Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Complete 64oz & 32oz Bottle Packaging Line – Inline Filler, Capper, Labeler, and Coder

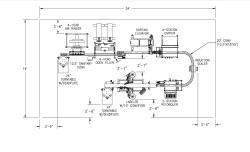

Used Inline Filling Systems Liquid Bottle Filling Line. Line was set up to run 64oz rectangular bottles and 32 oz square containers with 53mm caps. Containers were either front and back or 3 sided wrap on the square bottle. Line consists of 45" diam stainless steel unscrambling table with variable speed drive and square bottle orientor, Inline Filling Model FOFNT48 4 head overflow filler with drip tray, 1" diameter nozzles, indexing gating system, washdown capable, AB PLC and color HMI, overflow tank with pump. Stainless steel 4-1/2" wide conveyor chain, Computorue NT automatic capper (currently set on 53mm caps) with cap size range up to 120mm. Container range: 1-1/2" - 15" (height) x 1/2" - 7" (width). Has 5.0LH bulk cap elevator/sorter. Enercon model Super Seal 75 induction cap sealer, with air cooling. Universal CP-1000 front and back labeler with wrap station. Video Jet 1220 Ink jet coder, and 45" diameter s/s accumulation table. Mfg. 2019.

🏭 Manufacturer Info

Inline Filling Systems (IFS) is a U.S.-based manufacturer of advanced liquid packaging equipment, specializing in inline overflow fillers, cappers, and turn-key bottling lines. Their equipment is known for precision, flexibility, and ease of use, especially in sanitary and industrial environments.

📝 Description

This Used Inline Filling Systems Liquid Bottle Filling Line (Mfg. 2019) was designed to run 64 oz rectangular bottles and 32 oz square containers with 53mm caps, supporting both front/back and 3-sided wrap labels. The line features a 4-head overflow filler, automatic capper, induction sealer, labeler with wrap station, and ink jet coder, making it a complete turnkey system for liquid product bottling and packaging.

Components Included:

-

45" Stainless Steel Unscrambling Table with variable speed and square bottle orientor

-

Inline Filling Systems Model FOFNT48 Overflow Filler

-

4 heads with drip tray

-

1" diameter nozzles

-

Indexing/gating system

-

Washdown capable

-

Overflow tank with pump

-

Allen Bradley PLC with color HMI

-

-

4-1/2" Stainless Conveyor Chain

-

Computorue NT Automatic Capper

-

Cap range up to 120mm

-

Currently set for 53mm caps

-

Includes 5.0 LH cap elevator/sorter

-

-

Enercon Super Seal 75 Induction Cap Sealer with air cooling

-

Universal CP-1000 Labeler with front/back and wrap label capability

-

Videojet 1220 Inkjet Coder

-

45" Stainless Steel Accumulation Table

⚙️ Specifications

-

Bottle Types: Rectangular (64 oz) and Square (32 oz)

-

Cap Size Range: Up to 120mm (currently set to 53mm)

-

Container Dimensions:

-

Height: 1.5" – 15"

-

Width: 0.5" – 7"

-

-

Filler: Inline FOFNT48 Overflow Filler

-

4 heads, 1" dia nozzles

-

Washdown capable

-

PLC & Color HMI

-

-

Capper: Computorue NT with bulk cap elevator

-

Labeler: Universal CP-1000

-

Front/back or 3-sided wrap station

-

-

Induction Sealer: Enercon Super Seal 75

-

Inkjet Coder: Videojet 1220

-

Year Manufactured: 2019

🧰 Applications

-

Personal care and household product filling

-

Chemical packaging (cleaners, degreasers)

-

Food and beverage bottling

-

Automotive and industrial fluids

-

Nutritional supplement bottles

-

Agriculture and garden care products

-

Sanitizers and disinfectants

-

Cosmetic lotions, soaps, and gels

📦 What Products Would This Be Used For?

-

Multi-surface cleaners

-

Dish soaps

-

Lotions and body washes

-

Hand sanitizers

-

Detergents

-

Plant food or fertilizers

-

Engine oil or coolant

-

Liquid supplements

-

Hair care products

-

Degreasers and solvents

-

overflow filler

-

bottle capper

-

induction sealer

-

bottle labeler

-

inkjet coder

-

4-head filler

-

Inline Filling Systems

-

wrap labeler

-

bottle unscrambler

-

cap elevator

-

used inline bottle filling line

-

64 oz bottle filling machine

-

wraparound labeler with front and back

-

automatic capper with elevator

-

induction sealing system for bottles

-

overflow filler for liquid packaging

-

Videojet ink coder used

-

Universal CP-1000 labeler

-

Computorue NT capper with sorter

-

liquid packaging line with coder and sealer

-

Used Inline Filling Systems overflow filling line with capper and labeler

-

Complete turnkey bottle filling and capping line for 64oz and 32oz containers

-

Liquid product packaging system with induction sealer and inkjet coder

-

FOFNT48 4-head overflow filler with drip tray and washdown capability

-

Capper and elevator system set for 53mm caps, expandable to 120mm

-

Labeling line with wrap and front/back application for square bottles

-

Automatic liquid filling system with Allen Bradley PLC control

-

Energy-efficient induction sealing with air-cooled Super Seal 75

-

Stainless steel bottling line with conveyors and accumulation

-

Used packaging line for personal care, chemicals, or sanitizers

-

bottle filling system

-

overflow filler used

-

automatic capper

-

bottle labeler wrap

-

induction sealing line

-

PLC controlled filler

-

inkjet bottle coder

-

stainless packaging line

-

complete bottling system

-

liquid filling equipment

-

buy used bottle filler

-

sell overflow filling line

-

used capper for sale

-

buy labeling machine

-

purchase induction sealer

-

bottle filling system for sale

-

used 64 oz bottle filler

-

sell bottling equipment

-

complete packaging line available

-

used liquid filling line

Used Inline Filling Systems Liquid Bottle Filling Line. Line was set up to run 64oz rectangular bottles and 32 oz square containers with 53mm caps. Containers were either front and back or 3 sided wrap on the square bottle. Line consists of 45" diam stainless steel unscrambling table with variable speed drive and square bottle orientor, Inline Filling Model FOFNT48 4 head overflow filler with drip tray, 1" diameter nozzles, indexing gating system, washdown capable, AB PLC and color HMI, overflow tank with pump. Stainless steel 4-1/2" wide conveyor chain, Computorue NT automatic capper (currently set on 53mm caps) with cap size range up to 120mm. Container range: 1-1/2" - 15" (height) x 1/2" - 7" (width). Has 5.0LH bulk cap elevator/sorter. Enercon model Super Seal 75 induction cap sealer, with air cooling. Universal CP-1000 front and back labeler with wrap station. Video Jet 1220 Ink jet coder, and 45" diameter s/s accumulation table. Mfg. 2019.

🏭 Manufacturer Info

Inline Filling Systems (IFS) is a U.S.-based manufacturer of advanced liquid packaging equipment, specializing in inline overflow fillers, cappers, and turn-key bottling lines. Their equipment is known for precision, flexibility, and ease of use, especially in sanitary and industrial environments.

📝 Description

This Used Inline Filling Systems Liquid Bottle Filling Line (Mfg. 2019) was designed to run 64 oz rectangular bottles and 32 oz square containers with 53mm caps, supporting both front/back and 3-sided wrap labels. The line features a 4-head overflow filler, automatic capper, induction sealer, labeler with wrap station, and ink jet coder, making it a complete turnkey system for liquid product bottling and packaging.

Components Included:

-

45" Stainless Steel Unscrambling Table with variable speed and square bottle orientor

-

Inline Filling Systems Model FOFNT48 Overflow Filler

-

4 heads with drip tray

-

1" diameter nozzles

-

Indexing/gating system

-

Washdown capable

-

Overflow tank with pump

-

Allen Bradley PLC with color HMI

-

-

4-1/2" Stainless Conveyor Chain

-

Computorue NT Automatic Capper

-

Cap range up to 120mm

-

Currently set for 53mm caps

-

Includes 5.0 LH cap elevator/sorter

-

-

Enercon Super Seal 75 Induction Cap Sealer with air cooling

-

Universal CP-1000 Labeler with front/back and wrap label capability

-

Videojet 1220 Inkjet Coder

-

45" Stainless Steel Accumulation Table

⚙️ Specifications

-

Bottle Types: Rectangular (64 oz) and Square (32 oz)

-

Cap Size Range: Up to 120mm (currently set to 53mm)

-

Container Dimensions:

-

Height: 1.5" – 15"

-

Width: 0.5" – 7"

-

-

Filler: Inline FOFNT48 Overflow Filler

-

4 heads, 1" dia nozzles

-

Washdown capable

-

PLC & Color HMI

-

-

Capper: Computorue NT with bulk cap elevator

-

Labeler: Universal CP-1000

-

Front/back or 3-sided wrap station

-

-

Induction Sealer: Enercon Super Seal 75

-

Inkjet Coder: Videojet 1220

-

Year Manufactured: 2019

🧰 Applications

-

Personal care and household product filling

-

Chemical packaging (cleaners, degreasers)

-

Food and beverage bottling

-

Automotive and industrial fluids

-

Nutritional supplement bottles

-

Agriculture and garden care products

-

Sanitizers and disinfectants

-

Cosmetic lotions, soaps, and gels

📦 What Products Would This Be Used For?

-

Multi-surface cleaners

-

Dish soaps

-

Lotions and body washes

-

Hand sanitizers

-

Detergents

-

Plant food or fertilizers

-

Engine oil or coolant

-

Liquid supplements

-

Hair care products

-

Degreasers and solvents

-

overflow filler

-

bottle capper

-

induction sealer

-

bottle labeler

-

inkjet coder

-

4-head filler

-

Inline Filling Systems

-

wrap labeler

-

bottle unscrambler

-

cap elevator

-

used inline bottle filling line

-

64 oz bottle filling machine

-

wraparound labeler with front and back

-

automatic capper with elevator

-

induction sealing system for bottles

-

overflow filler for liquid packaging

-

Videojet ink coder used

-

Universal CP-1000 labeler

-

Computorue NT capper with sorter

-

liquid packaging line with coder and sealer

-

Used Inline Filling Systems overflow filling line with capper and labeler

-

Complete turnkey bottle filling and capping line for 64oz and 32oz containers

-

Liquid product packaging system with induction sealer and inkjet coder

-

FOFNT48 4-head overflow filler with drip tray and washdown capability

-

Capper and elevator system set for 53mm caps, expandable to 120mm

-

Labeling line with wrap and front/back application for square bottles

-

Automatic liquid filling system with Allen Bradley PLC control

-

Energy-efficient induction sealing with air-cooled Super Seal 75

-

Stainless steel bottling line with conveyors and accumulation

-

Used packaging line for personal care, chemicals, or sanitizers

-

bottle filling system

-

overflow filler used

-

automatic capper

-

bottle labeler wrap

-

induction sealing line

-

PLC controlled filler

-

inkjet bottle coder

-

stainless packaging line

-

complete bottling system

-

liquid filling equipment

-

buy used bottle filler

-

sell overflow filling line

-

used capper for sale

-

buy labeling machine

-

purchase induction sealer

-

bottle filling system for sale

-

used 64 oz bottle filler

-

sell bottling equipment

-

complete packaging line available

-

used liquid filling line

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory