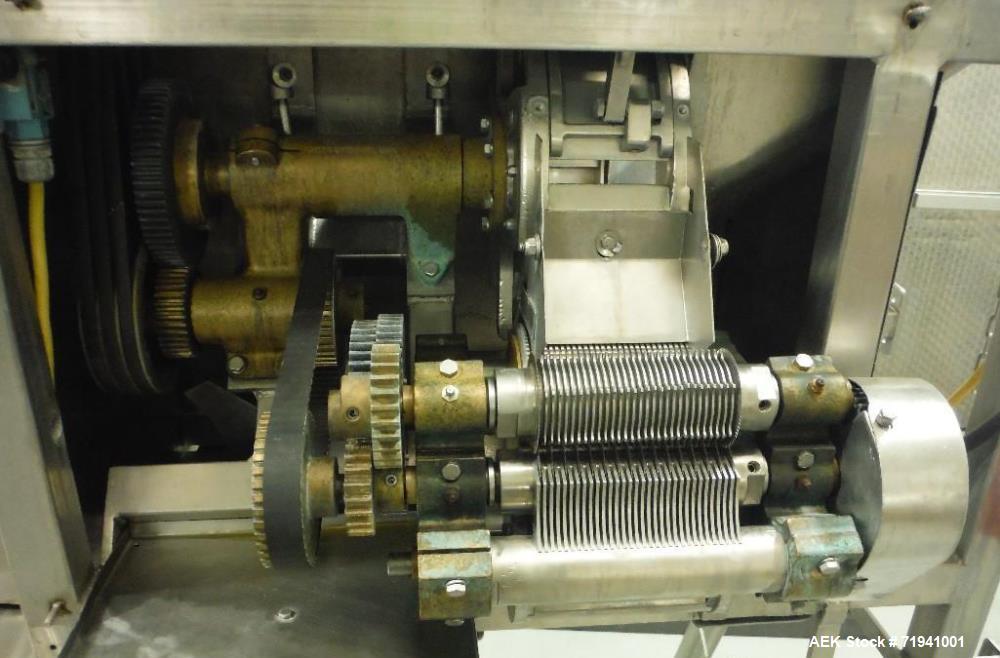

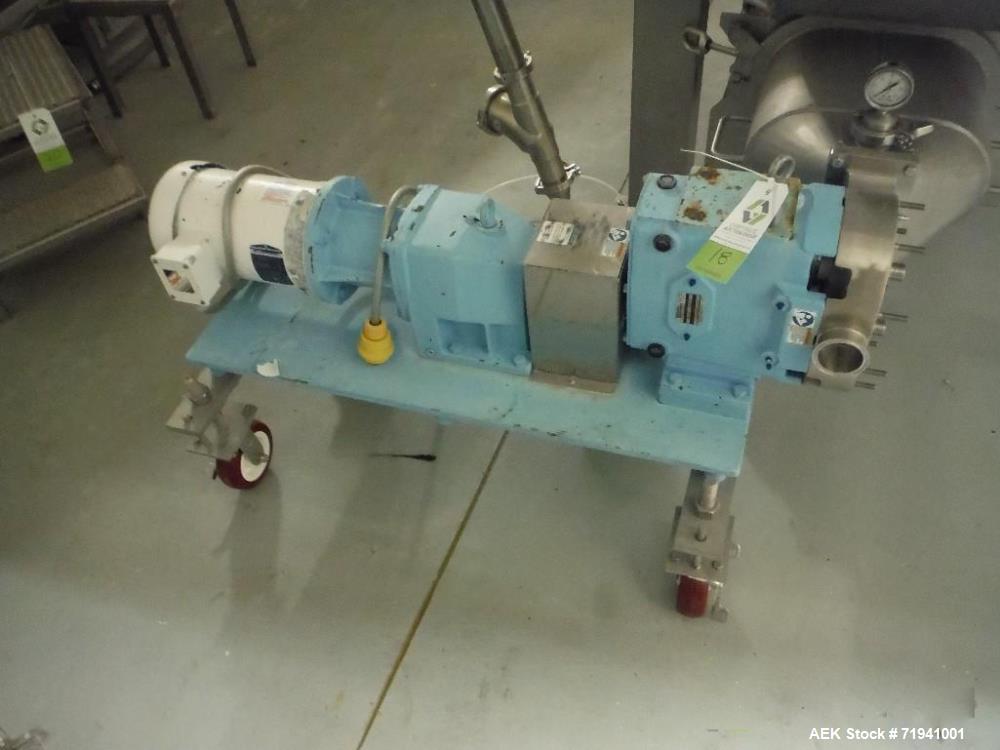

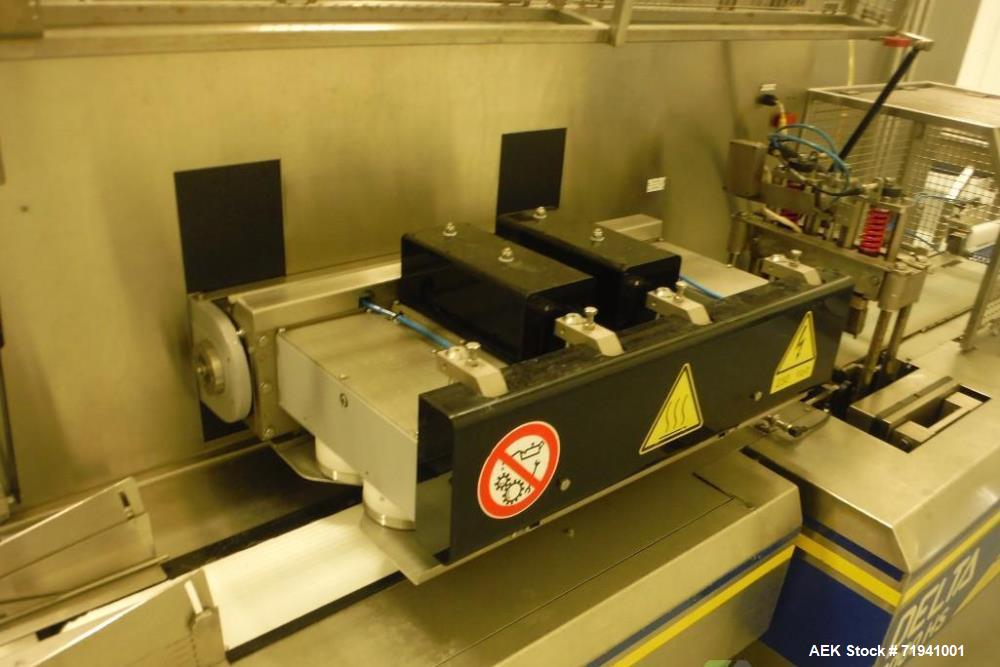

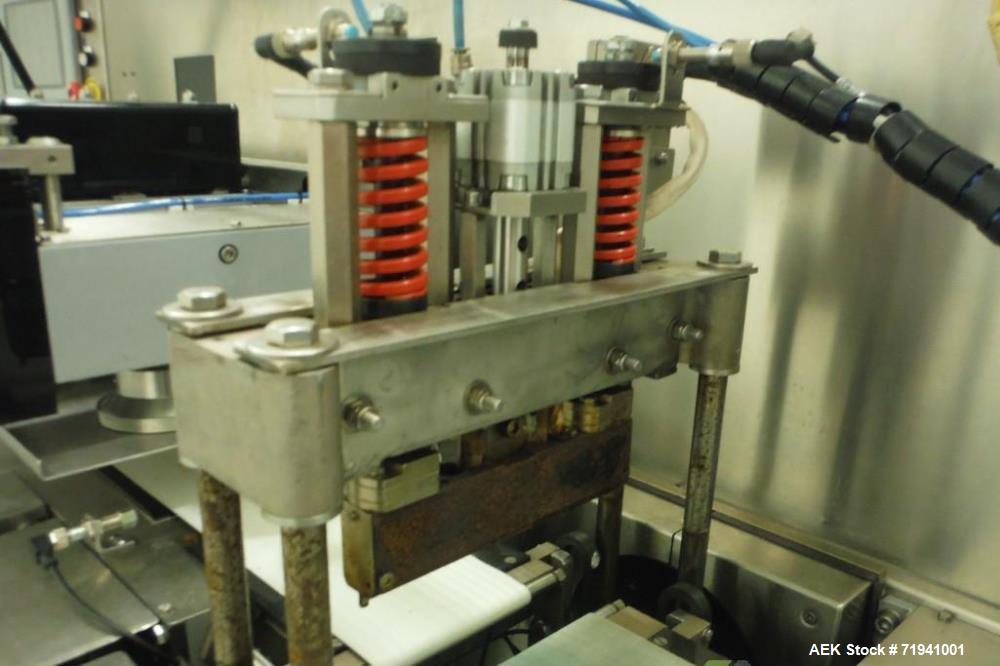

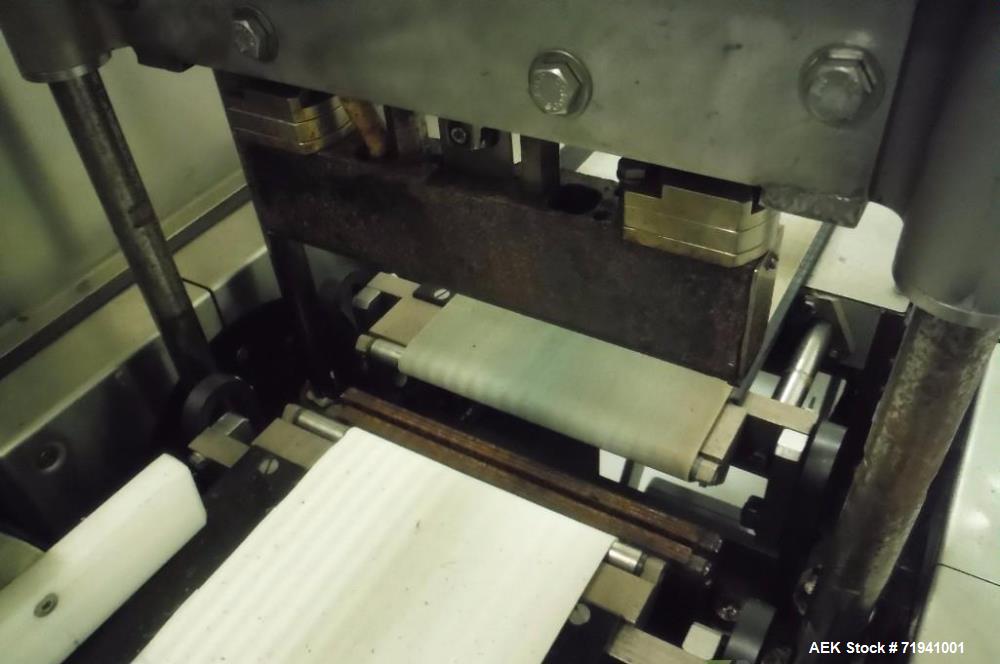

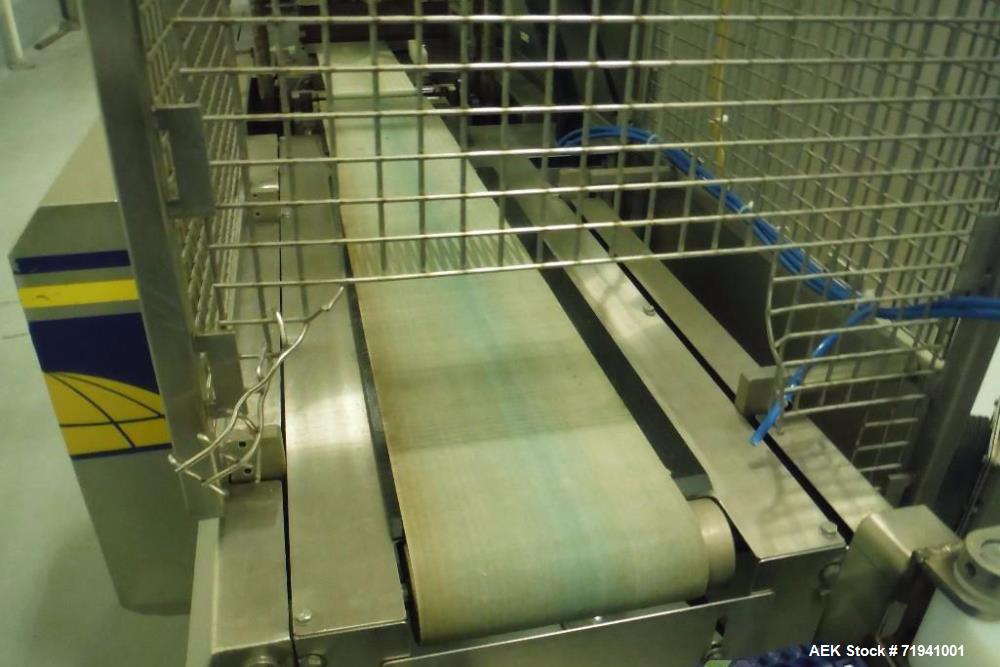

Used Complete Flexline Frozen Meal Kitchen and Assembly Production Line. Accuracy: Precision meal component placement within a tray. Variety: 11 depositing stations for meal components, sauce, glaze with a combination of equipment depositing and hand placement. Flexibility: Multiple meal assembly and packaging options: With or without a tray or carton, carton or bag, small or large meals. USDA (not RTE). Four key production unit operations: sauce and pasta cooking - meal assembly - freezing - packaging. Sauce cooking: 3,800 lb. batch hot sauce capability, 5,000 lb. batch cold sauce capability, wide variety of sauces, high/low fat, thick/thin, cream, tomato, soy base, sauce with particulates (mushrooms, meats, vegetables), technology is vacuum chilling. Pasta Cooking: 6,000 lb./hr. capacity. Meal Assembly: Ingredient size possibilities: Green peas to green beans, rice pilaf to 5" long linguini. Ingredient shape possibilities: broccoli spears to cubed potatoes, baby carrots to bowtie pasta. Ingredient texture possibilities: mashed potatoes to firm peppers and artichokes to green beans. 11 deposting stations: (3) Hand place, (2) scale, (3) fillers, (2) volumetric, fillers, (1) garnish applicator. C02 Freezer has a capacity of 11,000 lbs per hour. Packaging: Package is One Frozen Piece vs Frozen Loose component bag. Tray Types: paperboard, plastic, aluminum. Major Equipment List. Rietz stainless steel ribbon blender, (33) stainless steel totes, Urschel RA dicer, Blentech cookers, vacuum systems, Breddo Likwifier, stainless steel tanks and kettles, 2012 Kliklok carton former, 2011 Raque conveyor system, Mepcaco tote dumps, 2011 Raque carton lidder, Marton/Baron stainless steel spiral freezer. Stainless steel centrifugal and positive displacement pumps, conveyors, elevators, and much more.

Used Complete Flexline Frozen Meal Kitchen and Assembly Production Line. Accuracy: Precision meal component placement within a tray. Variety: 11 depositing stations for meal components, sauce, glaze with a combination of equipment depositing and hand placement. Flexibility: Multiple meal assembly and packaging options: With or without a tray or carton, carton or bag, small or large meals. USDA (not RTE). Four key production unit operations: sauce and pasta cooking - meal assembly - freezing - packaging. Sauce cooking: 3,800 lb. batch hot sauce capability, 5,000 lb. batch cold sauce capability, wide variety of sauces, high/low fat, thick/thin, cream, tomato, soy base, sauce with particulates (mushrooms, meats, vegetables), technology is vacuum chilling. Pasta Cooking: 6,000 lb./hr. capacity. Meal Assembly: Ingredient size possibilities: Green peas to green beans, rice pilaf to 5" long linguini. Ingredient shape possibilities: broccoli spears to cubed potatoes, baby carrots to bowtie pasta. Ingredient texture possibilities: mashed potatoes to firm peppers and artichokes to green beans. 11 deposting stations: (3) Hand place, (2) scale, (3) fillers, (2) volumetric, fillers, (1) garnish applicator. C02 Freezer has a capacity of 11,000 lbs per hour. Packaging: Package is One Frozen Piece vs Frozen Loose component bag. Tray Types: paperboard, plastic, aluminum. Major Equipment List. Rietz stainless steel ribbon blender, (33) stainless steel totes, Urschel RA dicer, Blentech cookers, vacuum systems, Breddo Likwifier, stainless steel tanks and kettles, 2012 Kliklok carton former, 2011 Raque conveyor system, Mepcaco tote dumps, 2011 Raque carton lidder, Marton/Baron stainless steel spiral freezer. Stainless steel centrifugal and positive displacement pumps, conveyors, elevators, and much more.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory