Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

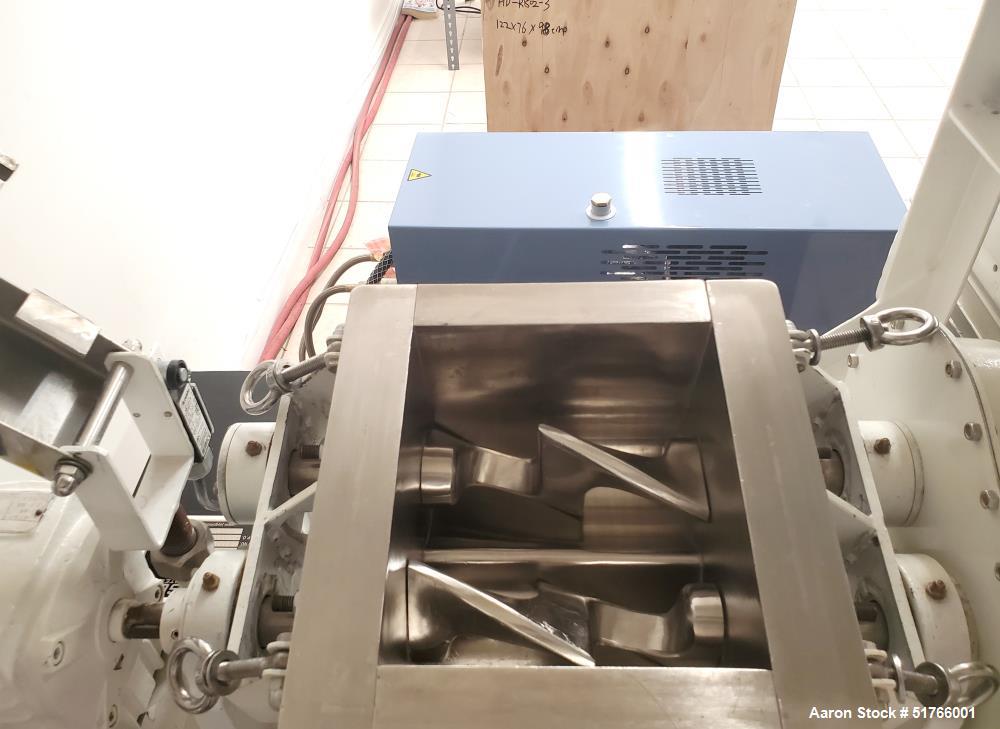

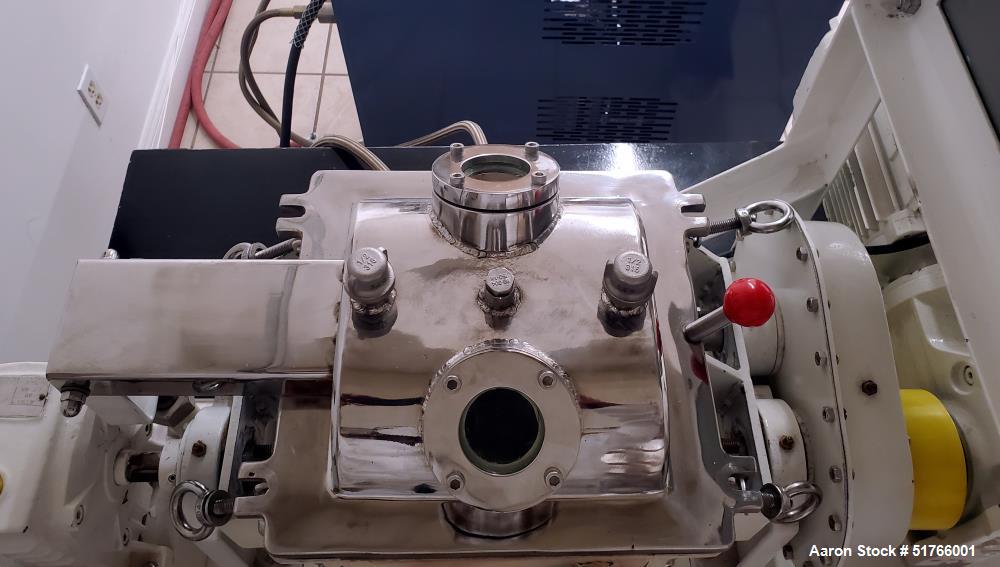

Used Jaygo Laboratory Double Arm Sigma Blade Mixer

Used Jaygo Laboratory Double Arm Sigma Blade Mixer, Model NHF-5 Capacity: Total: 5 liters Working: 3 liters (Actual working capacity is product dependent). Contact parts: 304 Stainless Steel. Double trough shell with end plates fabricated from steel plate. Trough and end plates are ground and polished smooth. Blades: 304 Stainless Steel cast Sigma blades, tangential mixing action, including Stainless Steel shafts supported by outboard bearings and driven by heavy-duty gearing. Jacket: On trough, designed for 14.9 psig pressure water or oil at 425 F. Insulation and sheathing over all jacketed surfaces. NPT jacket connections on upper sections of mixer trough. Drain in bottom center of jacket. Shaft Seals: Standard packing glands with braided PTFE and adjustable followers. Cover: 304 SS domed cover, with O-ring in groove, lift handle, limit switch, FNPT connection in cover center, quick-release clamps, and hinge at side of mixer trough. Discharge: Mixer tilted manually with worm-wheel gearbox assistance. Drive: 1HP TEFC motor direct connected to right angle gearbox, coupling, and end case gear reducer. Blades speed is variable Approx. 070 RPM front blade and 050 RPM rear blade (ratio between blade speeds is fixed). Guards: All gears, couplings, and rotating shafts guarded to prevent operators from contact. Frame: Mixer body mounted on Carbon Steel support table on wheels. Finish: All product contact parts are polished to uniform finish. All non-product contact parts are 304 SS buffed uniform finish or carbon steel painted. Controls: NEMA 4 enclosure mounted on machine frame and wired to motor and limit switch, with following operators push buttons: Mix/Stop; Emergency Stop; Speed Potentiometer with Digital Speed Readout (front blade speed); Power On light; Power Disconnect ;Step up transformer installed on lower shelf and wired to mixer control panel; Customer to wire 208V/3/60Hz electrical supply to step up transformer

Used Jaygo Laboratory Double Arm Sigma Blade Mixer, Model NHF-5 Capacity: Total: 5 liters Working: 3 liters (Actual working capacity is product dependent). Contact parts: 304 Stainless Steel. Double trough shell with end plates fabricated from steel plate. Trough and end plates are ground and polished smooth. Blades: 304 Stainless Steel cast Sigma blades, tangential mixing action, including Stainless Steel shafts supported by outboard bearings and driven by heavy-duty gearing. Jacket: On trough, designed for 14.9 psig pressure water or oil at 425 F. Insulation and sheathing over all jacketed surfaces. NPT jacket connections on upper sections of mixer trough. Drain in bottom center of jacket. Shaft Seals: Standard packing glands with braided PTFE and adjustable followers. Cover: 304 SS domed cover, with O-ring in groove, lift handle, limit switch, FNPT connection in cover center, quick-release clamps, and hinge at side of mixer trough. Discharge: Mixer tilted manually with worm-wheel gearbox assistance. Drive: 1HP TEFC motor direct connected to right angle gearbox, coupling, and end case gear reducer. Blades speed is variable Approx. 070 RPM front blade and 050 RPM rear blade (ratio between blade speeds is fixed). Guards: All gears, couplings, and rotating shafts guarded to prevent operators from contact. Frame: Mixer body mounted on Carbon Steel support table on wheels. Finish: All product contact parts are polished to uniform finish. All non-product contact parts are 304 SS buffed uniform finish or carbon steel painted. Controls: NEMA 4 enclosure mounted on machine frame and wired to motor and limit switch, with following operators push buttons: Mix/Stop; Emergency Stop; Speed Potentiometer with Digital Speed Readout (front blade speed); Power On light; Power Disconnect ;Step up transformer installed on lower shelf and wired to mixer control panel; Customer to wire 208V/3/60Hz electrical supply to step up transformer

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory