Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

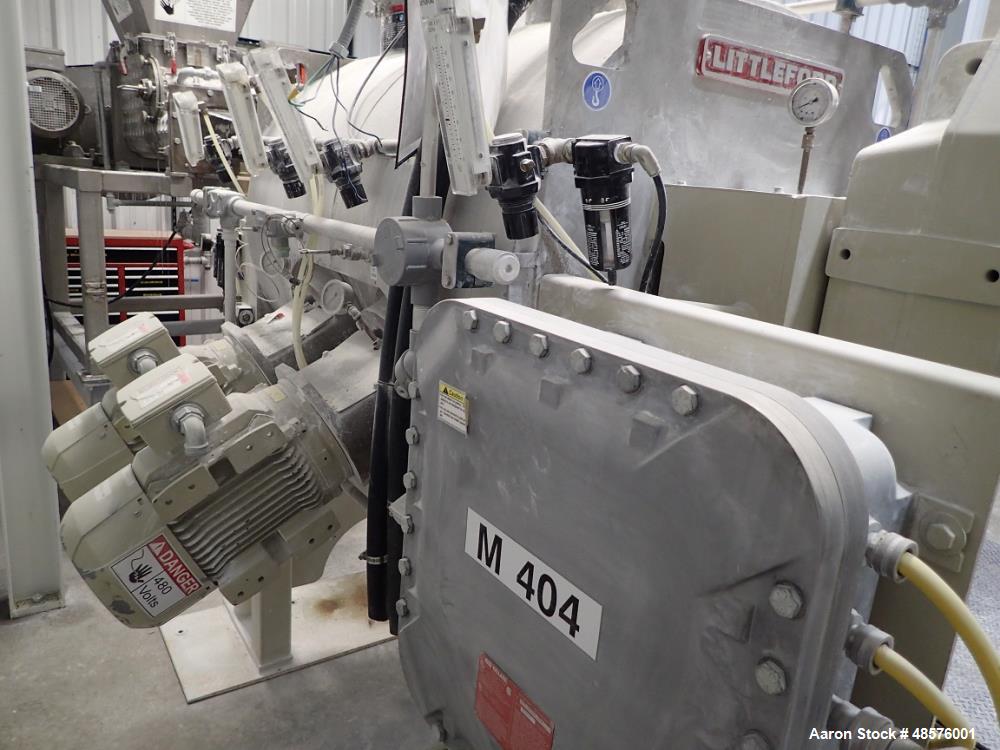

Used Littleford Plow Mixer, Model FKM-600D (2Z).

Used Littleford Plow Mixer, Model FKM-600D (2Z). Approximate 22 cubic feet (600 liter) total vessel capacity, 13 cubic feet nominal working capacity, 7-15 cubic feet working range. Internal FV. Jacket: A fully stayed, 90 PSIG @ 330ºF, ASME code constructed, 304 Stainless Steel jacket of labyrinth design to insure uniform flow. Interior of mixer and all product contact surfaces constructed of Type 304 Stainless Steel polished to #120 grit cross pad finish. Exterior stainless steel is polished to #80 grit cross pad finish. Exterior non-stainless steel is painted manufacturer's standard ivory. 15 HP, explosion proof Class I, Group D, Division 2, inverter duty motor, rated for 460 volt, 3 phase, 60 Hertz input power. Drive consists of a Falk 08UJ2A flange mounted speed reducer direct driven by main drive motor. Two (2) high speed, coupled chopper assemblies, each powered by a 10 HP, Class I, Group D, Division 2 motor, rated for 460 volts, 3 phase, 60 Hertz input power. The chopper shafts are 1" diameter and the chopper blade assembly is Littlefords special patented 4-point flat blade with carbide tips. Charging Port: One (1) 15" diameter flanged charging port is located on top center of mixer. The charge port body is extended by 12" for installation of the 3" Tri-Clover port for the two-fluid nozzle assembly. Vent Port: An oversize 15" diameter flanged vent port is mounted on top of mixer complete with vent extension and vent bag. The vent extension has one (1) 3" Tri-Clover port for the two-fluid nozzle assembly described below. The vent bag is also oversized to allow for proper venting of the mixer. Vent Bag Shroud: A 304 stainless steel shroud located around vent bag and mounted to vent extension with a 3" NPT connection to customers in-house dust collection system. Discharge: A 15" diameter flanged port located on bottom of mixer complete with gasketed contour door, pneumatically operated. Seals: Air purge seals installed on main and chopper shafts. An air manifold complete with valves, gauges, flow meters and regulators is included. The drive end seal is 3" diameter, the stub end seal is 2" diameter. Liquid Injection System: Two (2) tower mounted liquid injectors, for liquid addition. The extended charge port body and vent extension will each have one (1) 3" Tri-Clover port with a two fluid, air atomizing nozzle installed in it. Two (2) lance type liquid injectors, one (1) installed on the front falling side on each chopper shaft centerline, for liquid addition. Two (2) liquid injection ports with contour plugs, one (1) installed below each chopper assembly, for future addition of liquid injection lances. Thermocouple Port: One (1) thermocouple port with thermowell is mounted on back side of mixer for customer's temperature indicator. Built 2008.

Used Littleford Plow Mixer, Model FKM-600D (2Z). Approximate 22 cubic feet (600 liter) total vessel capacity, 13 cubic feet nominal working capacity, 7-15 cubic feet working range. Internal FV. Jacket: A fully stayed, 90 PSIG @ 330ºF, ASME code constructed, 304 Stainless Steel jacket of labyrinth design to insure uniform flow. Interior of mixer and all product contact surfaces constructed of Type 304 Stainless Steel polished to #120 grit cross pad finish. Exterior stainless steel is polished to #80 grit cross pad finish. Exterior non-stainless steel is painted manufacturer's standard ivory. 15 HP, explosion proof Class I, Group D, Division 2, inverter duty motor, rated for 460 volt, 3 phase, 60 Hertz input power. Drive consists of a Falk 08UJ2A flange mounted speed reducer direct driven by main drive motor. Two (2) high speed, coupled chopper assemblies, each powered by a 10 HP, Class I, Group D, Division 2 motor, rated for 460 volts, 3 phase, 60 Hertz input power. The chopper shafts are 1" diameter and the chopper blade assembly is Littlefords special patented 4-point flat blade with carbide tips. Charging Port: One (1) 15" diameter flanged charging port is located on top center of mixer. The charge port body is extended by 12" for installation of the 3" Tri-Clover port for the two-fluid nozzle assembly. Vent Port: An oversize 15" diameter flanged vent port is mounted on top of mixer complete with vent extension and vent bag. The vent extension has one (1) 3" Tri-Clover port for the two-fluid nozzle assembly described below. The vent bag is also oversized to allow for proper venting of the mixer. Vent Bag Shroud: A 304 stainless steel shroud located around vent bag and mounted to vent extension with a 3" NPT connection to customers in-house dust collection system. Discharge: A 15" diameter flanged port located on bottom of mixer complete with gasketed contour door, pneumatically operated. Seals: Air purge seals installed on main and chopper shafts. An air manifold complete with valves, gauges, flow meters and regulators is included. The drive end seal is 3" diameter, the stub end seal is 2" diameter. Liquid Injection System: Two (2) tower mounted liquid injectors, for liquid addition. The extended charge port body and vent extension will each have one (1) 3" Tri-Clover port with a two fluid, air atomizing nozzle installed in it. Two (2) lance type liquid injectors, one (1) installed on the front falling side on each chopper shaft centerline, for liquid addition. Two (2) liquid injection ports with contour plugs, one (1) installed below each chopper assembly, for future addition of liquid injection lances. Thermocouple Port: One (1) thermocouple port with thermowell is mounted on back side of mixer for customer's temperature indicator. Built 2008.

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory