Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: websales@aaronequipment.com

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

Used Aaron Process 200 Gallon Stainless Steel Vacuum Dryer – Jacketed & ASME Rated

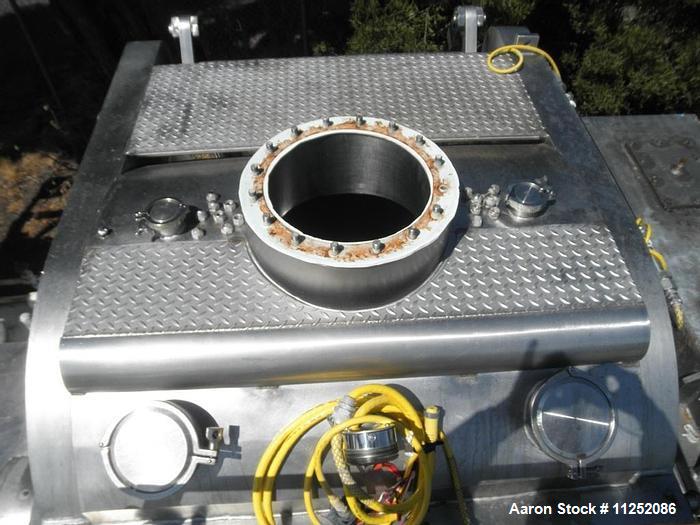

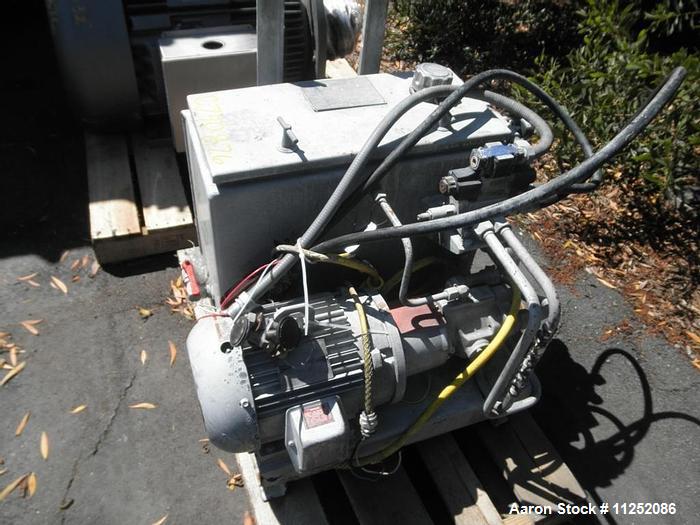

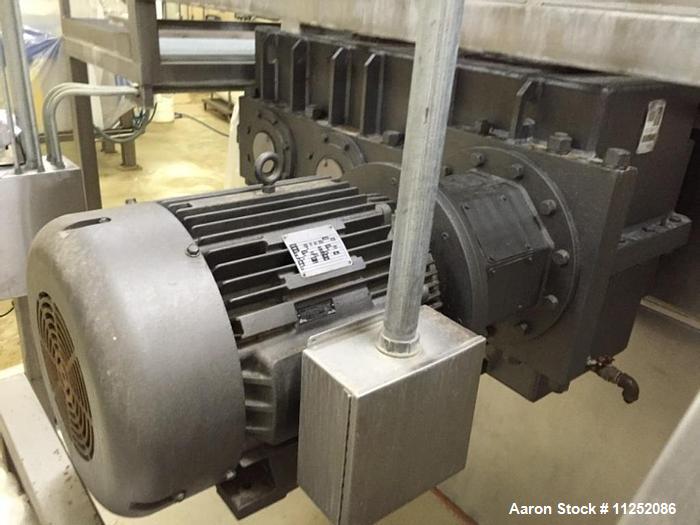

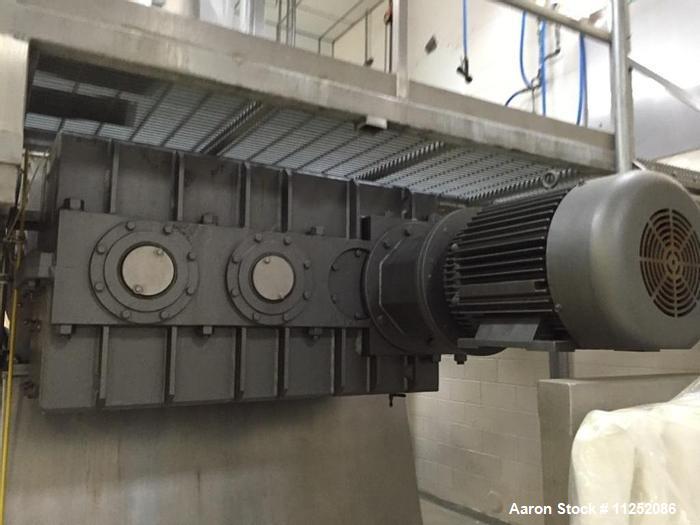

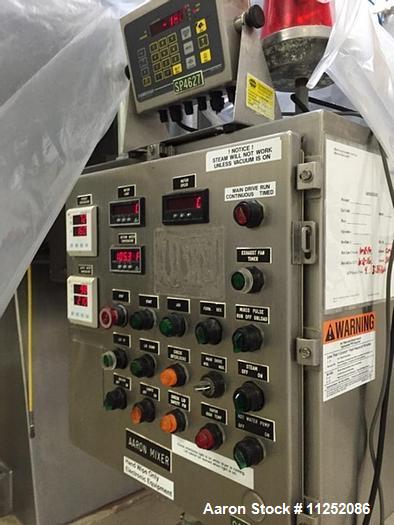

Used Aaron Process Vacuum Dryer with Cored Shafts and Jacketed Trough. All Stainless Steel construction, 200 gallon capacity. All parts are insulated and sheathed with 304 Stainless Steel and polished to 150 - 180 grit finish. Mixing/drying chamber includes vacuum cover and is jacketed. Rated for 200 PSI at 450 degree F / -20 degree F. ASME code constructed. Mixing chamber measures 48" x 40" x 44" deep and includes (2) 6" diameter flanged discharges with ball valves. Blades are overlapping double nobben blades and driven by 125 hp motor thru heavy duty gearbox. Previously used in clean room type environment. Complete with control panel and unitized on heavy duty frame. Includes main control panel, power panel with starters and VFD's, steam-to-water heat exchanger for heating of jacket and hydraulic pump/reservoir for opening vessel lid. Also includes top mounted, stainless steel Mikro Pulsaire dust collector. Model 10-2-FV TR, rated for 11. Mfg 2000.

Manufacturer Information:

- Manufacturer: Aaron Process

- Type: Vacuum Dryer with Cored Shafts & Jacketed Trough

- Capacity: 200 Gallons

- Material: 304 Stainless Steel (Insulated & Sheathed)

- Previous Use: Clean Room Environment

Description:

This used Aaron Process 200-gallon vacuum dryer is a high-performance industrial drying system designed for efficient drying and mixing in pharmaceutical, chemical, and food processing applications. Constructed with all stainless steel components, the unit is insulated and sheathed with 304 stainless steel and polished to a 150-180 grit sanitary finish.

The mixing/drying chamber features a vacuum cover and a jacketed trough, ASME code construction, and is rated for 200 PSI at 450°F to -20°F. The chamber measures 48" x 40" x 44" deep and includes (2) 6" diameter flanged discharges with ball valves for efficient product flow.

The system utilizes overlapping double nobben blades, driven by a 125 HP motor through a heavy-duty gearbox, ensuring thorough and consistent drying/mixing. The dryer is fully equipped with a main control panel, power panel with starters and VFDs, and a steam-to-water heat exchanger for jacket heating. A hydraulic pump/reservoir allows for easy vessel lid opening, and a top-mounted stainless steel Mikro Pulsaire dust collector is included for effective dust control.

Specifications:

- Capacity: 200 gallons

- Material: 304 stainless steel (insulated & sheathed)

- Finish: 150-180 grit polished finish

- Mixing/Drying Chamber:

- Vacuum cover & jacketed trough

- ASME code construction

- Rated for 200 PSI at 450°F to -20°F

- Dimensions: 48" x 40" x 44" deep

- (2) 6" diameter flanged discharges with ball valves

- Mixing System:

- Overlapping double nobben blades

- 125 HP motor with heavy-duty gearbox

- Control & Additional Features:

- Main control panel

- Power panel with starters & VFDs

- Steam-to-water heat exchanger for jacket heating

- Hydraulic pump/reservoir for vessel lid opening

- Top-mounted stainless steel Mikro Pulsaire dust collector

- Model: 10-2-FV TR

Applications:

- Pharmaceutical & chemical drying processes

- Food processing & ingredient blending

- Powder & granule drying

- Heat-sensitive product drying

- Industrial vacuum drying operations

Products That Would Use This Dryer:

- Active pharmaceutical ingredients (API)

- Nutritional powders and protein blends

- Chemical powders and industrial materials

- Food-grade powders and additives

- Heat-sensitive specialty materials

- Paul O Abbe

- Used Industrial Equipment

- Used Equipment

- Aaron Process

- Used Vacuum Dryer

- Vacuum Dryer

- Used Process Dryer

- Stainless Steel Dryer

- Industrial Mixing Dryer

- Used Aaron Process Vacuum Dryer

- 200 Gallon Stainless Steel Dryer

- Jacketed Vacuum Dryer for Sale

- Industrial Vacuum Drying System

- ASME Code Stainless Steel Dryer

- High-Capacity Process Dryer

- Used 200 Gallon Stainless Steel Vacuum Dryer for Sale

- ASME Code Jacketed Vacuum Dryer with Cored Shafts

- High-Temperature Vacuum Drying System with Insulation

- Stainless Steel Vacuum Dryer with 125 HP Motor and Gearbox

- Used Aaron Process 200 Gallon Stainless Steel Vacuum Dryer with Jacketed Trough

- Industrial Vacuum Drying System with Control Panel and Heat Exchanger

- Heavy-Duty Vacuum Mixer Dryer with Overlapping Double Nobben Blades

- ASME Code Stainless Steel Vacuum Dryer with Mikro Pulsaire Dust Collector

Used Aaron Process Vacuum Dryer with Cored Shafts and Jacketed Trough. All Stainless Steel construction, 200 gallon capacity. All parts are insulated and sheathed with 304 Stainless Steel and polished to 150 - 180 grit finish. Mixing/drying chamber includes vacuum cover and is jacketed. Rated for 200 PSI at 450 degree F / -20 degree F. ASME code constructed. Mixing chamber measures 48" x 40" x 44" deep and includes (2) 6" diameter flanged discharges with ball valves. Blades are overlapping double nobben blades and driven by 125 hp motor thru heavy duty gearbox. Previously used in clean room type environment. Complete with control panel and unitized on heavy duty frame. Includes main control panel, power panel with starters and VFD's, steam-to-water heat exchanger for heating of jacket and hydraulic pump/reservoir for opening vessel lid. Also includes top mounted, stainless steel Mikro Pulsaire dust collector. Model 10-2-FV TR, rated for 11. Mfg 2000.

Manufacturer Information:

- Manufacturer: Aaron Process

- Type: Vacuum Dryer with Cored Shafts & Jacketed Trough

- Capacity: 200 Gallons

- Material: 304 Stainless Steel (Insulated & Sheathed)

- Previous Use: Clean Room Environment

Description:

This used Aaron Process 200-gallon vacuum dryer is a high-performance industrial drying system designed for efficient drying and mixing in pharmaceutical, chemical, and food processing applications. Constructed with all stainless steel components, the unit is insulated and sheathed with 304 stainless steel and polished to a 150-180 grit sanitary finish.

The mixing/drying chamber features a vacuum cover and a jacketed trough, ASME code construction, and is rated for 200 PSI at 450°F to -20°F. The chamber measures 48" x 40" x 44" deep and includes (2) 6" diameter flanged discharges with ball valves for efficient product flow.

The system utilizes overlapping double nobben blades, driven by a 125 HP motor through a heavy-duty gearbox, ensuring thorough and consistent drying/mixing. The dryer is fully equipped with a main control panel, power panel with starters and VFDs, and a steam-to-water heat exchanger for jacket heating. A hydraulic pump/reservoir allows for easy vessel lid opening, and a top-mounted stainless steel Mikro Pulsaire dust collector is included for effective dust control.

Specifications:

- Capacity: 200 gallons

- Material: 304 stainless steel (insulated & sheathed)

- Finish: 150-180 grit polished finish

- Mixing/Drying Chamber:

- Vacuum cover & jacketed trough

- ASME code construction

- Rated for 200 PSI at 450°F to -20°F

- Dimensions: 48" x 40" x 44" deep

- (2) 6" diameter flanged discharges with ball valves

- Mixing System:

- Overlapping double nobben blades

- 125 HP motor with heavy-duty gearbox

- Control & Additional Features:

- Main control panel

- Power panel with starters & VFDs

- Steam-to-water heat exchanger for jacket heating

- Hydraulic pump/reservoir for vessel lid opening

- Top-mounted stainless steel Mikro Pulsaire dust collector

- Model: 10-2-FV TR

Applications:

- Pharmaceutical & chemical drying processes

- Food processing & ingredient blending

- Powder & granule drying

- Heat-sensitive product drying

- Industrial vacuum drying operations

Products That Would Use This Dryer:

- Active pharmaceutical ingredients (API)

- Nutritional powders and protein blends

- Chemical powders and industrial materials

- Food-grade powders and additives

- Heat-sensitive specialty materials

- Paul O Abbe

- Used Industrial Equipment

- Used Equipment

- Aaron Process

- Used Vacuum Dryer

- Vacuum Dryer

- Used Process Dryer

- Stainless Steel Dryer

- Industrial Mixing Dryer

- Used Aaron Process Vacuum Dryer

- 200 Gallon Stainless Steel Dryer

- Jacketed Vacuum Dryer for Sale

- Industrial Vacuum Drying System

- ASME Code Stainless Steel Dryer

- High-Capacity Process Dryer

- Used 200 Gallon Stainless Steel Vacuum Dryer for Sale

- ASME Code Jacketed Vacuum Dryer with Cored Shafts

- High-Temperature Vacuum Drying System with Insulation

- Stainless Steel Vacuum Dryer with 125 HP Motor and Gearbox

- Used Aaron Process 200 Gallon Stainless Steel Vacuum Dryer with Jacketed Trough

- Industrial Vacuum Drying System with Control Panel and Heat Exchanger

- Heavy-Duty Vacuum Mixer Dryer with Overlapping Double Nobben Blades

- ASME Code Stainless Steel Vacuum Dryer with Mikro Pulsaire Dust Collector

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory