Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Paper Converting Machine Company Alcohol Wet Wipes Converting and Wrapping

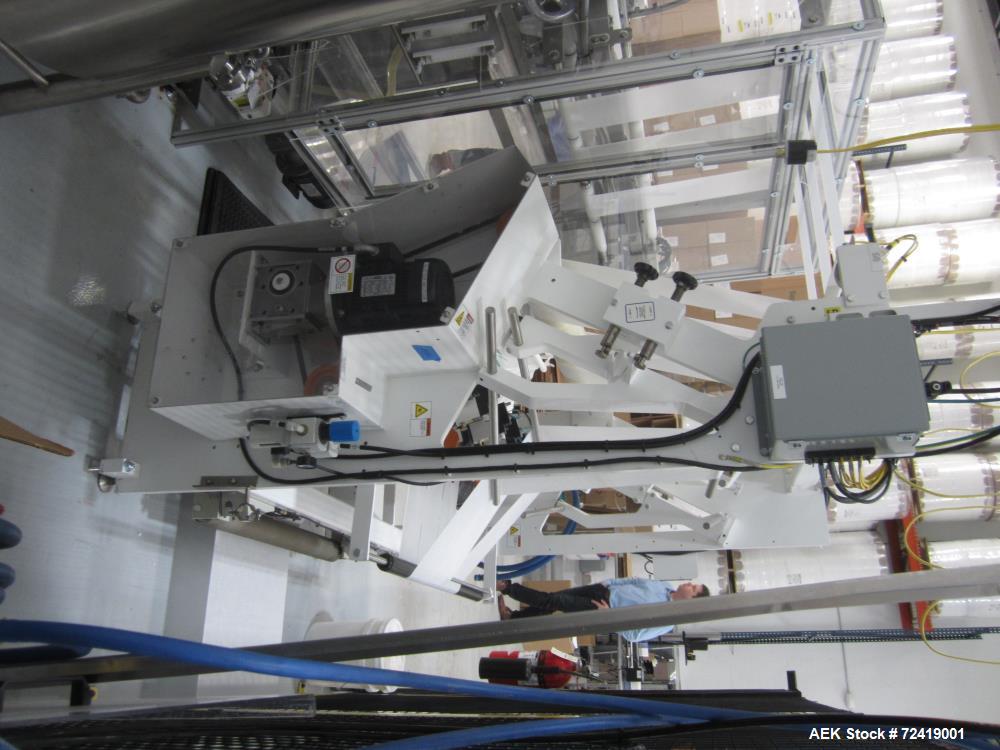

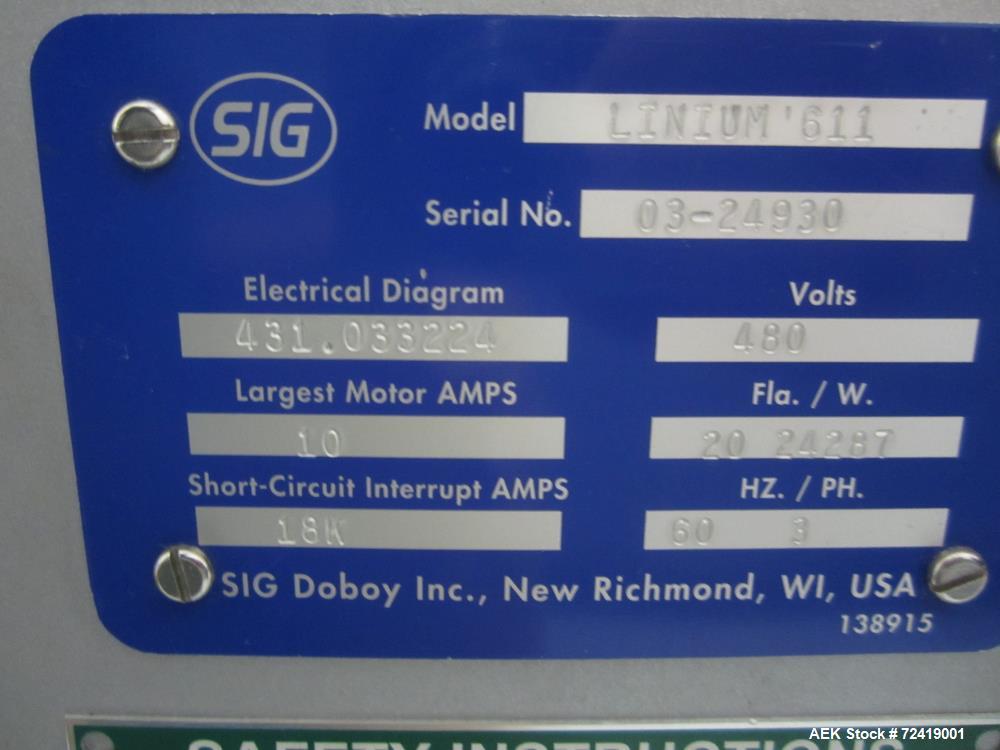

Used Paper Converting Machine Company Barry-Wehmiller Wet Wipes Complete System. Exfoliating facial cleansing wet wipe system. Marlin Flex cross folder, Model CF01-00013, unwinder, heated embossing unit, wetting applicator, Allen Bradley panelview 1500p, Sterling water chiller, SS single wall tank, 36" diameter x 36" straight side, Cleveland agitator, 20" diameter manway, CIP spray ball, 2 hp SS centrifugal pump with AB powerflex40, Multi-conveyor 90 degree conveyor, white plastic interlock belt, 8" wide x 36" tall, overall 48" long x 36" wide, SS frame, washdown motor, Multi conveyor compression conveyor, white vinyl belt, 60" long x 8" wide x 36" tall, SS frame, washdown motor and drive; Allen Bradley Controls; Cut speed: 2000 wipes per minute; Stacker speed: 100 stacks per minute (25 stacks per minute per lane); Stack count range: 4-100; Stack height range 10 mm (0.39") to 90 mm (3.54"); Cutoff length range: 170 mm (6.69") to 210 mm (8.26") maximum Folded width range: 50 mm (1.97") to 115 mm (4.5"), (change parts required for 65 mm to 90 mm folded width); 480V, 60 Hz, 3 phase; Maximum Undwind Roll width: 860 mm (34"); Maximum unwind roll diameter: 1500 mm (60"); Parent roll core diameter: 171 mm (6.75"). Includes Bosch Linium model 611 Horizontal wrapper and integrated conveyor. Film registration. Last running embossed wet wipes with 75% alcohol content.

| Manufacturer | Paper Converting MachinePaper Converting Machine |

| Model | CF01-00013 |

| Category | Packaging EquipmentPackaging Equipment |

| Subcategory | Complete Packaging Line - OtherComplete Packaging Line - Other |

Manufacturer Information

- Brand: Paper Converting Machine Company (PCMC) / Barry-Wehmiller

- Condition: Used

- Previous Use: Exfoliating Facial Cleansing Wet Wipe Production

- Processing Speeds:

- Cut Speed: Up to 2,000 wipes per minute

- Stacker Speed: 100 stacks per minute (25 stacks per minute per lane)

Description

This PCMC Barry-Wehmiller Wet Wipes Production System is a fully automated wet wipe manufacturing line, designed for high-speed, precision cutting, folding, wetting, and packaging of exfoliating facial cleansing wipes.

The system includes the Marlin Flex Cross Folder (Model CF01-00013) with an unwinder, heated embossing unit, and wetting applicator, ensuring precise folding and uniform liquid application. The Allen Bradley PanelView 1500p control system provides intuitive operation and process monitoring.

A Sterling Water Chiller and 36” stainless steel single-wall mixing tank with a Cleveland agitator and CIP spray ball allow for consistent solution mixing and hygiene maintenance. The system also includes a 2 HP stainless steel centrifugal pump (AB PowerFlex40-controlled) for liquid distribution.

The integrated multi-conveyor system consists of:

- 90-degree plastic interlock belt conveyor (washdown-rated motor, stainless steel frame)

- Compression conveyor with a white vinyl belt (60” long x 8” wide x 36” tall)

For final packaging, the system includes a Bosch Linium Model 611 Horizontal Wrapper with film registration and an integrated conveyor, optimizing the wrapping and sealing process.

Specifications

- Processing Speed:

- Cut Speed: Up to 2,000 wipes per minute

- Stacker Speed: Up to 100 stacks per minute (25 stacks per minute per lane)

- Stack Count Range: 4 - 100 wipes

- Stack Height Range: 10 mm (0.39") - 90 mm (3.54")

- Cutoff Length Range: 170 mm (6.69") - 210 mm (8.26")

- Folded Width Range: 50 mm (1.97") - 115 mm (4.5") (Change parts required for 65 mm to 90 mm folded width)

- Unwind Roll Specs:

- Max Roll Width: 860 mm (34")

- Max Roll Diameter: 1,500 mm (60")

- Core Diameter: 171 mm (6.75")

- Electrical Requirements: 480V, 60 Hz, 3 Phase

- Packaging System: Bosch Linium Model 611 Horizontal Wrapper with Film Registration

Included Equipment

- Marlin Flex Cross Folder (Model CF01-00013) – Unwinder, heated embossing unit, wetting applicator

- Allen Bradley PanelView 1500p Controls – Centralized system monitoring and operation

- Sterling Water Chiller – Maintains solution temperature

- Stainless Steel Mixing Tank (36" Dia. x 36" Straight Side) – Equipped with:

- Cleveland Agitator

- 20" Diameter Manway

- CIP Spray Ball

- 2 HP Stainless Steel Centrifugal Pump (AB PowerFlex40 Controlled)

- Multi-Conveyor System:

- 90-Degree Plastic Interlock Belt Conveyor (Washdown Motor, Stainless Steel Frame)

- Compression Conveyor (60” Long x 8” Wide x 36” Tall)

- Bosch Linium Model 611 Horizontal Wrapper with Film Registration & Integrated Conveyor

Applications

- Personal Care & Cosmetics – Exfoliating facial wipes, makeup remover wipes

- Sanitizing & Disinfecting Wipes – Alcohol-based wet wipes for hygiene

- Household Cleaning Wipes – Multipurpose and disinfectant wipes

- Industrial & Specialty Wipes – Degreasing and surface cleaning wipes

- Medical & Healthcare Wipes – Alcohol, antibacterial, and gentle cleansing wipes

Compatible Products

- Fully automated wet wipe production and packaging lines

- Liquid mixing and dispensing systems for wet wipes

- Industrial horizontal wrappers and film registration systems

- Wet wipe converting equipment for high-speed production

- Wet wipes machine, PCMC wet wipes system, industrial wipe production

- Used PCMC Barry-Wehmiller wet wipe production line, high-speed facial wipe manufacturing system, automatic wet wipe converting and packaging line

- PCMC Barry-Wehmiller complete wet wipe production system with Bosch Linium wrapper, high-speed 2,000 wipes per minute industrial wet wipes machine, used wet wipe processing system with embossing and liquid application

Used Paper Converting Machine Company Barry-Wehmiller Wet Wipes Complete System. Exfoliating facial cleansing wet wipe system. Marlin Flex cross folder, Model CF01-00013, unwinder, heated embossing unit, wetting applicator, Allen Bradley panelview 1500p, Sterling water chiller, SS single wall tank, 36" diameter x 36" straight side, Cleveland agitator, 20" diameter manway, CIP spray ball, 2 hp SS centrifugal pump with AB powerflex40, Multi-conveyor 90 degree conveyor, white plastic interlock belt, 8" wide x 36" tall, overall 48" long x 36" wide, SS frame, washdown motor, Multi conveyor compression conveyor, white vinyl belt, 60" long x 8" wide x 36" tall, SS frame, washdown motor and drive; Allen Bradley Controls; Cut speed: 2000 wipes per minute; Stacker speed: 100 stacks per minute (25 stacks per minute per lane); Stack count range: 4-100; Stack height range 10 mm (0.39") to 90 mm (3.54"); Cutoff length range: 170 mm (6.69") to 210 mm (8.26") maximum Folded width range: 50 mm (1.97") to 115 mm (4.5"), (change parts required for 65 mm to 90 mm folded width); 480V, 60 Hz, 3 phase; Maximum Undwind Roll width: 860 mm (34"); Maximum unwind roll diameter: 1500 mm (60"); Parent roll core diameter: 171 mm (6.75"). Includes Bosch Linium model 611 Horizontal wrapper and integrated conveyor. Film registration. Last running embossed wet wipes with 75% alcohol content.

Manufacturer Information

- Brand: Paper Converting Machine Company (PCMC) / Barry-Wehmiller

- Condition: Used

- Previous Use: Exfoliating Facial Cleansing Wet Wipe Production

- Processing Speeds:

- Cut Speed: Up to 2,000 wipes per minute

- Stacker Speed: 100 stacks per minute (25 stacks per minute per lane)

Description

This PCMC Barry-Wehmiller Wet Wipes Production System is a fully automated wet wipe manufacturing line, designed for high-speed, precision cutting, folding, wetting, and packaging of exfoliating facial cleansing wipes.

The system includes the Marlin Flex Cross Folder (Model CF01-00013) with an unwinder, heated embossing unit, and wetting applicator, ensuring precise folding and uniform liquid application. The Allen Bradley PanelView 1500p control system provides intuitive operation and process monitoring.

A Sterling Water Chiller and 36” stainless steel single-wall mixing tank with a Cleveland agitator and CIP spray ball allow for consistent solution mixing and hygiene maintenance. The system also includes a 2 HP stainless steel centrifugal pump (AB PowerFlex40-controlled) for liquid distribution.

The integrated multi-conveyor system consists of:

- 90-degree plastic interlock belt conveyor (washdown-rated motor, stainless steel frame)

- Compression conveyor with a white vinyl belt (60” long x 8” wide x 36” tall)

For final packaging, the system includes a Bosch Linium Model 611 Horizontal Wrapper with film registration and an integrated conveyor, optimizing the wrapping and sealing process.

Specifications

- Processing Speed:

- Cut Speed: Up to 2,000 wipes per minute

- Stacker Speed: Up to 100 stacks per minute (25 stacks per minute per lane)

- Stack Count Range: 4 - 100 wipes

- Stack Height Range: 10 mm (0.39") - 90 mm (3.54")

- Cutoff Length Range: 170 mm (6.69") - 210 mm (8.26")

- Folded Width Range: 50 mm (1.97") - 115 mm (4.5") (Change parts required for 65 mm to 90 mm folded width)

- Unwind Roll Specs:

- Max Roll Width: 860 mm (34")

- Max Roll Diameter: 1,500 mm (60")

- Core Diameter: 171 mm (6.75")

- Electrical Requirements: 480V, 60 Hz, 3 Phase

- Packaging System: Bosch Linium Model 611 Horizontal Wrapper with Film Registration

Included Equipment

- Marlin Flex Cross Folder (Model CF01-00013) – Unwinder, heated embossing unit, wetting applicator

- Allen Bradley PanelView 1500p Controls – Centralized system monitoring and operation

- Sterling Water Chiller – Maintains solution temperature

- Stainless Steel Mixing Tank (36" Dia. x 36" Straight Side) – Equipped with:

- Cleveland Agitator

- 20" Diameter Manway

- CIP Spray Ball

- 2 HP Stainless Steel Centrifugal Pump (AB PowerFlex40 Controlled)

- Multi-Conveyor System:

- 90-Degree Plastic Interlock Belt Conveyor (Washdown Motor, Stainless Steel Frame)

- Compression Conveyor (60” Long x 8” Wide x 36” Tall)

- Bosch Linium Model 611 Horizontal Wrapper with Film Registration & Integrated Conveyor

Applications

- Personal Care & Cosmetics – Exfoliating facial wipes, makeup remover wipes

- Sanitizing & Disinfecting Wipes – Alcohol-based wet wipes for hygiene

- Household Cleaning Wipes – Multipurpose and disinfectant wipes

- Industrial & Specialty Wipes – Degreasing and surface cleaning wipes

- Medical & Healthcare Wipes – Alcohol, antibacterial, and gentle cleansing wipes

Compatible Products

- Fully automated wet wipe production and packaging lines

- Liquid mixing and dispensing systems for wet wipes

- Industrial horizontal wrappers and film registration systems

- Wet wipe converting equipment for high-speed production

| Manufacturer | Paper Converting Machine |

| Model | CF01-00013 |

| Category | Packaging Equipment |

| Subcategory | Complete Packaging Line - Other |

- Wet wipes machine, PCMC wet wipes system, industrial wipe production

- Used PCMC Barry-Wehmiller wet wipe production line, high-speed facial wipe manufacturing system, automatic wet wipe converting and packaging line

- PCMC Barry-Wehmiller complete wet wipe production system with Bosch Linium wrapper, high-speed 2,000 wipes per minute industrial wet wipes machine, used wet wipe processing system with embossing and liquid application

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory